Leuven, 18th may ObjectStore

advertisement

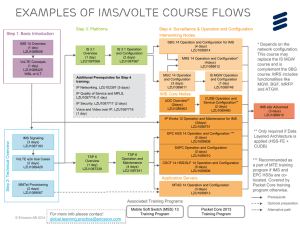

1 © Copyright 1998 INCOMPRO IMS CONSORTIUM Task 2.1 : KBS architecture development and platform implementation Consiglio Nazionale delle Ricerche Istituto di Tecnologie Industriali e Automazione GRAP Gruppo Robotica Applicata INTB Leuven, 18th may © Copyright 1998 INCOMPRO IMS CONSORTIUM Methodology for KBS development It comprises 5 phases, each one characterized by precise goals to be achieved and clear relationships with the other phases. Each phase is subdivided into a number of specific tasks, each one devoted to achieve a precise subgoal. Tasks can be performed by executing specific activities, which define at grater level of detail what to do and how. The five phase are: • • • • • Phase 1 – Plausibility study Phase 2 – Construction of the demonstrator Phase 3 – Development of the prototype Phase 4 – Implementation and installation of the target system Phase 5 – Maintenance INTB Leuven, 18th may 2 3 © Copyright 1998 INCOMPRO IMS CONSORTIUM Phases and main products Plausibility study Construction of the demonstrator plausibility study report demonstrator demonstrator report prototype Development of the prototype development support system Implementation and installation of the target system target system Maintenance INTB Leuven, 18th may prototype report maintenance support system target system report possible interventions © Copyright 1998 INCOMPRO IMS CONSORTIUM Phase 1: Plausibility study The plausibility study encompasses the following main goals: analyzing the application domain (material design and production process design); analyzing the requirements and the project goals; identifying the main functional, operational, and technical specifications of the KBS, and the acceptance criteria; developing a draft architectural design and a draft external (DoD/FEA) connections design. The product of the plausibility study is the plausibility study report. It is a technical document which illustrates the activities done and the results obtained. INTB Leuven, 18th may 4 © Copyright 1998 INCOMPRO IMS CONSORTIUM Phase 1: Plausibility study The concept of plausibility includes the following aspects: technical feasibility of the KBS application based on domain characteristics; state of the art of the available technologies; introduction of the KBS in its operational place and environment; economic suitability issues. INTB Leuven, 18th may 5 © Copyright 1998 INCOMPRO IMS CONSORTIUM Phase 2: Construction of the demonstrator The main goal of the construction of the demonstrator is to develop and demonstrate a first, limited version of the KBS in order to meet the following issues: obtaining a concrete insight in the complexity of the problem considered, and validating, refining, and, if necessary, revising technical decision outlined in the plausibility report; collecting useful feedback from the users, and refining the identification of requirements and definition of KBS specification stated in phase 1. INTB Leuven, 18th may 6 © Copyright 1998 INCOMPRO IMS CONSORTIUM Phase 2: Construction of the demonstrator The products of this phase are: a running KBS functionality demonstrator, which anticipates the system performance on a limited and meaningful part of the considered problem; the demonstrator report, which contains a synthesis of the activities carried out and a detailed illustration of the results achieved. INTB Leuven, 18th may 7 © Copyright 1998 INCOMPRO IMS CONSORTIUM Phase 3: Development of the prototype The main objective of this phase is to find the most suitable technical solutions for the application considered, and to implement them in a running system. The products of this phase are: a full KBS, called prototype, which can adequately meet all functional specifications stated; a set of software tools which supports the construction of the knowledge base of the prototype; the prototype report, which contains a synthesis of the activities carried out and a detailed illustration of the results achieved. INTB Leuven, 18th may 8 © Copyright 1998 INCOMPRO IMS CONSORTIUM Phase 3: Development of the prototype The prototype, although satisfying the functional specifications stated, is not the final output of the production process, since: it is not installed in the real operational environment, but it is running only in the development environment (if necessary, connections with DoD/FEA are simulated); it has only been tested with sample data prepared by the system designer with the support of experts and users. INTB Leuven, 18th may 9 © Copyright 1998 INCOMPRO IMS CONSORTIUM Phase 4: Implementation and installation of the target system The goal of this phase is to develop a complete KBS. It must have the same behavior of the prototype, but in addition it must be: installed in the real operational environment (VEE); filed tested with a selection of real data; eventually delivered to the end-users for routine operation. INTB Leuven, 18th may 10 © Copyright 1998 INCOMPRO IMS CONSORTIUM Phase 4: Implementation and installation of the target system The products of this phase are: the target system, that is, the final output of the whole KBS production process; the maintenance support system, that is the specific system devoted to support effective and efficient maintenance; the target system report, which contains a synthesis of the activities carried out and a detailed illustration of the results achieved. INTB Leuven, 18th may 11 © Copyright 1998 INCOMPRO IMS CONSORTIUM Phase 5: Maintenance This phase starts after the delivery of the target system to the user for the operational use. In this phase the developer collects feedback from the end-users in order to schedule possible maintenance interventions. INTB Leuven, 18th may 12 © Copyright 1998 INCOMPRO IMS CONSORTIUM Draft of Architecture KBS Design System Overview Technical Details Platform Scheme INTB Leuven, 18th may 13 © Copyright 1998 INCOMPRO IMS CONSORTIUM System Overview Structure Our KBS integrates the conventional KB with a OODBMS. Motivations Integration of KB e DBMS exploits intelligence of KB and OODBMS efficiency in management complex structured data. K.B provides data-driven computation and expressive power in D.B interrogation Semantic Data Model : EER+OO The semantic data model encapsulates in Extended Relational Model the multi-level abstraction paradigm of OO INTB Leuven, 18th may 14 © Copyright 1998 INCOMPRO IMS CONSORTIUM Technical Details KBS-Shell integrates Rule-based and OO programming paradigms in Java environment DBMS is an OODBMS with OO-query language which may interfaced with C++ and SQL KBS/ DBMS Interface Java/CORBA with Object Persistence External interface Interface with STEP/EXPRESS data format from CAD/CAE is performed by a OO-translator INTB Leuven, 18th may 15 16 © Copyright 1998 INCOMPRO IMS CONSORTIUM Platform Scheme JAVA Environment OPSJ-Shell OPSJ-Shell OPSJ-Shell CORBA- IDL ObjectStore INTB Leuven, 18th may STEP-file ST-ObjectStore CAD/CAE © Copyright 1998 INCOMPRO IMS CONSORTIUM Sw Tools for System development Expert System Shells OPSJ is an OPS5 + OO which may be embedded in a Java package OODBMS Objectstore: is an OODBMS with a C++/Java interface Internal Interface Java/CORBA Development Tools Integration CAD/CAE <-> DBMS ST-Objectstore is an OO-translator based on ROSE class library INTB Leuven, 18th may 17 © Copyright 1998 INCOMPRO IMS CONSORTIUM OPSJ Motivations: Meets the requirement of rule-based + OO integration Can be embedded in Java applications Technical Features OPSJ engine is written completely in Java OPSJ is designed to add rules to Java OPSJ, rules are grouped into units called "Knowledge Sources." Forward Chaining (Inductive paradigm) RETE-II Match Algorithm more efficient than CLIPS OO Pattern Matching of Java/CORBA Class in LHS INTB Leuven, 18th may 18 © Copyright 1998 INCOMPRO IMS CONSORTIUM ObjectStore Motivations: is an OODBMS Provides an Integrate Development Environment Provides a rich set of toolbox for integration with C++/Java applications May be easily interfaced with STEP/EXPRESS data format by the ST-Objectstore Tool. Technical Features Query Language OO embedded Query Language which can be interfaced with SQL Object Management Persistent Object Exportable toward Java Environment (Objectstore PE) INTB Leuven, 18th may 19 © Copyright 1998 INCOMPRO IMS CONSORTIUM ST-Objectstore Motivations Make easy the interfacing with CAD/CAE Systems,allowing Import/Export of STEP files from OODBMS Technical features ST-Objectstore is a special ROSE class library ST-Objectstore uses C++ class ST-Objectstore provides Object Persistence INTB Leuven, 18th may 20 21 © Copyright 1998 INCOMPRO IMS CONSORTIUM Knowledge Base Knowledge Based System: the Demonstrator task 2.1 INTB Leuven, 18th may © Copyright 1998 INCOMPRO IMS CONSORTIUM Motivations and goals Develop a running system: anticipate a sub-set of the functions; draft architectural design; domain experts and users concretely involved and committed. Two main goals: developing a better understanding of user requirements; identifying more detailed and precise specifications of the KBS. INTB Leuven, 18th may 22 23 © Copyright 1998 INCOMPRO IMS CONSORTIUM Component Component type Selection criteria Thickness FEM Process tool Exclusion KB KBS Selection Material design Computation Verification DB Materials & Processes Processes Computation Verification Geometry Computation Verification INTB Leuven, 18th may Constraints 24 © Copyright 1998 INCOMPRO IMS CONSORTIUM Openness and separation of concerns Openness. May vary: the number of clusters and modules; the relation between them; the external connections, without structure of the system. changing the Separation of concerns: every cluster and module has its own task, the modifications of the behaviour of one of them do not affect the behaviour of the others. INTB Leuven, 18th may 25 © Copyright 1998 INCOMPRO IMS CONSORTIUM Computation/Verification modules Historical data (domain specific) Input Action Computation Verification External tools INTB Leuven, 18th may Output KB KBS Materials Processes Constraints ... 26 © Copyright 1998 INCOMPRO IMS CONSORTIUM Example: the blade Component blade Exclusion Component type INTB Leuven, 18th may water 27 © Copyright 1998 INCOMPRO IMS CONSORTIUM Exclusion DB Exclusion Chemical Mechanical Fiber % Eliminates all materials that do not respond to the characteristics required by the specific component and by its type. INTB Leuven, 18th may Thickness Cost ……. 28 © Copyright 1998 INCOMPRO IMS CONSORTIUM Selection • After the exclusion, a subset of materials remains. • The demonstrator shows the list of the candidate materials, among which the user can choose one or more. • The present demonstrator lets the user choose only one. Selection criteria Epoxy-Kevlar INTB Leuven, 18th may Selection 29 © Copyright 1998 INCOMPRO IMS CONSORTIUM Composite design Thickness 12 mm Material design Computation Verification • The thickness of the component when made of traditional material; this information can be retrieved from an external DB. • Retrieving characteristics from the KBS database for the preparation of the first design of the composite. INTB Leuven, 18th may DB Chemical Mechanical Fiber % Thickness Cost ……. 30 © Copyright 1998 INCOMPRO IMS CONSORTIUM Verification of the composite Material design Computation FEM Verification • Connection with a external tool, testing the composite properties. • The control can loop to the previous cluster to compute another candidate solution or discard the material. INTB Leuven, 18th may 31 © Copyright 1998 INCOMPRO IMS CONSORTIUM Process tools Process tool Yes Processes Computation Processes Verification • The system indicates the best available process tool. • Actually, the demonstrator considers only one possible process that can modify the laminate. INTB Leuven, 18th may 32 © Copyright 1998 INCOMPRO IMS CONSORTIUM Geometry Geometry Computation Verification • This is module. just a verifying • The demonstrator verifies whether the thickness of the laminate is within a given range. INTB Leuven, 18th may Constraints 33 © Copyright 1998 INCOMPRO IMS CONSORTIUM Output KBS Composite specifications DoD INTB Leuven, 18th may • The thickness of the laminate • The composite material • The number of plies • The sequence model • An indication of the final cost.