Feed Formulation

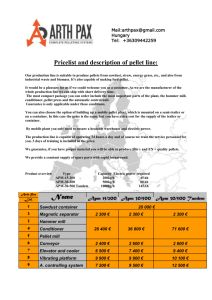

advertisement

Feed Formulation and Manufacture Dr. Joe M. Fox MARI-5314 from Lovell, Akiyama and Dominy Computer Formulation of Feeds • Least-cost feed formulation: a feed formula that is both nutritionally-complete (within limits) and with a minimum ingredient cost (within limits) • now-a-days is developed and completed through the use of computers using linear-programming software • typical packages: Brill, Mix-it, Agridata • used by most feed mills/manufacturers Least-cost Formulation • Least-cost feed formulations require that the following information be provided: cost of feed ingredients nutrient content of feed ingredients nutritient requirement of the animal availability of the nutrient to the animal minimum-maximum restrictions on levels Least-cost Formulations • Costs of feed ingredients and nutrient content are fairly available for most commercial feedstuffs • costs can be evaluated on a daily basis • nutrient requirements are fairly well known • the most critical piece of information regards digestibility/availability of nutrients within the feed ingredient • various indices: DE, ME, APD, etc. • these can be set in formula w/restrictions Least-cost Formulation • these are nutrient and ingredient restrictions that have been used for least cost formulation of catfish feeds • theoretically, protein level does not have to be restricted if essential amino acid requirements are well-known • for catfish, if the minimum requirements for lysine and the sulfur-containing AA’s are met, other EAA requirements are also met Least-cost Formulations • Other restrictions: minimum available phosphorus and digestible energy • only maximum calcium is typically considered due to availability in water • whole fish or other animal protein sources have been shown beneficial for catfish feeds • cottonseed meal is restricted to 10% due to gossypol (protein) content (toxic) • xanthophyll content often restricted due to it causing yellow discoloration of fish at high concentrations Least-cost Restrictions for Shrimp Feeds Least-cost Formulations: other restrictions • Limitations to computer formulations exist and should be recognized • where the computer says its ok, the experienced formulator knows differently • example: too high fat content for pelleting • example: sorghum might be as good as corn in an extruder, but not a pelletizer • this is why advantages are maximized when a number of options are available Computer Formulation of Feeds • Originally, the development of feed formulations was a real task • mathematical models for formulating nutritionally-adequate diets at lowest cost were available • however, everything had to be hand calculated • feed formulation: the preparation of nutritionallycomplete diets for feeding animals Least-cost Formulations: other restrictions • In many cases, logistics of obtaining ingredients and their storage limit the number of ingredients • availability of feedstuffs is not as important as having the option to substitute • must also take into consideration the physical, palatability, and toxicological properties of the feed • nutrient availability also varies Least-cost Formulations: restrictions • As mentioned, most least-cost formulae are derived by linear programming • it has its disadvantage in that it uses data out of the NRC handbook for fixed, maximum growth rates • it does not take into consideration optimum return on growth for various feed nutrient concentrations • this requires regression analysis • regression analysis is now being integrated into poultry formulae, probably not yet available for fish Part 2: Feed Production Largely provided by Wenger, Inc. and Akiyama Feed Production • Two major methods: pelletizing and extrusion • steam pelleting produces a dense pellet that sinks rapidly in water • extrusion produces a low density feed particle that has a tendency to float • steam pelleting uses moisture, heat and pressure to agglomerate ingredients into larger, homogenous particles • steam added to the ground feed mash (mix) partially gelatinizes starch, binding ingredients Pelletizing Feeds • Generally, steam is also added prior to passing the mash through the pellet die • this increases its moisture content to 15-18% • temperature goes up to about 85oC • steam pelleted feeds must be firmly bonded for satisfactory stability in water • starch is important for adequate binding • fat and fiber are antagonistic to process • supplemental fat not added if pelleting Pelletizing Feeds • All conventional pellet mills include the following equipment: • variable speed feeder • conditioning chamber • die and roller assembly • speed reduction device • prime mover • base • the variable speed feeder provides a continuous, controlled flow of feed mix Pelletizing Feeds: conditioning • The conditioning chamber is actually a mixer with either fixed or movable paddles • conditioning is accomplished by the addition of controlled amounts of steam • steam liberates natural oils, partially gelatinizes starches, increases temp, increases moisture • starch gelatinization: loss of birefringence or the irreversible rupture of the native secondary bonds in the crystalline region of the starch granule • the speed reduction device is added to reduce motor speeds to that of the die head • this is absolutely critical for the production of consistent-sized particles Pre-conditioning gelatinization process machine Sinking vs. Floating Feeds Typical Pellet Mill Typical Pellet Mill Process Flow Typical Pellet Mill Die Assembly Comparison: extrusion vs. pelleting Process flow diagrams Typical Extruder (side view) Comparison: pelletized vs. extruded feeds Pellet Comparison: continued Price Comparison Pellet Appearance • Feed pellets should contain no fractures • fractures are indicative of poor processing and conducive to poor water stability • fractures allow water to seep into pellet more rapidly, pellet hydrates, breaks • feed pellets should not clump together (indivative of poor drying, results in poor nutritional quality, stability) • “fines” from bags should total less than 2% • result: you lose money, get poor water quality Feed Pellet Size • What feed pellet size you feed is determined by age of animal • size of particle must be the one most efficient for location and consumption by animal • proper nutrient package, right size, welldistributed • smaller pellets usually imply easier distribution • feed particles range in size from less than 50 µM to over 1/8 in. diameter Feed Pellet Size • Larvae: <50, 50-125, 250, 500 µM, according to larval substage • postlarvae: flakes, fine crumbles (500 µM) • juveniles to 2-3 g: medium crumble (1mm) to coarse crumble (2mm) • 3-6 g: short pellet (3/32 x 2-4 mm) • 6-10g: medium pellet (3/32 x 6 mm) • 10-16 g: long pellet (3/32 x 10 mm) • over 16 g: 1/8 in. diam, various lengths • point: one pellet per shrimp per feeding Feed Pellet Size • For a 2mm x 6mm pellet, you have approximately 1 million pellets per 100 lb bag • if your 10 ha pond has 2 million shrimp in it (20 per sqm), feeding two 100 lb bags gives each shrimp 1 pellet/feeding • 20 pellets per sqm pellet density