CH-14-AGGREGATE-PLANG

advertisement

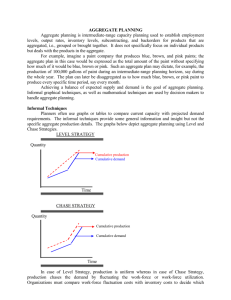

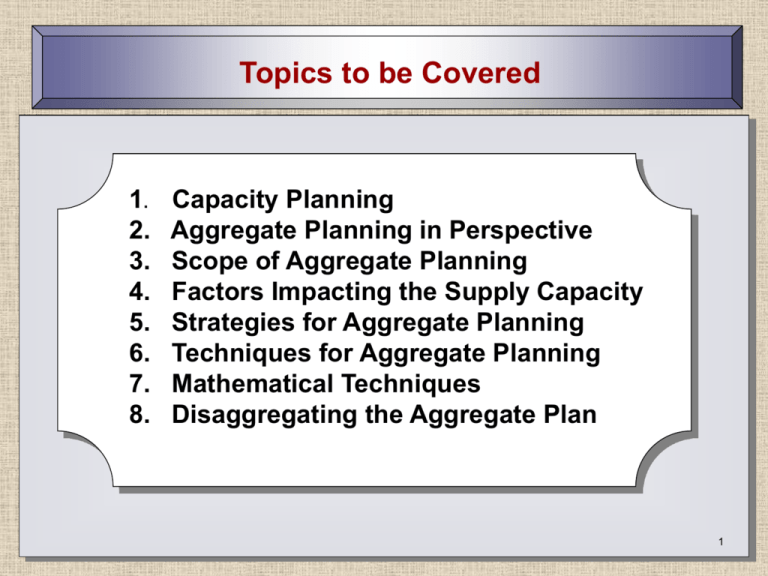

Topics to be Covered 1. 2. 3. 4. 5. 6. 7. 8. Capacity Planning Aggregate Planning in Perspective Scope of Aggregate Planning Factors Impacting the Supply Capacity Strategies for Aggregate Planning Techniques for Aggregate Planning Mathematical Techniques Disaggregating the Aggregate Plan 1 How Does Capacity Planning Fit In The Production Cycle. Make or Buy Forecasting Facility Definition Resource Planning Aggregate Plan Master Production Schedule Rough Cut Capacity Planning Detailed Capacity Planning Purchasing MRP Shop Floor Control 2 Capacity VS Utilization Capacity - Peak quantity created over a period of time - Peak Capacity does not include scheduled breaks & planned maintenance - Effective Capacity does include scheduled breaks & planned maintenance & other planned events. Utilization -the relationship between what is actually produced vs what can be produced. (Actual/Capacity x 100%) Capacity Cushion - The difference between full capacity and Utilization (Cushion = 100% - Utilization) 3 Facility Planning Need to be part of the total operations strategy and not a series of capital budget decisions Amount of capacity; size of unit; timing of capacity changes; long run needs Factors: Predicted demand Costs of facilities Economies of scale vs Diseconomies of scale Likely behavior of competitors Business strategy International Considerations 4 Facilities Strategy Styles: Try not to run out Cushion? Build to average demand Maximize utilization Timing: Preempt the competition Wait and see 5 Strategy & Facility Types Product Focus (55%): One product family; large market Transportation costs low & high economies of scale Market Focused (30%): located in singular or few market served; service oriented High transportation cost & quick service needed Process Focused (10%): 1 or 2 key technologies; component parts General Purpose (5%) several product types; several different processes low volumes of any one product type 6 Aggregate Planning in Perspective • Capacity Decisions are on Three Levels. • Long Term Intermediate Term Short Term • Long Term Decisions - Decisions necessary to decide the absolute max capacity. • Product or Service Selection • Facility Size & Layout • Location • Equipment Type • Intermediate or Aggregate Decisions - Decisions necessary to meet expected demand not in the immediate future. • General levels of employment • Output per year • Inventories (Average Target) • Long Term decisions set the baseline or constraints for the intermediate decisions. • Short Term Decisions • This month’s output • Machine loading • Job sequencing • Aggregate decisions set the constraints for short term decisions 7 Minimizing Costs thru Balancing Aggregate Planning seeks to balance Demand and Capacity by minimizing total costs. (Big Picture) Capacity Demand Pricing Promotion Backorders New Demand $ Costs When: Demand > Capacity Capacity > Demand Labor Equipment Capital Inventory Subcontracting Backordering 8 Factors Impacting the Supply Capacity • Hire & Fire Workers • Low Morale; Costs; • Overtime • Good Short term solution; Restrictions Burn-out; Lower Production • Part-Time Workers • Good for certain industries • Possible restrictions • Inventories • Good Supply Control • Costs: Warehousing; Obsolesce; Deterioration; Breakage; Spoilage; Cost of Capital • Subcontracting • Make or Buy • Sometimes cheaper for one of your non-core capabilities • Constraints: Quality Control; schedule control; transportation • Backorders • Cost depends on Product, market position & customer loyalty 9 Scope of Aggregate Planning Aggregate Planning combines the capacity requirements for the demand of all products or services provided by the company. • Why do we Use Aggregate Planning? • Match Supply and Demand. • Plan for adequate production capability is available. (Rough Cut Capacity Planning) • Plan for adequate input resources. (labor & raw materials) • Plan for adequate product demand. • Aggregate Planning begins with a Forecast of Demand. • Time horizon is typically 1 year. • Combine individual product demand forecast. • Forecast aggregate demand directly. • What do we need to Know to Begin Aggregate Planning? • Facility Capacity. • Available Resources, Raw Materials, Labor, etc. • Forecast Demand For each period. • Any Special Company Constraints. • labor policies; Inventory policies 10 Strategies for Aggregate Planning • The Operations Manager generally has control only over capacity. • Several Strategies are Available • Maintain a Level Work Force. • Maintain a Steady Output Rate • Match Demand period by period • Abrupt changes in Output and Workforce required. • Use a combination of decision strategies • The most common and flexible is to use a combination of strategies. • The specific strategy will depend on the market trend. • If there is only a short term change in demand then maintaining a steady workforce is preferred. • If there is a long term change in demand then a change in Output and workforce may be required. • Use variations in inventories, subcontracting, backlog, & overtime to supplement short term changes. The preferred strategy is sufficiently flexible to feasibly match supply and demand within legal constraints, Company policy and at a minimal cost when faced with varying conditions. 11 Aggregate Planning Problem Demand: Jan Feb Mar Apr May Jun 650 700 850 700 650 500 Supply: Regular Workers: 120 units per worker per month Inventory: 200 units at beginning; need 100 at end Overtime: 15% max Subcontract: 10% Backorder: Not allowed Costs: Regular Time : $15/hour per worker Inventory: $1/unit /month OT :150% of Regular Subcontract: $20 per unit Hiring = $100 Firing = $250 12 Techniques for Aggregate Planning • Aggregate Planning techniques fall within two categories: Informal & Mathematical • Informal is used most, as Mathematical requires some model development. • General Procedure for Developing an Aggregate Plan: 1. Determine demand for each period. 2. Determine capacities for each period. (Regular time, overtime, subcontracting) 3. Determine company policies that are pertinent. (Safety stock, max inventory, allowable overtime) 4. Determine unit costs for regular time, overtime, subcontracting, holding costs, backorders, and other relevant costs. 5. Develop alternative plans and compute the cost for each. 6. Select the most satisfactory feasible solution. • Informal Approach • Consists of developing simple tables or graphs that enable the planners to visually compare projected demand requirements with existing capacity. (spreadsheets) • Alternatives are usually evaluated in terms of their overall costs. • The chief disadvantage is the significant amount of time to achieve an optimal solution. • Alternatives are not always feasible nor optimal based on company constraints. • The main advantages are the simplicity and the visual nature. 13 • Persistence, experience and luck are part of defining a good plan Informal Method Period Forecast OUTPUT Regular Overtime Subcontract Output - Forecast Inventory Ending Average Backlog Costs($) Output Regular Overtime Subcontract Hire/Layoff Inventory BackOrders Total ($) 1 2 3 4 5 6 TOTAL Reg = $10 OT = $15 SC = $13 Inv = $ 1 BL = $ 5 Hire = $ 17 Fire = $22 14 Mathematical Techniques • • • • • • • • • • Linear Decision Rule (Holt, Modigliani, & Simon) Management Coefficient Parametric Production Planning Search Decision Rule Production Switching Heurestic Linear Programming Transportation Method Goal Programming’ Mixed Integer Programming Simulation Linear Programming • Objective Equation: • Minmize Z = Reg Prod Costs + Hiring Costs + Firing Costs + Holding Costs + Subcontracting Costs + Overtime Costs • Minimize Z= (Cw Wt + Ch Ht + Cf Ft + C i It + Cs S t + Co Ot) • Constraints: W t-1 + H t - F t = W t (Balance Work Force) I t-1 + k W t + S t + O t - D t = I t ( Balance of Inventory) Dt-kWt+It =Pt (Balance Production) 15 Disaggregating the Aggregate Plan • As the short term plan is dependent upon the aggregate plan, it is necessary to translate this plan into meaningful numbers in the short term. • Breakdown the aggregate plan into specific product requirements. • To determine labor, material and inventory requirements • A general plan was developed in units that applied across product lines. Now how do we convert those units into specific product lines? • This can be difficult. • This disaggregation results in a Master Production Schedule. • Shows quantity and timing of specific goods 16 Review of Aggregation • The Purpose of Aggregate Planning is to develop a feasible Production Plan on an aggregate level that achieves a balance of expected demand and supply, while considering the minimization of cost. • Because the Supply of resources and the Demand for product can vary, Aggregate Planning tries to provide a leveling effect to reduce abrupt changes to the factors of production. • Aggregate Planning is medium range capacity planning • typically 3 to 18 months horizon • Aggregate Planning is essentially a big-picture approach to planning. • The focus is on capacity • Think in terms of units that are common across product lines • Labor hours • Machine Hours/ month • Output rates of similar products 17