- the Journal of Information, Knowledge and Research in

advertisement

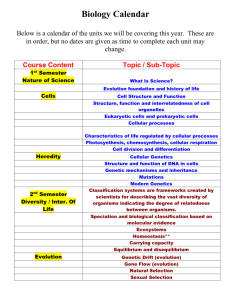

JOURNAL OF INFORMATION, KNOWLEDGE AND RESEARCH IN MECHANICAL ENGINEERING CELL FORMATION APPROCHES/ TECHNIQUES – A STUDY H.D.VIRANI1, PROF. K.R.GAWANDE2 AND S.B.RAJAVIR3 1M.E. (CAD/CAM) Student, Dept. of Mechanical Engineering/ C.U.Shah College of Engineering and Technology/ Wadhwan City, Surendranagar, Gujarat, India. 2 A. Professor, Dept of Mechanical Engineering/ C.U.Shah College of Engineering and Technology/ Wadhwan City, Surendranagar, Gujarat, India. 3 A. Professor, Dept of Mechanical Engineering/ Takshashila College of Engineering and Technology/ Kalawad Road, Rajkot, Gujarat, India. hiteshvirani@gmail.com ABSTRACT : In the recent years, Cellular manufacturing has received considerable interest from practitioners and academicians. Cellular Manufacturing System (CMS) has been emerged as a vital approach for batch and job production environment. Cell Formation (CF), one major problem associated with CMS, involves the process of Grouping the parts with design and manufacturing features into part families and corresponding machines into Machine Cell. Group Technology has been an essential tool for developing a CMS. This paper aims to discuss various approaches and techniques for CF and emphasized the significant research workdone in past over the years and attempts to points out the gap in research of past studies. Keywords : Cellular Manufacturing, Array Based Clustering, Fuzzy Clustering, Artificial Intelligence 1. INTRODUCTION Our manufacturing world continues to become more complex brought principally global competition, cost and profitability pressures, and rapidly advancing technology. Manufacturing industries are under great pressure caused by the rising costs of energy, labor, capital, and intensifying worldwide competition. While these trends will remain for a long time, the problems facing manufacturing today run much deeper. In many cases they stem from the very nature of the manufacturing process itself. “Man is a user of tools. Those who recognize the tools of tomorrow and learn how to use them today, assure themselves of a place in tomorrow’s prosperity.” The concept of flexible automation evolved through efforts to more efficiently and effectively utilize and control assets, information, and resources in a changing economic climate. Automated cells and systems have grown from concept to reality in light of installed systems currently in place throughout the United States, Japan, and Europe. And they are projected to grow dramatically over the next several years as manufacturing strive to become more comfortable with the increasing installed base of cells and systems and the dynamic forces of competitiveness, productivity and profitability. Flexible manufacturing cells and systems represent an avenue of change for manufacturers that helps to bridge the gap between technology, competition and profitability through a highly specialized and focused approach to manufacturing effectiveness [1]. Cellular Manufacturing is an application of group technology in which dissimilar machines or processes have been aggregated into cells, each of which is dedicated to the production of a part or product family or a limited group of families. CM is one of the major concepts used in the design of Flexible manufacturing Systems. CM, also known as group production or family programming, can be described as a manufacturing technique that produces families of parts within a single line or cell of machines. Cellular Manufacturing (CM) has been proved as a sound approach for improving operations in batch and job shop environments. In cellular manufacturing, Group Technology is used to form part families based on similar processing requirements. Parts and machines are then grouped together based on sequential or simultaneous techniques [2]. This approach results in cells where machines are located in relative proximity based on processing requirements rather than similar functional aspects. Decision-making and accountability are more locally focused, often resulting in quality and productivity improvements. 2. APPROCHES FOR CELL FORMATION In general, Cell Formation Techniques can be broadly classified. ISSN 0975 – 668X| NOV 10 TO OCT 11 | VOLUME – 01, ISSUE - 02 Page 36 JOURNAL OF INFORMATION, KNOWLEDGE AND RESEARCH IN MECHANICAL ENGINEERING Descriptive Procedures, Cluster Analysis, Graph Partitioning, Artificial Intelligence, Mathematical Programming 2.1 Descriptive Procedures In general, descriptive procedures can be classified into three major classes. The first class, which is referred to as part families identification (PFI), begins the cell formation process by identifying the families of parts first and then allocates machines to the families. The second class, which is referred to as machine groups identification (MGI). The third class of the descriptive procedures, which is referred to as part families/machine grouping (PF/MG), identifies the part families and machine groups simultaneously. PFI methods can be sub classified as those based on informal systems (e.g., rules of thumb, visual examination or other criteria) and those based on formal coding and classification systems. The role of group technology (GT) codes in the context of cellular manufacturing is primarily as an aid in identifying the part families to which production cells should be dedicated. Further analysis is required before a family of parts to be manufactured in a cell, and the machines, which will comprise that cell, can be specified. MGI procedures consider the CF problem as a two stage process where in the first stage of their analysis, machines are grouped based on information available in part routings and then in the second stage, parts are allocated to machine groups. When a CF approach attempts to group parts into part families and machines into machine groups simultaneously, then such an approach can be classified as PF/MG. Burbidge [3] proposed one of the earliest PF/MG descriptive approaches for the CF problem which is referred to as Production Flow Analysis (PFA). PFA is a technique, which analyses the information given in route cards to form cells. A manual method for CF called "Nuclear Synthesis" is proposed where manufacturing cells are created around "key machines". E1-Essawy [4] proposed a method called Component Flow Analysis (CFA) at about the same time. In some respects, the methodology of CFA does differ from that of Burbidge's PFA procedure since the latter first partitions the problem, whereas the former does not. 2.2 Procedures Based on Cluster Analysis Cluster analysis is composed of many diverse techniques for recognizing structure in a complex data set. The main objective of this statistical tool is to group either objects or entities or their attributes into clusters such that individual elements within a cluster have a high degree of "natural association" among themselves and that there is very little "natural association" between clusters. Clustering procedures can be classified as: 2.2.1 Array-based clustering techniques, In array based clustering, the processing requirements of components on machines can be represented by an incidence matrix, as shown in Figure. 1. This is referred to as the machine-component matrix ‘MPIM’. The machine-component matrix has zero and one entries (aij). A "1" entry in row i and column j (aij = 1) of the matrix indicates that component j has an operation on machine i, whereas a "0" entry indicates that it does not. The array based techniques try to allocate machines to groups and components to associated families by appropriately rearranging the order of rows and columns to find a block diagonal form of the aij = 1 entries in the machine component matrix. The literature yields at least eight array-based clustering algorithms, namely, Bond Energy Analysis by McCormick et al. [5], Rank Order Clustering by King [6], Modified Rank Order Clustering by Chandrasekharan and Rajagopalan [7], Direct Clustering Analysis by Chan and Milner [8], Cluster Identification method by Kusiak and Chow [9]. 2.2.2 Hierarchical clustering techniques In hierarchical clustering, the data in the machinecomponent matrix are not partitioned into groups or cells in one step. Rather they are first separated into a few broad cells, each of which is further divided into smaller groups, and each of these further partitioned, and so on until terminal groups are generated which cannot be subdivided. Essentially hierarchical techniques may be subdivided into agglomerative methods which proceed by a series of successive fusions of the M machines or the P parts into groups, and divisive methods which partition the set of M machines (P parts) successively into finer groups. All the agglomerative hierarchical techniques ultimately reduce the data to a single cluster containing all the machines (parts), and divisive techniques will finally split the entire set of machines (parts) into M (P) cells each containing a single machine (part). Hierarchical classifications may be represented by inverted tree structures or dendograms, which are two dimensional diagrams illustrating the fusions or divisions, which have been made at each successive stage of the analysis. In the context of CF, only agglomerative clustering techniques have been used. The most widely used technique is single linkage. More recently, the problem of "chaining" due to the use of single linkage has been investigated and hence, the average linkage algorithms have been recommended for CF. A new hierarchical clustering algorithm for CF referred to as the Set Merging algorithm has also been proposed by Vakharia and Wemmerlov [10]. Fusions are based on similarities between machines or parts. 2.2.3 Non-hierarchical clustering techniques. Non-hierarchical clustering methods are iterative methods and they begin with either an initial partition of the data set or the choice of a few seed points. In either case, one has to decide the number of clusters ISSN 0975 – 668X| NOV 10 TO OCT 11 | VOLUME – 01, ISSUE - 02 Page 37 JOURNAL OF INFORMATION, KNOWLEDGE AND RESEARCH IN MECHANICAL ENGINEERING in advance. Arbitrariness in the choice of seed points (or initial partition of data) could lead to unsatisfactory results. Non-hierarchical procedure has been developed by Chandrasekharan and Rajagopalan [7]. 2.3 Graph Partitioning Approaches Graph partitioning methods treat the machines and/or parts as vertices and the processing of parts as arcs connecting these nodes. These models aim at obtaining disconnected sub graphs from a machinemachine or machine-part graph to identify manufacturing cells. Rajagopalan and Batra [7] suggest the use of Jaccard's similarity coefficients and graph theory to form machine groups. Each vertex in the graph represents a machine type and the edge connecting vertices j and k is introduced in the graph only if the "similarity" between the machine types is greater than a pre specified threshold value. After all allowable edges have been introduced, cliques are formed. These cliques are then merged to create cells so that intercellular moves are minimized. An upper limit on cell size constrains the number of machines in each partition. During the process high and balanced machine utilization are strived for and machine loads are used to determine the number of machines of a given type needed for each cell. Faber and Carter [11] developed a graph theoretic algorithm for grouping machines and parts into manufacturing cells by converting the machine similarity matrix into a cluster network. The cluster network is partitioned into cells by solving a minimum cost flow problem. Kumar et al. [12] developed a 0-1 quadratic programming with linear constraints to solve the part grouping problem. The quadratic model has been converted to two linear problems and dealt with the k-decomposition problem. Askin and Chiu [13] proposed a cost-based mathematical formulation and heuristic solution for the CF problem. The Kernighan and Lin graph partitioning method was adapted and applied in a two phase partitioning algorithm. The first phase assigns parts to specific machines. The second phase groups machines into cells. Vohra et al. [14] proposed a network-based algorithm to minimize the amount of machining times performed outside the part primary cells. Wu and Salvendy [15] developed a network model to partition the machine-machine graph into cells by considering operation sequences. 2.4 Artificial Intelligence Approaches Elmaghraby and Gu [16] presented an approach for using domain specific knowledge rules and a prototype feature based modeling system to automate the process of identifying parts attributes and assigning the parts to the most appropriate manufacturing cell. The expert assignment system is based on the geometric features of the parts, characteristics of formed manufacturing cells, parts functional characteristics and attributes, as well as domain specific manufacturing knowledge. Kusiak [17] developed a pattern recognition based parts grouping which is similar to the grouping in GT. The basic difference between these two approaches is in the degree of automation. Application of artificial neural networks to CF problems has been proposed by Karapathi and Suresh [18]. 2.5 Mathematical Programming Approaches Mathematical programming methods can be further classified into three major groups based on the type of formulation: 2.5.1 Linear programming (LP) Linear programming is a concept of expressing the interrelationship of activities of a system in terms of a set of linear constraints in non-negative variables. A program, that is, values of the variables is selected which satisfies the constraints and premises a linear objective function in these variables. LP based CF methods have been proposed by Purcheck [19] and Olivia-Lopez and Purcheck [20]. They essentially apply the technique of combinatorial grouping and LP to the CF problem. LQP models have been proposed by Kusiak [17], Boctor [21] and many others. GP models have been proposed by Shafer and Rogers [22]. 2.5.2 Goal programming (GP) Goal programming is a model and associated algorithm to minimize the absolute value of deviations from a set of values called goals subjected to technological constraints. 2.5.3 Dynamic programming (DP) Dynamic programming determines the optimum solution to “n” variable problems by decomposing it into “n” stages with each stage constituting a single – variable sub problem. The computational advantage is that DP optimizes single-variable sub-problems. However, because of the nature of the stage differs depending on the optimization problem, DP does not provide the computational details for optimizing each stage. 3. SHORTCOMINGS OF PAST RESEARCH There has been a lot research work done by various researchers on cell formation techniques. Majority of the published works on cellular manufacturing pay very little attention towards production planning and control activities of cellular manufacturing. Many current cellular manufacturing applications are running in a non optimal environment and their performance could be improved by optimizing the parameters. But from the available literature most of the cell formation techniques/algorithm does not discuss the optimal size of the cell and the optimal number of cells, should be formed for a given problem. The techniques discussed above also don’t investigate the effect on different performance measures if the number of cell / cell size/composition of cells varied [23]. ISSN 0975 – 668X| NOV 10 TO OCT 11 | VOLUME – 01, ISSUE - 02 Page 38 JOURNAL OF INFORMATION, KNOWLEDGE AND RESEARCH IN MECHANICAL ENGINEERING 4. CONCLUSION Various techniques and methodology have been briefly studied with their salient features. The study brings the attention towards the need for designing the cellular manufacturing system for optimal performance as most of the past research work has been concentrated to the clustering of the machine and parts into cell and part families. So, acute need is to develop the models to specify the optimal number of groups and optimal production mix subject to technological and logistical constraints for optimal performance of cellular manufacturing system. There is need to develop more efficient solution tools enabling system designer to achieve good solution in reasonable processing time. 5. REFERENCES: [1] William W. Lugen, “Flexible Manufacturing Cells and Systems”, Prentice Hall [2] Parashar B.S.N. and Somasundar H.V., (1998)., “Cellular Manufacturing: A Taxonomic Review of Different Approaches”, I.E. Journal, Vol. 27, no 12, pp.12-19 [3] Burbidge, J.L., (1971),”Production Flow Analysis”, The Production Engineer, Vol. 50, pp.139 [4] EI- Essawy, J.Torrence, (1972), “Component Flow Analysis- An Effective Approach to Production Systems Design”, The Production Engineer, Vol. 51, pp.167-172 [5] McCormick W.T., Schweitzer P.J., and White T.E., (1972), “Problem decomposition and data recognition by a clustering technique”, Operation Research, Vol.20 pp.993-998. [6] King J.R., (1980), “Machine Component Grouping in Production Flow Analysis: An Approach using Rank Order Clustering Algorithm”, International Journal of Production Research, Vol. 80. pp. 213-219. [7] Chandrasekharan M.P., and Rajagopalan R., (1989), “Groupablity: An analysis of the properties of binary data matrices for Group Technology”, International Journal of Production Research, Vol. 27, no. 6, pp. 1035-1040. [8] Chan H.M. and Milner D.A., (1982), “Direct clustering algorithm for group formation in cellular manufacturing”, Journal of Manufacturing Systems, Vol.1, pp.65-71. [9] Kusiak A. and Chow W.S., (1987), “Efficient solving of the group technology problem”, Journal of Manufacturing Systems, Vol.6, pp.117. [10] Vakharia A. J. and Wemmerlov U. (1995), “A comparative investigation of Hierarchical clustering techniques and dissimilarity measures applied to the cell formation problem” [11] Faber Z. and Carter M.W., (1986), “A new graph theory approach for forming machine cells in cellular production systems” In Flexible manufacturing systems: Methods and Studies, ed. A.Kusiak. North-Holland New-York, pp. 301-312. [12] Kumar K.R. and Vanneli A.,(1987), “Strategic subcontracting for efficient disaggregated manufacturing”, International Journal of Production Research, Vol.25, no.12, pp. 1715-1721. [13] Vohra T., Chen D.S., Chang J.C. and Chen H.C., (1990), “A network approach to cell formation in cellular manufacturing”, International Journal of Production Research, Vol.28, pp. 2075-2081. [14] Askin R.G. and Chiu K.S., (1990), “A graph partitioning procedure for machine assignment and cell formation in group technology”, International Journal of Production Research, Vol.28, pp. 15551561. [15] Wu N. and Salvendy G., (1993), “A modified network approach for the design of cellular manufacturing system”, International Journal of Production Research, Vol.31, pp. 1409-1413. [16] Elmaraghy H.A. and Gu P.,(1998), “Feature based expert parts assignment in cellular manufacturing”, Journal of Manufacturing systems, Vol.8, pp.139-144 [17] Kusiak A., 1987, “The generalized group technology problem”, International Journal of Production Research, Vol.25, pp.561-567 [18] Kaparthi S., and Suresh N.C., (1992), “MachineComponent cell formation in Group Technology: A Neural network Approach”, International Journal of Production Research, Vol.30, no.6, pp. 1353-1359. [19] Purcheck G.F.K., (1975), “A Linear Programming method for the combinatorial grouping of an incomplete set”, Journal of cybernetics, Vol.5, pp.51-58. [20] Olivia-Lopez E. and Purcheck G.F.K., (1979), “Load balancing for group technology planning and control”, International Journal of MTDR, Vol.19, pp. 259-268. [21] Boctor F.F., (1991), “A linear formulation of the machine-part cell formation problem”, International Journal of Production Research, Vol.29, pp.343-348 [22] Shafer S.N. and Rogers D.F., (1991), “A goal programming approach to cell formation problems”, Journal of Operations management, Vol.10, pp.28-34 [23] Ali K. Kamrani, Hamid R. Parsaei and Donald H. Liles, “Planning, Design and Analysis of Cellular manufacturing Systems”, Elsevier Science B.V. ISSN 0975 – 668X| NOV 10 TO OCT 11 | VOLUME – 01, ISSUE - 02 Page 39