redesigning the recycling container

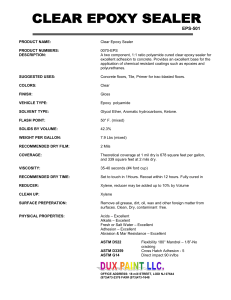

advertisement