Thermal - University of Colorado Boulder

advertisement

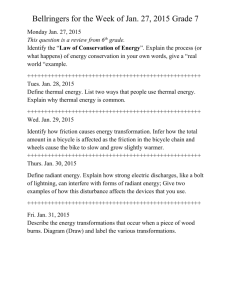

Manufacturing Status Review February 3, 2015 Project Manager: Gabrielle Massone Systems Engineer: Jesse Ellison Deputy Project Manager Financial Lead Tanya Hardon Software Lead: Cy Parker Optics Lead: Jon Stewart Mechanical Lead Jake Broadway JB Young and Keith Morris Lockheed Martin (LMCO) Test and Safety Lead: Franklin Hinckley Thermal Lead: Brenden Hogan Customers: Brian Sanders Colorado Space Grant (COSGC) Faculty Advisor: Dr. Xinlin Li Dept. Aerospace Engineering Laboratory for Atmospheric and Space Physics (LASP) Electrical Lead: Logan Smith Purpose and Objectives Schedule Manufacturing Status Budget 1 Presentation Overview Project Purpose and Objectives Schedule Manufacturing Status • • • • Optical and Mechanical Thermal Electronics and Software Testing Budget Concluding Statements Purpose and Objectives Schedule Manufacturing Status Budget 2 PROJECT PURPOSE AND OBJECTIVES Purpose and Objectives Schedule Manufacturing Status Budget 3 Phoenix Mission Objective Develop a proto-flight, angular-velocity sensor payload that can observe an object in mid-wave infrared and determine the angular velocity of the object in the field of view Proto-flight Unit: Defined as hardware that is designed to flight form-factor, but will be tested exclusively on the ground and is not required to undergo environmental testing. Purpose and Objectives Schedule Manufacturing Status Budget 4 Mission Concept Example angular velocity sensor concept ω 6U CubeSat with Rate Sensor Payload Observing asteroid in FOV Characterize rotation of asteroid for rendezvous operations Bennu 101955 Asteroid Video courtesy of www.asteroidmission.org Purpose and Objectives Schedule Manufacturing Status Budget 5 Mission Concept Use this sequence of images to determine the object’s angular velocity vector in the camera FOV Report this observed rate to the bus Effectively an infrared angular velocity sensor Purpose and Objectives Schedule Manufacturing Status Budget 6 Design Overview Phoenix Interfaces with the 6U LMCO Bus • Inhabits 1/3 of spacecraft volume Phoenix CPE’s: 1. Optics and Mid Wave IR Imaging system 2. Thermal Control System 3. Supporting Electronics 4. Software Angular Velocity Determination Algorithm 10 cm Purpose and Objectives Schedule Manufacturing Status Budget 7 SCHEDULE Purpose and Objectives Schedule Manufacturing Status Budget 8 Critical Path Optics: • • Mirrors Complete: 3/15 Integrated by: 3/24 Electronics: • Integrated by: 3/20 Thermal: • Integrated by: 3/20 Software: • Integrated by: 3/18 Testing: • TVAC 1st week of April at LMCO Today Purpose and Objectives Schedule Manufacturing Status Beginning of Full System Tests Budget 9 OPTICAL AND MECHANICAL Purpose and Objectives Schedule Manufacturing Status Budget 10 Mechanical Overview Structural Panels Maximize radiative surface area Provide mounting to other components Create stand-alone electronics module Focusing Mechanism Ensures optics are placed within tolerance Allows focus to be changed if needed Bus Interface Tabs Mechanical mounting to bus High thermal resistivity Purpose and Objectives Schedule Manufacturing Status Budget 11 Detailed Design Ritchey-Chretien Optics Design - Ray Trace Diagram Incoming Light Ray Hyperbolic Primary Mirror On-axis ray 9.5 cm Hyperbolic Secondary Mirror nBn Focal Plane 14.3 cm Primary Mirror Specs Diameter Vertex Radius Conic Constant Surface Irregularity Surface Finish Scratch-Dig Final Coating Purpose and Objectives 95 + 0.05 mm 407.4 + 0.4 mm -1.19 λ/10 @ 3.5 µm 120 Å rms 60-40 Gold Schedule Secondary Mirror Specs Diameter Vertex Radius Conic Constant Surface Irregularity Surface Finish Scratch-Dig Final Coating Manufacturing Status 34 + 0.05 mm 294 + 0.4 mm -13.92 λ/10 @ 3.5 µm 120 Å rms 60-40 Gold Budget 12 Component Status Component Priority Source Progress Next Steps Machining Time Structure Panels Mid In-house Jig made, 2/4 machined Machining Remaining Panels One Day Focusing Mechanism Mounts Low In-house 4/8 Machined Machining Remaining parts < One day Focusing Mechanism Stages High In-house 0/3, Delayed due to focal plane size uncertainty Final focal plane fit, machining 1.5 weeks Secondary Mirror Mount High In-house Stock Squared Machining part 3 days Bus Interface Tabs Mid In-house 0/3 Machining 2 Weeks Fasteners, Springs, Pins Mid McMaster Arrived None N/A Micrometers High Altos Photonics Ordered Wait for Arrival Scheduled arrival 2/11 Purpose and Objectives Schedule Manufacturing Status Budget 13 Component Status Component Priority Source Progress Next Steps Lead Time Bandpass Filter Low Edmund Optics In-house Assembly None Cold Stop Low In-house Finished CAD model Machining, Painting, and Assembly None Primary & Secondary Mirrors High In-house, Denver Metal, etc. Started machining mirror blanks to be sent out for coating Machining, Coating, Machining, Coating, and Assembly 4 weeks PSF Testing Optics & Laser High Lockheed Martin, Thorlabs Once mirror cost determined, be able to know how many testing optics we can afford Assembly and 2-3 weeks surface treatment Purpose and Objectives Schedule Manufacturing Status Budget 14 Future Work Determine suppliers to diamond turn mirror blanks • Cost & Lead time Hand polish extra mirrors Manufacture cold stop Find 3.39 um HeNe laser for PSF testing Purchase or borrow required optics for PSF testing Purpose and Objectives Schedule Finish Machining Components Paint Structural Panels Integration and assembly of components and mechanisms Focusing Procedure (PSF) Wire Harnessing and Thermal Braid Mounting Manufacturing Status Budget 15 THERMAL Purpose and Objectives Schedule Manufacturing Status Budget 16 System and Hardware Cooling • Passive cooling using high emissivity radiators • Active cooling using thermal electric coolers Isolation • Interface panels isolate from conduction • MLI Isolates from radiation Thermal Sensors 8 Total Radiators MLI Layers Thermal Electric Coolers White Paint Not Shown in Model • MLI Insulation • Thermal Epoxy Thermal Strap Bus To Structure Titanium Panels Purpose and Objectives Schedule Manufacturing Status Budget 17 Component Status Component Priority Source Progress Platinum RTD’s Low QTI Sampled and tested in Integrate to the house system and test None Thermal Electric Coolers Med Laird Components selected and samples in house Test samples and order system components 2 Weeks White Paint Low Krylon Component selected and supplier located Purchase and coat the outer radiators Less then 1 Week Thermal Braids Low McMaster Component selected and mounting creation in progress Order straps and integrate to the TEC interface Less then 1 Week Titanium Interfaces Med McMaster Beginning creation of the set-ups and paths Machine all three interfaces None MLI High Dunmore/ Lockheed Ordered Receive and Integrate 3 Weeks Thermal Epoxy Low McMaster Epoxy selected Will buy when needed for assembly Purpose and Objectives Schedule Next Steps Manufacturing Status Budget Lead Time Less then 1 Week 18 Future Work High priority • Machine the three titanium interface panels needed structure completion. • Long machining time. • Obtain & assemble MLI and integrate to the system. • Potential for long lead time. • Assemble TEC stack and integrate to the focal plane. • Delicate work with fragile components. Normal Priority • Coat all radiating surfaces in white paint. • Integrate the thermal braids to the structural panels using epoxy. • Integrate thermal sensors to components. Purpose and Objectives Schedule Manufacturing Status Budget 19 ELECTRONICS Purpose and Objectives Schedule Manufacturing Status Budget 20 Electrical Overview Custom Boards • Power and Thermal Board • Shorter lead-time • Low cost • Required to power Image Processing Board • Required to control Thermoelectric Coolers • Image Processing Board • Long lead-time • High cost • Required to capture an image off of the sensor Purpose and Objectives Schedule Manufacturing Status Budget 21 Component Status Printed Circuit Board Schematics Schematic Review Layout Layout Review Ordered Image Processing Done Done Placement This Friday Monday Power and Thermal In-Progress In-Progress Placement This Friday Monday (Feb 6th) (Feb 9th) (Feb 6th) • Schematics Reviewed by • Dr. Lawrence • Bobby • Trudy • Lockheed • Internal Members (Logan and Jesse) • Layout • In-Progress • Got quote from fabricator Purpose and Objectives Schedule Manufacturing Status Budget (Feb 9th) Future Work Bring Up Plan Order two Power and Thermal Boards • Professionally assemble one board at Advanced Assembly • Hand assemble other board Order one Image Processing Board • Too complex to assemble by hand (BGAs, etc…) Work on FPGA logic and software during fabrication and assembly Purpose and Objectives Schedule Manufacturing Status Budget 23 SOFTWARE Purpose and Objectives Schedule Manufacturing Status Budget 24 Software Overview Purpose: Determine the angular velocity vector of a target object from a sequence of images and report this solution to the bus System Control Communicate with LMCO Bus & parse bus commands Gather data from power board Command TEC temperature set-point Image processing Filter image Determine delta vectors Determine Angular Determine rotation attitude Velocity from Sequence Compress raw image for transfer to bus of Images Purpose and Objectives Schedule Manufacturing Status Budget 25 Component Status Component Priority Source Progress Next Steps Dev Time Bus Communication Module Low In-house Implemented and Tested None None Image Interface Module Med In-house Module Implemented Testing 1 week Rate Determination Algorithm High In-house Working with MATLAB simulation to quantify error Rate Portion Implementation, Characterization 4 weeks Optical Flow Module High In-house Optical flow implemented in MATLAB C/C++ Implementation 2 weeks Thermal Control Module Med In-house Design Started Finish Design, Begin Implementation 3 weeks Noise Reduction and Image Compression Low In-house Researched Implement Best Options 1 week Purpose and Objectives Schedule Manufacturing Status Budget 26 Future Work Test image interface module Implement angular velocity determination in C/C++ Implement optical flow in C/C++ Implement Thermal Control Module Integrated Image Capture Test Purpose and Objectives Schedule Manufacturing Status Budget 27 TESTING Purpose and Objectives Schedule Manufacturing Status Budget 28 System Testing Overview Integrated System Thermal Test: • Verify thermal control system can maintain the focal plane at its operating temperature of 150K in the presence of the heat load from the bus under representative environmental conditions (vacuum and cold surroundings) Integrated System Optics Test • Verify that the system can capture an image sequence and determine the angular velocity vector of the target from the captured sequence Representative Image Purpose and Objectives Schedule Manufacturing Status Budget 29 Component Status Integrated Phoenix Hardware Bus Simulator Cooling Jacket (filled with dry-ice & alcohol slurry) Purpose and Objectives Schedule Manufacturing Status Budget 30 Component Status Component Priority Source Progress Next Steps Lead Time Cooling Jacket Low McMaster, in-house Steel stock in-house Machining and Assembly None Cold Background Low McMaster, in-house Steel stock in-house Machining and Assembly None Test Target High In-house Possible surface Assembly and 1 week treatments identified surface treatment (paint, surface roughness, oxidation, etc…) Collimating Optics High Alkor Provisional partselection: plano-convex lens Order Lens 4 weeks Bus Simulator Low In-house Software interface complete, electrical interface defined Electrical interface assembly 1 week Purpose and Objectives Schedule Manufacturing Status Budget 31 Future Work Machine cooling jacket, background, bus simulator • Not high tolerance or complex Seal cooling jacket and background • Braze seams to prevent coolant leaks Finalize collimating optic • Dependent on optics path forward Coordinate Thermal Vacuum testing with Lockheed Finish subsystem test procedures • Finalize details • Procedures for optics contingencies Purpose and Objectives Schedule Manufacturing Status Budget 32 BUDGET Purpose and Objectives Schedule Manufacturing Status Budget 33 Overall Cost Plan Total Funds Available: $20,000 ($5000 ASE Dept + $15000 Customer) $4,658 23% $3,795 19% $990 5% Component Status Cost Purchased $ 1,482.06 To be Purchased $ 9,857.00 Margin (20 %) $ 4,000 Contingency $ 4660.94 Total Project Cost $ 20,000 $2,142 11% $4,000 20% $3,082 15% $933 5% $400 2% Optics Structures Thermal Testing Electronics Miscellaneous Margin Contingency Purpose and Objectives Schedule Manufacturing Status Budget 34 Purchased Components Item Description Category Vendor Price Quantity Needed Cost Received BandPass Filter Optics Edmund Optics $ 395.00 1 $ 395.00 Yes Stock Aluminum Structures Metal Super Markets $ 232.97 1 $ 232.97 Yes Stock Titanium Structures Metal Super Markets $ 169.35 1 $ 169.35 Yes Other – Screws, Punch Pin, etc… Structures Mc-Master Carr $ 197.56 1 $ 197.56 Yes Micrometer Structures Altos Photonics $ 66.00 3 $ 198.00 No Platinum RTD’s Thermal QTI $ 0.00 12 $ 0.00 Yes TEC – 2 Stage Thermal Laird $ 0.00 2 $ 0.00 Yes Stock Steel Testing Metal Super Markets $ 123.08 1 $ 123.08 Yes Binding - FFR Misc. Ink Spot $ 47.07 1 $ 47.07 Yes Shipping Misc. N/A $ 119.01 1 $ 119.01 Yes Total $ 1,482.04 Purpose and Objectives Schedule Manufacturing Status Budget 35 Components to Purchase Item Description Category Vendor Estimated Price Quantity Needed Cost Projected Lead Time Diamond Tooling Optics TBD $ 3,000.00 1 $ 3,000.00 2-3 weeks Plating Optics TBD $ 200.00 2 $400.00 1 week TEC’s 1-Stage Thermal DigiKey $ 15.00 4 $ 60.00 3 days TEC’s 2-Stage Thermal DigiKey $ 140.00 2 $ 280.00 3 days TEC’s 5-Stage Thermal DigiKey $ 380.00 1 $ 380.00 3 days Thermal Braids Thermal Mc-Master Carr $ 75.00 1 $ 75.00 3 days Thermal Paint Thermal Az Technology $ 350.00 1 $ 350.00 1-2 weeks Thermal Epoxy Thermal Master Bond $ 500.00 1 $ 500.00 1 week Insulation Thermal Dunmore $ 500.00 1 $ 500.00 3 weeks Board PCB’s Electronics Royal Circuits $ 791.00 2 $ 1,582.00 1-3 weeks Board Components Electronics Multiple $ 750.00 2 $ 1,500.00 1 week Collimator Testing Edmund Optics $ 500.00 1 $ 500.00 1-2 weeks Misc. Supplies Structures/ Testing/Misc. Multiple $ 360.00 1 $ 730.00 1-3 days Total $ 9,857.00 Purpose and Objectives Schedule Manufacturing Status Budget 36 Financial Pareto’s Breakdown of Currently Purchased Components $2,000.00 Breakdown of Components to Purchase 100% $1,800.00 90% $1,600.00 80% $1,400.00 70% $1,200.00 60% $1,000.00 50% $800.00 40% $12,000.00 100% 90% $10,000.00 80% 70% $8,000.00 60% $6,000.00 50% 40% $4,000.00 $600.00 30% $400.00 20% $200.00 10% $- 30% 20% $2,000.00 10% $- 0% 0% Raw Cost Cumulative Cost Raw % Cumulative % Purpose and Objectives Schedule Manufacturing Status Budget 37 CONCLUDING STATEMENTS 38 Conclusions Thank you for your time Acknowledgements PAB Faculty and Staff Faculty Advisor • Dr. Xinlin Li Our customers • Brian Sanders (COSGC) • JB Young (LMCO) • Keith Morris (LMCO) 39 References [1] Adams, Arn. "ADVANCES IN DETECTORS: HOT IR Sensors Improve IR Camera Size, Weight, and Power." Laser Focus World. PennWell Corporation, 17 Jan. 2014. Web. 13 Sept. 2014. [2] "An Introduction to the NBn Photodetector." UR Research. University of Rochester, 2011. Web. 12 Sept. 2014. [3] "ARCTIC: A CubeSat Thermal Infrared Camera." TU Delft. Delft University of Technology, 2013. Web. 13 Sept. 2014. [4] Cantella, Michael J. "Space Surveillance with Infrared Sensors." The Lincoln Laboratory Journal 1.1 (1989): n. pag.Lincoln Laboratory. MIT, June 2010. Web. 9 Sept. 2014. [5] Cleve, Jeffrey V., and Doug Caldwel. "Kepler: A Search for Extraterrestrial Planets." Kepler Instrument Handbook (2009): n. pag. 15 July 2009. Web. 12 Sept. 2014. [6] "James Webb Space Telescope - Integrated Science Instrument Module."ISIM. Space Telescope Science Institute, n.d. Web. 13 Sept. 2014. [7] "NBn Technology." IR Cameras. IRC LLC, n.d. Web. 13 Sept. 2014. [8] Nolan, M.C. et al, “Shape model and surface properties of the OSIRIS-Rex target Asteroid (101955) Bennu from radar and lightcurve observations,” Icarus, Vol. 226, Issue 1, 2013, pp. 663-670. [9] Otake, Hisashi, Tatsuaki Okada, Ryu Funase, Hiroki Hihara, Ryoiki Kashikawa, Isamu Higashino, and Tetsuya Masuda. "Thermal-IR Imaging of a Near-Earth Asteroid." SPIE: International Society of Optics and Photonics. SPIE, 2014. Web. 13 Sept. 2014. [10] "Spitzer Space Telescope Handbook." Spitzer Space Telescope Handbook 2.1 (2013): n. pag. Spitzer Space Center, 8 Mar. 2013. Web. 8 Sept. 2014. [11] Vanbebber, Craig. "Lockheed Martin Licenses New Breakthrough Infrared Technology." Lockheed Martin Corporation, 7 Dec. 2010. Web. 9 Sept. 2014. 40 BACKUP SLIDES 41 CubeSat Bus Design Constraints Bus Electrical Constraints 3.3 V 6.0 A Max 12 V 4.0 A Max Unregulated Voltage 6.5 V – 8.6 V 6.0 A Max Total Power 5 W Nominal Average 15 W Peak Command Communication Bus SPI Slave High-Speed Communication Bus Ethernet, Magnetics-Less Differential Backup Communication Bus I2C Regulated Voltage Lines Bus Structural Constraints Total Volume 2U (10x10x20 cm) Total Mass 2.66 kg + 0.1 kg/ - 0.5 kg 42 Critical Project Elements Critical Element Subsystem Driving Requirements Capture Mid Wave Infrared (MWIR) image Optical The payload shall determine the angular velocity and axis of rotation of an observed object (O.2), The payload shall use the 3.5 µm mid-wave infrared (MWIR) wavelength (O.3) Control focalplane to operating temperature of ≤ 150 K Thermal The payload shall maintain all components in their operating temperature ranges (O.4) Determine angular velocity vector of object in sensor field of view Software The payload shall determine the angular velocity and axis of rotation of an observed object (O.2) Provide a hardware platform for the software Electrical The payload shall determine the angular velocity and axis of rotation of an observed object (O.2) Purpose and Objectives Design Solution Requirement Satisfaction Verification/Validation Planning 43 Functional Block Diagram Purpose and Objectives Design Solution Requirement Satisfaction Verification/Validation Planning 44 Design Overview Infrared Optics and Focusing • • Two Mirror Design Manually adjust position of primary mirror using micrometers • Precision: 1 micron • Total Travel: 5 mm Bus Interface Side 45 Design Overview Infrared Optics and Focusing • • Two Mirror Design Manually adjust position of primary mirror using micrometers • Precision: 1 micron • Total Travel: 5 mm Hyperbolic Primary Mirror Hyperbolic Secondary Mirror Focal-Plane 3-Axis Focusing Mechanism Micrometer Primary Mirror Secondary Mirror Purpose and Objectives Design Solution Requirement Satisfaction Verification/Validation Planning 46 Design Overview Thermal Control • • • Thermal Electric Cooler Thermal braids to exterior radiator panels Focalplane requires cooling to 150 K for operation in infrared band Purpose and Objectives Design Solution Requirement Satisfaction Verification/Validation Planning 47 Design Overview Thermal Control • • • Thermal Strap Thermal Electric Cooler Thermal braids to exterior radiator panels Focalplane requires cooling to 150 K for Image Sensor operation in infrared band Module Thermoelectric Coolers MWIR Focalplane Operates ≤ 150 K Purpose and Objectives Design Solution Requirement Satisfaction Verification/Validation Planning 48 Design Overview Electronics Software • • • • • • MWIR Sensor module Image Processing board Power and thermal control board Image Purpose and Objectives Design Solution Requirement Satisfaction Capture and save IR image Determine rate of object in FOV Verification/Validation Planning 49 Design Overview Electronics Software • • • • • • MWIR Sensor module Image Processing board Power and thermal control board Image Capture and save IR image Determine rate of object in FOV Power and Thermal Control Board Sensor Interface Module Purpose and Objectives Design Solution Requirement Satisfaction Verification/Validation Image Processing Board Planning 50 OPTICS BACKUP 51 Requirements Requirement Driver The optical system shall have a diffraction limited spot size of less than 20 µm at a 3.5 µm wavelength Detector pixel size The optical system shall image at the 3.5 µm wavelength Customer The optical system shall have an SNR of no less than 6 Image processing The optical system tolerances shall change the spatial cutoff frequency by no more than 15 percent Imaging quality & mechanical feasibility 52 Mirror Fabrication Process 1. 2. 3. 4. 5. 6. Mirrors out of aluminum blanks in AES shop Thermal cycled & re-machined to remove stresses Sent to Denver Metal Finishing for nickel plating Sent to TBD supplier to be diamond turned Gold deposited on mirrors in CNL thermal evap System specifications tested using PSF testing Process Cost Nickel Plating $300 Diamond Turning ~$3000-5000 Gold Deposition $200 Estimated Total $3500-5500 53 Bandwidth COTS bandpass filters work for our application Low cost, low lead time Pass band: 3.32 – 3.60 µm 3.46 µm Bandpass Filter 2.OPT.2 Transmittance Capture images at the 3.5 µm wavelength Wavelength (nm) Overview Baseline Design Optics Thermal Electrical/Software Testing Logistics 54 Spot Size Spot sizes calculated using Zemax simulations Optically Limited Designs Diffraction Limited Designs On & Off Axis Beams Diffraction Limited 2.OPT.1 Diffraction limited spot size < 20 µm at λ =3.5 µm Overview Baseline Design Optics Thermal Electrical/Software Testing Logistics 55 Sampling Sampling size is the detector pixel size (i.e. 12 µm) Nyquist Theorem • Diffraction limited spot size < 20 µm at λ =3.5 µm sampling size = optical spot size Oversampling • 2.OPT.1 sampling size < optical spot size Nyquist Sampling Normalized Diffraction Limited Spot Cross Section Oversampling Spot Size Overview Baseline Design Nyquist sampling versus over-sampling, exaggerated for effect Optics Thermal Electrical/Software Testing Logistics 56 Signal to Noise Ratio (SNR) Assuming operation at 3.32-3.60 µm wavelengths Primary source of noise: thermal background and dark current SNR ≥ 6 reduces probability of false alarms from noise to ~10-12 in sensing and tracking functions Signal to Noise Ratio vs. Range from Target 2.OPT.3 SNR SNR ≥ 6 SNR = 6.28 Range (km) Overview Baseline Design Optics Thermal Electrical/Software Testing Logistics 57 Probability of Detection Kamerman estimation • Assumptions: SNR > 2, 10−12 < 𝑃𝑓𝑎 < 10−3 1 𝑃𝑑 = ∗ 1 + erf 2 1 1 + 𝑆𝑁𝑅 − 𝑙𝑛 2 𝑃𝑓𝑎 Thus for SNR > 6 and 𝑃𝑓𝑎 < 10−10 the probability of detection is essentially 100 percent 58 Thermal Stresses Z-axis thermal expansion • Focusing @ 300K • Take images @ 230K • dL = 233 µm 𝛼𝑎𝑙𝑢𝑚 = 22.2 ∗ 10 𝑑𝐿 = 𝛼𝑎𝑙𝑢𝑚 𝐿 𝑑𝑇 𝑑𝑇 = 70 𝐾 𝐿 = 0.15 𝑚 −6 1 𝐾 X,Y-axis thermal expansion • Will not change focus Steady-state temperature operation • Max dT ~ 4K (Simulink simulation) • dL ~ 10 µm • Far below tolerances and depth of focus z y x 59 Aberrations Seidel Coefficients (in 𝜆): 60 nBn Detector InAs N-doped Semiconductor Layers Sandwiching 100 nm AlAsSb Barrier Reduced Dark Current, Operating Temp. of 140+ K vs 77 K (Traditional) Figures courtesy of: Applied Physics Letters, October 9, 2006 - 151109 61 Imaging Results Simulated Image of Optical System Note blur at edge of field of view Overview Baseline Design Optics Thermal Electrical/Software Testing Logistics 62 TESTING BACKUP 63 Cooling Jacket 64 Test Target Surfaces Paint • White and black paint are both high emissivity at IR • Paint emissivity much higher than polished metal (0.85 versus 0.05) and net emissivity a function of paint thickness Surface roughness • Increased surface roughness increases emissivity (0.30 versus 0.10, varies with surface roughness) Oxidation • Oxidized metal has higher emissivity (0.40 versus 0.10 for aluminum, varies depending on degree of oxidation) Images from http://www.reliableplant.com/Read/14134/emissivity-underst-differencebetween-apparent,-actual-ir-temps 65 Test Target Contrast Background at 195K (dry ice) and emissivity of 0.03 (aluminum foil) Target • Temperature: 295K • Mean emissivity: 0.3036 • Minimum emissivity: 0.1154 (polished copper) • Maximum emissivity: 0.4918 (partially oxidized copper) 66 Collimating Optic Plano-convex lens • • • • • • Between payload and test target Cold background behind target $500 Four-week lead time Less than full aperture diameter which reduces contrast 1m or 2m focal length • 3.24cm or 4.68cm test target Parabolic Mirror • On far side of test target • Payload is background • Possible background uniformity issues but can crop image • Target obstructs field of view which reduces contrast • $465 67 Optics Contingency (1) Integrated System Thermal Test • Unchanged, uses unsurfaced mirrors as thermal masses Electronics • Power board fully testable • Image close target without optics to verify image sensor interface • Image sensor interface core has test mode to verify hardware without image sensor Image Capture Command Main Processor and Memory Test Image Image Sensor Interface Core 68 Optics Contingency (2) Software • Feed algorithm simulated images to verify optical flow and rate determination modules • Have option to replace image sensor interface core with new core that provides simulated images, from the perspective of the software this is identical to nominal operations Test Computer / FPGA Core Unmodified Software Modules Mechanical • Focusing mechanism still fully testable 69 LOGISTICS BACKUP 70 Work Products Breakdown Structure Structures Electronics* Thermal Software • Primary & Secondary Mirror Drawings • Rev 1 Board Schematics • Block Diagram of Thermal Paths • Communications Module • Rev 1 Board Layout • Focusing Mechanism Drawings • Rev 1 Populated Board • Resistance Values for Thermal Contacts • Sensor Interface Module • Thermal Mounting Hardware Drawings • Load/Vibration Analysis on Mirror Supports • Drawing Package for all Components • Drawing Tree • CAD Model • Machined Components • Rev 1 Board Test Report • Rev 2 Board Schematics • Rev 2 Board Layout • Rev 2 Populated Board • Rev 2 Board Test Report • Integrated Electronics • Simulink Model • Thermal Desktop Model • Integrated Thermal System • Rate Determination Module • Image Interface Module • Temperature Control Module Optics • Thermal Background Calculations • Photon & SNR Budgets • Mirror Designs • Baffle & Cold-Stop Design • Focused Optical Assembly • OP Code Dictionary • Software Reference Document • Software Package • Assembled Units * These deliverables pertain to both the Power and C&DH Board 71 Work Products Breakdown Structure Management Testing Systems • PDD • Procedure for TVAC Test • CDD • Procedure for Optics Test • Test Procedures per Subsystem • PDR Presentation • Integration Procedures • ICD per Subsystem • CDR Presentation • MSDS Documentation • Integrated Payload • FFR • Liner for Optics Test • MSR Presentation • Payload Bracket for Optics Test • TRR Presentation • AIAA Paper • Payload to Bus ICD • SFR • Aligned & Focused Collimator • Test Target • Bus Simulator for TVAC Test • Test Results 72