QMCF Technology - Tartu Biotehnoloogia park

advertisement

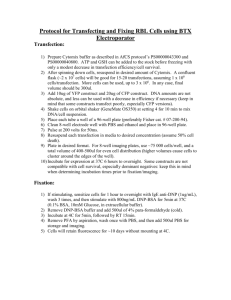

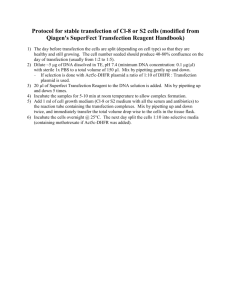

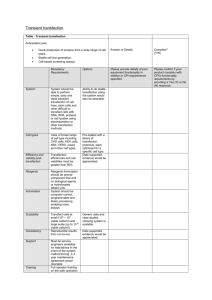

Icosagen Story by Mart Ustav Tartu Biotechnology Park 29.04.2015 1 www.icosagen.com Curriculum vitae Mart Ustav 1. 2. 3. 4. 5. 6. 7. Education – Organic and Bioorganic Chemistry, 1972, Univ. Of Tartu Military service – 1972-1974 Institute of Cybernetics, Tallinn – researcher, enzyme kinetics 1975 Ph.D. – rRNA-protein interactions, Tartu University, 1976-1979 Post-doctoral Fellow – Uppsala University 1982-1985 Senior scientist, Head of Laboratory of Oncogenesis, UT 1985-1989 Visiting scientist – Cold Spring Harbour Laboratory, Long Island, NY, USA (1989-1992) 8. Professor of Microbiology and Virology 1992-2007, Univ. of Tartu Director of the Institute of Molecular and Cell Biology 1997-2001 9. Howard Hughes Medical Institute Fellow, USA 1995-2005 10. Member of the Academy of Sciences of Estonia 2001 11. Professor of Biomedical Technology 2007…., Director of the Institute of Technology, University of Tartu, 20022007, 2012…. 2 www.icosagen.com The first 10-years story 1999 • Quattromed was founded as a molecular diagnostic company providing services to Estonian medical institutions. 2001 FIT Biotech Oy acquired 22.3% of the Quattromed shares and established FIT Biotech Oy Eesti filiaal 2005 • Diversification of medical services and establishment of Quattromed Cell Factory as a subsidiary company 2008 • A leading medical diagnostics and biotechnology group in Estonia, 80 FTE; revenue EUR 3.5M • Activities: • medical diagnostics: molecular diagnostics, clinical chemistry, hematology, cytology, immunology etc • molecular- and cell biology products and services • immunoanalysis products and services for detection of allergic causativ proteins in rubber products • Q3: the medical diagnostic subsidiary along the trademark Quattromed was sold to private equity firm. Restructuring of the group and business model. • Establishment of Icosagen Group www.icosagen.com Icosagen Group CEO Mart Ustav, professor of biomedical technology, University of Tartu 49 FTE, 8 PhDs ISO 9001:2008, ISO 17025, GLP 6 patent families/25 patents (EU, US, CA, JP, AU, CH, IN) Partners in several international collaboration projects 4 www.icosagen.com Biotech and Protein Production Company in Estonia Icosagen Cell Factory Eerika tee 1, Ülenurme vald, 61713 Tartumaa, Estonia Tel: +372 737 7070 E-mail: info@icosagen.com Tartu, Estonia 2 www.icosagen.com Icosagen Group Icosagen Management, financing, QC/QA, Sales&Marketing Products/Services: catalog products (antibodies, proteins, ELISA kits); food safety/quality control. Icosagen Cell Factory R&D, Business Development Products/Services: technology licensing, protein production services IcoPark Established in 2013. Development the infrasturcture of Icosagen Group Icosahedron with 20 identical tringular facets. Icosagen, a company of variety of options for every facet of icosahedron 6 www.icosagen.com Technology Developer and Service Partner for Global Pharma and Biotech Industry Development and production of recombinant proteins Development and sales of catalogue products Proteins, Poly- and monoclonal antibodies, VLPs Antibodies, proteins, ELISA kits Business Fields Quality control laboratory testing services Food microbiology, latex allergen testing 5 www.icosagen.com Collaborative research and development, technology licensing Technology Developer and Service Partner for Global Pharma and Biotech Industry Animal Cell as the Factory – Design, Engineering and Exploitation Mart Ustav Bio- and medtech business: real stories and opportunities Tallinn, February 12th, 2015 Market, drugs and money Market for prescription drugs in 2013 was 559 billion USD. Market for prescription drugs in 2020 will be 793 billion USD. 32% of all drugs approved by FDA during last 10 years are produced from cultured cells – it means that these are developed also using cultured cells 60% of all new drugs will be biologics (proteins, antibodies etc.) 10 www.icosagen.com QMCF Technology 11 www.icosagen.com Two Kinds of Technologies are Available for Protein Production for drug development Transient System, where proteins are expressed from extrachromosomal plasmids Stable Cell Lines, where proteins are expressed from the chromosomes However, there is a huge gap between them! 12 www.icosagen.com QMCF System Consists of Two Components CHO85 cell line that expresses factors for plasmid maintenance and replication. QMCF plasmids that carry elements for replication and mainenance. Origin of replication (Py LT) Maintenance (EBNA1) EBNA1 Py LT 13 www.icosagen.com Chromatin attachment N-terminal TA domain of E2 is responsible for chromatin attachment Sufficient number of E2 binding sites, defined as minichromosome maintenance element (MME) McBride, 2006 E2 TA hinge DBD QMCF Plasmids Are Maintained in Dividing Cells pQMCF plasmids are maintained at the level of ~200 copies/cell Conventional plasmids get lost in dividing cells Plasmid Chromosome 15 www.icosagen.com QMCF Plasmids Are Maintained in Dividing Cells Southern blot analysis of hNGF and human IgG1 antibody expression vector 48 hrs and 16-18 days after transfection (doubling time ~15 h) 12 www.icosagen.com QMCF Technology Is Scalable and More Convenient Than Transient Protein Production In transient system, transfection has to be done in a large volume, few days before protein production In QMCF system is scalable and transfection is done conveniently in a small volume Therefore QMCF Technology is also well suited for the High-Throughput Screening applications Volume of the cell culture Transient transfection (1 L culture, (1mg DNA) 16 L Start of the production, Shift to 30 oC cell culture expansion 4L 1L 0.25 L 60 mL 15 mL QMCF transfection (1 mL culture, 1mg DNA) 4 mL 1 mL 13 www.icosagen.com 1 2 4 6 8 10 12 Time (days) 14 16 … pQMCF-T Vectors Are Superior for Transient Production Objective: In order to increase the productivity of QMCF system, we inserted replication enhancer into the pQMCF vectors (T-plasmids) pQMCF pQMCF-T Results: 18 Relative Plasmid Copy Number Relative Productivity Antibody CDNF Antibody CDNF pQMCF 1.0 1.0 1.0 1.0 pQMCF-T 3.0 3.2 1.5 2.6 www.icosagen.com CDNF QMCF Technology Bridges „the Gap“ in Protein Production Transient systems are the best for a fast production of small-scale protein amounts. However, it is not feasible if large amounts of proteins are required. Production of large amounts of protein demands cell line development and stable expression of your favourite protein. Icosagen Cell Factory has developed QMCF technology to optimize the mid-scale protein production. Stable cell lines QMCF Transient suitable unsuitable 0.01 19 www.icosagen.com 0.1 1 10 100 … Protein quantities (grams, IgG) Icosagen Cell Factory Provides Protein Production Services by Using QMCF Technology 20 www.icosagen.com Small Scale Protein Production Services (<100mg of Protein (IgG)) Week 1 Week 2 Week 3 We use NOVEL peptide-based Transfection Reagent 007. Transfection efficiency is 80-95% in CHO85 cells with excellent cell recovery 21 www.icosagen.com Transfection Agent 007 New generation peptide-based vehicle for efficient delivery of nucleic acids for the transfection of mammalian and insect cells Arukuusk, P. et. al.. Biochim Biophys Acta. 2013 May;1828(5):1365-73 100 Transfection effieciency is up to 95% in CHO cell lines in seerum-free conditions with an excellent cell recovery 60 40 20 22 www.icosagen.com EB NA LT 85 CH O -S 0 CH O EGFP% 80 Medium Scale Protein Production (<10g of Protein (IgG)) Together with Cell Bank Generation! Cell bank generation in 2 weeks after transfection Production cell bank generation Week 1 23 Week 2 www.icosagen.com Week 2-3 Week 4 Week 5 Stable Production from QMCF Cell Bank 1st batch from transfection (mg/L) h-IgG1 - 144 + 21 Production of the GDNF-family neural growth factor by using CHOEBNALT85 suspension cell line. Production were started from two different cell banks independently (lanes 1 and 2). 24 www.icosagen.com 2nd batch from WCB (mg/L) - 186 +12 Storage period of cell bank 12 months QMCF Technology Licensing Feasibility License Technology evaluation in 6 month period Research License or Limited Research License In-house activities Commercial License Production of catalog products, or diagnostic kit, or custom production services for third parties, etc 25 www.icosagen.com QMCF Technology Applications: Designing New CHO Cell Lines 26 www.icosagen.com CHO is Great, but it is not Perfect! Modifications can be introduced into CHO cell lines to improve their production properties. These modifications include introduction, upregulation or downregulation of certain cellular factors: • Components of post-translational modification pathways (e.g. protease cleavage, glycosylation) • Factors related to cellular growth and/or metabolism • Components of secretion machinery Many combinations have to be analysed in order to determine the effects and side effects. Usually it is done by genome editing, which is time-consuming and expensive. 27 www.icosagen.com Designing New CHO Cell Lines by Using QMCF System QMCF system is a useful tool for designing novel CHO cell lines: Modifications are tested first in QMCF system and then the most optimal configurations are used for engineering new CHO cell lines. For this purpose we designed pQMCF vectors with two expression cassettes or Protein of interest Expression Factor 28 www.icosagen.com shRNA Protein of interest Production of Mature Proteins by Protease Co-expression • Furin is an endopeptidase responsible for the proteolytic maturation of many precursor proteins in mammalian cells. • The levels of furin are very low in most cells (including CHO cells). Objective: To achieve pro-protein maturation by the co-expression of hFurin from pQMCF plasmid Results: pro-protein pro-protein hFurin mature protein 29 www.icosagen.com CHO85 hFurin Cell Line (3A5) for Complex Protein Production Based on the positive results from pQMCF plasmid, we have generated CHO85 cell line (3A5) with stable expression of hFurin. Target protein (48h) Furin M hFurin does not affect cell growth Cell # Cell Growth 1.00E+10 Furin pro-GDNF 1.00E+09 1.00E+08 GDNF 1 2 3 CHO85 3A5 30 www.icosagen.com 1.00E+07 1.00E+06 0 1 2 3 4 5 6 7 8 9 days 3A5 pQ3 CHO85 pQ3 3A5 pQ3T CHO85 pQ3T Production of Glycoproteins in CHO85 Cells with Downregulated Slc35A2 Slc35A2 transports UDP-galactose from the cytosol into Golgi vesicles where glycosyltransferases function. Objective: To increase the homogenicity of glycosylated proteins by downregulation of Slc35A2 Case study: Transient production of EPO in CHO85 cells EPO Isoelectric focusing EPO EPO 31 www.icosagen.com QMCF Technology Applications: Development of Monoclonal Antibodies 32 www.icosagen.com Two Approaches Are Used for the Development of Monoclonal Antibodies (mAbs) Immunization B-cells Hybridoma based methods Recombinant methods mAbs mAbs + information about antigen binding site 33 www.icosagen.com Development of Recombinant mAbs by Using QMCF Technology Isolation of VH and VL coding regions and generation of enriched scFv-Fc library in pQMCF plasmids Panning: Enrichment of antigen specific B-cells VH VL Fc VH VL Fc VH VL Fc VH VL Fc VH VL Fc VH VL Fc VH VL Fc VH VL Fc VH VL Fc Isolation of B-cell population (e.g. from spleen or blood) Generation of Antibodies produced in single clones E. coli CHO85 cells plasmid DNA Identification of antigen specific scFv-Fcs by ELISA #3-22 A B C D E F G H 34 www.icosagen.com 1 0,97 0,91 0,78 0,36 0,39 0,23 0,2 0,52 2 0,93 0,92 0,94 0,83 0,71 0,86 0,83 0,19 3 0,73 1,01 0,92 0,44 0,63 0,74 0,62 0,22 4 1,42 1,06 0,48 0,88 0,67 0,38 0,81 0,57 5 0,65 1,3 0,89 1,25 1 1,01 0,89 2,31 6 1 0,34 0,59 1,32 1,2 0,76 0,86 1,14 7 0,57 0,95 0,42 0,73 1,05 1,4 1,1 0,68 8 0,84 1 0,65 1,17 0,97 0,93 0,51 0,93 9 0,84 0,44 0,62 1 0,68 1 0,85 0,72 10 0,41 1,25 0,39 0,98 0,38 0,88 0,71 0,6 11 0,26 1,82 0,59 0,72 0,74 1,69 0,73 0,53 12 0,26 1,82 0,59 0,72 0,74 1,69 0,1 0,1 Cloning and Expression in mammalian system mAbs mAbs are mayidentified not work and sinceproduced identified in mammalian in E.coli system cells ! Design and Production of Desired Final Product Icosagen Cell Factory can generate recombinant mAbs from mouse and chicken B-cells or hybridomas. Production protocols for recombinant rabbit mAb are under development. Example of purified human antibody We can redesign the mAb to: 35 human antibodies (IgG1, IgG2, IgG4) mouse antibodies (IgG1, IgG2a, IgG2b) chicken antibodies (IgY) chimeric antibodies antibody fragments single chain molecule fusion proteins bispecific antibodies (bi-scFV-Fc, DVD-Ig, Crossmab) www.icosagen.com M 1 2 3 Summary Proprietary QMCF Technology for fast, scalable and cost-effective production of proteins, antibodies and VLPs QMCF Technology can be used also for the design of new cell lines and for the generation of monoclonal antibodies. Strong scientific team: principal scientists with 20+ year of experience in the field of molecular/cell biology 36 www.icosagen.com Thank you! Icosagen AS Icosagen Cell Factory OÜ IcoPark OÜ www.icosagen.com info@icosagen.com 37 www.icosagen.ee www.icosagen.com

![[4-20-14]](http://s3.studylib.net/store/data/007235994_1-0faee5e1e8e40d0ff5b181c9dc01d48d-300x300.png)