SUBMISSION GUIDELINES FOR 2007 ISB CONGRESS

advertisement

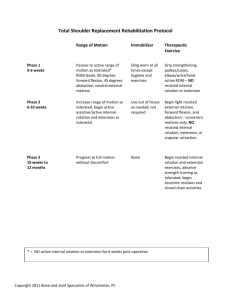

Strategy of Controlling a Free Hanging Humerus in an Experimental Test Setup by using an Inertial Measurement Unit IMU 1 Daniel Tomas, 2Patrick Stäheli, 2 Walter Siegl, 1Daniel Baumgartner IMES Institute for Mechanical Systems, ZHAW Winterthur, Switzerland 2 IEFE Institute for Energy Systems and Fluid Engineering, ZHAW Winterthur, Switzerland 1 INTRODUCTION METHODS The human shoulder was often biomechanically analysed by using experimental test setups. Active motion of the glenohumeral joint was performed with a so called dynamic shoulder model. Necessary shoulder muscle forces were measured to abduct the upper arm to a specific arm angle. Detailed functional models were built by Wuelker et al [1] and Sharkey et al [2] in the early 90’s to analyse the force distribution at the rotator cuff. These models are able to measure a stepwise increase of the muscle forces up to a maximum value. If a specific arm angle has to be achieved, the muscle forces need to be incrementally adapted. Inertial Measurement Unit IMU In order to acquire the mentioned humeral movement, an Inertial Measurement Unit (Sparkfun, USA) was used and placed distally at the humerus dummy. The IMU is able to measure rotation around every axis of its orthogonal coordinate system, as well as the acceleration in every direction of the coordinate system. By attaching the IMU to the humerus and processing the provided signals, it is possible to measure the abduction angle (Alpha) and the rotation angle (Beta) of the humerus. The angles Alpha and Beta are used as Set Point (SP) for the two control loops. Figure 1: Dynamic shoulder models of Wuelker et al. (left) and Sharkey et al., including a humerus and scapula of the shoulder. Mentioned existing models are therefore not position controlled with respect to predefined arm angles. In order to be able to achieve reproducible arm angles, the system, and in particular the humerus, needs to be controlled by a system which acquires the current arm position. As a consequence, a novel shoulder model was built by considering a closed loop control system using an Inertial Measurement Unit (IMU) as a 3D position sensor. The IMU signal is used to steer the individual muscle forces in real time to achieve predefined humerus angles. If the system is able to reproducibly apply specific arm angles, primary implant stability tests for multiple cycles will be possible to perform. Figure 2: Schema of the novel shoulder simulator including actuators and measurement devices for muscle and joint loads. KMD IMU EPOS MMA SMA MMR SMR SM Kraftmessdose/Load cell Inertial Measurement Unit Maxon EPOS 2 Master Motor Abduction Slave Motor Abduction Master Motor Rotation Slave Motor Rotation Scapula Motor (Deltoideus Muscle) (Supraspinatus Muscle) (Infraspinatus/Teres Minor) (2 Segments of Subscapularis) Controller The controller includes two control circuits, one for the abduction (CA) and one for the rotation (CR) of the humerus. The CA is configured as a master and the CR as a Slave. Each of these control loops includes two linear actuators, again based on a Master/Slave configuration, each with its own controller (Fig. 3 and 4). Abduction control circuit The CA system receives its initial SP from the user as a target angle for Alpha. Based upon the difference between the SP and the actual Alpha value the CA calculates a target position for the position controller of the Master Motor Abduction (MMA) and sends it over the CAN-Bus. Based on the angle Alpha, the Scapula Motor (SM) contributes always with one third of the total humerus abduction. The load cell, which is mounted in line with the MMA, measures the applied force needed to perform the abduction of the humerus, one third of this actual force value will be the new target value for the Slave Motor Abduction (SMA), which is sent over the CAN-Bus to the corresponding position controller. Figure 3: Block diagram to control the abduction angle of the humerus. Scapular rotation provides half of the thoraco-humeral abduction. MCA SCA MCR SCR Master Controller Abduction Slave Controller Abduction Master Controller Rotation Slave Controller Rotation Rotational control circuit The second controller CR uses a SP from the user as a target angle for Beta and sends the calculated values to the Master Motor Rotation (MMR) which follows the same behaviour as the MMA. The Slave Motor Rotation (SMR) obtains a user input as SP for the target force. Both SPs for the MMR and SMR should be kept over the complete abduction cycle. Figure 4: Block diagram to control the rotational angles of the humerus around the longitudinal axis. RESULTS By now a first attempt of the CA system has been programmed, implemented and tested. After first measurements, the realised system is able to perform the required boundary conditions. Master motor (representing Deltoideus) and Slave motor (representing Supraspinatus) are in the predefined ratio of 3:1. After first measurements, one abduction cycle 0°85°-0° needs about 20 seconds. This does not fulfil the expected goal of around 5 seconds. Especially for long term testing, the cycle time has to be reduced significantly, so that a ten thousand cycle test can be finished in less than fourteen hours. Afterwards, the CR system, which has been tested individually, can be implemented and tested; this can only be done with a correctly working CA system. DISCUSSION AND CONCLUSIONS So as to achieve the mentioned limit, the CA system has to be made faster without losing the already gained accuracy. Finally, a combination of Abduction and Rotation will be in the focus for further investigations. REFERENCES 1. Wuelker N, et al. Acta Orthop. Scand., 65(4): 442-446, 1994 2. Sharkey NA, et al., Journal of Orthopaedic Research, 12 (5): 699-708, 1992 ACKNOWLEDGEMENTS The scientific work was financially supported by the Zurich University of Applied Sciences.