Flow Time

advertisement

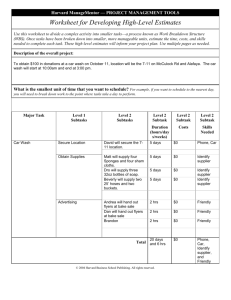

III. Operational Measures • Flow Time • Capacity and Flow Rate 1 Operational Measures and Direct Cost Inputs Outputs • Inventory (in production setting, referred to as Working in Process WIP): the number of units contained within the process. – Working capital shown in your balance sheet • Flow Time (throughput time): the time it takes a unit to get through the process. – Shorter flow times reduce the time delay between occurrence of demand and its fulfillment in the form of supply • Flow Rate (throughput rate, output rate): the rate at which the process is delivering output. – Higher flow rate generates more revenues shown in your income statement when capacity is tight. – The maximum rate with which the process can generate supply is called the capacity of the process. • Direct Cost: incurred when transforming a unit from input to output2 Flow Time • Flow Time = Meas. & Mix Spoon 1 min. Take Orders 1 min. 5 min. Pick Fillings Clean & Hash 3 min. 2 min. Spread Toppings 2 min. Load & Set Timer 1 min. Bake Box 8 min. 1 min. Payment 1 min. • Theoretical vs. Actual Flow Time – Actual = Value-Added and Non-Value-Added Activities – Active and Non-Active Times VA Active NVA Non-Active • Flow Time efficiency 3 Flow Time Efficiency Industry Process Average Flow Time Theoretical Flow Time Flow Time Efficiency Life Insurance New Policy Application 72 hrs. 7 min. 0.16% Consumer Packaging New Graphic Design 18 days 2 hrs. 0.14% Commercial Bank Consumer Loan 24 hrs. 34 min. 2.36% Hospital Patient Billing 10 days 3 hrs. 3.75% Automobile Manufacture Financial Closing 11 days 5 hrs 5.60% 4 Performance in Auto Industry GM Ford DaimlerChrysler Toyota Honda Nissan Flow Time (hrs) 40.5 39.9 44.8 31.1 29.1 27.6 Quality (probs/car) 1.46 1.62 1.54 Market Share 28% 21% 13.2% Profit/car in 2001 $367 <0 <0 1.45 Business Week, March 25, 2002 Flow Time (hrs) GM Ford DaimlerChrysler Japanese Automakers 26 27 31 17-22 Business Week, April 21, 2003 5 Levers for Reducing Flow Time • See page 73-76: 4.5 – 4.6 • Flow time: • Levers: 6 Capacity (units/unit time) • Capacity: maximal units a process can process per unit of time – Capacity of a Single Resource oven Process time Tp • Capacity of the oven = – Capacity of c Identical Resources • capacity of bake operation = c ovens Process time Tp – Capacity of a network of resources (system capacity) 7 Flow Rate (units/unit time) • Flow rate: the units that a process actually does process per unit of time Input rate Output rate R • Flow rate R = • Cycle time = • Process utilization = • Pipeline Principle: In the long run, on average, input rate = output rate R 8 Flow Rate (cont.) • Time to produce X units = • Time to complete X units starting with an empty system • Utilization of a resource in the process R c Process time Tp r= 9 Bottlenecks Tp c=2 c=1 c=3 c=1 10 min. 8 min. 20 min. 5 min. 10 Bottlenecks: Multiple types of flow units 2 1 3 1 Cookies 10 min. 8 min. 20 min. 5 min. Pizzas 15 min. 12 min. 40 min. 7 min. 11 Bottlenecks: Multiple flows 8 min. Spoon Mix 10 min. 20 min. Bake cookies Bake bread 15 min. 1 min. Pay 12 Levers for Increasing Throughput • See page 99: 5.7. Levers for Managing Flow Rate • Throughput: • Levers: 13 Case Discussion: Manzana Insurance 1991 Second Quarter Performance 14 Manzana Insurance (cont.) Underwriting Team #1 Distribution Clerks (4) Underwriting Team #2 41 min./request Weighted average Raters (8) 70.4 min./request Policy Writers (5) 54.8 min./request Underwriting Team #3 28.4 min./request 15 Today’s Takeaways Operational Measures: – Flow Time • • • Critical path Theoretical vs. actual, value added vs. non value added Levers for improving flow time – Flow Rate (cycle time) • • • Capacity, bottleneck, levers for improving throughput Utilization, server or machine idle time Pipeline principal – Inventory (next lecture) 16