Metals – their properties, structure and bonding

advertisement

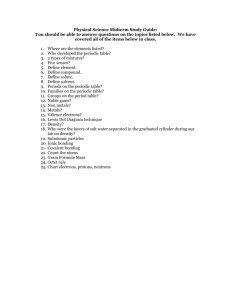

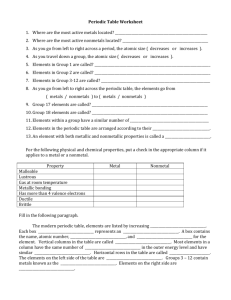

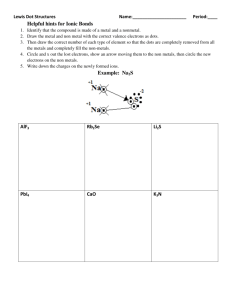

Metals – their properties, structure and bonding L.O: To understand how the structure of metals affect their properties Electrons and metallic bonding How is the sea of electrons involved in metallic bonding? What is the structure of metals? Metals are giant structures of atoms. The atoms in a pure metal are in tightly-packed layers, which form a regular lattice structure. The outer electrons of the metal atoms separate from the atoms and create a ‘sea of electrons’. These electrons are delocalized and are free to move through the structure. The metal atoms become positively charged ions and are attracted to the sea of electrons. This strong attraction is called metallic bonding. 3 of 13 sea of electrons metal ions © Boardworks Ltd 2011 Metallic structures 4 of 13 © Boardworks Ltd 2011 4 marks Why do metals have high melting and boiling points? Gold, for example, has a melting point of 1064 °C and a boiling point of 2807 °C. - Strong forces of attraction - Between positive ions and negative electrons - Sea of delocalised electrons - As metallic bonds are so strong a large amount of force is needed to break them 5 of 13 © Boardworks Ltd 2011 Properties of metals: conductivity Can you explain why metals conduct? Think about metallic bonding. Metals are good conductors of: heat – the free electrons can take in heat energy, which makes them move faster. They can then transfer the energy throughout the lattice. electricity – the free electrons can carry an electrical charge. Silver is the best conductor of electricity and copper is the second best. Why is copper used instead of silver for electrical wires? Can you explain why some metals are more conductive? • Do you think the length or diameter of a wire will affect its conductivity? Why? • How could you test this? What is resistance? – Rough Notes Electricity in wires is a flow of electrons along the wire. As the electrons move along the wire they collide with the metal atoms (positive ions). The negative electrons get attracted to the positive ions; so if there are more of them (e.g. in a longer wire) there is more resistance, as the electrons have to pass more positive ions – this is called electrostatic resistance. Resistance is a measure of how much a material tries to stop electricity passing through it. Properties of metals: density Metal ions form a lattice which is more tightly packed and denser than the lattices in ionic compounds Metals generally have a very high melting and boiling point because metallic bonds are very strong and so a large amount of energy is needed to break them. Strength Layers of atoms can slip over each other in metal grains when a force is applied, but this slippage stops at grain boundaries. grain boundary: where one grain meets another The smaller the grains, the shorter the distance the atom layers can move. This means that metals with smaller grains are stronger and harder than metals with larger grains. Which metals have small grains? The faster that molten metal is cooled, the smaller the grain size. Properties of metals: strength Metals are usually tough, not brittle. When a metal is hit, the layers of the lattice just slide over each other. The metallic bonds do not break because the electrons are free to move. force When the ions move the electrons distribute themselves evenly so the ions don’t repel like in ionic compounds This means that metals are: malleable – they can be bent and pressed into shape; ductile – they can be drawn out into wires. Strengthening metals Metals can be made stronger by adding another element when the metal is molten. The atoms of the new element spread through the crystal structure. force force Because the atoms of the added element are larger, they make it difficult for layers of metal atoms to slide. This makes the metal less malleable and less ductile. This process is called alloying, and the new substance is called an alloy. Different types of alloys Adding different elements to metals creates different alloys, with different properties. Usually, other metals are added, for example: zinc, magnesium and copper are added to aluminium to create an alloy that is light but very strong. This is used in building aircraft. chromium and nickel are added to iron to make stainless steel, which is resistant to corrosion. tin and lead are mixed together to create solder, which has a low melting point and is used to join other metals together. Metals and metallic bonding Multiple-choice quiz