Document

1.

Introduction: -

Ethylbenzene is an organic compound with the formula C

6

H

5

CH

2

CH

3

.

This aromatic hydrocarbon is important in the petrochemical industry as an intermediate in the production of styrene, which in turn is used for making polystyrene, a commonly used plastic material. Although often present in small amounts in crude oil, ethylbenzene is produced in bulk quantities by combining benzene and ethylene in an acid-catalyzed chemical reaction:

C

6

H

6

+ C

2

H

4

→ C

6

H

5

CH

2

CH

3

C

6

H

6

+n C

2

H

4

→ C

6

H

5

(CH

2

CH

3

) n

Catalytic dehydrogenation of the ethylbenzene then gives hydrogen and styrene. It has been used as a solvent for aluminum bromide in the anhydrous electrodeposition of aluminum. Ethylbenzene is also an ingredient in some paints, and solvent grade xylene is nearly always contaminated with a few percent of ethylbenzene. Unlike its isomer, xylene, ethylbenzene has a very irritating odor.

Fig.1-3-D Model of Ethylbenzene Fig.2-Chemical structure of Ethylbenzene

1991

1992

1993

1994

1995

1996

1997

1998

1984

1985

1986

1987

1988

1989

1990

1999

2000

2001

2002

2003

2004

2005

2.

History: -

Ethylbenzene was first produced on a commercial scale in the 1930s by

Dow Chemical in the United States and by BASF in the Federal Republic of Germany.The ethylbenzene-styrene industry remained relatively insignificant until World War II.

3.World Production of Ethylbenzene:

Ethylbenzene is traditionally ranked as one of the top 50 chemicals produced in the United States. Table-1 shows the historical production volumes of ethylbenzene from 1983 to 2005.

Year

1983

Production in thousands of metric tons

3,583

Production in billions of pounds

7.9

5171

5035

5352

5398

6194

4699

5432

5743

3447

3356

4082

4218

4491

4173

3810

5945

5968

4642

5412

5578

5779

5251

11.4

11.1

11.8

11.9

13.7

10.4

12.0

12.7

7.6

7.4

9.0

9.3

9.9

9.2

8.4

13.1

13.2

10.2

11.9

12.3

12.7

11.6

2

7,000

6,000

5,000

4,000

3,000

2,000

1,000

0

1980 1985 1990 1995 2000 2005 2010

Years

Fig.3 World production of ethylbenzene

Table-2 Manufacturers and Annual Production Capacity of

Ethylbenzene

3

Demand :

- in

1999: 13,193 million pounds; 2000: 13,444 million pounds; 2004:

14,552 million pounds, projected. Demand equals production plus imports (insignificant in 1999 and 2000) less exports (1999: 22 million pounds; 2000: 80 million pounds).

DEMAND

14,600

14,100

13,600

13,100

1998 1999 2000 2001 2002 2003 2004 2005

Year

Fig.4 Demand of Ethylbenzene

Growth:

-

Historical (1995 - 2000): 0.7 percent per year; future: 2.0 percent per year through 2004.

Price:

-

Historical (1995 - 2000): High, $0.25 per pound, bulk, f.o.b. Houston, TX, list; low, $0.25, same basis. Current: $0.25, same basis.

4

4. Commo n Uses

-

All the ethylbenzene (EB) produced is used in the manufacture of styrene monomer (SM). The main uses for styrene include polystyrene

(PS), expandable polystyrene (EPS), styrene copolymers (such as acrylonitrile-butadiene-styrene (ABS) resins, styrene-acrylonitrile (SAN) and styrene-butadiene latexes), styrene-butadiene rubber (SBR) and unsaturated polyester resins.

(1) 99% of ethylbenzene production is used as a raw material for producing styrene.

Fig.5 Styrene

(2) Polystyrene is one of the most widely used kinds of plastic.

Fig.6 Plastics

5

(3) Polystyrene foams are good thermal insulators.

Fig.7 Thermal insulators

(4) Extruded polystyrene foam (XPS) has air inclusions which gives it moderate flexibility, a low density, and a low thermal conductivity.

(5) Copolymers (Acrylonitrile butadiene styrene- Most electronics cases are made of this form of polystyrene-. SAN is a copolymer of styrene with acrylonitrile)

(6) Other refinery streams containing ethylbenzene can be used as components that are blended into gasoline and jet fuel.

(7) Mixed xylenes is recovered from crude oil by ethylbenzene used in the following applications:

• Spray (aerosol) paints

Fig.8 Spray paints

•

Primers:

-Paint removers and paint thinners

Fig.9 Paint thinner

6

• Wood stains

•

Varnishes

Fig.10 Wood stains

Fig.11 Varnishes

7

5.Feedstock and Product description:

5.1 Feedstock

Fig.12 Benzene

Name: Benzene

Chemical formula: C 6 H 6

What is Benzene

- Benzene is a cyclical, six carbon, six hydrogen molecule. It is a clear, colourless, volatile liquid with a characteristic ‘aromatic’ smell. Benzene is extracted from two primary sources: from pyrolysis gasoline (pygas) which is a co-product of ethylene manufacture, or from reformate, a stream resulting from the catalytic reforming process used to produce high octane gasoline. Benzene can also be derived from toluene via two on-purpose routes: hydrodealkylation and disproportionation

.

How is benzene used

-

Benzene is an important basic chemical, produced in large quantities and traded internationally. It is widely used in the industrial sector, where it is combined and processed with other basic chemicals (such as ethylene or propylene) to produce countless consumer goods.

The largest derivative outlet for benzene is ethylbenzene, an intermediate used in the production of styrene, which is further converted into materials such as polystyrene. It is also widely used to produce cumene, which in turn leads to phenol, a component in phenolic resins and adhesives; cyclohexane, a precursor of caprolactam and adipic acid, both used in nylon; and aniline, a

8

material needed to produce methylene diphenyl diisocyanate (MDI) which is used in urethanes and other speciality applications.

The end result is a variety of products that we all use everyday: clothing, packaging, paints, adhesives, unbreakable windows, plywood, computer casings, compact discs, dyes, agrochemicals, pharmaceuticals and many more.

9

Table-3 Benzene Physical and Chemical Properties

Molecular weight

Color

Physical state

Melting point

Boiling point

Density at 15 °C,g/cm³

Odor

Odor threshold:

Water

Air

Taste threshold

Solubility:

Water at 25 °C

Organic solvents

Partition coefficients:

Log Kow

Log Koc

Vapor Pressure at 20 °C

Henry's law constant at 25 °C

Autoignition temperature

Flash point

Flammability limits in air

Conversion factors

Explosive limits

78.11

Clear, colorless liquid

Colorless to light yellow liquid

5.5 °C

80.1 °C

0.8787

Aromatic

2.0 mg/L

Detection range: 34-119 ppm

0.5-4.5 mg/L w/w: 0.188%

Alcohol, chloroform, ether, carbon disulfide, acetone, oils, carbon, tetrachloride, glacial acetic acid

2.13

1.8-1.9

75 mm Hg

5.5x10ˉ ³ atm-m³/mol

498 °C

-11 °C (closed cup)

1.2% (lower limit; 7.8% (upper limit))

1 ppm=3.26 mg/m³ at 20 °C and

1atm pressure; 1 mg/m³=0.31 ppm

1.4% (lower limit); 8% (upper limit)

10

Name: Ethylene

Chemical formula: C 2 H 4

Fig.13 Ethylene

What is ethylene

- Ethylene also known as ethene - is a key building block for the petrochemical industry. It is a colourless, flammable gas with a slightly sweet odour and is the main product of the steam cracking of hydrocarbons such as naphtha and gas oil. In this process, the feedstock molecules are ‘cracked’ at high temperatures and in the presence of steam to produce, among other things, hydrogen, ethylene, propylene, butadiene, benzene and toluene.

How is ethylene used ?

- The applications of ethylene are numerous and ethylene derivatives are traded around the world.

Polyethylenes of various density and melt flow account for more than

50% of world ethylene demand. The primary use of polyethylene is in film applications for packaging, carrier bags and trash liners. Other applications include injection moulding, pipe extrusion, wire and cable sheathing and insulation, as well as extrusion coating of paper and cardboard.

Shell chemicals companies are also leading producers of three other principal ethylene derivatives: ethylene oxide, styrene monomer (via ethyl benzene) and linear higher olefins.

11

Ethylene oxide is a key raw material in the production of surfactants and detergents. It is also used to manufacture ethylene glycols, which are in turn used in soft drinks and food packaging and textiles, and to make ethylene oxide glycol ether solvents.

Styrene monomer is used principally in polystyrene for packaging and insulation, as well as in styrene butadiene rubber for tyres and footwear.

Linear higher olefins are used as base materials for the manufacture of detergents, plasticisers, synthetic lubricants and additives, but also as comonomers in the production of polyethylenes.

12

Table-4 Ethylene Phyiscal and Chemical Properties

Appearance

Odour

Odour Threshold pH

Boiling Point

Melting/freezing point

Flash point

Explosion / Flammability

Auto-ignition temperature

Vapor Pressure

Specific gravity

Density

Water solubility n-octanol/water partition

Coefficient (log Pow) Vapor density (air=1)

Henry's Coefficient

Koc

State of aggregation

Thermal conductivity

Viscosity

Surface tension

Molecular weight

Colourless . Gas at Standard

Temperature and Pressure. Liquid under pressure

.

Faint . Sweet .

700 ppm

Not applicable.

-103.7 °C / -154.7 °F

-169.2 °C / -272.6 °F

-136 °C / -213 °F

3.1 - 32 %(V)

450 °C / 842 °F

4,275 kPa at 1.9 °C / 35.4 °F

0.568 at -104 °C / -155 °F

568 kg/m3 at -104 °C / -155 °F

131 mg/l at 25 °C / 77 °F Slight

1.13

0.975 at 0 °C / 32 °F

22000 Pa.m3 / mole (Mackay model )

2 (QSAR )

Gas

0.0002 J/s/cm2/°C at 0.000000 °C /

32.000 °F

0.01 centiPoise at 20 °C / 68 °F

14 mN/m at -104 °C / -155 °F

28 g/mol

13

Name: Water

Chemical formula: H2O

Fig.14 Water

What is water

-

Water is an ubiquitous chemical substance that is composed of hydrogen and oxygen and is essential for all known forms of life.

In typical usage, water refers only to its liquid form or state, but the substance also has a solid state, ice, and a gaseous state, water vapor or steam. Water covers 71% of the Earth's surface On Earth, it is found mostly in oceans and other large water bodies, with 1.6% of water below ground in aquifers and 0.001% in the air as vapor, clouds

(formed of solid and liquid water particles suspended in air), and precipitation. Oceans hold 97% of surface water, glaciers and polar ice caps 2.4%, and other land surface water such as rivers, lakes and ponds 0.6%. A very small amount of the Earth's water is contained within biological bodies and manufactured products.

Table-5 Water Physical and Chemical Properties

Molecular weight

Molar mass

Appearance

Density

Melting point

Boiling point

Acidity (pKa)

Basicity (pKb)

Refractive index

Viscosity

H2O

18 g/mol

White solid or almost colorless

1000 kg/m³, liquid (4°C)

917 kg/m³, solid

0 °C, 32 °F (273.15 K)

100 °C, 212 °F (373.15 K)

15.74 (~35-36)

15.74

1.3330

0.001 Pa at 20 °C

14

5.2 Products

Name: Xylenes

Chemical formula: C

8

H

10

Fig.15 From left to right O-xylene, M-xylene, and P-xylene respectively

What are xylenes

- Xylenes are extracted or distilled from reformate, a stream derived from the refining of high-octane motor gasoline. They can also be produced from toluene using the disproportionation process. They are colourless, sweet-smelling liquids that are very flammable.

- Xylenes occur as three isomers, each having two methyl groups attached to a basic benzene hydrocarbon ring. The type of isomer is distinguished by the position of the methyl groups on the ring. Paraxylene has the methyl groups attached on opposite sides of the ring, ortho-xylene has the two methyl groups next to each other, while meta-xylene has them positioned with one carbon in between the two groups. Shell chemicals companies primarily supply xylenes as a mixed stream, although various processes can be used to separate and/or convert the isomers.

How are xylenes used

- Some mixed xylenes are used as solvents and in the printing, rubber, and leather industries. However, most mixed xylenes are separated and the individual isomers consumed in specific end-uses. Para-xylene is primarily used as a feedstock for terephthalic acid, a key component

15

in polyethylene terephthalate (PET) resins. Ortho-xylene is used in plasticisers, medicines, and dyes.

Mixed xylenes are also a desirable gasoline component, but are blended less often than toluene because there is greater demand and higher value in their chemical applications

.

Table-6 Xylene Chemical and Physical Properties

Appearance

Odour

Odour threshold

Boiling point

Melting / freezing point

Flash point

Explosion / Flammability limits in air

Auto-ignition temperature

Vapor pressure

Density

Water solubility

Solubility in other solvents

Molecular weight

Colorless . Liquid

Aromatic .

0.27 ppm

Typical 136 - 145 °C / 277 - 293 °F

> -48 °C / -54 °F

Typical 23 - 27 °C / 73 - 81 °F (Abel)

1 - 7.1 %(V)

432 - 530 °C / 810 - 986 °F (ASTM E-

659)

Typical 4.5 kPa at 50 °C / 122 °F

Typical 0.8 - 1.2 kPa at 20 °C / 68 °F

Typical 0.2 kPa at 0 °C / 32 °F

Typical 870 kg/m3 at 15 °C / 59 °F

(ASTM D-1298)

0.175 kg/m3

Miscible.

106.16 g/mol

16

Name: Ethylbenzene

Chemical formula

:

C

6

H

5

CH

2

CH

3

Fig.16 Benzene

Table-7 Ethylbenzene Chemical and Physical Properties

Molecular weight

Color

Physical state

Melting point

Boiling point

Density at 20 o c/4 o c

Density at 25 o c/4 o c

Odor

Organic solvents

Autoignition temperature

Flash point

Flammability limits

Conversion factors

Solubility in water at 25 o c

Vapor pressure at 25 o c

Henrys law constant at 25 o c

106.17 colorless

Liquid

-95 o c

136.2

o c

0.867

0.866

Sweet, gasoline-like

Miscible with usual organic solvents

Soluble in alcohol and ether

810 °F (432 °C)

70 °F (21 °C)

0.8 (lower) vol%- 6.7 (upper) vol%

1 mg/m³= 0.230 ppm

160 mg/L

1.27 kpa (9.53 mm Hg)

8.43*10 -3 atm-m 3 /mol

17

Name: Polyethylbenzene

Chemical formula: C

6

H

5

(CH

2

CH

3

) n

What is Polyethylbenzene

- The Polyethylbenzene bottoms stream is a co-product of ethyl benzene manufacture. Ethyl benzene is produced through alkylation of benzene with ethylene. The product is a mixture of the following aromatic compounds: diethylbenzene, triethylbenzene, 1,1diphenylethane, 1,2-diphenylethane and diphenylmethane

How is PEB used

- PEB is a liquid used as a solvent, which is used for carbonless copy paper after addition of colourless dyes, and is also used as fuel, which is burnt on site.

Table 8 Polyethylbenzene Physical and Chemical Properties

Appearance pH

Flash point

Vapor pressure

Vapor density (Air=1)

Boiling point

Solubility (in water)

Melting point

Specific gravity

Evaporative rate

Clear liquid

NA

> 58 °C (>136.4 °F)

1.1 mmHg at 25 °C (77 °F)

4.6

180 °C (356 °F) – 182 °C (359.6 °F)

Soluble in hydrocarbon solvents; insoluble in water

-45.33 °C (-49.56 °F)

0.87 at 15.6 °C (60 °F)

1.2

18

6. Process Technology

6.1 of E thylbenzene

Alkylation of Aromatic Hydrocarbons

- Most of the industrially important alkyl aromatics used for petrochemical intermediates are produced by alkylating benzene with monoolefins. The most important monoolefins for the production of ethylbenzene, cumene, and detergent alkylate are ethylene, propylene, and olefins with 10-18 carbons, respectively.

This section focuses primarily on these alkylation technologies.

6.2 Alkylation of Benzene With E thylene

- Considerable amount of polyethylbenzenes are formed as side products in this process, which can be carried out in the liquid or in the vapor phase.

in the liquid phase processes, AlCl3 is the most widely used catalyst , but other catalysts , such as BF 3 ,FeCl 3 ,ZrCl 4 ,SnCl 4 ,H 3 PO 4 also alkalineearth phosphates , also are used commonly . The reaction is carried out at atmospheric pressure at 85 - 95 C.

The vapor phase ethylation of benzene is common practice, especially in the United States, and typically is carried out at about 300 C and 40-

65 bar over acidic heterogeneous catalysts such al Al 2 O 3 . SiO 2 , the catalyst is the non-corrosive boron trifluoride supported on a modified anhydrous alumina, which is also active for de- and transalkylation an unusually wide range of ethylene concentration (5-95%) in the feed gas can be used, such as that in the off-gas form catalytic cracking.

19

6.3

The Third Generation Vapor Phase Alkylation Process

Table 9 Design Bases and Assumptions

Reactor Alkylation Reactor

One reactor with fix fixed beds and interstage ethylene/aromatics quench

ZSM-5

Secondary

Reactor

One fixed bed

Catalyst

Catalyst life (years)

Reactor temperature (

C)

Reactor Pressure (psig)

WHSV

2

390-445

300

3 Ib of ethylene/Ib of catalyst/hr

TRA-1 or 65% zeolite and

35% alumina

2

400

100

5 Ib of total feed/Ib of catalyst/hr

_ Superficial velocity

(ft/sec, empty reactor)

Feed ratio (mol/mol)

Conversion (%)

Selectivity to EB (mol%)

Overall selectivity (mol%) to EB

Plant yields (mol%)

2

7.6(benzene/ethylene)

7.2 (phenyl/ethyl group)

99.7 on ethylene

13.0 on benzene

95.2

99.5

On ethylene 99.2

On benzene 98.7

Net consumption/production

(Ib/Ib of EB):

Ethylene

Benzene

Vent gas

Residue

0.26678

0.74490

0.00239

0.00897

2.9

(benzene/PEB)

_

44.3 on PEB

~100a

20

6 .3

1 Process Description:

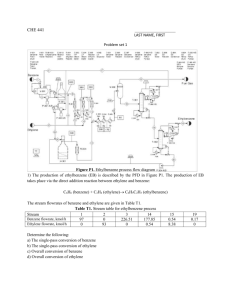

- Table-9 sets forth the design bases and assumptions. Figure 17 shows the flow diagram for the third-generation process which consists of alkylation and EB recovery sections. Table 10 lists the stream flows.

Table 11 summarize the major equipment.

- The aromatics stream, which primarily contains benzene with some EB from benzene fractionator in the EB recovery section, is divided into two streams. One is preheated in effluent exchanger E-101 by exchanging heat with the reactor effluent; further heating to 405°C

(760°F) in feed process heater F-101 follows. The other stream is combined with a fraction of the feed ethylene and preheated in effluent exchanger E-102 before being fed to the interstages of the alkylation reactor for quenching.

- Alkylation reactor R-101 consists of six beds packed with zeolite catalysts. The operation of the reactor and the generation of the catalyst are similar to that of the second-generation process, except that generation is carried out only once a year, and an electrical heater instead of a fired heater is used. The reactor effluent is cooled to 271°C (520°F) by preheating the dry aromatics in the effluent exchangers, before being fed to benzene fractionator C-202 in the EB recovery section.

- The recycled PEB from the EB recovery section joins a vapor stream consisting of aromatics and entrained water from the overhead of the benzene fractionators, and is passed through the flue stack of the feed process heater before being fed to secondary reactor R-102 . In the secondary reactor, PEB reacts with benzene by transalkylation at 400 o C (752 O F). The co nearly 100%.

nversion of PEB is 44.3%, with selectivity to EB of

- In the EB recovery section, reactor effluent from the secondary reactor is fed to vent gas scrubber C-201 to remove entrained water, which is sent for treatment. The aromatics in the gas stream are condensed by generating low-pressure (25 psig) steam in the overhead condenser; the noncondensable light paraffins are purged and credited as fuel.

- The dry aromatic stream from the bottom of C-201, fresh benzene from benzene feed tank T-151, and the cooled effluent from the alkylation reactor are fed to benzene fractionators C-202. The aromatic stream overhead is partially condensed to generate medium pressure

(150 psig) steam. After phase separation in the reactor feed

21

accumulator, the liquid phase is routed to the alkylation section and the vapor stream is sent to join.

Table.10 Stream flows

Stream flows, LB/HR

4 5 6 7

Light paraffins

Ethylene

Benzene

MOL

WT

28.1

78.1

1

-

-

108,601

2

39

38,875

-

3

1

-

12,683

135

38

818,961

Ethylbenzene

Xylenes

Polyethylbenz ene

Water

Heavies

Total (Ib/hr)

Total (kg/hr)

106.2

106.2

18

-

-

-

-

-

54

-

108,655

49,284

-

-

38,914

17,625

12,321

55

4,965

2

12

30,039

13,625

8,190

110

1

-

-

827,435

375,313

8 9

203

79

15,045

5

1

-

-

-

-

6,068

54

8,913

20

5060

122,844

1,228

17

-

115

32

696,11

7

34

33,821

-

6,962

93

1

-

-

-

56

-

15,389

6,980

-

12

15,047

6,825

-

-

129,169

58,589

-

-

703,32

0

319,01

7

-

-

33,855

15,356

22

Light paraffins

Ethylene

Benzene

MOL

WT

10

337

11

203

Table .10 (Continue)

12

203

28.1

78.1

117

712,856

79

15,045

79

12,747

Stream flows, LB/HR

13

-

-

-

14

202

79

64

15

-

-

134

Ethylbenzene 106.2

147,604

Xylenes

Polyethylben zene

Water

Heavies

Total (Ib/hr)

Total (kg/hr)

106.2

18

177

4,081

-

1177

866,349

392,964

6,073

55

8,913

12,321

55

4,965

56

12

30,436

13,805

56

12

30,438

13,806

-

-

-

56

-

50

23

16

-

-

-

17

-

-

-

18

-

-

134

-

-

-

4

-

349

158

151,73

0

121

9,046

6,068

54

9,044

-

-

131

145,66

2

67

2

-

1,189

162,22

0

73,581

-

1,189

16,355

7,418

-

1,177

1,308

593

-

-

145,86

5

66,162

23

6.3

2 Thermodynamics and kinetics of reactions:

Ethylbenzene from benzene and ethylene by alkylation: vapor phase

The main reaction is the exothermic alkylation of benzene with ethylene:

C

6

H

6

(g) + n C

∆H O

R

=

2

H

4

(g) → C

6

H

5

CH

2

CH

3

(g)

25.20 kcal/g

The major side reactions are the production of polyethylbenzene (PEBs) with two to six ethyl groups:

mol

C

6

H

6

(g) + n C

2

∆H O

R

H

= -

4

(g) → C

6

H

5

24.83 kcal/g

(CH

2

CH

3

mol

) n

(g)

Where n= 2 to 6 and the ∆H O

R is the average heat of reaction per mole of ethylene. Diethylbenzene is the dominant PEB, and the distribution shifts toward diethylbenzene as the aromatic/ethylene (A/E) ratio increases. Other side reactions produce light paraffins, xylenes, cumene, compounds with boiling point between those of EB and diethylbenzene, and polycyclic compounds. Two distinct vapor-phase alkylation processes are employed commercially: the widely used zeolite based process and the process based on Lewis acid catalysts such as boron trifluoride.

Ethylbenzene from benzene and ethylene by liquid alkylation:

phase

Two alkylation processes are used commercially to produce EB from liquid phase benzene feed. One is widely employed and uses AlCl

3 catalyst. The other, a relatively new process developed by Lummus

Crest/Unocal/UOP, uses a zeolite catalyst.

The main reaction and the major side reactions are similar to those in vapor-phase alkylation, except that the aromatic reactant and the products are in the liquid form :

C

6

C

6

H

6

H

6

(l) + n

∆H

∆H

O

R

(l) + n C

O

R

C

=

2

H

=

2

H

-

4

27.19 kcal/g

4

(g) → C

6

(g) → C

6

H

H

5

CH

2

5

25.82 kcal/g -

mol

(CH mol

2

CH

3

(l)

CH

3

) n

(l)

24

Where n=2 to 6 and the H of ethylene.

6.4 Catalysts :

O

R is the average heat of reaction per mole

6.4

1 Zeolite

Fig.18 Zeolite

- Zeolites are microporous, alumino silicate minerals commonly used as commercial adsorbents. The term zeolite was originally coined in 1756 by Swedish mineralogist Axel Fredrik Cronstedt, who observed that upon rapidly heating the material stilbite, it produced large amounts of steam from water that had been adsorbed by the material. Based on this, he called the materials zeolite, from the Greek (zeō), meaning ''boil'' and (lithos), meaning ''stone''.

- Synthetic zeolites are widely used as catalysts in the petrochemical industry, for instance in fluid catalytic cracking and hydro-cracking.

Zeolite confined molecules in small spaces, which causes changes in their structure and reactivity. The hydrogen form zeolites (prepared by ion-exchange) are powerful solid-state acids, and can facilitate a host of acid-catalyzed reactions, such as isomerisation, alkylation, and cracking.

25

6.4-2 Aluminium chloride

Fig.19 Aluminium chloride

Aluminium chloride (AlCl

3

) is a compound of aluminium and chlorine.

The solid has a low melting and boiling point, and is covalently bonded. It sublimes at 178 °C. Molten AlCl

3

conducts electricity poorly, unlike more ionic halides such as sodium chloride. It exists in the solid state as a six-coordinate layer lattice.

AlCl

3

is probably the most commonly used Lewis acid and also one of the most powerful. It finds widespread application in the chemical industry as the classic catalyst for Friedel-Crafts reactions, both acylations and alkylations. It also finds use in polymerization and isomerization reactions of hydrocarbons. Aluminium also forms a lower chloride, aluminium(I) chloride (AlCl), but this is very unstable and only known in the vapor phase.

26

Table.11 Major Equipments of Vapor-Phase Alkylation Third-Generation

Process

Reactors :

R-101

R-102

Alkylation reactor

Secondary reactor

Columns :

C-201

C-202

C-203

C-204

Vent gas scrubber

Benzene fractionator

Ethylbenzene column

Polyethylbenzene column

Heat Exchangers :

E-101

E-102

E-201

E-202

E-203 A&B

E-204

E-205

E-206

E-207

E-208

E-209

E-210

Effluent Exchanger

Effluent Exchanger

LP Steam generator

Scrubber condenser

Fractionator condenser

Fractionator reboiler

EB Column condenser

EB Column reboiler

Air cooler

PEB Column condenser

PEB Column reboiler

Residue cooler

Process Furnaces :

F-101 Feed process heater

Tanks :

T-151

T-201 A,B

T-202

Benzene feed tank

EB Rundown tanks

Slop tank

27

T-251 Residue storage tank

Table.11 (Continue)

Pressure Vessels :

V-201

V-202

V-203

V-204

V-205

V-206

Miscellaneous equipment :

M-101

Package units :

G-251

Scrubber reflux drum

Reactor feed accumulator

EB Reflux drum

PEB Reflux drum

MP Steam drum

LP Steam drum

Regeneration electrical heater

Hot oil system

28

6.5 The Vapor Phase Second G eneration Alkylation Process :

6.5

1 P rocess Description

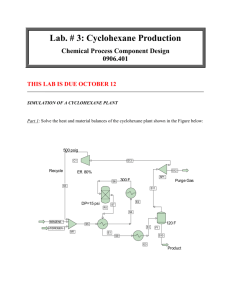

- Figure 20 shows the flow diagram for the process, which consists of

a) Alkylation section.

b) EB recovery section.

The aromatic stream which consists of benzene and some EB from the

EB recovery section of the plant is preheated and vaporized in effluent exchanger E-101 by exchanging heat with the reactor effluent. A fraction of the aromatic stream is diverted as quench streams the rest is further heated in feed process heater F-101 to 416 °C (780 °F). The recycled peb from the EB recovery section of the plant is passed through the flue stack of the feed process heated before being combined with the aromatic stream and fed to the reactor system.

Alkylation section:

Alkylation and transalkylation are carried out either in alkylation reactor

R-101A or B while the other is being regenerated or is on standby. Each reactor consists of four beds packed with zeolite catalysts. A vapor made up of hot aromatics and ethylene is fed to the first catalytic bed at 300 psig. Because the reaction is exothermic, an adiabatic temperature rise occures across the bed. The reaction mixture is the puenched by additional benzene and ethylene before moving to the second catalytic bed further reaction and quenching occur sequentially in the other beds. The reactor effluent is cooled to 274 °C

(525 °F) by preheating the dry aromatics in the effluent exchanger and is fed to the bottom of prefractionator C-201 in the EB recovery section.

With an overall aromatics/ ethylene (A/E) ratio of 7.6 based on benzene/ethylene feed molar ratio (of based on a phenyl/ethyl group ratio) and a weight hourly space velocity (WHSV) of 3 based on ethylene, the conversion based on ethylene is 99.7% and the selectivity to EB is 98.3mol% by- product are light paraffins, peb, heavies, and impurities in EB product. Peb, produced by side reactions and recycled from the EB recovery section, reacts with benzene by transalkylation and builds up to an equilibrium level.

The reactors operate in cycles at least 3 months in length. The catalyst is regenerated as soon as ethylene conversion falls below the desired

29

level by the controlled burning of coke for 36 hours in a hot nitrogen and air mixture preheated to 400 °C (752 °F) in regeneration-fired heater F -102 the regeneration gas is burned in the feed process heater.

EB recovery section :

In the EB recovery section, fresh benzene from tank T-151 is fed to vent gas scrubber C-202 to remove entraned water, which is sent for treatment. The heat is supplied by the noncondensable gas stream from reactor feed accumulator V-201. The aromatics in the gas stream are condensed by generating low - pressure (25 psig) steam in the overhead condenser.

The noncondensable light paraffins are purged and credited as fuel.

The dry aromatic stream from the bottom of C-202 joins with the overhead from benzene fractionator C-203. The combined stream is sent to the top tray, and the reactor effluent from the alkylation section is fed to the bottom tray of prefractionator C-201. As the reactor effluentis condensed and withdrawn from the bottom of the prefractionator, the heat released is used to recover an aromatic stream containing a part of the uncomverted benzene and some EB .

The aromatic stream, in turn, is partially condensed to generate medium -pressure (150 psig) steam. After phase separation in the reactor feed accumulator, the liquid phase is routed to the alkylation section and the noncondensable gas stream is fed to the bottom of C-

202

The bottom stream from the prefrationator is sent to benzene fractionator C-203 to complete the separation of the unconverted benzene from the alkylated products. From the overhead of C-203, the recovered benzene is recycled to the reactor system via the prefractionator. The bottoms from C-203 are fed to EB column C-204 to recover EB overhead. After being cooled to 66 °C (150 °F) by passing through air cooler E-208, EB is sent to rundown tanks T-201 A&B. The bottoms from C-204 are fed to column C-205, where PEB is recovered overhead and recycled to the alkylation section. Residue from the bottom of C-205 is sent to storage and id credited as fuel. In columns

C-203 through C-205, hot oil is used in the reboilers and low-pressure steam is generated in the condensers.

Benzene feed tank T-151 has a storage capacity of 5 days. NO storage is provided for ethylene feedstock, which is assumed to be delivered by pipeline. A slop tank is provided for the temporary storage of out-ofspecification substances. Given the assumption that an integrated styrene plant is on an adiacent site, the storage capacity for EB rundown tanks T-201 A&B is 2 days.

30

Table.12 Major Equipment of Vapor-Phase Alkylation Second-

Generation

Reactor :

R-101 A,b Alkylation reactor

Columns :

C-201

C-202

C-203

C-204

C-205

Heat Exchangers :

E-101

E-201

E-202

E-203

E-204

E-205

E-206

E-207

E-208

E-209

E-210

E-211

Prefractionator

Vent gas scrubber

Benzene fractionator

Ethylbenzene column

Polyethylbenzene column

Effluent exchanger

MP steam generator

LP steam generator

Scrubber condenser

Benzene column condenser

Benzene column reboiler

EB column condenser

EB column reboiler

Air cooler

PEB column condenser

PEB column reboiler

Residue cooler

Process Furnaces :

F-101

F-102

Tanks :

T-151

T-201 A,B

T- 202

Feed process heater

Regeneration fired heater

Benzene storage tank

EB rundown tanks

Slop tank

31

T-251 Residue storage tank

Table.12

(Continue)

Pressure Vessels:

V-201

V-202

V-203

V-204

V-205

V-206

V-207

Reactor feed accumulator

Scrubber reflux drum

Benzene reflux drum

EB reflux drum

PEB reflux drum

MP steam drum

LP steam drum

Package units :

G-251 Hot oil system

6.6 The liquid P hase Alkylation Process Using Z eolite Catalyst:

6.6

1 Process D escription :

- The aromatic stream which consists of benzene and some EB from the

EB recovery section is preheated in effluent exchangers E-103A&B by exchanging heat with the combined effluent of the alkylation and the transalkylation reactors. Subsequently, the aromatic stream is further heated in feed preheater E-104 to 263 °C (505 °F). Most of the aromatic stream is combined with ethylene to feed alkylation reactor R-101. A small fraction of the aromatic stream, together with the recycled PEB from the EB recovery section, is diverted to feed transalkylation reactor

R-102.

The alkylation reactor consists of four stages. All of the benzene required for alkylation is charged into the first stage while fresh ethylene is introduced into all the four stages. Each stage is packed with zeolite catalyst. Under about 500 psig opertaion pressure, benzene and heavier aromatics remain in the liquid form. with a total benzene/ethylene feed molar ratio of 7.2 and a total WHSV of 5.9

(equivalent to a WHSV of 0.27 based on ethylene ), the conversion based on ethylene is nearly 100% , and selectivities to EB AND PEB are

91.8mol% and 6.6 mol% , respectively.

32

After being separated, PEB is fed to the transalkylation reactor to produce more EB. Other by-products include light paraffins, heavies, and impurities (grouped as xylenes) in the EB product because the alkylation is exothermic , an adiabatic temperature rise occures across the catalytic bed the rise is limited to less than 56 °C (100 °F) by coordinating the ethylene feed rate to each stage. The effluents from the first two stages are cooled to generate medium - pressure (150 psig) steam in alkylation intercoolers.

E-101 & E-102, respectively the effluents are further quenched by mixing with the fresh ethylene introduced to the next stage of the reactor. The reactors operate in cycles of 1 year, and the catalyst is regenerated during plant shutdown.

In separate transalkylation reactor R-102,EB is also produced by transalkylation.after reaction with benzene, PEB reaches equilibrium.

The reaction is carried out almost isothermally at 250 ºC (482 ºF) and

510 psig in the presence of a zeolite catalyst similar to the one used for alkylation.

The liquid effluents from the alkylation and transalkylation reactors are combined and cooled to 195 ºC (383 ºF) in effluent exchangers E-103A&B by exchanging heat with aromatic feed stream from the EB recovery section.

The combined effluent is then flashed at 135 psig in flash drum V-201 to vaporize some of the benzene .the resulting vapor stream, together with the vapor effluent from the alkylation reactor, is sent to the bottom of vent gas scrubber C-201 to strip off the light paraffins and to supply heat to the scrubber .in the meantime, fresh benzene from tank T-151 is fed to C-201 to remove entrained water ,which is sent for treatment .the noncondensable light paraffins from the C-201 overhead are purged and credited as fuel.

From the bottom of C-201, the dry aromatic stream is combined with the liquid phase from the flash drum to feed benzene fractionator C-202. The aromatic stream, consisting mainly of benzene, is recovered from the overhead of C-202 and is recycled to the alkylation section. The bottoms from C-202 are fed to column C-203 to recover EB overhead. After being cooled to 66 ºC (150 ºF) in air cooler E-206, EB is sent to rundown tanks T-201

A&B. The bottoms from C-203 are fed to column C-204, which is operated under vacuum, where PEB is recovered overhead. The recovered PEB stream is recycled to the transalkylation reactor. Residue from the bottom of C-204 is sent to storage and is credited as fuel. In column C-202 through C-204, hot oil is used in the reboilers and low pressure steam is generated in the condensers.

33

E-101

E-102

E-103 A,B

E-104

E-201

E-202 A,B

E-203

E-204

E-205

E-206

E-207

E-208

E-209

Benzene feed tank T-151 has a storage capacity of 5 days; no storage is provided for the ethylene feedstock, which is assumed to be delivered by pipeline. A slop tank is provided for the temporary storage of out of specification substances. EB rundown tanks T-201 A&B have a storage capacity of 2 days, given that an integrated styrene plant is assumed to be on an adjacent site.

Table.13

Major Equipment of Liquid-Phase Alkylation Using Zeolite

Catalyat

Reactors :

R-101

R-102

Alkylation reactor

Transalkylation reactor

Columns :

C-201

C-202

C-203

C-204

Heat Exchangers :

Vent gas scrubber

Benzene fractionator

Ethylbenzene column

Polyethylbenzene column

Alkylation intercooler

Alkylation intercooler

Effluent exchangers

Feed preheater

Scrubbeer condenser

Fractionator condensers

Fractionator reboiler

EB column condenser

EB column reboiler

Air cooler

PEB column condenser

PEB column reboiler

Residue cooler

34

Table.13 (Continue)

Tanks :

T-151

T-201 A,B

T-202

T-203

T-251

Benzene feed tank

EB rundown tanks

PEB surge tank

Slop tank

Residue storage tank

Pressure Vessels :

V-201

V-202

V-203

V-204

V-205

V-206

V-207

Flash drum

Scrruber reflux drum

Fractionator reflux drum

EB reflux drum

PEB reflux drum

MP stream drum

LP stream drum

Package units :

G-251

G-252

Regeneration system

Hot oil system

6.6

2 Th e Liquid Phase Alkylation Process Using AlCl

3

Catalyst

- Fresh benzene and recycled aromatics consisting mainly of benzene are fed to benzene drying column C-101 to remove entrained water and light paraffins . A small fraction of the dried aromatics is cooled by exchanging heat with the fresh benzene before being used as a scrubbing medium in HCL scrubber C-201.The liquid effluent from C-201 is combined with most of the dried aromatics from C-101,the PEB recycled from the EB recovery section, and the ALCL3 prepared in catalyst complex drum V-103 .the combined stream is introduced into the bottom of alkylation reactor R-101,avertical brick-lined vessel,while ethylene and HCL are fed into the reactor through spargers. An inert

35

gas blanket is applied to control the pressure at about 100 psig. The reactor temperature is held at 160 °C (320 °F) by using the heat of reaction to generate low pressure steam in E-104.from the overhead of

R-101,the vent gas is purged to C-201 for HCL recovery.

The liquid alkylation from R-101 overflows to flash drum V-201 where it is flashed at 32 psig to remove dissolved HCL. The resulting vapor phase is partially condensed to recover most of the aromatics. The noncondensable is mixed with the vent gas from R-101 and scrubbed with benzene and a dilute caustic solution in HCL scrubbers C-201 and

C-202, respectively, before final disposal. the liquid effluent is cooled to

49 °C (120 °F) and washed first with water, then once each with a caustic soda solution and water .the aqueous layer produced after the first water wash is concentrated in evaporator E-204 to form a solution

25%ALCL3 and 1%HCL that can be used as a from subsequent washing stages and with the effluent of vent gas scrubber C-202 to form a slightly alkaline solution for disposal.

The operations of benzene fractionator C-301,EB column C-302,and

PEB column C-303 are similar to those for the process using zeolite catalyst.five days of capacity is provided for storing caustic soda as a

50% solution and 30 days for ALCL3 .Anhydrous HCL is assumed to be delivered by tube trailers.

Acid brick lined carbon steel or Hastelloy B IS the material of construction for equipment exposed to HCL or ALCL3.

Table.14

Major Equipment of Liquid-Phase Alkylation Using Aluminum

Chloride Catalyst

Reactors:

R-101 Alkylation reactor

Columns:

C-101

C-201

C-202

C-301

C-302

C-303

Benzene drying column

HCl Scrubber

Vent gas scrubber

Benzene fractionator

Ethylbenzene column

Polyethylbenzene column

36

Heat Exchanger:

E-101

E-102

E-103

E-104

E-201

E-202

E-203

E-204

E-205

E-301

E-302

E-303

E-304

E-305

E-306

E-307

E-308

E-309

Tanks :

T-151

T-201

T-251

T-252

T-301

T-302 A,B

T-303

T-304

T-351

Table.14 (Continue)

Fresh benzene preheater

Drying column condenser

Drying column reboiler

LP steam generator

Flash vapor condenser

Effluent air cooler

Effluent cooler

HCl evaporator

Waste condenser

Product preheater

Benzene column condenser

Benzene column reboiler

EB column condenser

EB column reboiler

Air cooler

PEB column condenser

PEB column reboiler

Residue cooler

Benzene storage tank

Product surge tank

AlCl

3

Solution tank

Caustic supply tank

Benzene recycle tank

EB rundown tanks

PEB surge tank

Slop tank

Residue storage tank

37

Pressure Vessels:

V-101

V-102

V-103

V-104

V-201

V-202

V-203

V-204

V-205

V-301

V-302

V-303

Package Units:

G-101

G-351

Table.14 (Continue)

Drying column reflux drum

Catalyst hopper

Catalyst complex drum

LP steam drum

Flash drum

Condensate separator

Water wash settler

Caustic wash settler

Water wash settler

Benzene reflux drum

EB reflux drum

PEB reflux drum

Pneumatic conveyor system

Hot oil system

38

6.6

3 Process D iscussion :

- In the liquid phase process the alkylation reactor operates at higher pressure but lower temperature than the vapor phase alkylation process. The lower operating temperature prolongs catalyst life, reduces energy costs, and allows the use of carbon steel as the material of construction. Furthermore, the feed fired heater is much smaller because of lower operating temperature and no requirement for feed vaporization, unlike the vapor phase process which needs additional heat exchangers to recover the energy input. In addition, the liquid phase process minimizes xylene formation, there-by allowing for a smaller EB column than in the vapor phase process.

By-products of this process are: a) Light paraffins b) PEB c) Impurities light paraffins and d) heavies, which are mostly polycyclic compounds such as diphenylmethane and diphenylethane, are credited as fuel .

6.6

4 Design Requirements:

For alkylation reactor :

- The number of stages and the amount of ethylene introduce into each stage are designed to limit the temperature rise in each stage and to ensure that the temperature of the effluent from each stage is higher than the outlet temperature of the preceding stage. An alkylation reactor with several stages allows the overall benzene/ethylene ratio tobe reduced, while maintaining high enough ratio in each stage to reduce temperature rise ,there by improving selectivity and prolonging catalyst life. An excess of benzene is also required in the transalkylation reactor to preserve catalyst activity and to shift the equilibrium toward

EB.

39

6.7

6.7

-

Other Process:

1 Process

Mobil -

Description:

Badger Process

-

The reactor (see Fig.22) typically operates at 400-450ºc and

2-3MPa (20-30 bar).at this temperature >99% of the net process heat input and exothermic heat of reaction can be recovered as steam. The reaction section includes two parallel multibed reactors, fired heater, and heat recovery equipment. The high activity catalyst allows transalkylation and alkylation to occur simultaneously in a single reactor.

Because the catalyst slowly deactivates as a result of coke formation and required periodic regeneration, two reactors are included to allow uninterrupted production; one is on stream while the other is regenerated. The catalyst is less sensitive to water, sulfur, and other poisons than the lewis acid catalysts.

The reactor effluent passes to the purification section as a hot vapor.

This stream is used as the heat source for the first distillation column, which recovers the bulk of the unreacted benzene for recycle to the reactor. The remaining benzene is recovered from a second distillation column. The ethylbenzene product is taken as the overhead product from the third column .the bottom product from this column is sent to the last column, where the recyclable alkylbenzenes and polyalkylbenzenes are separated from heavy nonrecyclable residue. the low-viscosity residue stream ,consisting mainly of diphenylmethane and diphenylethane, is burned as a fuel.

The mobil-Badger process also can use dilute ethylene feedstocks. In semicommerical applications, the process has operate on streams containing as little as 15mol% ethylene.

40

6.8 Comparison:

- Compared with the second generation processes, the thirdgeneration process achieves higher selectivity, has lower capital cost, and improves on energy efficiency as a result of the following changes:

- The prefractionator has been eliminated; fresh benzene is fed directly to the benzene fractionator.

- Only one alkylation reactor with six beds is required, instead of two four-bed reactors.

- A small secondary reactor has been added, primarily for transalkylation.

41

7. Economic Analysis

- For the vapor-phase alkylation: Third-Generation

- Raw Materials

Benzene

Ethylene

Catalyst and

Chemicals

Gross Raw

Materials

Unit Cost

15.7 ¢ /LB

23.5 ¢/LB

_

_

Consumption/LB

0.74490 LB

0.26668 LB

_

_

¢/LB

11.69

6.27

0.03

17.99

- By-Product(s)

Fuel (Vent Gas)

Fuel (Residue)

Total By-

Products

Unit Cost

1.70

$

/MMBTU

1.98 $/MMBTU

_

Consumption/LB

-0.00004 MMBTU

-0.00015 MMBTU

_

¢/LB

-0.01

-0.03

-0.04

7.1 Comparison of the Economics of Different Generations of the Process:

- Investment ($ millions)

Battery limits

First Generation

32.7

Second

Generation

25.5

Third

Generation

23.3

42

Off-sites

Total Fixed

Captial

20.7

53.4

16.1

41.6

16.4

39.7

- Production Costs (¢/Ib)

Variable costs

Net

Production

Cost

Product Value

Raw Material

By-Products

Utilities

Second

Generation

17.88

19.22

20.12

18.07

-0.06

-0.13

Third

Generation

17.85

19.16

20.02

17.99

-0.04

-0.10

Zeolite-

Based

Liquid-

Phase

18.03

19.31

20.13

18.12

-0.06

-0.03

AlCl3-

Based

Liquid-

Phase

17.89

19.19

20.03

17.92

-0.02

-0.01

8 Conclusion :

- Like the second generation process, the third generation process recovers about 95% of the reaction heat and process heat input by low and medium pressure steam generation.

- The alkylation reactor operates in cycle of at least 1 year, and the catalyst is regenerated during annual plant maintenance. As a result, only one reactor is required. Because PEB is recycled to the secondary react, the selectivity to EB in the alkylation reactor of the third generation process is slightly lower than that of the second generation. However, when the reaction in the secondary reactor is taken into account, the overall selectivity is 99.5mol%, which is higher than the 98.3mol% of the second generation process.

- Unlike the second-generation process, in which the benzene fractionator and prefractionator are separate columns and the latter does not have reflux, the third generation has a large benzene fractionator and a lower EB concentration in the distillate because of reflux. Less EB looping in the reaction section is thus required.

- Xylene formation can be reduced by diverting a fraction of the recycled PEB to the last catalyst bed of the alkylation reactor .in the third-generation process, the use of the secondary reactor serves a

43

similar purpose. The third generation has high over all selectivity to EB, reduced xylenes formation, and a smaller EB column than the second generation.

That’s why we suggested the third-generation process flowsheet.

Appendix

1. Appendix A: Material safety data Sheet (MSDS).

2. Appendix B: Process flowsheets.

3. Appendix C: Graphs and plots.

44

Appendix A

Material safety data sheet (MSDS) for ethylbenz ene:

- Fire

- Flammable.

- Flashback along vapor trial may occur.

- Vapor may explode if ignited in an enclosed area.

- Flash point: 80 °F O.C: 59 °F C.C.

- Flammable limits in air :( 1.0%-6.7%)

- Exposure

Vapor

Imitating to eyes, nose and throat.

- If inhaled will cause dizziness or difficult breathing.

Liquid

- Will burn skin and eyes.

- Harmful if swallowed.

- Water Pollution

- Harmful to aquatic life in very low concentrations.

- Fouling to shoreline.

- May be dangerous if it enters water intakes.

- Health Hazards

45

- Symptoms Following Exposure: inhalation may cause imitation of nose

,dizziness, depression.

- Moderate imitation of eye with corneal injury possible. Imitates skin and may cause blisters.

- Chemical Reactivity

- Reactivity with water: No reaction.

- Reactivity with common material: No reaction.

- Stability during transport: Stable.

- Neutralizing agents for acids and caustics: Not pertinent.

- Polymerization: Not pertinent.

- Inhibitor of polymerization: Not pertinent.

Safety Procedures:

- Fire

- Wear goggles. self comained breathing apparatus. and rubber over clothing (including gloves)

- Extinguish with dry chemical, foam or carbon dioxide

- Water may be ineffective on fire.

- Cool exposed containers with water.

- Exposure

Vapor

- Move to fresh air.

- If breathing has stopped, give artificial respiration.

- If breathing is difficult, give oxygen

Liquid

46

- Remove contaminated clothing and shoes.

- Flush affected areas with plenty of water.

- If in eyes, hold eyelids open and flush with plenty of water.

- If swallowed and victim is conscious, have victim drink water or milk

Do not induce vomiting.

Water Pollution

- Notify local health and wildlife officials.

- Notify operators of nearby water intakes.

Health Hazards

Treatment of Exposure:

- Inhalation: if ill effects occure, remove victim to fresh air, keep him warm and quiet, and get medical help promptly; if breathing stops, give artificial respiration.

- Ingestion: induce vomiting only upon physician`s approval; material in lung may cause chemical pneumonitis.

- Skin and Eyes: promptly flush with plenty of water (15 min. for eyes) and get medical attention; remove and wash contaminated clothing before reuse.

47

Appendix B

48

49

50

51

52

53

Appendix C

54

55

References:

Websites:

1) www.dow.com

2) wikipedia.org

3) google.com

Books:

1) Industrial organic chemistry - Klaus Weissermel, Hans-Jürgen Arpe

2) Handbook of petrochemicals production processes By Robert Allen

Meyers

3) Applied chemical engineering process

4) Encyclopedia of chemical process and design

5) Encyclopedia of technology - fourth edition – volume 2 - Mary Howe-

Grant

)

6) Ullmann's encyclop edia of industrial chemistry

10 - Wolfgang Gerhartz – Y. Stephen Yamamoto

5 th edition volume

7) SRI of Styrene.

56

College of Engineering and Petroleum

Chemical Engineering Department

Plant Design (ChE 491)

Literature Survey

Produ ction of Ethylbenzene

Group Members:

Barjas Alotaibi Mutlaq AL-shammari

Mohammad AL-kashan

Ahmad Boland Nasser Sohail

Presented by:

Prof. Mohamed A. Fahim Eng. Yusuf Ismail Ali

57

Table of Content

Subject

Introduction

Histroy

World Production

Common uses

Feedstock and product description

Process technology

Comparison

Economic Analysis

Conclusion

Appendix

Page number

1

2

2

5

8

19

41

42

43

44

58