The fermentation of sugar

advertisement

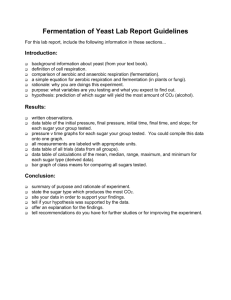

The fermentation of sugar: Which sugar is the best? Summary Fermentation, it’s an important subject in recent studies for new ways of transportation. In the search of new cleaner energy source, bio-ethanol is one of the possibilities for a new cleaner fuel to be used in transportation, and to produce bio ethanol, you need a fermentation process. In fermentation processes there are different factors, or variables, which can be varied in order to get the best results in producing bio-ethanol. So we asked ourselves if we couldn’t change the type of sugar to produce ethanol more efficiently. We followed the fermentation process with 4 types of sugars namely dextrose, fructose, granulated sugar and cane sugar. We measured the loss of mass, which a bottle experience because CO2 gas was produced. The result of our experiment concluded that cane sugar is the most efficient way to produce bio-ethanol. Since we only tested 4 types of sugar this also poses the question of finding an even more efficient sugar to produce ethanol. Introduction To measure how good the fermentation process is, you can directly measure the amount of ethanol produced, which is the most straightforward way, but a more often used method is measuring how much CO2 is produced in the process. This is a perfectly viable method, because in every fermentation process an equal amount of CO2 is produced compared to the amount of ethanol produced. The natural process of producing sugar is called photosynthesis, namely: 6 CO2 (g) + 6 H2O (g/l) C6H12O6(s) + 6 O2 (g) This is an endothermic reaction that can only take place under the influence of sunlight. After the sugar is produced, yeast cells can ferment glucose without oxygen or sunlight, using the following reaction: C6H12O6(s) 2CH3CH2OH (l) + 2CO2 (g) The purpose of fermentation is to make that sugar into a fluid which can be used as a fuel for transportation. In our experiment we tested the different types of sugar available in your local supermarket, which in our case are Dextrose, Fructose, cane sugar and granulated sugar. And our hypothesis is that dextrose and Fructose, which are both monosaccharides, will be the best sugars to be used in the fermentation process, because disaccharides need to be hydrolyzed first, before they can be fermented, which costs time and energy and thus will make the process less efficient. The goal of our experiment was, as we mentioned in the summary to find out which sugar is the most efficient in producing ethanol. In our experiment we decided to not only do our measurements in grams, but keep the calculations in grams as much as possible, because in production environments this is much more important. Control variables in our experiment include, but are not limited to: Temperature, air pressure, water pH, amount of sugar, amount of yeast and the type of bottle used. Experimental procedure and approach weighed the bottles before the 2 weeks were over to check on the process and if the experiment was going properly, this however wasn’t relevant for the hypothesis we were trying to prove. After the 2 weeks we reweighed the bottles and calculated the loss of mass they experienced, which also was the mass of the CO2 gas that was produced. After this we put it in table 1 to compare the differences between the 4 sugars. The measurements of the 2 series were averaged and put into a graph as you can see in figure 1. Finally we made table 2 in which we put the calculated average production of ethanol and the amount of ethanol produced per gram of sugar. weight in gram We started with getting 45 grams of each Results sugar twice and also 1 gram of yeast per Before measuring we opened the bottles to bottle (8 bottles). We did the experiment let out the CO2 gas, because we wanted to twice to get more accurate results and rule know the remaining weight of the bottle out any small mistakes and/or faults in our without the CO2 gas. Before doing this we procedure that would otherwise tamper also confirmed that there were bubbles with our results. escaping from the airlock. After getting 8 bottles of 0.5 L we started We made table 1, which includes the to fill them with 45 grams of sugar and 1 weight that was lost from the bottle and gram of yeast each until we had 2 bottles was released in the air as CO2 gas. We can filled with dextrose, 2 bottles filled with assume that all the mass that was lost has fructose, 2 bottles filled with granulated been converted into CO2 gas. sugar and 2 bottles filled with cane sugar. After this we labelled average difference in weight between start and end of the them to indicate which sugar they contained and experiment which series it was. The labelled bottles were 25 filled up to 250 ml of tap water. Each bottle that was 20 filled with the water was shaken for a minute, after 15 which we placed the airlocks on top of the 10 bottles so the CO2 gas could escape but the 5 mixture isn’t exposed to the open air. Drawing 1 0 shows how the experiment dextrose fructose granulated sugar cane sugar looked. Then we weighed the mass of each bottle and Figure 1. This shows the average release of wrote it down. We then left them to let the CO2 gas versus the four different sugars. fermentation process do its work. We also Reeks1 Sugar used Weight difference (g) (serie 1) Weight difference (g) (serie 2) Difference between serie 1 and serie 2 (g) Dextrose 21 20 1 Fructose 20 17 3 Granulated 24 21 3 sugar Cane 23 23 0 sugar Table 1: the masses of CO2 gas that have been released, the difference between the two series and the average weight of the CO2 gas that is released. Data analysis We presented the averaged loss of mass by the release of CO2 gas. We’ll calculate the amount of ethanol produced by finding out how much mol CO2 gas has been produced and find out which sugar produces ethanol the most efficient. To make the values more comprehensible we have put them in table 2. To calculate the amount of ethanol produced we used the reaction: C6H12O6 → 2C2H5OH + 2CO2 for dextrose and fructose. C12H22O11 + H2O→ 4C2H5OH + 4CO2 for granulated sugar and can sugar (sacharose). With the reaction formula we can calculate the amount of ethanol if we know the amount of CO2 produced. As you can see the relation between CO2 and ethanol are the same with both the monosaccharide and disaccharide namely 1 ethanol molecule for every CO2 molecule produced. For Dextrose the calculation was: 20.5g/44.01u = 0.466 mol CO2 which means 0.466 mol ethanol. To convert this figure into gram 0.466 mol * 46.068u= 21.45 gram ethanol. This has been done for every sugar and put into the table. We added 45 grams of every sugar so we can also calculate the amount of ethanol produced per gram sugar. Average weight difference (g) 20.5 18.5 Dextrose 22.5 fructose 23 Granulated sugar Cane sugar Average weight of CO2 produced by the fermentation (g) Average weight of ethanol produced (g) Ethanol produce d per gram sugar (g) 20.5 18.5 22.5 21.5 19.4 23.6 0.48 0.41 0.50 23 24.1 0.51 Table 2: the average weight of CO2 produced with the weight of ethanol produced to show how efficient each sugar is in producing ethanol by fermentation. Conclusion and discussion By confirming that bubbles were escaping from the airlock and the loss of weight of the bottle it’s certain that CO2 gas was produced by the yeast. If you look at table 2 you can see that disaccharides clearly produce more ethanol than the monosaccharides. The disaccharides produce on average about 20% more ethanol than the monosaccharides, which is a substantial amount more. In our experiment we encountered several problems which ultimately led to what became our odd results. At first there wasn’t enough yeast, so we had to wait a day for our second serie to start, but this shouldn’t have affected our results. Another thing we had a problem with was that at first we only had 3 sugars, because the fructose was delayed, so we actually had 3 different times at which we started our experiment. This shouldn’t matter either, because we were only looking for the total amount of CO2 produced, and not how fast that would happen. Even though the things that went wrong shouldn’t have affected our results, something clearly went wrong, as disaccharides should normally be less effective as monosacharides because disaccharides first need to be hydrolyzed before they can be used in the rest of the chemical process. It could also just be that our hypothesis was wrong and the fact that you simply have different amounts mol of sugar in the same amount of gram with the disaccharides and the monosaccharides can convert faster but don’t have enough mol sugar to be more efficient than the disaccharides and therefore our experiment showed that the disaccharides were more efficient. Perhaps there were other factors/control variables in the experiment which we have overlooked, but greatly affect the experiment, possibilities are that the products produced in the chemical process are actually slowing the yeast down or even killing it, like ethanol or the CO2 or maybe we need to monitor the pH of all the solutions because one sugar/yeast combination produces more acid than the other.