Waste Transformation Trough Aerobic Composting

advertisement

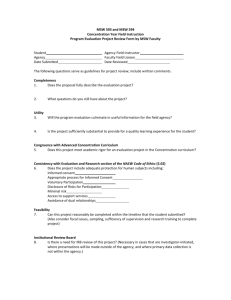

Presentation Outline Introduction Reuse and Recycling Opportunities For Waste Materials Materials Recovered At Drop – Off and Buy Back Centers Operations For the Separation Of Waste Materials Introduction to the Unite Operation Used For the Separation and Processing of Waste Materials Facilities for Handling, Moving, and Storing Waste Materials Development and Implementation of MRF Waste Transformation Through Combustion Impacts of Source Reduction and Waste Recycling on Waste Transformation Process Introduction Separation, Processing and Transformation make up the fourth of the functional elements of solid waste management system the methods now used to recover source separated wastes materials include curb side collection and home owner delivery of separated materials to drop off and buy back centers. The further separation and processing of waste that have been source separated occur at MRF or at large integrated MR-TF. Chemical & biological transformation process are used to reduce the volume and weight of waste requiring disposal and to recover conversion products and energy in the form of heat. The most commonly used chemical transformation process is combustion which is used in conjunction with the recovery of energy in the form of heat. The most commonly used biological transformation process is aerobic composting. Reuse & Recycling Opportunities for Waste Materials Materials separated from MSW can be used directly as: raw material for remanufacturing and reprocessing feedstock for production of biological and chemical conversion products fuel source for the production of energy land reclamation Reuse opportunities for the materials separated from MSW are reported in Table 9-1. In assessing the opportunities for recycling, the available options for separation and processing of waste materials, the economics of material recovery and material specifications are critical Reuse & Recycling Opportunities for Waste Materials Reuse & Recycling Opportunities for Waste Materials Materials Recovered at Drop- off & Buy Back Center Drop- off Centers a drop-off program requires residents or business to separate recyclable materials at the source & bring them to a specified dropoff or collection center. Low participation can be a problem in achieving the diversion rated desired from these programs. Drop-off centers also requires residents and business to store the materials until sufficient material is collected to warrant a trip to the drop-off center. To encourage participation, most successful programs have made drop-off centers as convenient to use as possible (e.g., drop off points at shopping centers are common, in many communities combination drop –off and buy back centers are located at MRF, mobile collection centers which can be moved to a new locations periodically. Materials Recovered at Drop- off & Buy Back Center Materials Recovered at Drop- off & Buy Back Center Materials Recovered at Drop- off & Buy Back Center Buy – Back Centers Buy – Back refers to a drop-off program that provides a monetary incentive to participate In type of this program, the residents are paid for their recyclable either directly or indirectly through a reduction in monthly collection and disposal fees. Other incentive systems include contests t or lotteries Options for the separation of waste materials Separation is a necessary operation in the recovery of reusable materials from municipal solid waste. Separation can be accomplished either at the source of the generation or at MRFs. Waste separations at the source is usually accomplished by manual means, the number & types of components separated will depend on the waste diversion program. Additional separation and processing will be usually required before these materials can be reused or recycled. MRFs & MR-TFs are used for : the further processing of source separated waste the separation & recovery of reusable & recyclable materials from commingled MSW improvement inequality ( specification) in the simplest term, AMRF can function as centralized facilities for the separations, cleaning & shipping of large volume of materials recovered from municipal solid waste Options for the separation of waste materials The separation of waste materials from MSW can be accomplished manually or mechanically. Manual separation is used almost exclusively for the separation of waste at the source of generation. Many of the early MRFs built in 1970 s were designed to separate the waste components mechanically. Unfortunately, none of these early facilities is currently in operation, primarily because of mechanical problem. The currant trend is to design MRFs based on the integration of both manual and mechanical separation functions Options for the separation of waste materials Two types of MRF: MRF for Source – Separated Waste MRF for commingled MSW The sophistication of the MRF will depend on the number and types of the components to be separated the waste diversion goals established for the waste recovery program the specifications to which the separated products must conform Introduction to the Unit Operation Used for the Separation and Processing of Waste Materials Unit operations used for the separation and processing of separated and commingled wastes are designed to Modify the physical characteristics of the wastes so that the waste components can be removed easily Remove specific components and contaminants from the waste stream process and prepare the separated materials for subsequent uses Commonly used unit operations for processing of MSW are summarized in Table 9-3 Introduction to the Unit Operation Used for the Separation and Processing of Waste Materials Introduction to the Unit Operation Used for the Separation and Processing of Waste Materials Size Reduction Size reduction is the unit operation in which as collected waste material are mechanically reduced in size The objective of size reduction is to obtain a final product that is reasonably uniform and considerably reduced in size in comparison with its original form. Note that size reduction does not necessarily imply volume reduction. In some situations, the total volume of the material after the size reduction may be greater than that of the original volume. Size reduction equipment used for the processing of wastes includes Shredders Glass crushers Wood grinders Introduction to the Unit Operation Used for the Separation and Processing of Waste Materials Shredders the three most common types of shredding devices used to reduce the size of MSW are • Hammer mill • Flail mill • Shear shredder Introduction to the Unit Operation Used for the Separation and Processing of Waste Materials Glass Crushers o glass crushers are used to crush glass container and other glass products found in MSW o glass is often crushed after it has been separated to reduce storage and shipping costs o crushed glass can also be separated optically by color. However, because the equipment of the optical sorting of glass is expensive and on-line reliability of such equipment has not been good, optical sorting is not used commonly at present Wood Grinders o Typically, most wood grinders are wood chippers, used to shred large pieces of wood into chips, which can be used as a fuel and finer material which can be composted Introduction to the Unit Operation Used for the Separation and Processing of Waste Materials Screening Screening is used to separate mixtures of materials of different sizes The principal applications of screening devices in the processing of MSW include: o removal of oversized materials o removal of undersized materials o separation of waste into light combustible and heavy combustible o recovery of paper, plastic and other light materials from glass and metal o Separation of glass, girt and sand from combustible materials o Separation of rocks and oversized debris from soil excavated at construction sites o removal of oversized materials from combustion ash Introduction to the Unit Operation Used for the Separation and Processing of Waste Materials Screening The types of screen used most commonly for the separation of solid waste materials are o Vibrating screens o Rotary screens o Disc screens • self cleaning • adjustability with respect to the spacing of the discs on the drive shafts Insert Figure 9-8 Introduction to the Unit Operation Used for the Separation and Processing of Waste Materials Introduction to the Unit Operation Used for the Separation and Processing of Waste Materials Density Separation (Air Classification) Air classification is used to separate light materials from heavier material, based on the weight difference of the material in an air stream. Introduction to the Unit Operation Used for the Separation and Processing of Waste Materials Magnetic Separation Magnetic separation is a unit whereby ferrous metals are separated from waste materials (Source – separated, commingled and shredded MSW) by utilizing their magnetic properties The specific location (s) where ferrous materials are recovered will depend on o The objectives to be achieved such as the reduction of wear and tear on processing and separation equipment o The degree of product purity to be achieved o The required recovery efficiency Densification (compaction) Densification is a unit operation that increases the density of waste materials so that can be stored and transported more efficiently Several technologies are available for the densification of solid wastes and recovered materials including baling, cubing and pelleting. Introduction to the Unit Operation Used for the Separation and Processing of Waste Materials Balers balers reduces the volume of waste for storage , prepare the waste for marketing and increase the density of the waste thereby reducing the shipping costs the materials most commonly baled include paper, cardboard, plastics, aluminum and tin cans and large metal component Introduction to the Unit Operation Used for the Separation and Processing of Waste Materials Can Crushers Can Crushers are used to crush aluminum and tin cans, thus increasing their density and reducing handling and shipping costs. Typically, aluminum cans are crushed and blown into large transport trailers for shipping. Facilities for Handling, Moving and Storing Waste Material To handle, move and store at MRFs, the following are used: Conveyors Conveyor facilities (picking belts) in conjunction with the manual separation of waste Pneumatic conveyor Movable and fixed waste-handling equipment Scales Storage facilities Facilities for Handling, Moving and Storing Waste Material Conveyors Conveyors transfer wastes from one location to another The principal types may be classified as hinge, bucket, belt drag, vibrating and pneumatic The conveyance of unprocessed commingled wastes with conveyors has not been trouble free conveyors have been damaged by solid wastes dropped onto them, especially those containing some of the heavier components often found in the waste. Problems have also developed at transfer points (e.g., where the waste are discharged from one conveyor to another) waste spillage and overflows are common Facilities for Handling, Moving and Storing Waste Material Conveyor Facilities Used in Conjunction with the Manual Sorting of Waste The manual separation of wastes at a MRF is usually accomplished by removing the individual waste components from the waste stream To improve the separation of waste components from commingled MSW, plastic bags used for on-site storage must be open and the contents spread out on the belt. The design of facilities for sorting waste components depends to a large extent on the o characteristics of the waste o number of commingled recyclable items that are to be separated o throughput capacity of the facility o width of the belt o speed of the belt o the average thickness of the waste materials on the belt Facilities for Handling, Moving and Storing Waste Material Conveyor Facilities Used in Conjunction with the Manual Sorting of Waste The manual separation of wastes at a MRF is usually accomplished by removing the individual waste components from the waste stream To improve the separation of waste components from commingled MSW, plastic bags used for on-site storage must be open and the contents spread out on the belt. The design of facilities for sorting waste components depends to a large extent on the o characteristics of the waste o number of commingled recyclable items that are to be separated o throughput capacity of the facility o width of the belt o speed of the belt o the average thickness of the waste materials on the belt Facilities for Handling, Moving and Storing Waste Material Facilities for Handling, Moving and Storing Waste Material Pneumatic Conveyors pneumatic conveying can be defined as materials transport using air as the transport medium. Two types of pneumatic transport system (positive pressure and vacuum) Velocities needed for the pneumatic transport of unprocessed solid waste are in the range of 4800 to 6000 ft/min. Facilities for Weighing weighing facilities are an important and necessary part of any MRF the types of weighing facilities used at MRFs vary from the small scales used to weigh the amounts of wastes brought in by individuals to the platform scales used for weighing collection vehicles Facilities for Handling, Moving and Storing Waste Material Storage facilities Materials that have been separated and processed must be stored until a buyer picks them up. In some facilities, space is provided for materials to be displayed for viewing by purchasers Key considerations are these: will the buyer provide storage containers for recovered materials with what frequency will the buyer pick up and remove prepared materials from MRF is it possible to rent temporary storage facilities for the processed materials away from the MRF Development and Implementation of MRFs Development and Implementation of MRFs Development and Implementation of MRFs Development of Separation Process Flow Diagrams A process flow diagram is defined as the assemblage of unit operations, facilities and manual operations to achieve a specified waste separation goal or goals. The following factors must be considered in the development of the process flow diagrams: o identification of the characteristics of the waste materials to be processed o consideration of the specifications for the recovered materials now and in the future o the available types of equipment and facilites o For example, specific waste materials cannot be separated effectively from commingled MSW unless bulky items are first removed. o A typical process flow diagram for the separation of source – separated paper and cardboard is shown in Fig. 9-20a Development and Implementation of MRFs Development and Implementation of MRFs Material Balances and Loading Rates Once the process flow diagram has been developed, the next step in the design of MRF is to estimate the quantities of materials that can be recovered and the appropriate design loading rates. the expected process loading rates must be known in order to select and size equipment properly. Loading rate for a given process are based on a mass balance Loading rates for most processes are expressed in tons per hour. In determining the design loading rates, one should make careful analysis to determine the number of hours per day and the year equipment will be operated. Based on 1820 operating hours per year, the base hourly loading rate is given by the following expression: Loading rate, ton/h = (Number of ton/year / 1820 processing h/yr) Development and Implementation of MRFs System Layout and Design the layout and design of the physical facilities that make up the processing facilities will depend on the types and amounts of materials to be processed. Important factors in the layout and design of such system include o the methods and means by which the waste will be delivered to the facility o estimates of material delivery rates o definition of the materials loading rates o development of materials flows and handling patterns within MRF o Development of performance criteria for the selection of equipment Development and Implementation of MRFs Typical Materials Recovery Facilities for Source – Separated Wastes in this text book, there are two types of MRFS o MRF designed to process source – separated wastes o MRF designed to process garden trimmings and wood wastes Development and Implementation of MRFs Development and Implementation of MRFs Development and Implementation of MRFs Development and Implementation of MRFs Development and Implementation of MRFs Planning and Design Process for MRFs The planning and design of MRFs involve three basic steps o Feasibility analysis the purpose of the feasibility analysis is to decide whether the MRF should be built the feasibility study should provide the decision makers with clear recommendations on the technical and economic merits A typical feasibility analysis may contain sections dealing with integrated waste management plan, conceptual design, economics, ownership and operation, and procurement o Preliminary design the preliminary design includes development of the process flow diagram development of material mass balances and loading rates for the unit operations that make up the MRF and the layout of the physical facilities the cost estimate developed in the feasibility study is refined in the preliminary design report using actual price quotations from venders Development and Implementation of MRFs Planning and Design Process for MRFs o Final design final design includes preparation of final plans and specifications that will be used for construction A detailed engineers cost estimate is made based on materials take offs and vender quotes the cost estimate will be used for the evaluation of contractor bids if the traditional procurement process is used Development and Implementation of MRFs Issues in the Implementation and Operation of MRFs the principal non-engineering issues associated with the implementation of the MRFs are related to o Siting o Environmental emissions • traffic, noise, odor, dust, airborne debris, liquid discharge, visual unsightliness and vector control o Public health and safety o Economics Development and Implementation of MRFs Waste Transformation Trough Combustion Transformation processes are used to reduce the volume and weight of waste requiring disposal and to recover and to recover conversion products and energy The organic fraction of MSW can be transformed by a variety of chemical and biological processes. The most commonly used chemical transformation process is combustion, which can be used to reduce the original volume of the combustible fraction of MSW by 85 to 95 percent. In addition, the recovery of energy in the form of heat is another attractive feature of the combustion process Although combustion technology has advanced in the past two decades, air pollution control remains a major concern in the implementation Waste Transformation Trough Combustion Waste Transformation Trough Combustion The principal elements of solid wastes are carbon, hydrogen, oxygen, nitrogen and sulfur. Under ideal conditions, the gaseous products derived from the combustion of MSW with stoichiometric amount of air would include CO2, H2O, N2, SO2. the basic reactions for the oxidation of the carbon, hydrogen and sulfur contained in the organic fraction of MSW are as follows For carbon, C + O2 For Hydrogen, 2H2+O2 For Sulfur, S+O2 CO2 2H2O SO2 Waste Transformation Trough Combustion Waste Transformation Trough Combustion Types of Combustors Solid waste combustors can be designed to operate with two types of solid waste fuel Mass-Fired Combustor Refuse – Derived Fuel – Fired Combustors Energy Recovery Energy can be recovered from the hot flue gases generated by combusting processed MSW or from unprocessed MSW Either hot water or steam can be generated. Hot water can be used for low-temperature industrial or space heating applications Steam is more versatile, as it can be used for both heating and generating electricity. Waste Transformation Trough Combustion Volume Reduction Among the factors that must be considered in assessing the combustion process for MSW are the amount of residue remaining after combustion and whether auxiliary fuel will be required when heat recovery is not of primary concern The amounts of residue depends on the nature of the wastes to be combusted Waste Transformation Trough Combustion Waste Transformation Trough Combustion Waste Transformation Trough Combustion Issues in the Implementation of Combustion Facilities Siting o in many communities, combustion facilities are located in remote locations within the city limits or at the landfill sites Air Emissions o the operation of combustion facilities results in the production of a variety of gaseous and particulate emissions, many of which are thought to have a serious health impacts o In some cases, the cost and complexity of the environmental control systems are equal or even greater than the cost of the combustion facilities Disposal of Residue o Bottom ash o fly ash o scrubber product o Management of these soild residuals is an integral part of the design and operation of a combustion facility ( ash is now disposed of in lined MSW landfill or in double lined monofills devoted solely to the disposal of ash Waste Transformation Trough Combustion Liquid Emissions liquid emissions from combustion facilities can arise from one or more of the following sources o wastewater from the ash removal facilitis o effluent from wet scrubbers o Wastewater from pump seals, cleaning, flushing, and general housekeeping activities o Wastewater from treatment systems used to produce high quality boiler water o Cooling tower blowdown o The proper handling and disposal of these liquid emissions is also an important part of the design of combustion facilities Economics o the best way to compare alternatives is by the use of life cycle coasting, which accounts for operating and maintenance costs over the lifetime of the system Waste Transformation Trough Aerobic Composting With the exception of plastic, rubber components, the organic fraction of most MSW can be considered to be composed of proteins, amino acids, lipids, carbohydrates, cellulose and ash Waste Transformation Trough Aerobic Composting The general objectives of composting are o to transform the biodegradable organic materials into a biologically stable material and in the process reduce the original volume of waste o to destroy pathogens, insect eggs and other unwanted organisms and weed seeds that may present in MSW o to retain the maximum nutrients ( nitrogen, phosphorus and potassium content) o To produce a product that can be used to support plant growth and as soil amendment In general, the chemical and physical characteristics of compost vary according to the nature of starting material , the condition under which the composting operation was carried out and the extent of the decomposition. Waste Transformation Trough Aerobic Composting When added to soil, compost has been found to lighten heavy soils, to improve the texture of light sandy soil, and to increase the water retention capacity of most soil. Process Description Most modern composting operations consists of three basic steps o preprocessing of the MSW o decomposition of the organic fraction of the MSW o preparation and marketing of the final compost product Waste Transformation Trough Aerobic Composting Waste Transformation Trough Aerobic Composting Process Design and Control Although the composting process is easy to grasp conceptually, the actual design and control of the process are quite complex Important process variables that must be considered in the design and operation of composting facilities include o Particle size o particle size distribution of the materials to be composted o Seeding and mixing requirements o The required mixing/turning schedules o Total oxygen requirements o moisture contents o temperature and temperature control o carbon – nitrogen ratio of the waste to be composted o pH o degree of decomposition o respiratory quotient o control of pathogens Waste Transformation Trough Aerobic Composting Composting Techniques Windrow Composting Aerated Static Pile Composting In-Vessel Composting Systems Waste Transformation Trough Aerobic Composting Waste Transformation Trough Aerobic Composting Waste Transformation Trough Aerobic Composting Waste Transformation Trough Aerobic Composting Process Application Composting is an increasingly popular waste management option as communities look for ways to divert portions of the local waste stream from landfills. The principal applications of composting are for o Yard wastes o Organic fraction of MSW o partially processes commingled MSW o co-composting of the organic fraction of MSW with wastewater sludge Waste Transformation Trough Aerobic Composting Issues in the Implementation of Composting Facilities the principal issues associated with the use of compost process are o the production of odors o the presence of pathogens o the presence of heavy metals o the definition of what constitutes and acceptable compost o unless the questions related to these issues are resolved, composting may never be a viable technology Waste Transformation Trough Aerobic Composting Production of Odors it is fair to say that every existing composting facility has had an odor event and in some numerous events. As a consequence, facility siting, process design and biological odor management are of critical importance Facility Siting important issues in siting as related to the production and movement of odors include proper attention to local microclimates as they affect the dispersion of odors, distance to odor receptors, the use of adequate buffer zones and the use of split facilities ( use of different locations for composting and maturation operations) Waste Transformation Trough Aerobic Composting Proper Process Design and Operation if composting operations are to be successful, special attention must be devoted to the following items o preprocessing o aeration requirements o temperature control o turning and mixing requirements Biological Odor Management Cause of odors in composting operations include o law carbon to nitrogen ratio o poor temperature control o excessive moisture o poor mixing o in enclosed facilities, odor control facilities such as packed towers, spray towers, activated carbon contactors , biological filters have been used for odor management Waste Transformation Trough Aerobic Composting Public Health Issues: the absence of pathogenic organisms is critical if the product is to be marketed for use in application where the public health may be exposed to the compost In general, most of pathogenic organisms found in MSW and other organic materials to be composted will be destroyed at the temperature and exposure times used in controlled composting operations ( typically 55C for 15-22 days Product Quality Product quality can be defined in terms of o nutrient content o organic content o pH o texture o particle size distribution, moisture content, the presence of foreign material , the presence of pathogenic organisms and the concentration of heavy metals Impact of Source Reduction And Waste Recycling on Waste Transformation Processes As more state adopt legislation mandating the development of waste diversion and recycling progrms, the quantities and composition of the wastes collected will change. The impact of change in composition will vary depending on the other types of waste management programs that are in place. Impact of Source Reduction And Waste Recycling on Waste Transformation Processes