Useful Microbiological Testing in Food Safety & Quality Management

advertisement

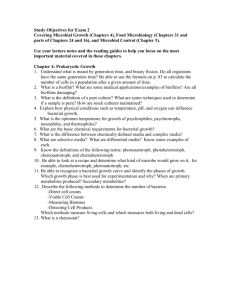

1 Useful Microbiological Testing in Food Safety & Quality Management Katherine M.J. Swanson, Ph.D. Vice President Food Safety Ecolab President-Elect IAFP Arkansas Association for Food Protection Springdale, AR September 14, 2011 2 Discussion Topics International Association for Food Protection greeting Different tests serve different purposes Testing for maximum value Our mission is working To provide food safety professionals worldwide with a forum to exchange information on protecting the food supply IAFP Annual Meeting the leading food safety conference European and International Symposia European 2012 Warsaw, Poland 2011 Ede, The Netherlands 2010 Dublin, Ireland International 2012 Latin America - Argentina 2011 Asia Pacific - Australia 2010 Latin America - Colombia IAFP Publications Affiliate Connections 48 Affiliates worldwide North America – 35 South/Latin America – 3 Europe – 4 Asia – 4 Australia & Oceania – 2 Connect with food safety professionals in your area by joining or forming an IAFP Affiliate! Service and Growth Opportunities Committees Standing Committees Special Committees Task Forces Professional Development Groups (PDGs) Diverse focus groups in 20 specialized areas Affiliate Council Delegates from 48 Affiliate organizations, with representation on IAFP Executive Board Recognition for Achievements Black Pearl Award Awards for excellence in specific disciplines of food safety – 10 Travel Awards for government employees – 4 Association honors – 4 Cooperative Awards – 3 Student Awards and scholarships – 13 Affiliate Awards – 5 Benefits of Membership IAFP Report monthly newsletter Online membership directory & FPT Involvement in Committees and Professional Development Groups Discounted rates for: IAFP’s scientific journals IAFP annual meeting and international symposia Educational workshops Food safety booklets, icons, and other established resources 3-A Sanitary Standards Flexible Membership Plans Base Membership $55 Base Membership for Students $27.50 www.foodprotection.org 12 Different Tests Serve Different Purposes 13 Microbial Testing “Microbial testing” means different things to different people Reams of data Detective game to identify unknown or causative agent Presence/absence or qualitative reaction that’s observed Quantitative measurement of the microbiological status of a sample or lot Presentation focuses on process control and product acceptance OR 14 The Purpose of a Test Determines: The target Indicator or pathogen The method Time to results, accuracy, repeatability, etc. The sample Environment, line residue, end product, location collected, size/ number of samples The frequency Daily, weekly, monthly, etc. or event triggered The interpretation Investigational, routine, regulatory, etc. The action Rejection, process adjustment, recall, outbreak investigation, etc. 15 International Commission on Microbiological Specifications for Foods Founded in 1962 to advance scientific concepts for government and industry consideration to: Reduce foodborne illness Facilitate global food trade Focus on testing applied to foods Membership 6 Academia, 6 Government, 5 Industry from 11 Countries All work is voluntary and without honoraria Partners with FAO, WHO, ILSI, IUFoST, IAFP etc. Provides advice through books, papers, workshops, etc. Advice has no official status 16 When & Where to Test for Food Safety Management When there is good evidence that: There is a microbiological problem - Food safety or quality - Historical or current AND Testing will help to control the problem 17 Target Organism Examples ICMSF Hazard Categories EXAMPLES Utility Spoilage, reduced shelf life, no health concern Total counts, yeast, mold, etc. Indicator Measure of GHP or process control Coliforms, generic E. coli, Enterobacteriaceae, etc. Moderate hazard Not life threatening, short duration, self limiting, no sequelae S. aureus, B. cereus, C. perfringens, Norovirus, etc. Serious hazard Incapacitating, usually not life threatening Salmonellae, Shigella flexneri, Yersinia enterocolitica, etc. Severe hazard Life threatening, chronic sequelae, or long duration OR E. coli O157:H7, C botulinum toxin or Cronobacter (infants) Designed for sensitive subpopulation From ICMSF Book 7 18 Key ICMSF Sampling Plan Terms n Number of sample units analyzed c Maximum number of sample units with unsatisfactory test results m Level that separates acceptable quality from marginally acceptable or unacceptable quality M Level above which is unsatisfactory or requires further investigation 19 Choosing m and M m Relative proportion of sample units in a lot No concern M Some concern Mean log count Decisive concern 20 ICMSF Suggested Sampling Plans FOR LOT ACCEPTANCE TESTING Likely Change Before Consumption Hazard Group Reduce No Change Increase Utility Case 1 Case 2 Case 3 n=5, c=3 n=5, c=2 n=5, c=1 Case 4 Case 5 Case 6 n=5, c=3 n=5, c=2 n=5, c=1 Case 7 Case 8 Case 9 n=5, c=2 n=5, c=1 n=10, c=1 Case 10 Case 11 Case 12 n=5, c=0 n=10, c=0 n=20, c=0 Case 13 Case 14 Case 15 n=15, c=0 n=30, c=0 n=60, c=0 Indicator Analytical unit = 25g Moderate Serious Severe 21 Probability of Acceptance Sample Size Influence on Probability of Acceptance m=0 1.2 74% n = 15 n = 30 55% n = 60 86% 1 0.8 0.6 0.4 0.2 0 0 1% 5 10 % Defective 15 20 22 Testing to Maximize Value 23 Useful Microbial Testing Identification of contamination sources Environmental monitoring to identify potential harborage sites Utility and indicator organisms to verify effective controls & trends Effective processing Effective control of post process contamination Investigation sampling for problem solving 24 Process Example Process 1 Ingredients Packaging Line A Process 2 Packaging Line B Process 3 What action do you take when an unacceptable result is found on Line B? 25 Result Format Influences Information Provided Quantative Presence/Absence 5 Log (CFU/g) Positive Negative 4 3 2 1 0 0 10 Lot Number 20 0 10 Lot Number 20 26 5 5 4 4 Log (CFU/g) Log (CFU/g) Trend Analysis Can Inform Process Control 3 2 3 2 1 1 0 0 0 10 0 20 5 4 4 Log (CFU/g) Log (CFU/g) 5 3 2 3 2 1 1 0 0 10 Lot Number 20 Lot Number Lot Number 0 10 20 0 10 Lot Number 20 27 Testing Considerations Primary production Ingredients In-process Processing environment Shelf life End product 28 Book 8 Contents Part 1-Principles Utility of microbial testing for safety & quality Validation of control measures Verification of process control Verification of environmental control Corrective action to re-establish control Microbial testing in customersupplier relationships Part 2 – Product Categories Meats Poultry Seafood Feed & pet food Vegetables Fruits Spices, dried soups, flavorings Cereals Nuts, oilseeds, dried legumes Cocoa and confectionery Oil based foods Sugar, syrups, honey Beverages Water Dairy products Eggs Shelf stable, heat treated foods Infants and young children Formulated foods 29 Primary Production Included when production conditions have a major influence on the microbial quality or safety Fruits, vegetables, spices, meat, poultry and fish products Examples of samples to consider Irrigation water Fertilizer Feed Other on-farm practices 30 Ingredient Testing May be useful for some applications and not others Example - cocoa powder: Used in chocolate, no heat treatment ? Used in ice cream mix that is subsequently pasteurized Question Is control at the ingredient step necessary? 31 In-Process Testing Verify a kill step or predict potential recontamination Examples Intermediate product, line residues, tailings, wash water Typically indicators with quantitative results Questions: Is the process needed to control a microbial concern? Is testing needed to verify: - the process is functioning as intended or - contamination is not occurring in the process? 32 Processing Environment Testing Use to verify that the environment is under appropriate hygienic control Examples Swabs or sponges for equipment or in the environment Rapid testing to verify cleaning & sanitation adequacy Identify harborage sites that can contaminate end product Frequently, earlier detection of issues than end product testing Questions considered: Does the environment need to be controlled to prevent contamination? Will testing be beneficial to verify control? 33 Shelf Life Testing Relevant for products subject to microbial spoilage Purpose – verify microbial stability for the product life cycle May predict issue before they are experienced in the market place Questions considered: Is shelf life limited by a microbiological safety or quality concern? Is shelf-life testing feasible? 34 End Product Testing Demonstrate successful application of controls or assess the status of a lot when no other information exists. Alternative sampling plans may be appropriate, for example: Fewer samples for on-going surveillance activity More samples when investigating significant process deviations or outbreaks. Questions considered: Is end product testing necessary to verify the overall manufacturing process? Is end product testing relied upon for ensuring the safety or quality of the lot? 35 Example: Dried Ready-to-Eat Cereal Relative importance Useful testing Critical ingredients Medium In-process High Test appropriate product residues and in-line samples for Salmonella. Typical guidance levels: Salmonella – absent Processing environment High Test for Salmonella and Enterobacteriaceae in the processing environment Typical guidance levels: Enterobacteriaceae – 100-1000 cfu/g Salmonella – absent Shelf-life Not relevant Test for mycotoxins if confidence in raw grains is low Test nuts, cocoa, and other sensitive ingredients with no subsequent kill step for Salmonella if confidence in supplier is low. - 36 Example: Dried Ready-to-Eat Cereal (continued) Relative importance Useful testing End product High Testing for Enterobacteriaceae is recommended to verify process control. Product Dried cereal Low Microorganism Enterobacteriaceae Analytical method ISO 21528-2 Sampling plan & limits/g Case n c m M 2 5 2 10 102 Testing for pathogens is not recommended during normal operation when GHP and HACCP are effective as confirmed by above tests. When above testing or process deviations indicate a possible safety issue, test for Salmonella. Product Dried cereals Sampling plan & limits/25g Microorganism Analytical method Case n c m M Salmonella ISO 6579 11 10 0 0 - 37 Example: Comminuted Meat Relative importance Useful testing Critical ingredients Low to high Pre-testing beef trimmings for E. coli O157:H7 may be useful when confidence in supplier control is low. In-process Low Routine in-process samples are not normally collected. Samples of meat at various stages of processing can be used to establish a baseline and understand changes in the microbial population during processing. Processing Low environment Sample equipment surfaces before start-up to verify efficacy of cleaning and disinfecting. Typical levels encountered may vary by surface type. Shelf life Routine shelf life testing of refrigerated raw meat is not recommended. Shelf life testing may be useful to validate code dates of new retail products or when new packaging systems are installed. Low 38 Example: Comminuted Meat (continued) Relative importance Useful testing End product Medium Test freshly packaged product for indicators for on-going process control and trend analysis using internally developed guidelines. Levels for processing do not apply during distribution or at retail. Product Microorganism Raw, comminuted meat E. coli Analytica l method ISO 16649-2 Sampling plan & limits/g Case 4 n c m M 5 0 0 - Medium Routine testing is not recommended for salmonellae. In regions where ground beef is a continuing source of E. coli O157:H7 illness, the following criteria are recommended. Product Microorganism Analytical method Ground beef E. coli O157:H7 ISO 16654 Sampling plan & limits/25g Case n c m M 14 30 0 0 - 39 Microbial Sampling Summary Testing safety “into” products usually does not work because of sampling probability Testing is recommended to generate meaningful data Impact quality or safety Verify appropriate controls or direct corrective action Focus on verification of process control preferred Environmental monitoring Selected sampling tailored to the line to verify control 40 Acknowledgements ICMSF Dr. Martin Cole, CSIRO, Australia (Chair) Dr. Russ Flowers, Silliker Group, United States Dr. Fumiko Kasuga, National Institute of Health, Japan (Secretary) Dr. Bernadette Franco, Universidade de São Paulo, Brazil Dr. Jeff Farber, Health Canada (Treasurer) Dr. Leon Gorris, Unilever, China Dr. Anna Lammerding, Public Health Agency, Canada Dr. Xiumei Liu, CDC China Dr. Lucia Anelich, Consumer Goods Council, South Africa Dr. Tom Ross, University of Tasmania,, Australia Dr. Robert Buchanan, University of Maryland, United States Dr. Katie Swanson, Ecolab, United States Dr. Jean-Louis Cordier, Nestle, Switzerland Dr. Marta Taniwaki, Instituto de Tecnologia de Alimentos, Brazil Dr. Ratih Dewanti, Bangalore Agricultural University, Indonesia Dr. Marcel Zwietering Wageningen University, The Netherland Dr. Wayne Anderson, Ireland Food Safety Authority 41 Reference www.slideshare.com