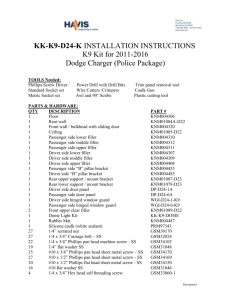

notes! - Havis Inc.

advertisement

KK-K9-C22-K INSTALLATION INSTRUCTIONS K9 Kit for 2011-2016 Chevy Caprice TOOLS Needed: Phillips Screw Driver Standard Socket set Metric Socket set Power Drill with Drill Bits Wire Cutters /Crimpers Awl and 90° Scribe Trim panel removal tool Caulk Gun PARTS & HARDWARE: QTY DESCRIPTION 1 Floor 1 Ceiling 1 Front wall / bulkhead with sliding door 1 Rear wall 1 Rear wall upper support bracket 2 Rear floor support bracket 2 Upper “B” pillar bracket 1 Passenger side floor support bracket 1 Driver side floor support bracket 1 Passenger side upper filler 1 Driver side upper filler 1 Passenger side lower filler 1 Driver side lower filler 1 Rubber Mat 1 Driver side door panel 1 Passenger side door panel 1 Driver side hinged window guard 1 Passenger side hinged window guard 1 Dome Light Kit 1 Silicone caulk (sealant) 18 1/4 x 3/4” Carriage bolt – Stainless Steel 18 1/4” serrated nut 19 1/4 x 3/4” Phillips pan head screw - Stainless Steel 18 1/4 Flat washer - Stainless Steel 28 #10 x 1/2 Phillips pan head sheet metal screws - SS 21 #10 x 3/4 Phillips pan head sheet metal screws- SS 15 #10 Flat washer-SS 2 7/16” x 3” Hex head bolt 2 7/16” Flat washer 2 2” long x 1.25” OD Aluminum spacer 2 8 mm x 25 mm Hex head bolt 2 3/8” Flat washer PART # KNM004323 KNM004497 KNM004493 KNM004324 KNM004326 KNM004589 KNM004496 KNM004505 KNM004506 KNM004499 KNM004501 KNM004498 KNM004500 KNM004762 DP-C22-1A DP-C22-6A WGI-C22-1-K9 WGI-C22-6-K9 KK-K9-DOME PRM97343 GSM32024 GSM30170 GSM34102 GSM31048 GSM34169 GSM34170 GSM31046 GSM34034 GSM31008 CM003247 GSM33721 GSM31007 Document1 rev 2-14 NOTES! Read all instructions before installing any Havis, Inc. products. Use hardware provided with install kit. Vehicle battery should be disconnected during installation. It will need to be temporarily reconnected to move electric seats or check electric door locks. KK-K9-C22-K Assembly (Door panels and window guards not shown) KNM004499 Passenger side upper filler KK-K9-DOME Dome Light kit KNM004501 Driver side upper filler KNM004497 Ceiling KNM004496 “B” Pillar Brackets (One each side) KNM004326 Rear wall upper support bracket KNM004493 Front Wall KNM004324 Rear Wall KNM004500 Driver side lower filler KNM004505 Passenger side floor support bracket KNM004589 Rear floor support brackets (One each side not shown) KNM004506 Driver side floor support bracket KNM004323 Floor Document1 rev 2-14 Remove rear passenger door panels first. Remove screw under door armrest. (T20 Torx) Remove / unsnap entire door panel from door. (Trim removal tool) Reattach window switch to original plug. Neatly wire tie the switch assembly, speaker wire and latch / lock cables so they do not interfere with the window operation. Double check latch, lock and window operation prior to attaching door panel. Underneath door handle, remove plastic cover and screw. (T20 Torx) Note: A small 90° scribe helps to pick plastic covers off. Disconnect latch and lock cables from door panel. Place K9 kit door panel onto door. The top will hook onto rubber molding. Position so it is centered on the door. Push down firmly on panel. Drill mounting holes with 5/32” drill bit. Attach door panels with #10 x 3/4 Phillips pan head sheet metal screws. Remove screws at bottom of door panel. (T20 Torx) Remove window switch from door panel. Remove door speaker. (T20 Torx) NOTE: Window guards are shipped flat. On the edge of a work bench, bend a contour in the middle of the guard so it will match the window frame contour. Document1 rev 2-14 Center and attach the window guard assembly to the door panel with #10 x 1/2” Phillips pan head sheet metal screws. With upper bracket still attached to guard, position so bracket fits evenly at top. Hold in place and mark location for frame mounting screws. Drill mounting holes with 5/32” drill bit. Attach bracket to window frame with #10 x 3/4 Phillips pan head sheet metal screws. Window Guard and Door panel installation complete. View of rear seat before removal. Remove rear seat. Some hardware to be reused. Temporarily remove lower sill trim. (T-20 Torx) Document1 rev 2-14 Pull rubber floor mat down to exposed location of a 7/16” threaded nutsert at bottom of “B” pillar. Use 2” long x 1.25” OD Aluminum spacer as a template to outline hole to be cut in rubber mat. Cut rubber mat so spacer fits in against steal body frame. Attach passenger side lower mount bracket to body with 7/16” x 3” Hex head bolt and flat washer Bolt goes trough spacer. Tighten bolt. Use Awl (or other pointed tool) to locate center of nutsert. Place spacer into location. One each side. Temporarily remove lower “B” pillar trim. Mark location. Attach driver side lower mount bracket to body with 7/16” x 3” Hex head bolt and flat washer Bolt goes trough spacer. Tighten bolt. Temporarily remove upper “B” pillar trim. (T-20 Torx) Document1 rev 2-14 Locate 8mm nutsert in upper “B” pillar. Temporarily remove lower / outboard seat back nuts. (13 mm) Place floor on top of floor brackets. Loosely attach floor to brackets with 1/4 x 3/4” Carriage bolts and serrated nuts. Attach “B” pillar brackets with 8 mm x 25 mm Hex head bolt. One each side. RE: 2011-2013 Caprice Attach rear floor support bracket with OEM nuts previously removed. One each side. Attach rear upper support bracket To rear bulkhead with 1/4 x 3/4 Round head Phillips bolts. Remove rear seat belt assembly. RE: 2014+ Caprice. Attach rear floor support brackets to the inboard studs with OEM nuts previously removed from seat back. (outboard studs no longer included on 2014) Loosely rear bulkhead to floor with 1/4 x 3/4 Round head Phillips bolts and flat washers. Document1 rev 2-14 Loosely attach upper “B” pillar brackets to front bulkhead with 1/4 x 3/4” Carriage bolts and serrated nuts. With location of “B” pillar brackets now determined. Mark and cutout notch upper “B” pillar trim for bracket. One each side. Loosely front bulkhead to floor with 1/4 x 3/4 Round head Phillips bolts and flat washers. Use an Awl or other pointed tool to help align mounting holes. Loosely attach to front and rear bulkheads with 1/4 x 3/4” Carriage bolts and serrated nuts. Attach dome light with # 10 x 1/2” sheet metal screws Attach upper and lower trim panels to rear bulkhead with # 10 x 1/2” sheet metal screws and flat washers With all parts now in place, drill and attach rear upper support bracket to metal seat backer with #10 x 3/4 Phillips pan head sheet metal screws. Check position of all parts and tighten all hardware. View of “B” pillar brackets completely installed Attach upper and lower trim panels to ceiling and floor with 1/4 x 3/4 Round head Phillips bolts and flat washers. Neatly silicone / caulk the lower seams to shed water out of vehicle. Note: The floor pan is designed to minimize the need for sealant. Caulk (sealant) is mostly needed where the floor meets the door sill and lower filler panels. Document1 rev 2-14 After silicone is dry (preferably overnight), place rubber mat into K9 insert. Example mounting location for the optional Hot-N-Pop exhaust fan. # KK-K9-HA-FKT-10 10” fan mounts to window guard. Example mounting location for the optional Hot-N-Pop door gas spring. View of completed KK-K9-F16-K installation. NOTE: This photo shows the older Front Bulkhead. Newer design has a lower door to improve driver visibility. Document1 rev 2-14