Has the Moor…

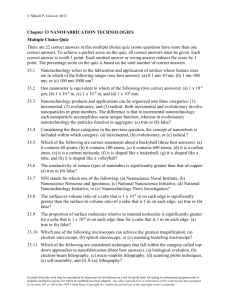

advertisement

From transistor to Integrated Circuits of today – the Roadmap József Gyulai Professor Emeritus Chair Electronic Devices, BME-BUTE, Res. Centre for Natural Sci., Inst. Tech. Phys.& Matl. Sci. As a materials scientist, I’m biased: most influential invention of the 20th century was the transistor, and its application in integrated circuits • • • • • • • MOS patent of Lilienfeld (as early as 1925!), functioning product: Sah and Atalla (in 1960) Mataré (1944) Bardeen-Brattain, point contact (1949), Shockley – pnp (1950, 1951) Integrated circuit, Kilby (1959), Noyce (1961) CCD, Boyle, Smith (1969) Nobel prizes – near microelectronics J. Bardeen, W.H. Brattain, W. Shockley, transistor (1956) L. Esaki, I. Giaever, B.D. Josephson, application of tunneling (1973) K. von Klitzing, quantum Hall-effect (1985) E. Ruska electron microscope, G. Binnig, H. Rohrer tunnel microscope (1986) Z.I. Alferov, semiconductor laser, H. Kroemer, UHF transistor, optics, J. S. Kilby, integrated circuit (2000) W.S. Boyle, G.E. Smith, CCD optics, Charles K. Kao, optical fiber (2009) A. Geim, K. Novoselov, graphene (2010) Geim was awarded in 2000 with shared IgNobel prize IgNobel: “first make people laugh, then make them think”: diamagnetic levitation 1T- 10T field is enough for levitation of living bodies As most beautiful invention, I consider the laser, because only theories existed (population inversion) • Transistor had a predecessor, the vacuum radio tube, • However, many were thinking whether the „vacuum space” among crystalline atoms behaves similarly – the basis of today’s ”electronic materials science”... • On a vision drawing of mine from the 1970-s, processes of the unipolar transistor recall a car race in a stalactite cave; – A – a free flying „ballistic” electron; – B – electron deflected by defects, which heat the crystal Metallization S – source G – gate D – drain, in the back, invisible Basic processes in production of monolithic integrated circuits • Sequence of few hundred steps of about ten different physical, chemical processes • "Front end" and "Back end" • Thin film forming, • Thin film removing, • Structuring processes “Front end” processes • Thin film forming processes – Oxidation, thermal – Ion implantation – Film forming • physical, • chemical (Chemical Vapor Deposition, CVD) – Diffusion • Thin film removing processes, etching – Wet chemical – Gas phase – plasma enhanced – Special etching techniques • Lateral structuring processes – Photolithography UV, DUV, EUV – Electron-, ion beam lithography Miniaturization • Key to success of microelectronics was that “scale down”: works: transistor with shrunk dimensions has the same characteristics except for heat dissipation... • Small sizes are important not only for portability, small power consumption, but • reliability is equally important characteristics which improves with amount of intelligence stacked into the device – works internally and does not ask questions which often lead to mistakes. • A good figure of merit is one mistake for 1010 steps, which with added redundant organization can still be improved. ”Moore’s Law” • “Doubling the number of elements on the chip yearly”... “may work till end of the seventies…” – says Gordon Moore (Electronics, 38(8), apr.19,1965) • We may say that this is a generic law, which is more of a law in economy than of technology – production only satisfies market demands! • International Technology Roadmap for Semiconductors, ITRS: http://public.itrs.net/ a four-yearly study with biannual corrections An example from ITRS: Difficult technology tasks, 2011: black “known by industry”, Yellow “needs development” , white “no known solution”, “red brick wall” – to date always found solution... (PROCESS INTEGRATION, DEVICES, AND STRUCTURES Success of ITRS on 2010 issue, http://public.itrs.net/ How long will this work? Another, recent example from ITRS: Difficult technology tasks, 2013: (Lithography challenges) Moore’s Law today "Der Mohr hat seine Arbeit getan, der Mohr kann gehen." (F. Schiller: Fiesco; or, the Genoese Conspiracy) “The Moor has done his work—the Moor may go” May he go, really? • Today, device dimensions smaller than a virus • Scale down may work till 2020, but question goes not only for memories and processor, but for telecommunication, etc., too. • Silicon has a curse: being an indirect semiconductor, thus, laser action cannot be made on usual ways… • Nanocrystals, however, can produce coherent light Storage Class Memory MLC Multi/level Cell, STT Spin-transfer torque... PC Phase change... SCM: Storage Class Memory Non-volatile memory forecast • Going 3D, i.e., to stacked structures, NAND and NOR Flash memory, scaling down to 12 nm half-pitch looks straightforward till 2028 • Research is needed for magnetic/spin torque and for resistive devices • Reliability issue is difficult because of complex structure: failure mechanisms are very different for transistors, for interconnects, etc. May lead e.g., to need of optical or carbon based interconnects “Breakthrough“ techniques in lithography Maskless lithography (ML2) • nano imprint, only 1:1 transfer • Directed self-assembly – will it satisfy quality conditions? Thermal noise works against zero defect solutions Hot areas in our field • Computer in telecommunication – – – – Mobile devices Wear-on devices Ambience intelligence (intelligent car, intelligent “mote”) Acoustic devices • “Revolution” of sensors and coupled actuators – Can be biomaterial, too… – Automation of transport • Micro- és nanotechnology – „Energy harvesting” • “Revolution” of lighting – Light emitting diode (LED), Organic LED • Priorities in EU: – „Energy efficient buildings”, – „Green car”, – „Factory of the future” ITRS Roadmap 2013 Conclusions • • • “First of all, the aggressive bi-annual introduction of new semiconductor technologies allowed ICs, consisting of even hundreds of million of transistors, to be produced cost effectively. This made it possible to integrate extremely complex systems on a single die or in a single package at very attractive prices. Furthermore, progress in packaging technology enabled the placement of multiple dies within a single package. These categories of devices are defined as system on chip (SOC) and system in package (SIP). Second, manufacturers of integrated circuits offering foundry services were able to provide, once again, the “New ASICs” at very attractive costs. This led to the emergence of a very profitable business for design “only” houses, i.e., companies that do not manufacture ICs themselves, but produce the designs that are manufactured elsewhere. Third, development of sophisticated equipment for advanced integrated circuits proliferated to adjacent technology fields and by so doing the realization of flat panel displays (FPD), MEMS sensors, radios and passives, etc., was made possible at reasonable costs. Under these conditions system integrators were once again in the position to fully control system design and product integration. “ European Conclusions • European industry and additional financing from tax payers’ money through the European Union (EU) • Way of operation of the European industry doesn’t differ much from ones in other parts of the world • EU operates organization (Directorate General, DG) to convey funding mostly on open channels with an application, preview, funding, judged by deliverables • I, personally, am a member of the so-called Nano, Materials and Biotech Program Committee (NMBP) belonging to the group funding applied research and innovation – the committee to decide for topics and allocated funding for the years to come. No influence on review process and bound by succession of applications based on qualification by reviewers. • The Framework Programs close and a new application system, the Horizon 2020 starts. Top quality science is a base of future technologies, modern working places and of societal well-being. Europe’s best interest to support good scientists, keep them here and attract others to Europe Ensure best infrastructures for such a work Strategic investments support present day innovation (Factory of the Future, micro- and nanoelectronics, information and communication technology, ICT, industrial biotechnology, space research) Europe has to attract more private investments into innovation. Europe needs more innovative SMEs to enhance number of working places Innovation should proceed in problems important for society (E.g.: climate change, problems of environment, energy supply, transport) Look for breakthrough, multidisciplinary solutions Test solutions, then implement + joint programmes of Member states + H2020 contest for prizes + …. TRL: Technology readiness level Basic research: …Experimental and/or theoretical activity aiming at gaining new information on basic properties of phenomena, observable facts without the goal of applications… Applied research: … original research aiming at practical application…. Experimental development: …activity based on research and practical experience aiming at preparation of new materials, products, structures, systems or new improved services TRL has many stages ranging from observation of basic principles to proven controlled quality production stage. RIA: Research and Innovation Action Description: Action primarily consisting of activities aiming to establish new knowledge and/or to explore the feasibility of a new or improved technology, product, process, service or solution. For this purpose they may include basic and applied research, technology development and integration, testing and validation on a small-scale prototype in a laboratory or simulated environment. TRL 1-5-(6) IA: Innovation Actions Description: Action primarily consisting of activities directly aiming at producing plans and arrangements or designs for new, altered or improved products, processes or services. For this purpose they may include prototyping, testing, demonstrating, piloting, large-scale product validation and market replication. Projects may include limited research and development activities. TRL (3-4)-5-9 CSA: Coordination and support actions Description: Actions consisting primarily of accompanying measures such as standardisation, dissemination, awarenessraising and communication, networking, coordination or support services, policy dialogues and mutual learning exercises and studies, including design studies for new infrastructure and may also include complementary activities of strategic planning, networking and coordination between programmes in different countries. TRL nem releváns SME (Small and Medium Enterprizes) instrument Description: The SME instrument is targeted at all types of innovative SMEs showing a strong ambition to develop, grow and internationalise. It provides staged support covering the whole innovation cycle in three phases complemented by a mentoring and coaching service. Transition from one phase to the next will be seamless provided the SME project proves to be worth further support in a further evaluation. Each phase is open to new entrants. SME 1. megvalósíthatósági tanulmány – fix 50.000 EUR támogatás SME 2. innovációs projektek akár 1.5MEUR 70-100% támogatási arány Bármely TRL szinten https://ec.europa.eu/research/participants/portal/desktop/en/home.html My field - Ion implantation – a key technique 1. 2. 3. 4. 5. Patented by Shockley in 1957 – a bit of naïve form, but the restoration of defects with heat trsatment was included! This early patent became a fortune globally: when the need for the technique became general, the patent was worn out (17 years passed)... The Mayer group was a believer of ion implantation – first results proving this were achieved in years 1974-76 It was not consensus, in 1970, I’ve argued for implantation against an Intel engineer, who said “maybe will work to amorphize regions between devices for electric insulation” I’m talking on three tricks found by us within the Caltech-KFKI exchange research program, financed by NSF, which definitely contributed to fulfillment of Moore’s Law ”Moore’s Law” in my past • My being “best time, best place” postdoc stay at Caltech (196970) was preceded just by one year, when Intel (Moore, Noyce, Deal, Grove, Vadasz...) left Fairchild – the company supplying the forming Mayer group, including me, with project ideas (resulting 11 papers with my co-authorship within one year) • To my best knowledge, Intel’s start-up success was a simple trick: to line inner surface of the quartz tubes with polysilicon enabling to trap killer impurities, e.g., sodium, from heater elements of the furnace. • Thus, they were first to produce on a single chip – neighboring enhancement and depletion pairs of transistors, i.e., logic gates – This success might have been the cause that the young Intel refused to apply ion implantation. – In 1976, when a Caltech student of ours R.D. Pashley was hired by Intel, the strategy has changed. Dick Pashley – possibly my student with the highest career – invented the “flash memory”, recently in pension as Intel Vice-CEO...“ Three most important results of Caltech-KFKI Program, NSF, 1974-80 1. 2. 3. Two finding has led the silicon crystal industry of the whole world to abandon mass growing and selling (111)-oriented silicon and switch to (100)-oriented silicon 1. Thermal oxide grows with better quality on (100) – a result of Intel Co. might be more widely known, but the fact that 2. on (100)-oriented silicon implantation defects also regrow with better quality is of equal importance – an idea of our Caltech-KFKI group on a remarkable summer eve of 1974 and the overnight experiment performed by myself. This result, in combination with the idea of so-called “pre-amorphisation implant”,PAI, rendered implantation from physicists’ idea to production technology: pre-amorphization has aimed at two goals 1. it helps to avoid a basic uncertainty of pn-junction depth (xj) because no channeling of ions by crystal atoms can occur, 2. additionally, it makes use of the idea that thermal regrowth from a fully amorphous state leads to more perfect lattice than the one from a defected crystal. Accordingly, the proposed process was to ‘self-amorphize’ (with Si or Ge ions) the surface of the silicon wafer. Step two, implant the desired species into this amorphous layer. Step three, a low-temperature heat treatment is sufficient to restore good quality crystalline state, especially on (100) silicon, together with little or no diffusion of the implanted species brought simultaneously to lattice sites, which is needed for electrical activity.1975; Basic experiments were performed by my talented colleague, our first exchange person, László Csepregi. BME Course Caltech-Cornell-KFKI times (1974-86) • Pre-amorphization of SOS interface resulted in great improvement of radiation hard SOI circuits at Hughes, a work by SS. Lau, SE.Matteson, P.Revesz, Jim Mayer, J.Gyulai. J. Roth and TW. Sigmon • The Caltech-KFKI exchange program was probably the first between the two countries, which lasted till Afghanistan invasion by the Soviets in 1978. • After that, non-governmental sources were found and used to keep up the successful cooperation for a decade longer. Methods in nanotechnology • Scanning probes, also for moving individual atoms – lab technique Nanostructuring with focused ion beams, FIB, and nano CVD (LEO gym., MFA-ban) Our best: 20nm pore Nanoelectronics • Scale down cannot go ‘ad infinitum’, new solutions are needed (<14 nm node): • Smart cut© - “peel” bulk semiconductor materials, like were mica, to make nearly 2D substrates, for SOI wafers... • New materials for channel, higher mobility than that of Si: – Six Ge1-x – InGaAs (L.Czornomaz: Comp. Semicond, 1/2014, 32) – Graphene? Lithography solutions by the Biró group Worries of nanoelectronics • New solutions because of scale down limitations: – Instead of electron conduction, other binary systems, e.g., spin, ~tronics (D. Jamieson, Melbourne) – Optical data transport on chip instead of metallization – inevitable – Optics: plasmonics? – Analog vs digital systems – So-called biomimetic solutions • In my view, only solutions will ‘make it’ which fit into today’s foundries, albeit with slight modifications Insulator 28Si Substrate Quantumcomputer solutions “Qubit” denotes entangled particles E.g., seven qubit of 5 fluorine and 2 carbon can factorize 15: 3٠ׁ5=15 Radio waves trigger and NMR reads out the result 2012: Superconductiong stabilization (10 μs) of qubit using silicon technology! IBM Research Dicarbonylcyclopenta dienyl (perfluorobutadien-2yl) iron (C11H5F5O2Fe ) (ill. pentafluorobutadienyl cyclopentadienyldicar bonyl-iron complex) Our road to carbon nanotubes, CNT by chance, different materials were bombarded with 210 MeV-es ions, Ne, Kr, Xe Reliability (Swiss Fed. Labs for Matls Testing and Res.) • Care for non/scaling physical processes – Mass and heat diffusion, electrical conductivity, reaction kinetics, corrosion processes, etc., • Fatigue, friction, repair mechanisms are different in molecular and atomic scale • Redundancy is a way out, especially, when quantum physics comes into play • Requires research, modeling • Robust solutions are needed More Moore: Ultra Shallow Junctions • Weakness of PAI: implantation defects have ‘forward peaking’ character. I.e., near the surface vacancy-type, deeper interstitial-type defects dominate, thus perfect recombination is difficult. • Idea of PAI, with multiple energy was expected to deliver missing interstitials where vacancies dominate. However, interstitials of End-of-Range, EOR, defects cannot reach V-rich regions because of different diffusion lengths, • Applied strategies today: – sub-keV boron implant – channeling is almost fully missing, – Molecular ion implant to make cascades overlap, thus better amorphization (decaborane) – PAI, maybe combined with BF2+ molecular ion, Figure courtesy of M.I. Current – ”Cocktail” implant: non-doping, but diffusion barrier ions (N,F), in front of EOR to prevent I-outdiffusion 43 Vision • 20th century almost erased border between physics and chemistry, • In the 21st, I’m expecting this to happen towards biology • Arsenal of mathematics is improving simultaneously allowing ‘quasi-exact’ solutions to problems Worries of nanotechnology, 2 • Quality control – – • Analogue for nanotechnology is still beyond horizon – • Does an ‘accelerated evolution’ exist enabling quality control for nanotechnology? Quality control accepted and satisfactory, e.g., to traditional pharmaceutical industry cannot be applied in production of a quantum computer – – – • Today’s goal: so-called Total Quality Management, TQM, In biological systems evolution serves as “quality control”: 1. self-reproduction, 2. Random mutations (the ‘almost braque’), 3. Quality improves as result of natural selection In regular medicine, very low concentration of non-sensitized, inactive molecules makes no harm, in nanotechnology, we not only need all molecules functional, but their spatial position is equally essential: they must be produced at positions to be ‘addressable’ Reliability issue is difficult: reliability in nanoelectronics is based on same in microelectronics, but what if we are down at sizes of a biomulecule? Does a single virus possess ‘reliability’? Engineers’ thinking in biology - less antropomorphism • • • • • • E.g., case of stress protein, formed in bone marrow Swims or is drifted? Finds a damaged protein molecule, how? Detects damage, minuscule deformations, wrong aminoacid sequences; measures like an AFM in liquid? Then selects a protein part of its own with correct acid sequence, and substitutes the wrong one in the molecule important for the body Energetics is also a miracle as only atomic forces can play • I’m expecting understanding of all these on physical, mathematical models; • this would add to biology of the 21st century Nanoengine, growth of flagellum of bacteria ‘Escherichia Coli’ • Courtesy of Professors K. Namba (Osaka) and F. Vonderviszt (Univ. Pannonia, Veszprem, Hungary) • • • • • First the bearing is formed, Then a drill bit drills through the membrane of the cell Formation of a shaft is coming Followed by the growth of the flagellum A five finger form cover takes care that valuable plasma material should not go wasted in the liquid. • If problem, automatic restart follows Animation of flagellar growth (based on ten thousands of TEM pictures) Keiichi Namba and Ferenc Vonderviszt (VE) An area fitting our capabilities: Micro-Electromechanical Systems, MEMS • Using IC techniques to form non-IC structures • Demands on lithography is less stringent – micron size and below satisfactory • Enabled by development of specific etching techniques – Chemical, etch rate depending on dopant, crystalline orientation – Ion etch (DEEP-RIE: deep reactive ion etch, etc.) – Combined with e-beam lithography • Shown will be early results in our institute, other talks (P. Furjes) will deal with present status “Micro hot plate" – pellistor type gas sensor, MFA Heatable 200x200 μm2, Si platelet hanging over a cave formed by etching, suspended by four leads, 2 for current, 2 for Pt-thermometer Catalytic material is placed upon to oxidize organic gas molecules at hot plate temperature, “Artificial nose” Heater implanted conductor meander Thermometer Pt meander RESEARCH INSTITUTE FOR TECHNICAL PHYSICS AND MATERIALS SCIENCE -MFA, BUDAPEST SENSOR AND MICROTECHNOLOGY LABORATORY www.mfa.kfki.hu/laboratories/sensorics Mass flow controller Tactile sensor Heater Thermometer Nanogas project using carbon nanotubes, CNT • CNT must have defects, e.g., implantation defects Demo chemicals – water, – acetone, – ethylalcohol, – chloroform, – trichloretilene „Artificial nose" Investigation of wines of different wineries KF: Blaufrank, different years, Cabernet sauvignon of two wineries, and a Lindenblatter of Tokaj The future of sensorics and actuators • All events, processes in science reads about ‘effects’ let it be physical, chemical, biological, etc. • Any system subjected to external effect, influence (light, heat, bouncing body, chemical) will change its state which can be detected and characterized. • If we read this measurement backwards, can we conclude on character of the primary state on base at this second state? • We denote the external influence as a “sensor”, if only minute, negligible changes are caused by it on the original state. • If this change is undetectable with today’s techniques, we even quote the sensor as ‘non-destructive’... „Ceterum censeo...”: • Science and technology of today can only have one mission and maybe two main directions – corresponding somehow to preservation of self and of the race: 1. Search ways, modes whether, and if positive, how can 7 - 10 billion human live on Earth in kind of symbiosis with other forms of life?… 2. Extension of life span of individuals attracts great interest – causing unheard-of development of biological science If ‘recipes’ become known, will society absorb them and put into action in time? • To make that disciplined life tolerable, arts, literature, or for believers, religion would help … Buckminster Fuller, architect and one of Club of Rome founders: Operating Manual for Spaceship Earth - (1969) “…One outstandingly important fact regarding Spaceship Earth, and that is that no instruction book came with it…„ Biosphere, Montreal, 1967 Recyling economy – when? Fullerens Different types of scientists: talented, diligent, fortunate • • Either pair of properties may result in success in science; and all of them have properties that can be learned or is useful to be learned Supplement to talent: – Examine all results, explanation from its back side, inverse; you may find nonconventional jewel, but you may face a difficult life. – Dine together with your competitors – give and get information – Look out for unexpected chances… • Supplement to diligence: – Discuss and watch on conferences – it’s almost a substitution of literature studies; who chooses his/hers topic after literature, is late by at least half a year – Be in good terms with your more modern students – You should be the one who authors monograph of your suject (with super coauthors?) – Build your own database for words, notions you use to forget. • Supplement to fortune: – Remember, make note of names, of consorts, kids of your colleagues – keep accessible notes even in later years – Build contacts, especially, human ethical parts. – Don’t show a greedy face! – Be attentive, polite, but self-conscious Thank you for your attention