Presentation Title

advertisement

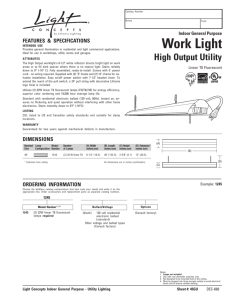

Energy Management Opportunities with Energy Efficient Lighting Your panelists – Benefits, Technologies & Services: Mike Carter and Mark Farrell, Energy Engineers 2 Lighting webinar benefits – – – – Bottom line cost savings today! Comfortable speaking with customers Knowledge of terms and pros/cons Awareness of energy efficiency opportunities Electric Intensity (kWh/sqft) Lighting Cooling (4.89) 30.4% Ventilation Office Equipment Miscellaneous Heating Cooking Refrigeration Water Heating Large Office Building 3 Contents – Energy Basics – Fundamentals of Light – Lighting Technologies – Lighting Controls – Lighting Maintenance – Business Solutions Toolkit – Incentives/Rebates 4 Energy basics – Power versus Energy Kilowatt (kW) is a measure of power, like the speedometer of your car that records the rate at which miles are traveled. Source: stock.xchng • A bigger engine is required to travel at a faster rate. Kilowatt-hour (kWh) is a measure of energy consumption, like the odometer on your car (miles). Energy cost = power (kW) x time (hrs) x price = kWh x $/kWh Source: Commonwealth of Kentucky • A 113-watt four lamp light fixture costs about $66 annually when operating 16 hr/day (113 W x 5,840 hr x $0.10/kWh ÷ 1,000 W/kW). 5 Energy basics – Lights do not consume more energy when they are first turned on. Includes high-intensity discharge (HID) lighting. – Pay the price for improved energy efficiency! The operating cost over the lifetime of a light fixture can far exceed the original purchase price. 6 Fundamentals of light – Lumens—A measure of the perceived power of light. Constant output regardless of distance from source. – Foot-candle—One lumen of light distributed over a square foot area. Depends on the distance from the light source. Does not hold for focused fixtures like flood lamps. Can be measured using light meter. 7 Lighting comparison – Lighting has many metrics. 60-watt incandescent ~ 850 lumens (100 CRI) ~ 14 lpw efficacy 32-watt T8 fluorescent ~ 2,800 lumens (83 CRI) ~ 88 lpw 400-watt metal halide ~ 24,000 lumens (65 CRI) ~ 60 lpw 400-watt high-pressure sodium ~ 45,000 lumens (22 CRI) ~ 112 lpw 8 Incandescent / halogen – 90% heat and 10% light (10 to 17 lumens per watt) – Energy Independence and Security Act (EISA) of 2007 establishes higher minimum efficiency standards for incandescent reflector lamps (R lamps). – Parabolic Aluminized Reflector (PAR#) lamps BR# (Bulged) and ER# (Ellipsoidal) • # —the diameter of the widest part of the lamp in eighths of an inch (R20 = 20/8 = 2.5" diameter) • EISA applies to > 2.25 " diameter 9 Incandescent / halogen – Flood lights Beam angle encompasses that part of the beam that varies from peak | brightness down to 50% of that intensity as measured in a plane through the nominal beam centerline. – New halogen bulbs offer up to 30% energy savings, instant on, no mercury, 100 CRI, and compliance with EISA 2007. Philips Halogena® Energy Saver/Energy Advantage (3,000 hrs) Sylvania Halogen SuperSaver® (1,000 hrs) GE Edison™ (2,500 hrs) 10 Source: Philips Lighting Fluorescent – Historical timeline 1838—Michael Faraday’s glow tubes 1850s—Glass-blower Heinrich Geissler 1880s—Alexandre E. Becquerel coated tubes 1893—Nikola Tesla induction tubes 1896—Thomas Edison patented x-ray lamp 1890s—Daniel McFarlane Moore 1901—Peter Cooper Hewitt mercury vapor lamp 1927—Edmund Germer patent 1936—GE’s George E. Inman patent 1938—First commercial fluorescent tubes 11 Fluorescent – Nomenclature (FxxT#) F—fluorescent Fxx—wattage (rapid start) or length (instant start) T- tubular; U—curved/bent Circline—circle T#—diameter in eighths of an inch Ballast Factor (BF)—ratio of output compared to reference ballast (not energy efficiency measure) • Affects both watts and lumens • Ranges from 0.6 to 1.3 – Fluorescent light emission is a chain reaction. 12 Fluorescent – T8 Types (Generations) Type Name Watts Lumens CRI Life (hrs, 000s) 1G 700 Series, Basic 32 W 2,800 75-78 15-20 2G 800 Series 32 W 2,850 3,000 82-86 24-30 3G Super, HO 32 W 2,950 3,200 82-86 24-30 4G Reduced Wattage, Energy Savers 23 W 25 W 28 W 30 W 2,000 2,400 2,750 2,850 82-86 Temp. sensitive, Instant start only 13 Fluorescent – Super T8 lamps, with high-efficiency ballasts, are high-lumen (>3000 versus 2,850 standard) and extended life (>24,000 versus 20,000 hours standard) products. Only saves energy when combined with a lower ballast factor ballast. Initial Lumens T8 Super T8 Type Watts Ballast Factor Fixture Lumens Fixture Watts LPW 2,950 33 0.85 2,496 28 89 3,200 34 0.78 2,496 26 96 – T5 series (good for indirect lighting like suspended lighting). Type Initial Lumens Watts LPW Life T5 2,900 28 W 104 24,000 hours T5HO 5,000 54 W 93 24,000 hours 14 Fluorescent – T8 versus T5 T5s (smaller diameter and shorter) not interchangeable with T8s. Six F32T8s equivalent to four F54T5HO. T5s have lower mercury content than T8s. T5 lumen maintenance better at higher ambient temperatures but worse in cold. Source: RPI Lighting Research Center • Holophane IntelliBay™ & IntelliVue™ • Lithonia I-BEAM™ System 15 Fluorescent – Replace existing T12 fluorescent lamps with T8 fluorescent lamps (up to 30% savings). Four-lamp T12 versus T8 Fixtures – Start modes Lamp Type Fixture Watts Fixture Lumens LPW F32T12 148 9,120 62 F32T8 113 10,600 94 Programmed start (in series) • Long preheat shuts down after start (up to 50,000 cycles). • Can be wired in parallel Rapid start (in series) • Simultaneous preheat stays on all the time (15,000 to 20,000 cycles). • Identified by 2-wires from ballast to each end of lamp. Instant start (in parallel) • No-preheat; high-voltage start (10,000 to 15,000 cycles). • Identified by 1-wire from ballast to each end of lamp. • Not good with occupancy sensors (<30 minute burn). 16 Fluorescent – Fluorescent ballasts Magnetic (60 Hz) • Core and coil Electronic (20 to 60 kHz) • 10% to 15% more efficient • NEMA Premium® Ballasts even better All ballasts consume power even without lamps (2-lamp example). • Electronic consumes 6 to 12 watts loaded and 3 to 7 watts open circuit. • Magnetic consumes 18 to 20 watts loaded and 6 to 10 watts open circuit. – Regulatory driver for electronic ballasts (T8 and T5 lamps) No magnetic ballasts manufactured for replacement after June 2010. 2009 DOE Energy Regulations—Beginning July 14, 2012, these regulations effectively eliminate most 4-ft T12, 8-ft (F96) T12 lamps, and 700 series (1st generation) T8 lamps 17 Fluorescent – Metal Halide (MH) versus Fluorescent for High-bay Probe start (PS) MH with low lumen maintenance (<65%) is best target for replacement. • EISA2007 imparts higher performance standards for PS MH. • The lumen maintenance of metal halides can decrease to 45% during its lifetime, whereas fluorescents maintain 90% to 95% in optimal conditions. Comparison • One PS MH with 20,000 EOL lumens at 320 system watts • Six F32T8 with 18,000 EOL lumens at 220 system watts Remember—lumen output of fluorescents declines with heat/cold. 18 Fluorescent – Compact Fluorescent Lighting (CFL) You get the same or more light output (lumens) with a 75% energy reduction and over six times the rated life! Up to 9,000 lumen output at 120 watts (PL-H high 4-pin) Energy savings far outweigh difference in lamp price. Power factor is typically 0.6, but power savings far outweighs low power factor. Issue of mercury content can be addressed. Use reflector flood CFLs (R-CFLs) in recessed can lights. Consider aluminum reflector CFL PAR lamps. Source: NREL Globes Candelabra 19 Fluorescent – Compact Fluorescent Lighting (CFL) Twister Single, double (T), triple (TR), quadruple (Q) twin-tube (turns) Integral ballast screw-in Modular external ballast pin-based • Gxx where xx is pin center-to-center dimension (G23 has 23mm dimension) » G23q where “q” means quad-pin base » G23d-x where “d-x” means the number of tubes (turns) • 2-pin with integral starter requires magnetic preheat ballast • 4-pin (quad) with external starter usually electronic ballast 20 Fluorescent – Induction (electrodeless) lighting High-frequency magnetron microwave power generator, magnetic field coupling device (antenna), and phosphor coated tube. Up to 100,000 hour rated lamp life • Lumen maintenance 70% at 60,000 hours • Efficacy of 70 to 75 lumens per watt Best applications have high labor cost. • • • • • • • • Parking garages Cold-storage rooms Inaccessible roadway tunnels and underpasses Illumination of roadway signs and inaccessible Source: Osram Endura/Sylvania IcetronTM Electrodeless Lamp advertisement boards Lighting over stairs or escalator wells Open mall atriums or ceilings in "big box" retail areas Pole-mounted luminaires for dusk-to-dawn illumination on a campus Industry, petrochemical, and offshore applications 21 High Intensity Discharge – Low Pressure Sodium Most energy efficient lighting source Not an arc source, so no glare 0 to 20 CRI – High Pressure Sodium Arc source with (20 to 65 CRI) 310 W and 360 W replacements exist for 400 W Electronic ballasts 5 to 20 W versus 50 to 70 W magnetic 22 High Intensity Discharge – Metal Halide Arc source with 60 to 95 CRI Quartz or ceramic transparent tubes • Ceramic (polycrystalline alumina—PCA) offers better lumen maintenance, color rendering (95 versus 65 CRI), and color stability. • Can operate on HPS ballasts (direct lamp replacement). – Smaller Size <150W HID Ballasts Generally 50% smaller in size (3" x 1.3" x 1.1") and lighter weight than standard magnetic ballasts Self-ballasted PAR30LN and PAR38 (1,200 initial lumens) CMH lamps replace 74W and 120W halogen bulbs Source: Osram-Sylvania 23 High Intensity Discharge – Sustained arc vs. fluorescent phosphor emission Watts Lumens Lumen Maintenance 1,000 W 47,500 65% 30 40 24,000 Low Pressure Sodium 135 W 22,000 >95% 150 10 18,000 High Pressure Sodium 400 W 45,000 75% 85 30 24,000+ Metal Halide** 452 W 40,000 70% 65 65 20,000 Type Mercury Vapor* LPW CRI Life (hrs) *Ballasts banned by EPAct2005 **Position dependent – Strike time (minutes) MV LPS HPS MH Probe MH Pulse Warm up 4-7 7-15 1-4 2-15 1-4 Restrike 3-6 1 0.5-1 5-20 2-8 24 High Intensity Discharge – Radio Frequency Lighting Luxim LiFi™ or Light Emitting Plasma™ (LEP) • An ac/dc converter generates an RF signal that is transmitted by a special cable to a quartz lamp embedded in a dielectric material. • Pemco Lighting Products STA-41-01 luminaire » 273 system watts » 23,000 initial lumens » 5,500K CCT/80 CRI » 50,000 hour rated life » Dimmable to 20% Source: Luxim 25 Solid state lighting – Light Emitting Diodes (LEDs) Electrical current driver circuit instead of ballast. Relatively low lumens per watt (30 to 35 lpw) historically, but now 45 to 60 lpw. Long life; years, not hours. • 70% lumen maintenance at 50,000 hours of operation. Frequent switching does not affect rated life for LEDs as it does for fluorescents. Directional nature of LED results in very high luminaire efficacy. Very compact and low-profile. Nothing to “break.” No abrupt failure mode. Source: NIST 26 Solid state lighting – Light Emitting Diodes (LEDs) Instant on (no warm-up time required). Does generate harmonics, but no reported problems. Some built-in surge and noise protection. Expensive initial cost. Heat sensitive. Exit Signs • Annual operating costs of $5 compared to $30 to $40 for incandescent or fluorescent. Compatible with battery backup (traffic lights). Source: stock.xchng 27 Lighting controls – Daylighting Skylights/lightpipes, clerestory windows, or roof monitors. Energy savings can range from about $0.25/ft2 to $0.50/ft2, depending on the building type, location, office area plan, and local cost of energy. Photosensor layout is important. Source: LightLouver LLC Occupancy sensors ◦ Ultrasonic has wider range than infrared but is prone to false positives. ◦ Can shorten life of fluorescents with instant start ballast. ◦ $30 to $150 cost. ◦ 2-year payback is normal. 28 Lighting controls – Dimming A solid-state dimmer works by using silicon-controlled rectifiers (SCRs). Radio frequency interference (RFI) can be a problem. Greatly increases bulb life for incandescent/halogens. Requires special dimming ballast for fluorescents. • 3-wire, 2-wire, or 4-wire. • Energy savings fairly linear with fluorescents. • Continuous or bi-level dimming HID lighting limited to 50% to 60% dimming. • Two-level for magnetic ballasts (non-linear energy savings). • Continuous for electronic ballasts (energy savings linear). • Lamp life degrades if dimming to less than 60% level. 29 Lighting controls – Digital Addressable Lighting Interface (DALI) A royalty-free, non-proprietary, two-way, open and interoperable digital protocol. The Gateway broadcasts commands to all digital ballasts across the signal cabling that connects the ballasts in parallel. A ballast only responds when the message contains its specific address. Sixteen programmable scenarios and groups stored in the ballast. 30 Lighting controls – Wireless Mesh Networks Redundant • Joining • Healing Spatial diversity • Different routes Temporal diversity • Try again later Source: Dust Networks 31 Lighting maintenance – Nine components of a good lighting maintenance program*: Group relamping Know your equipment Focusing and adjustment Verify lamp types and wattage Verify color temperature Confirm that everything is in working order Watch for compatibility issues Get rid of dirt Do not forget exterior lighting *"Everything You Need to Know About Maintaining Your Lighting System," by Jean Sundin, founder of Office for Visual Interaction, Inc. 32 Lighting maintenance – Group relamping recommended at 60% to 80% of rated life. Every 2 to 3 years for 20,000 hour fluorescents. Can be 30% to 40% cheaper to group relamp due to labor savings. Easier to schedule and outsource than spot relamping. Reduces improper mixing of different types of lamps. Normally done outside working hours. – Lighting failure modes Heat Voltage transients Vibration Bad electrical connection Improper cycling 33 The Business Solutions Toolkit – Reduce energy expenditures with free, online tools Energy benchmark data by business segment Efficiency recommendations by business segment Lighting, motor and other energy calculators Facility energy assessment… plus more – Get energy answers with live Web resources “Ask an Expert” service supplies direct answers to energy questions Searchable Energy Library and News resources Monthly electronic newsletter delivered to your e-mailbox 34 How to access the Toolkit – Links found on the Rocky Mountain Power website Can access direct at rockymountainpower.net/toolkit – Register to use the Toolkit and you will receive our monthly e-mail newsletter 35 What is in the Toolkit 36 Online business tools rockymountainpower.net/toolkit 37 Rocky Mountain Power FinAnswer Express – FinAnswer Express is for commercial and industrial customers– either retrofit or new construction – Pre-calculated incentives for high-efficiency lighting and HVAC equipment Custom incentives may be available for other types of equipment – Incentive process (pre-purchase agreement or post purchase application) varies by technology and project type Please understand the process before you purchase! – Check our website for on-line forms plus trade allies available to help – Also check for state and federal tax incentives at dsireusa.org 38 RMP Energy FinAnswer – Applies to comprehensive commercial or industrial projects– either new construction or commercial retrofit* Lighting and non-lighting projects can be packaged – Starts with an energy analysis to identify options and highest priority measures Commissioning is required for most measures – Incentives are project-based Payable by one-time lump sum check, per project – Incentive agreement must be signed before equipment is purchased – Check our website for participation steps and online forms *Commercial retrofit projects must be at least 20,000 sq. ft. to be eligible 39 Contacts – For more information please phone us: Call your Business Solutions Team for answers to service and account questions at 1-866-870-3419 – Visit our website at: Business program Web page – rockymountainpower.net/business Business Solutions Toolkit – rockymountainpower.net/toolkit – Or contact us directly: E-mail us at energy.expert@pacificorp.com Use our online inquiry form – rockymountainpower.net/inquiry Call our business Energy Services Hotline at 1-800-222-4335 40 © 2010 Tech Resources Inc.