chapter 1 - GEOCITIES.ws

advertisement

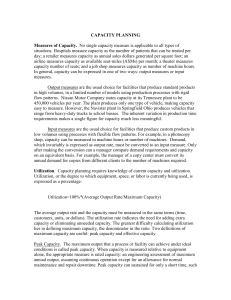

CHAPTER 8 CAPACITY THE CONCEPT Maximum rate of output for a process Inadequate capacity can lose customers and limit growth while excess capacity can drain company’s resources and prevent investments in more lucrative ventures To meet current and future demands Output measure : when a firm provides a relatively small number of standardized products/services or applied to individual process within the firm THE CONCEPT (continued) Input measure : low volume, flexible process (machine hours or number of machine) Utilization : the degree to which equipment, space or labor is currently being used = the percentage of average output rate to maximum capacity Maximum capacity is defined as peak capacity or effective capacity Peak capacity : the maximum output under ideal conditions, sustained for a short time, marginal method (overtime, extra shifts, reduced maintenance, etc) THE CONCEPT (continued) Effective capacity : maximum output that a firm can economically sustain under normal conditions or the greatest level of output the firm can reasonably sustain by using realistic employee work schedule and the equipment currently in place Increasing maximum capacity : line balancing, minimizing the idle time lost at upstream operations, maintaining the availability of materials & tools, avoiding/minimizing unproductive activities (setup, handling ECONOMIC OF SCALE The average unit cost can be reduced by increasing its output rate because : the fixed costs are spread over more units reducing construction cost cutting cost of purchased materials finding process advantages DISECONOMIES OF SCALE The average cost per unit increases as the facility’s size increases for it brings complexity, loss of focus, inefficiencies, loss of flexibility to respond changing demands CAPACITY STRATEGIES Sizing capacity cushions : average utilization rate should not get too close to 100% to avoid declining productivity. So the capacity cushion is the amount of reserve capacity that a firm maintains to handle sudden increase in demand or temporary losses of production capacity. Larger cushion when demand varies, future demand uncertain Timing and sizing expansion : expansionist (capacity lead, average capacity, one step expansion) strategies and wait-and-see (capacity lag, incremental) strategies CAPACITY STRATEGIES (continued) Linking capacity and other strategies : competitive strategies, quality management, capital intensity, resource flexibility, inventory, scheduling, location decisions STRATEGIES FOR MEETING DEMANDS (see Russell & Taylor) Aggregate production planning determines the resource capacity needed to meet demand over an intermediate time horizon. It becomes a challenge when demands fluctuate which can be met by : producing at a constant rate and using inventory to absorb fluctuations (level production) hiring and firing workers (chase demand) maintaining resources for high demand level STRATEGIES FOR MEETING DEMANDS (continued) increasing and decreasing working hours (overtime) subcontracting works using part time workers providing the service/product at a later time period (backordering) A SYSTEMATIC APPROACH TO CAPACITY DECISION Estimate future capacity requirements Identify gaps Developing alternative plans for filling the gaps Evaluate each alternative and make the final choice TOOLS FOR CAPACITY PLANNING Waiting line models and simulation : random and independent consumer behavior Decision trees : to anticipate any possible events such as competitor’s actions