CUSRIP 2011 Final Presentation

advertisement

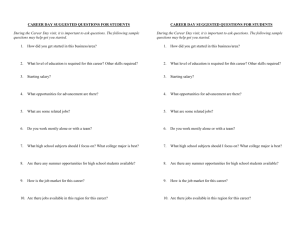

ChE #1: Engineering Polymers: How Plastics are Made The Cooper Union for the Advancement of Science and Art Summer Research Internship Program 2011 Plexiglas, or Polymethyl Methacrylate (PMMA) The Cooper Union for the Advancement of Science and Art Summer Research Internship Program 2011 A “Bubble Chair” An Aquarium The Cooper Union for the Advancement of Science and Art Summer Research Internship Program 2011 PMMA Properties Extremely transparent. Hard & Shatterproof. Thermoplastic: mold, melt, & remold again. Highly weather resistant. Doesn’t yellow over time. The Cooper Union for the Advancement of Science and Art Summer Research Internship Program 2011 PMMA Production Made in sheets, rods, tubes, or beads. Methyl Methacrylate(MMA) + Initiator. Benzoyl Peroxide(BP). Principles of Polymer Systems. Rodriguez et al. PMMA sheet: bulk polymerization in a batch reactor(BR) sheet mold. The Cooper Union for the Advancement of Science and Art Summer Research Internship Program 2011 PMMA REACTOR DESIGN We calculated that 100 aquariums (15L each) require 740kg of PMMA to make. Polymerization t:54 hrs MMA + Benzoyl Peroxide T=60°C 740kg PMMA Reactor Volume=780L Mold @ t=0 MMA: 9.43 mol/L BP:1.0x10-7 mol/L Mold @ t=54hrs The Cooper Union for the Advancement of Science and Art Summer Research Internship Program 2011 Polyether Ether Ketone (PEEK) The Cooper Union for the Advancement of Science and Art Summer Research Internship Program 2011 Polyether ether ketone (PEEK) An advanced engineering plastic High resistance to abrasion, chemicals, fire, hydrolysis, and radiation Applications: aviation, automobile, manufacturing, electronic apparatuses, and food and beverage industries The Cooper Union for the Advancement of Science and Art Summer Research Internship Program 2011 PEEK in Comparison to other Plastics Superior ductility High electrical resistance Low moisture absorption High thermal resistance http://www.quadrantplastics.com/na-en/products/injection-moldedsolutions/working-together/material-selection.html High Young’s Modulus The Cooper Union for the Advancement of Science and Art Summer Research Internship Program 2011 Sulfonation of PEEK H2SO4 Sulfonated PEEK (SPEEK) has improved solubility that allows it to be subjected to size exclusion chromatography, which gives it a better molar mass distribution Compared to the original PEEK, SPEEK has a longer molecular chain, which gives it superior mechanical properties The Cooper Union for the Advancement of Science and Art Summer Research Internship Program 2011 Reaction Kinetics C0 1 ln ln k3 k 2 ( 2 k t ) k 2 ( k t ) Ct e 2 e 3 k3 2k 2 k 3 2k 2 Source: Mechanism and kinetics of poly(ether ether ketone) sulfonation in concentrated sulfuric acid at room temperature by D Daoust, J Devaux, and P Godard Where C0 is the initial concentration and Ct is the concentration at reaction time t of the unsulfonated –OфO– groups, and k2 and k3 are the apparent rate constants at 20°C shown below: Concentrations of sulfuric acid (wt %) ka(h-1) k2 k3 95.9 4.9x10-3 2.7x10-3 96.8 7.2x10-3 3.2x10-3 97.7 19.3x10-3 10.3x10-3 98.6 48.0x10-3 19.8x10-3 The Cooper Union for the Advancement of Science and Art Summer Research Internship Program 2011 Results 97.7% of H2SO4 @ 20°C and a goal of 99.9% sulfonation: 26.4 days (extremely long time) 98.6% H2SO4 @ 20°C and a goal of 99% sulfonation: 8.7 days (shorter, but still very long time) Thus, the relatively shorter time to run the batch to sulfonate PEEK would be 8.7 days within 98.6% H2SO4 and 99% sulfonation May be possible to increase the speed with increased temperature The Cooper Union for the Advancement of Science and Art Summer Research Internship Program 2011 The Cooper Union for the Advancement of Science and Art Summer Research Internship Program 2011 Introduction • Polyacetal/Polyformaldehyde • Monomer: Formaldehyde HISTORY • 1920: Staudinger unsuccessfully researched • 1959: Delrin (POM) introduced into the market MARKET • Global Demand: 808 kt • Price: $1.29 – $1.38/ lb The Cooper Union for the Advancement of Science and Art Summer Research Internship Program 2011 Main Properties • • • • • • • Wear Resistant Impact Resistant Moisture Resistant Resistant to Most Organic Solvents High Creep Resistant Resistant to Low Temperatures Low Friction Coefficient The Cooper Union for the Advancement of Science and Art Summer Research Internship Program 2011 Uses Buckles Conveyor Belt Gears Snowboard Buckles The Cooper Union for the Advancement of Science and Art Summer Research Internship Program 2011 Production Process Carbon monoxide methanol formaldehyde Carbon Monoxide + Hydrogen produce methanol Methanol oxidizes to form formaldehyde Formaldehyde chain polymerizes to polyoxymethylene Solution Polymerization (Solvent: Heptane) Insoluble Polymer polyoxymethylene The Cooper Union for the Advancement of Science and Art Summer Research Internship Program 2011 Air 34,000 kg Production Process of Formaldehyde Reactor 1 : Silver Catalyst Vaporizer Reactor 2: Copper Catalyst 2,800 kg Water Methanol 5000 kg Polymerization reactor 1 million POM Gears Air Compressor Valve Heat exchanger Pure Formaldehyde 4,000 kg Water + Methanol Distillation System Absorber CO2 Methyl Formate 335 kg 13kg U.S. Patent: 6,147,263 The Cooper Union for the Advancement of Science and Art Summer Research Internship Program 2011 Polyphthalamide (PPA) The Cooper Union for the Advancement of Science and Art Summer Research Internship Program 2011 Polyphthalamide (PPA) • Comprised of HMD, TPA, IPA, and adipic acid. Hexamethylenediamine Terephthalic acid • Raw material: Castor bean plant • Used to make PA10T type of PPA Isophthalic acid Adipic acid • Provides the diamine portion of the polymer • Renewable resource The Cooper Union for the Advancement of Science and Art Summer Research Internship Program 2011 Properties Uses • high T • automotive resistance components • chemical • plumbing resistance • electronic • low creep connectors • harmless • MetaCork to the body • lamp sockets • flexible • fuel system • dimensionally components stable Oica.com (accessed July 19, 2011). “World Motor Vehicle Production by Country and Type”. • Demand has increased with the increase of production of motor vehicles (Desirable alternative to metal) • $2.72-3.18 per lb (fairly high price) The Cooper Union for the Advancement of Science and Art Summer Research Internship Program 2011 Polymerization Reactor Design • Interfacial • Multiple reactors involved to polycondensation reaction achieve a high molecular weight of between 1000 g/mol • Solution polymerization and 3000 g/mol (aqueous) • Batch reactor Batch reactor • Results: Multiple 2.14 L reactors running for 13.5 hours (based on Malluche et al., Polymer Engineering and Science, 2007) • Predicted design not very efficient, likely to switch to a different reactor configuration The Cooper Union for the Advancement of Science and Art Summer Research Internship Program 2011 POLYCARBONATE (PC) The Cooper Union for the Advancement of Science and Art Summer Research Internship Program 2011 POLYCARBONATE (PC) - PC is a high quality engineering plastic. - PC was invented by Dr. Fox and Dr. Schnell in 1953. - A thermoplastic that has excellent heat resistance good electrical insulation properties high transparency. Figure 1: PC has a high impact strength compared to those of other plastics The Cooper Union for the Advancement of Science and Art Summer Research Internship Program 2011 THERE IS PC ALL AROUND US PC is found in: -bottles -CDs & DVDs -tableware -containers -electrical shavers -cell phone cases -computers -vehicle lights -tubes -sheets -food mixers -glasses The Cooper Union for the Advancement of Science and Art Summer Research Internship Program 2011 THE DEMAND FOR POLYCARBONATE -In 2011, America’s demand for polycarbonate reached 1,780 million pounds. -From 1995 to 2011 there was a large increase in the demand (1,320 million pounds of PC) (Source: The Freedonia Group, Inc. “Polycarbonate demand to increase 5.2 percent annually” http://www.theiapdmagazine.com ©The Freedonia Group, Inc. 2002.) The Cooper Union for the Advancement of Science and Art Summer Research Internship Program 2011 PRODUCTION PROCESS Polymerization Mechanism: Step Growth Figure 3: Direct phosgenation (left) and transesterification (right) methods Type Of Polymerization: Bulk Polymerization Methods of Production: -Direct Phosgenation -Transesterification Materials Used For Direct Phosgenation: -Bisphenol A (BPA) -Phosgene Materials Used For Transesterification: -Bisphenol A (BPA) (Source: Green Industry“Examples of Safer Reactions” -Dimethyl Carbonate http://www.greener industry.org.uk.) The Cooper Union for the Advancement of Science and Art Summer Research Internship Program 2011 BULK POLYMERIZATION IN A BATCH REACTOR The overall objective is to design a batch reactor to produce a specified amount of polycarbonate via the transesterification of DPC with BPA. Both the volume of the reactor and the time required to run the reactor are essential to design a chemical plant. Figure 4: This is a diagram of a bulk polymerization The Cooper Union for the Advancement of Science and Art Summer Research Internship Program 2011 SPORTS BOTTLE PRODUCTION Make 1000 Sports Bottles: (450,000 g) TIME REQUIRED TO RUN A REACTOR: DPC x0 dx x 4kr x 20 8kr x0 x 4kr k f x 2 (Rate Constants were obtained from Hersh, and Choi., J. Appl. Polym. Sci., 1990) -It takes 0.34-0.71 seconds depending on the target chain length, which is really fast. VOLUME OF THE REACTOR: VPC = VDPC +VBPA = WDPC WBPA + rDPC rBPA - The volume for the reactor would be 390 L. The Cooper Union for the Advancement of Science and Art Summer Research Internship Program 2011 Kevlar Poly(para-phenylene terephthalamide) PPTA The Cooper Union for the Advancement of Science and Art Summer Research Internship Program 2011 Applications and Properties • Bulletproof vests • Car tires • Ropes and cables • • • • High tensile strength Lightweight Flexible Flame-resistant The Cooper Union for the Advancement of Science and Art Summer Research Internship Program 2011 Synthesis and Production • • • • Para-phenylenediamine Terephthaloyl chloride Condensation reaction Polymer is spun into fibers, then woven into fabric PPD TCL Kevlar The Cooper Union for the Advancement of Science and Art Summer Research Internship Program 2011 Reactor Design and Optimization • Highly reactive and exothermic → solution polymerization • Stirred batch reactor with a cooling water jacket N batches per day Batch reactor downtime • Cleaning tank • Filling tank for next batch N(t + td) = 86,400 seconds td = aV + b Thermodynamic data: Zhang, Tao, et al. A novel scalable synthesis process of PPTA by coupling n-pentane evaporation for polymerization heat removal. Chinese Chemical Letters, 2011. Kinetic data: Gupta, J.S., et al. Polymerization Kinetics of Rodlike Molecules under Quiescent Conditions. AIChE Journal , 2001, 1, p. 177. The Cooper Union for the Advancement of Science and Art Summer Research Internship Program 2011 Reactor Design and Optimization For 30 bulletproof vests per day (~10,000 per year): • • • • 90 kg of Kevlar N = 8 batches per day V = 11,000 L t = 3800 s (~1 hr) The Cooper Union for the Advancement of Science and Art Summer Research Internship Program 2011 By Nika Sabasteanski and George Kaufer The Cooper Union for the Advancement of Science and Art Summer Research Internship Program 2011 -Feedstock: Lactic Acid Lactide (isomers) -Polymerization: Ring Opening Polymerization -Benefits -Biodegradable Figure 1: Yogurt -Applications containers -Biomedical: Sutures -Food: Yogurt containers -Market -Cargill Dow Nature Works -Projections: 7% growth per year Figure 2: Sutures The Cooper Union for the Advancement of Science and Art Summer Research Internship Program 2011 Production Process -Production -Bulk Polymerization -Batch Reactor -Volume ≈ 2,400 L -Synthesis: Chain Growth Figure 3: Synthesis -Initiator, Catalysts -Found Information -Kinetic Parameters (used in program) -Chemical Properties -Method of Solution -MATLAB: Euler’s Method The Cooper Union for the Advancement of Science and Art Summer Research Internship Program 2011 MATLAB Program for Reactor Design clear all format long %Clears all stored variables %Displays numbers at double precision D = 0.02; N = 500; kp=0.901; ki=1; kt=1*10^-6; %Step size in minutes %Number of steps %l/mol*min %l/mol*min %l/mol*min M0=9.16; M=zeros(1,N); M(1)=M0; %Found initial concentration by dividing density of L-Lactide by the molecular weight of L-Lactide, L/mol %Initialize array of monomer concentrations %Picking the inital value of M to be M0 I0=1*10^-8; I=zeros(1,N); I(1)=I0; %L/mol, chosen %Initialize array of initator concentrations %Picking the inital value of I to be I0 P=zeros(1,N); P(1)=(kp*M0)/((kp*M0)+(2*kt*ki*I0*M0)^.5); t0 = 0; t=zeros(1,N); t(1)=t0; %Initial time in minutes %Initialize array of times %Picking the inital value of t to be t0 for i = 1:N dmdt = -kp*M(i)*(((ki/kt)*I(i)*M(i))^.5); didt=-ki*I(i)*M(i); t(i+1)=t(i)+D; M(i+1)=M(i)+D*dmdt; I(i+1)=I(i)+D*didt; P(i+1)=(kp*M(i+1))/(kp*M(i+1)+((2*kt*ki*I(i+1)*M(i+1))^.5)); end The Cooper Union for the Advancement of Science and Art Summer Research Internship Program 2011 Emissions and Byproducts -Emission -Byproduct -Carbon Dioxide -Normal Butanol (n-butanol) Figure 4: Carbon Dioxide Emissions from leading plastics The Cooper Union for the Advancement of Science and Art Summer Research Internship Program 2011 THANK YOU VERY MUCH The Cooper Union for the Advancement of Science and Art Summer Research Internship Program 2011