Supply Chain Management

advertisement

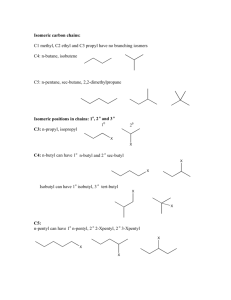

Supply Chain Management (SCM) Definisi SCM • SCM adalah koordinasi aliran bahan baku / material, informasi dan keuangan antar entitas yang berpartisipasi dalam transaksi bisnis – Aliran material : aliran produk secara fisik dari pemasok ke pelanggan, termasuk di dalamnya pengembalian produk (retur), layanan (services), pengolahan ulang (recycling) dan pembuangan (disposal) – Aliran informasi : meliputi ramalan permintaan, transmisi pembelian dan laporan status pengiriman barang – Aliran Keuangan : meliputi informasi kartu kredit, syarat kredit, jadwal pembayaran. Elemen Supply Chain Planning ce d Advan ing ul Sched Order t itmen Comm and Demm g in Plann mer Custo Order rtation o p s n T ra i ng Plann ution Distrib g in Plann e tectur i h c r A prise r e t n E Model Supply Chain Manufacturer • Financial / marketing–driven forcast • Master Scheduling • Replenishment based on distribution center inventory (preset safety stock level) • Manual purchase order and invoicing Retail Distribution Center • Order point based on warehouse inventory (safety stock level) and historical forecast • Deals, promotions and forward buying • Manual purchase orders, information entry and output Retail Store • Order point based on shelf inventory (safety stock level) and forecasts • Promotions • Manual entry of items to be ordered Manufacturer • Demand driven forcast based on POS data and product movement • Short cycle manufacturing • Advanced shipping notice and EDI services • Bar code scanners and UPC ticketing Retail Distribution Center • Automatic replenishment • Shipping container marking • Cross–dock receiving • EDI services Retail Store • POS data collection • Perpetual inventory checks • Automatic replenishment using EDI services Customer Purchase Merchandise Customer Purchase Merchandise Push–Based Supply Chain Pull–Based Supply Chain Proses Supply Chain Supply Chain Planning Information Flows Product Flows Supplier Product Flows Manufacturing Product Flows Distribution Payment Flows Supply Chain Execution Product Flows Retailer Consumer Strategi Supply Chain Current Store Customer 1-800 Retailer Manufacturer Supplier Enterprise Focus (Nabisco) Collaborative Systems Near Term Customer 1-800 Store Web Retailer Shared Market Data Emerging Customer Manufacturer The Web Manufacturer Supplier Partner Focus (P&G) Supplier Direct Focus (Dell) Virtual Fulfillment Arsitektur eSupply Chain Complete Order Life Cycle Partial Functional Solutions Complete Integrated Solution Commit Order Commitment Advanced Scheduling Schedule Make Demand Planning Transportation Planning Deliver Manufacturing Plan Distribution Planning Integrated Supply Chain Applications Cross – Functional Processes Breaking Down Enterprise Walls Aplikasi Piranti Lunak SCM Major Functional Areas Set of Key Activities in Each Functional Areas Manufacturing Engineering and product configuration, production planning and cost management, production execution and quality management Logistics Purchasing and order management, distribution, inventory and warehousing Financials General ledger, payables and receivables, billing, budgets and asset management Marketing Advertising, sales, order management, customer service and support and market research and strategy HRMS Payroll management, time and labor management, benefits administration and pension administration