2.7 (SPP) - Restek Corporation

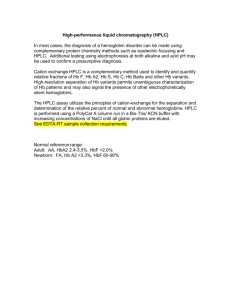

advertisement

Selling Restek LC Solutions for Analytical Scale Laboratories Part 1 – Discover - Assess the Workflow and Define the Opportunity Understanding Target LC Techniques Rick Lake Product Line Manager Liquid Chromatography 814-353-1300 x 2379 rick.lake@restek.com The Goal - Get a Column in a Method Additional Method Additional Method Validation LC Consultative Selling Approach Displaces current products, creates opportunity for future methods, and BUILDS TRUST in RESTEK STEPS 1 2 Discover PURPOSE RESULT Assess Workflows and Capabilities Develops Product Class Focus and Starting Product Fit Develops Problem/ Opportunity Statement Refine Assess a Definitive Need 3 Consult Find a Product or Solution that fits definitive need Present Product Recommendation and Proof Statements 4 Extend Cross-Selling of Associated products Expand the account possibility LC Consultative Selling Approach – Step 1 Identifying the Workflow – Dilute and Shoot Example Sample Preparation + Analyte Separation + Analyte Detection Discovery Questions – Step 1 Discovery Questions Defines What techniques are you currently utilizing? Which chromatographic needs are important and what product classes to initially focus on What is the technique focus for future method development (same or shifting)? What product class you should focus on for new methods and what the corporate need may be What instrumentation are they currently using (Manufacturer and Model)? Which product class you should focus on and what benefits to reinforce How many instruments are currently being utilized? Potential volume How often are they purchasing new instruments? Corporate growth goals and needs What types of Sample Preparation are you doing? Sample throughput and impact on chromatography Where do your methods come from (developed in-house or transferred)? Target contact, potential needs and potential volume The Differences Between Selling LC and GC • • • • All dimensions of columns can fit Makes and Models are very similar Customers looking for specific application No mobile phase! • • • • Product recommendation varies by instrument Makes and Models are very different Customers looking for technologies that improve performance Like specific application but can benefit from like examples LC Product Classes – Instrument Fit Conventional HPLC Intermediate HPLC Agilent 1200 Agilent 1260 Agilent 1290 • • • • • • 400 bar Highest system volume 600 bar Moderate system volume UHPLC 1000 bar Low system volume The main difference is the operating pressures and system volumes LC Differences and Classes Pressure Volume HPLC >1 ml of system volume <400 bar pressure IHPLC >0.2 ml of system volume <800 bar pressure UHPLC <0.2 ml of system volume <1000 -1200 bar pressure LC Brands and Models HPLC IHPLC UHPLC Waters Shimadzu Agilent Alliance Prominence / I series Acquity (multiple classes) Prominence UFLC-XR / I series 1260 /1200 RRLC H-Class 1100/1200 I-Class Nexera X2 1290 MS Differences and Classes Model determines sensitivity, available flow and speed of acquisition Relevant Techniques – Defined Technique Why Customers Use It? What are some common pain points? HPLC • Older technologies that are readily available • Not enough capital for newer instruments • Rugged instruments for Quality and MFG settings • Not a high sample throughput • Can be relatively inexpensive to maintain • Not fast • Low sample throughput • High solvent usage, not “green” • Accessories are becoming harder to find • Software is not supported as well Relevant Techniques – Defined Technique Why Customers Use It? What are some common pain points? (I)HPLC • Can be used to run faster than conventional HPLC • Not as expensive at UHPLC • More rugged than UHPLCcan be used in Quality and MFG settings • Less costly maintenance than UHPLC • Not as fast as UHPLC • Can struggle with system volume and lower ID • Cannot get full potential from UHPLC columns (often tried) • More expensive then UHPLC, often rivaling UHPLC Relevant Techniques – Defined Technique Why Customers Use It? What are some common pain points? UHPLC • Can greatly increase sample throughput • Very good for high sensitivity (low volume) • Every major manufacturer has a model • Can be lower solvent usage than HPLC • Very expensive • Not rugged • Clogging is an issue with parts and columns • Consumables have lower lifetime • Expensive to maintain- often involves service contract • Not rugged – research instruments Relevant Techniques – Defined Technique Why Customers Use It? What are some common pain points? LC-MS/MS • Most powerful analytical tool to date • High sensitivity lessens need for complex sample preparation • MRM can be used for sensitive and accurate quantitation • Lower sample prep can reduce consumable lifetime • Isobaric co-elution can be difficult to resolve • Matrix can cause ionization suppression • Narrow MRM windows can cause down time due to lack of repeatability • Expensive to maintain LC Product Classes – Technology Fit 5 µm 5 µm 3 µm HPLC 2.7 µm 5 µm 3 µm Intermediate 2.7 µm HPLC 2.7 µm UHPLC 1.9 µm Identify Column Dimensions by Technique Technique Product Class Customer Need Particle Diameter (dp) Internal Diameter (ID) Length (L) System Pressure Capacity, Volume and Flow Peak Capacity HPLC Ultra and Raptor 3 and 5 µm, 2.7 (SPP), 5 (SPP) 3.0 and 4.6 mm 100 to 150mm UHPLC Pinnacle DB and Raptor 1.9 µm, 2.7 (SPP) 2.1mm 50mm to 100mm HPLC - XR Raptor and Ultra 1.9 and 3 µm, 2.7 (SPP) 3.0 and 2.1mm 50 to 100mm Preparative Ultra 5µm and above Semi-Prep 10 to 21.2 mm ID Prep 30 to 50 mm ID LC-MS/MS Raptor 1.9, 3 and 5 µm (determine by front end) Capillary, 1.0 and 2.1mm 30 to 100mm Corporate Needs – Clinical Corporate Needs and Objectives: Novel ways to lower cost per injection Increase turn-around time by increasing sample throughput – screenings conducted in under 30 seconds, analyses under 5 minutes, large panels not to exceed 10 minutes Better detection limits for target compounds Minimize sample preparation steps and labor costs – no chemistry, laboratory miniaturization Minimize error in reporting and sample handling Development of screening analyses that lowers total number of tests needed as only the positive samples are sent downstream Training of inexperienced technicians Increased analytical up-time (columns and accessories) Key Focus for Product Positioning Better Data. Faster Throughput. Exceptional Value. Consumer Needs Restek Benefit Increase sample throughput • Decrease analysis time with selectivity or efficiency Increase instrument up time • Longer consumable lifetimes – better handle the effects of flow, pressure and matrix • High RT consistency (MRM windows) • Lower need to for RM events Lower detection of analytes • Peak shape and peak capacity • Better separation from matrix (lower Ion Suppression) • Better able to handle matrix Increased compound/isobaric separation • Better selectivity with simple mobile phases Refinement Questions – Step 2 Refine Questions Defines Where do your methods come from (developed in-house or transferred)? Target contact, potential needs and potential volume What are your corporate goals for your department? Corporate needs What columns are currently using? What do you like or dislike about them? Current technology focus and importance Are you satisfied with your current data quality? Chromatographic variables that are important to them If you could improve one thing, what would it be? Focus for product selection Framing the Opportunity/Problem So, you are interested in products that can help you ________? Example: So, you need to increase your productivity? • by lessening analysis times • by increasing your instrument up-time • by find products that will transition to future instrument purchases • by extending the lifetime of your consumables? Where we are? STEPS 1 2 Discover Refine PURPOSE RESULT Assess Workflows and Capabilities Develops Product Class Focus and Starting Product Fit Assess a Definitive Need Develops Problem/ Opportunity Statement Example: So, you are interested in ways that we can help your Shimadzu UFLC and AB Sciex 4500 run more urinary drug tests per day?