fig. 9 da form 2410 (repair/overhaul/gain)

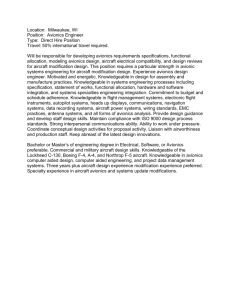

advertisement