SS-CHEG-8-3 - School of Engineering

advertisement

Program SELF-STUDY Report

Department of Chemical Engineering

June 2000

Table of Contents

Subject

A. Background Information

Degree Titles

Program Modes

Actions to Correct Previous Deficiencies

B. Accreditation Summary

1. Students

2. Program Educational Objectives

3. Program Outcomes and Assessment

4. Professional Component

5. Faculty

6. Facilities

7. Institutional Support and Financial Resources

8. Program Criteria

Appendix I - Addition Program Information

A. Table 1 - Basic Level Curriculum

Table 2 - Course and Section Size Summary

Table 3 - Faculty Workload Summary

Table 4 - Faculty Analysis

Table 5 - Support Expenditures

B. Course Syllabi

C. Faculty Curriculum Vitae

Appendix II - Guide to Course Selection (Chemical Engineering)

Page

A.

Background Information

A.1. Degree Titles

The official degree title is “Bachelor of Science in Engineering.” Chemical Engineering is further identified as the

major on the transcript. Double majors are similarly identified, e.g. “Chemical Engineering/Materials Engineering”

is used to indicate a double major in Chemical Engineering and Materials Engineering. A double major is earned by

meeting the requirements of both majors. A double major in Materials Engineering may be earned by choosing at

least fifteen credits of materials courses among the elective courses that a student takes. This particular form of the

double major ends with the class that entered in Fall 1999.

A.2. Program Modes

The Chemical Engineering program is offered as a day program at the basic level. Students can do most lower

division (freshman and sophomore) years at one of the Regional campuses of the University.

The Chemical Engineering program does not have a required co-op experience. Students may participate in a co-op

experience through the Cooperative Education Program of the Career Services Department. This is an individual

decision by the student. Students in their sophomore, junior, and senior years may participate. During the academic

year 1999-2000, three chemical engineering students pursued this option.

Students also have the opportunity to participate in the EUROTECH program. This program leads to two degrees,

one in engineering and the other in German. It includes a year in Germany that includes work with a German

company. There are currently two chemical engineering students in the program.

A.3. Actions to Correct Previous Deficiencies

School Wide

“There seems to be great variation in the thoroughness and quality of feedback provided to the students on writing

{in W courses}.”

ACTION: All departments in the School of Engineering have reviewed their W requirements and have come up with

department specific actions to correct the deficiency. In the CHEG department, W courses are CHEG 237W and

239W, the senior laboratories. Following the last visit, the CHEG department now schedules individual

student/faculty "report writing" consultation sessions in these courses. During these sessions, students receive

individual advice on report structure, grammar, style, technical content, data analysis, data presentation, and

statistics. Two full-time faculty members instruct the laboratory classes and grade all reports. Attendance at the

faculty/student meetings is mandatory and factored into the student's overall grade. In addition, a "model report" is

provided to the students at the beginning of semester in Cheg 237W as a common basis for students to judge their

own reports. Generally, our students and alumni comment favorably on the writing and presentation skills that they

acquire in CHEG 237 and 239.

“The public may have difficulty in discerning from catalog statements, and other documents the goals, logic of

selection, and in particular how the design experience is developed and integrated throughout the curriculum.”

ACTION: While information in the printed catalogs (p-catalog) identifies graduation requirements only, as mandated

by the university, the web-based electronic documentation (e-catalog) addresses the above issues by presenting a

more comprehensive description of the logic of course selection and integration of design. Also included in the ecatalog are clearly stated program goals and objectives. In addition, each department produces a "Guide to Course

Selection" which contains an even higher level of detail regarding the content and purpose of required courses

toward fulfillment of program objectives. The guide to course selection is published on the Chemical Engineering

Department Web page and is reference from both the p-catalog and the e-catalog. This guide is updated at

necessary.

Departmental

No departmental deficiencies were cited during our last review

B. Accreditation Summary

B1. Students

Students

Students are admitted to the School of Engineering with superior high-school records on a competitive basis. They

are required to have taken 4 years of English, 3.5 years (4 recommended) of math, 2 years of a foreign language (3

years of a single language is recommended to meet the University’s graduation requirements without additional

foreign language courses), 2 years of a laboratory science (chemistry or physics required), 2.5 years of social

science, and 2.5 years of other coursework for a total of 16 units. The average SAT score for the engineering class

admitted in 2000 was 1265 and the average high school class standing of those admitted in 2000 was the top 20%. At

the time of admission, students may receive advanced standing (including credit for certain freshmen courses) based

on their performance in Advanced Placement Examinations.

Student Advising:

All students accepted into the School of Engineering attend an orientation meeting during the summer, where they

register for their fall semester courses. They meet with the Associate Dean for Undergraduate Education to discuss

what to expect during their first semester, what services are available in the School and University, and what types of

courses they will be taking throughout their college careers. Individual departmental advisors are also present at the

orientation meeting to help with the registration and answer questions regarding their particular disciplines.

The Associate Dean also discusses the advising system for the School and encourages students to meet with their

advisor early in the semester, especially if they experience any difficulties with their beginning courses. All advisors

are faculty in the School. Students who have designated chemical engineering as their field of study are assigned an

advisor from the chemical engineering department. The Director of Student Advising handles undeclared student

advising until the student selects a major and can be assigned an advisor in the appropriate department. Once a

student is assigned an advisor in their department, they usually keep that advisor for the duration of their college

career.

The advisor provides direction and guidance to the student about career choices and how the engineering program

fits into these choices. The advisor provides help in the selection of courses and the meeting of School and

University requirements. Registration for courses is handled electronically. Before students can register, the advisor

must release an electronic bar to registration. Although the advisor is responsible for making appropriate academic

recommendations, students are responsible for their own academic progress.

Advising records for each student are kept by the faculty advisor, with a separate copy maintained by the Director of

Advising. Advisors are kept informed of the students' progress by transcripts sent out at the end of each semester.

Students with low semester GPAs or other deficiencies are sent notices, with copies forwarded to the advisor, to

schedule a meeting with their advisor. During the meeting, the student and advisor design a plan to correct the

deficiency.

Student graduation is dependent on meeting all curricular and GPA requirements set out by the department, school

and university. The degree program requires that each student to complete a total of 134 applicable credit hours and

earn at least a 2.0 (on a 4.0 basis) for all calculable Upper Division work (work in excess of the first 60 credits

earned). Students are on academic probation for the next semester if their performance is such that they are included

in any of the following groups:

Students who have completed their first Lower Division semester and have earned less than a 1.6 semester grade

point average on a 4.0 scale.

Students who have completed their second Lower Division semester and have earned less than a 1.8 semester

grade point average for that semester.

Students who have completed their third Lower Division semester and have earned less than a 1.9 semester

grade point average for that semester.

Students who have completed their fourth Lower Division semester and have earned less than a 2.0 semester

grade point average for that semester.

Students who have completed their first Upper Division semester (earned more than sixty credits) or more and

who have earned less than a 2.0 semester grade point average or Upper Division cumulative GPA.

The Dean of Students informs the student and the student’s advisor that a marked academic improvement in future

semesters is necessary to obtain the minimum scholastic standards. Students who fail to meet the minimum scholastic

standards for two consecutively registered semesters, or for three in the same division, or for a total of four in their

academic career, are subject to dismissal.

The School of Engineering requires a cumulative grade point average of at least 2.0 in all courses in mathematics,

physics, chemistry, and engineering applicable toward the degree in order for the student to be admitted to the junior

year in his/her selected major. The Assistant Dean for Undergraduate Affairs of the School of Engineering must

approve all exceptions to this.

Our advising system is designed so that advisors and students can contact each other regularly. Normally, a student

must meet with the advisor twice a year to discuss coursework and the program requirements and to register for the

next semester. To assist them in planning their program, each student is given the "Chemical Engineering

Department Guide to Course Selection" (see Appendix II). This document spells out details of the many

requirements of the academic program, provides information regarding choice of technical courses to meet program

objectives and outcomes, and shows how to fill out the plan of study. It also provides a brief overview of the

chemical engineering profession. In addition, each student receives a computer analysis of degree requirements that

have been met and that are still to be met (see PACE below).

Student Monitoring:

Two mechanisms are used to insure that students meet all ABET, Department, School, and University requirements:

a Plan of Study and a computerized degree audit system, PACE. Students must submit for approval a Plan of Study

during their Junior year, with the help and guidance of the advisor. This document lays out the details of the

student's academic program, and carefully indicates how all of the degree requirements, including ABET criteria,

will be satisfied.

Upon approval by the advisor, the initial Plan of Study is reviewed and approved by the Plan of Study Reviewer or

by the Department Head, and the Director of Advising. Care is taken at all levels to ensure that any accepted

program meets all requirements. Any plan revisions require the same approvals. In our Department, a faculty

member designated as Plan of Study Reviewer (Prof. Emeritus G.M. Howard), verifies all plans of study. Before

graduation, the final Plan of Study is used by the University Degree Auditor in the Registrar's Office to certify that

all the graduation requirements have been met. A copy of the plan of study form is shown on the next page.

The University has fully implemented a computer degree audit system called PACE (Programmed Academic

Curriculum Evaluation). PACE monitors the semester by semester progress a student makes towards his/her degree

requirements. A PACE audit is sent to both the faculty advisor and the student every semester. The report indicates

which requirements have been met and how they have been met and which requirements have not been met. For the

student, this helps eliminate last semester surprises. It gives both the advisors and students more time for meaningful

one-on-one program and career planning. Because credit restrictions are programmed into PACE, it effectively

provides an accurate report of students' degree credits.

Student evaluation:

In addition to monitoring credit hours, student learning outcomes are evaluated using "end of course" surveys. These

surveys are administered in every undergraduate course to both the students and the faculty. The purpose of the

survey is to determine "student level of attainment" of learning objectives from both the student's and the faculty's

perspectives. These are used in program outcome assessment. An example of this survey is included in section B

part 3 (Program Outcomes and Assessment). Evaluation of "student level of attainment" is based on sets of well

defined criteria to insure consistent and objective results. Faculty assessments are based on test results, homework,

quizzes, design projects, written and oral reports, and other means.

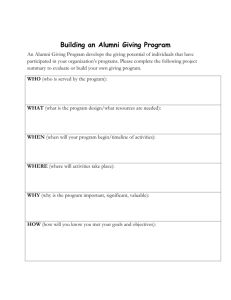

Sample Plan of Study Form

B2. Program Educational Objectives

The Chemical Engineering Department is committed to excellence in its undergraduate program and to maintaining

its accreditation status. In the Spring 2000, the Department implemented a formal process which continually reviews

and revises program objectives, outcomes and curriculum to meet current needs in chemical engineering education,

to meet the needs of our constituents, and to satisfy University and School missions and ABET/AIChE criteria.

Recommendations resulting from this process as well as other aspects of the undergraduate program are regularly

discussed at Departmental faculty meetings. The Mission, Approach, and Program Objectives of the Chemical

Engineering Department, determined using the process described later in this section are as follows.

Program Mission Statement, Approach and Objectives:

Mission

The Department of Chemical Engineering at the University of Connecticut prepares students for productive careers

in this versatile, dynamic, evolving discipline. Upon graduation, students will have learned skills in critical thinking,

problem solving, and communication necessary for success as practicing chemical engineers or in graduate studies.

Particular strengths of the department lie in the areas of biotechnology, advanced materials, computer applications

and environmental protection.

Approach

To achieve its mission, the Department of Chemical Engineering provides an intensive educational program with

faculty dedicated to developing the framework for and stimulating the desire to pursue ongoing active learning. A

thorough base in mathematics; physical science; engineering science; and laboratory, design, and communication

skills is given through course activities, individual and group-based projects, and independent research. The

curriculum also exposes students to relevant safety, environmental, social, and economic issues facing the engineer

in modern society. A low student to faculty ratio permits one-on-one contact with members of the faculty, creating

opportunities for independent research, active advising, and mentoring. The department also provides a student

experience that fosters leadership development, encourages creativity and intellectual curiosity, and demands

responsible behavior and high quality performance. Flexibility in the curriculum provides opportunities to pursue a

double major or minor, study abroad, or gain practical job experience through voluntary participation in an industrial

co-op program.

Program Objectives

I.

II.

Produce graduates who are able to adapt to and become successful, lifelong contributors to the everchanging discipline of chemical engineering.

Promote a sense of commitment, professional ethics and responsibility in students and forge life-long

mutually supportive relationships among graduates, academia, and industry.

The program mission statement and program objectives have been "published" on our web page and in our

undergraduate recruiting brochure. They are consistent with School of Engineering (SoE) and University missions in

that they strive to

1)..."build a challenging intellectual environment for all students...and examine all we do with a global perspective"

2)..."ensure that the student experience fosters the transmission of knowledge and inspires intellectual curiosity"

3)..."serve the state and its citizens in a manner that enhances the social and economic well-being of its communities"

The University of Connecticut Vision, Mission, Values and Goals statement, approved by the Board of Trustees on

February 10, 1995, can be found at http://www.uc2000.uconn.edu/part1.html and the School of Engineering's

Mission statement can be found at http://www.engr.uconn.edu/SoE/mission.html.

Constituencies:

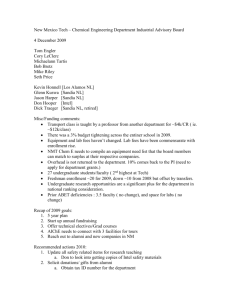

Program constituencies, as determined by the department and SoE ABET Assessment Committee, are faculty,

alumni, employers (as represented by our Advisory Board), school and university mission statements, and

ABET/AIChE criteria. The following table contains a list of our Advisory Board industrial affiliations along with a

list of the top ten employers of our graduates. The department has sought to choose advisory board members from

among these top employers.

Advisory Board Industrial Affiliation

Pfizer Central Research

Exxon

Uniroyal Chemical Company, Inc.

Cytech Industries

ABB Power Plant Laboratories

Olin Research Center

Top 10 Employers

Pfizer Inc. (1)

Exxon (2)

Uniroyal (3)

United Technologies (4)

Pratt & Whitney (5)

Cytech Industries (6)

ABB Combustion Engineering (7)

Olin Chemicals (8)

IBM (9)

Andersen Consulting (10)

Procter & Gamble

Union Carbide Corp.

Boelringer Ingelheim Pharmaceuticals, Inc.

Rogers Corporation

Advanced Fuel Research

Saint-Gobain Abrasives

Northeast Utilities System

Processes to Establish and Review Program Objectives:

The program objective process consists of two steps: 1. establish/review departmental objectives using input

from our constituents and results from our assessment process (every 5 years); and 2. Achieving those

objectives via curricular and extracurricular activities defined, reviewed and updated (yearly).

Establishing Program Objectives:

The process of establishing the departmental objectives begins with a critique of the old objectives, performed by the

Program Objective Review Committee (3 faculty within the department) during the summer a full year prior to the

desired deadline. This group develops a rough draft of new objectives, which are circulated to the faculty for review

and comment. Modifications are discussed and changes made in several iterations (5-6 drafts produced during the

fall semester). Following faculty approval, new objectives are sent via survey to the alumni for critique and

comment (at the beginning of spring semester). The objectives are also the topic of an Advisory Board meeting in

which board members are asked to develop "program objectives" in line with their needs. Results from these two

exercises, along with information from ABET workshops and input from SoE ABET committee members,

consultants from various academic institutes, school and university mission statements, and informal conversations

with local employers will be combined to shape the final draft of departmental objectives.

Final program objective approval is established by faculty vote at the end of the spring semester. This process will

be repeated every 6 years. Alumni survey results, Advisory Board input, and the developmental history of our

current program objectives are shown at the end of this section.

Reviewing Program Objectives:

Review of the stated program objectives will occur once every 6 years. This review will follow the same procedure

used to "establish program objectives" stated above. Program objective "update" will be the focus of one

faculty/advisory board meetings every 6 years, where program objectives will be scrutinized in light of collected data

(alumni surveys) and the changing needs of our constituencies. The next update will be due in the Spring 2006. As

changes are made in the objectives, the department's Undergraduate Program Committee (consisting of three

faculty members, including the Assistant Department Head) will monitor how these changes are incorporated into

curricular and extracurricular activities and ensure that they are carried out.

Process to Ensure Achievement of Objectives:

Each program objective is linked to one or more program outcomes. Specific student learning outcomes have been

identified and associated with each program outcome. Learning outcomes are then linked with courses and/or

activities contained in the program and required for degree fulfillment. Thus we strive to achieve our objectives

through our curricular and extracurricular activities.

To facilitate this process, we have split our curriculum into four major "areas" of concentration. The fundamental

area includes chemistry, physics, math, freshman engineering and our Introduction to Chemical Engineering course

(CHEG 203). The core area contains chemical engineering thermodynamics, transport phenomena, unit operations,

and kinetics. The integration area includes senior-level unit operations laboratories, design, and control. The

elective area encompasses all undergraduate elective courses. Program activities that contribute to the program

objectives through means other than courses are contained in extracurricular area .

The following table shows the contributions of the four curricular areas and the extracurricular area to the Program

Objectives, broken down by chemical engineering courses or activities. This table was developed by the assistant

department head based on the course syllabi and in consultation with course instructors.

B2- Table 1

CHEG Program Content & Contributions to the Program Objectives

Course

indicates significant contribution to the objective

Obj I - "adapt to and become

Obj II - "Promote a sense of prof.

successful, lifelong contributors to

ethics and responsibility...form

the field of chemical eng"

mutually supportive relationships.."

Fundamentals Area

Cheg 203 - Intro to Cheg

Core Area

Cheg 211 - Thermo I

Cheg 212 - Thermo II

Cheg 223 - Transport I

Cheg 224 - Transport II/Unit Ops

Cheg 251 - Process Kinetics

Integration Area

Cheg 237W - Senior Lab I

Cheg 239W - Senior Lab II

Cheg 243 - Process Design

Cheg 247 - Dynamics and control

Elective Area

Cheg 245, 256, 261, 283, 285,

295, 299

*

students are required to take 2 Cheg

electives and 4 professional electives

Extracurricular Area

Advising

AIChE Student Chapter

Internship/Coop/Eurotech

Low student/faculty ratio

7 's

7 's

Objective attainment will be assessed yearly using alumni surveys, advisory board input, alumni data base

statistics, Uconn Foundation records of alumni donations, and informal input from alumni, recruiters, and

company representatives. Assessment data will be collected, summarized and presented at the annual

faculty/program outcomes assessment meeting held in early June (as described in section B3). Program

modifications resulting from this meeting will then be put into place (i.e. changes in the assessment process, changes

in the curriculum, improvements in the advising system, greater flexibility in the curriculum, etc).

Specifically, attainment of Objective I will be determined by surveying alumni to assess:

1. general preparedness for and contributions to work in the field of chemical engineering. Questions

linking "preparedness" to specific elements of our curriculum will be included

2. starting and current salary

3. continuing education/short courses taken

4. professional meeting attended

5. publications, patents, and other activities

Alumni from 10, 5, and 2 years out were selected as survey recipients for the Spring 2000 "program objective"

evaluation. This particular survey sought to ascertain information regarding both the establishment and achievement

of objectives. A high response rate was achieved by offering incentives (basketball tickets!) for filling out and

returning the survey. Phone calls will be made to those alumni who do not respond within a certain time. A 43%

response rate on 70 surveys mailed out in the spring of 2000 was achieved using these techniques. Spring 2000

Alumni survey results are presented at the end of this section.

Attainment of Objective II will be determined using information from the alumni survey (or alumni database), the

advisory board, and the Uconn Foundation regarding:

1. Preparedness regarding impact of engineering in a global and societal context and understanding of

professional and ethical responsibility. Questions linking "preparedness" to specific elements of our

curriculum will be included

2. alumni/industry ties (employment history from alumni survey, )

3. industry/academia ties (the advisory board)

4. alumni/academia support (Uconn Foundation data on annual donations)

5. general satisfaction of alumni with their undergraduate education (from alumni survey)

Program Objectives Assessment Data:

Summaries of the data collected to evaluate Program Object I and II are presented below. A more detailed summary

of the Spring 2000 Alumni Survey is presented at the end of section B2.

Assessment Data for Program Objective I:

"Produce graduates who are able to adapt to and become successful, lifelong contributors to the

ever-changing discipline of chemical engineering"

1. General preparedness for work in the field of chemical engineering is evaluated by two questions from the alumni survey:

(a) "Rate you preparation for employment or grad school on the following scale:

1= not as well prepared

2= about average

3= better prepared

The Results from 30 respondents out of 70 surveys mailed

= 2.55

Representing the classes of '98, '93, and '88

.57

(b) "Rate Components of Your Undergraduate Education for VALUE (=How important they were in

attaining your first professional position and performing at that level) and QUALITY (=Did you Uconn

education prepare you adequately). B2 - Table 2 contains averaged results for components relating to

Objective I.

B2- Table 2

Spring 2000 Alumni Survey Results

Numerical Rating of Components of the Chemical Engineering Program

Pertaining to the Achievement of Objective I

Scale 1=lowest value/quality

5=highest value/quality

Basic Math (Calculus, Differential Equations)

VALUE

QUALITY

3.46 1.37

3.78 .91

Basic Sciences (Physics, Chemistry)

Problem Solving Skills

Computer Programming/Numerical Methods

General Software Applications

Special Software Applications (Process Simulations, etc)

Basic Chemical Engineering (Thermo, Trans, Kinetics)

Experimental/Research Methods and Analysis

Process Design and Economics

Process Control

Optimization

4.11 .88

4.55 .78

3.43 1.40

3.85 1.03

2.89 1.26

3.76 1.09

3.79 .94

3.48 .87

2.86 1.24

3.21 1.13

3.79 .88

4.20 .67

3.21 .83

3.22 .89

3.43 .88

4.17 .66

3.60 .78

3.38 .86

3.61 .92

3.03 .81

Model Development

2.86 1.14

3.82 1.09

4.55 .74

4.45 .91

4.55 .74

2.86 .85

3.89 .92

3.93 .75

4.03 .82

3.90 .72

Engineering Electives

Communications (Speech and Writing)

Ability to learn independently

Multidisciplinary Teamwork/Leadership

The "Bolded" text represents an area requiring discussion and possible modification

2.

3.

4.

5.

Starting and current salary information: no data available (question will be added to next survey)

Continuing education/short courses: no data available (question will be added to next survey)

Professional meetings: no data available (question will be added to next survey)

Publications, patents, other activities: no data available (question will be added to next survey)

Assessment Data for Program Objective II:

"Promote a sense of commitment, professional ethics and responsibility in students and forge

life-long mutually supportive relationships among graduates, academia, and industry."

1. General preparedness in the areas of professional ethics and social responsibility is evaluated by one question from the alumni

survey:

"Rate Components of Your Undergraduate Education for VALUE (=How important they were in attaining

your first professional position and performing at that level) and QUALITY (=Did you Uconn education

prepare you adequately). B2 - Table 3 contains averaged results for components relating to Objective 2.

B2- Table 3

Spring 2000 Alumni Survey Results

Numerical Rating of Components of the Chemical Engineering Program

Pertaining to the Achievement of Objective 2

Scale 1=lowest value/quality

5=highest value/quality

VALUE

QUALITY

Environmental, health and safety considerations

Professional and ethical responsibilities

3.93 .86

4.21 .82

3.36 .95

3.62 .90

Knowledge of Contemporary and Global Issues

3.59 .87

2.62 .90

The "Bolded" text represents an area requiring discussion and possible modification

2. Alumni/industry ties are obtained by asking for initial and current employer/position data on the alumni survey:

Results show that

19 out of 29 respondents are still employed by their initial employer (65%)

1 had graduated from graduate school and obtained a position in engineering

9 had changed employers (but were still in engineering or engineering related fields)

1 was no longer in an engineering position (3%)

3. Industry/academia support is evaluated by tracking monetary donations to the department, the number of

undergraduate scholarships sponsored, and the number of summer internships provided. This information is

presented in B2 - Table 4.

B2- Table 4

Academic

Year

97-98

98-99

99-00

History of Industrial Support to the Department

Monetary Donations to the

Number of Undergraduate

Department ($)

Scholarships Sponsored

$31,500

8 scholarships ($14,500)

$52,750

12 scholarships ($21,500)

$33,025

18 scholarships ($29,500)

Number of Summer

Internships Provided

2 internships ($10,000)

3 internships ($15,000)

3 internships ($15,000)

4. Alumni/academia support is evaluated by tracking alumni gifts to the University as shown in the following table.

B2- Table 5

History of Alumni Gifts to the University

97-98

98-99

99-00

5. General Satisfaction of alumni with their undergraduate education is evaluated using the Alumni Survey question

"Would you recommend UConn Chemical Engineering to friends and relatives?"

28 respondents answered yes...

2 respondents answered no....

market for Chem E's in the New England area was small - Uconn's program was small

market for Chem E's is quite small in area

First Cycle Improvements:

The results of the first cycle of evaluation were viewed with four main purposes in mind:

1. Produce an Objective Statement that accurately represents the needs of our constituents

2. Identify and correct Assessment Process deficiencies (deficiencies in our surveys, type of data collected)

3. Identify and correct Objective Attainment deficiencies (deficiencies in our curriculum)

4. Determine whether our Objectives are truly Meeting the Needs of our constituents

One problem occurred in the Objective Statement development process, namely that it was difficult to determine a

"proper" level of specificity to include in the statements. It was found that constituent input regarding objective

statements" was more detailed than warranted, i.e. the term "objective" is very loosely defined and can be interpreted

many different ways. For this reason, constituent input on our objectives was not directly incorporated into the

wording of the statements.

Being our first round of formal program assessment, several deficiencies were noted in our Assessment Process. In

particular, more information should be requested on the alumni survey to fully evaluate our performance on

Objective I. It is felt that the data gathered in support of Objective II is sufficient.

With the data gathered, we were able to confirm that our curricular and extracurricular programs are producing

satisfied, well prepared alumni and that we are Attaining our Program Objectives. Furthermore, our objectives

satisfactorily address the needs of our constituents. Therefore, only slight modifications to the educational program

have been proposed.

Based on the results of the first cycle of the objective identification/objective achievement process, several

improvements have been identified and will be incorporated in the next cycle. They are listed below:

B2- Table 6

Program Objective Process Improvements

Spring 2000

Objective Establishment & Achievement

Corrective Measures Employed

Process Deficiencies

Program Objectives Advisory board "program objectives"

Program objectives will not be modified to

require students to possess business skills

contain the words "business skills"(too specific)

immediately upon graduation

however business skills will be introduced into

the curricula via various methods mentioned

below

Alumni survey results in variety of

Alumni comments were incorporated by

suggestions concerning the objective

including the "Approach" paragraph between

statements (see Survey summary at the end

the Mission Statement and the Program

of this section)

Objectives

Alumni Survey No salary info gathered

Include the items noted on future alumni

No continuing edu info gathered

surveys

No publications/patents info gathered

No community service info gathered

No color coding to determine GPA

Sent to alumni 10 years out

Send survey to alumni less than five years out

Alumni Data Base Data Base updated and plans for continuous

In state of neglect

Maintenance implemented (secretarial time

allotted)

Objective Attainment Process Advisory Board desires more exposure to

Create a new elective "Engineering

Business skills

Entrepreneurship"

Create more flexibility in the course sequence

to facilitate student participation in Co-op.

Students desire better "advertisement" of

Advertise summer internships and other job

summer internship opportunities

opportunities on our web page and create links

with industry to facilitate student participation

in summer internships.

Data concerning summer internship

Keep better records of summer internship

participation was difficult to obtain

participation via formal senior exit survey

Alumni survey indicates need for more

We have recently begun and will continue to

Exposure to contemporary and global

increase the coverage of these issues in our

issues

elective courses.

Also, the number of required elective courses

will be Increased by one, thus increasing

exposure in these areas

Documents Relating to Section B2

Program Educational Objectives

1. Alumni Survey / Summary of Results - Spring 2000

2. Program Educational Objective / Advisory Board Input - Spring 2000

3. Developmental History of Current Program Objectives

Alumni Survey

Summary of Results

Spring 2000

Based on 30 responses (from a pool of ~70 potential respondents in graduating classes '98, '93,

and '88)

Employer / Position Summary 1st Job following B.S

Class

DEP

Permit Engineer

98

Clinipad

Industrial Eng

93

Kaman Aerospace

Liaison Eng

98

CYRO Industries

Tech Service Eng

98

Sartomer

Process Eng

98

FairPreene

Process Eng

98

ABD

Engineer

93

Fit Linxx

Internet Developer

98

Env Risk LTD

Env. Eng

88

Grad student

Biomedical eng

98

Pfizer

Assistant scientist II

98

Grad student

98

Teknor Apex Co

Polymer devel chemist

93

Ham Sundstrand

Chem/materials Eng

98

CYRO Industries

Product Eng

93

ABB

Nuclear Eng

98

Ham Standard

Analytical Eng

88

Metcalf & Eddy

Env Eng

93

Procter & Gamble

Eng/ Product devel

98

Grad student

Chem eng at Cornell

98

Cytec Industries

Production supervisor

93

CT DEP

Air poll control eng

98

Timet Castings

Metal control super

93

Dow Chemical

Production eng

88

Regeneron Pharm

Research Associate II

98

EWR

Process chemist

93

ISIS Chemicals

Chemist

88

TRC Env Consul

Asst Project manager

88

Proton Energy Sys

Staff Chemical Eng

98

Uniroyal Chemical

Engineer

98

Current Job

same

same

same

same

same

same

same

same

Jocobi, Kappel,etc

same

same

same

M.A. Hanna Eng Mat

same

Curtin Ins. Agency

March First

Veco Rocky Mt. Inc

Ensign-Bickford

same

Intel

same

same

Control Components

same

same

Mott Corp

Thomson Newspapers

Enviro Science Consul

same

same

same

same

same

same

same

same

senior eng

Web Devel

Lawyer

same

same

same

Senior chemist

same

Treasurer

Programmer

Sr Process Eng

Chemical Eng

same

Process Eng

same

Quality Control

Comm Devel Mngr

same

Sales eng

Sr. Network Eng

Env Consultant

same

same

Rate Components of Your Undergraduate Education

VALUE= How important they were in attaining your first professional position and performing at that level

QUALITY= Did your Uconn education prepare you adequately

Scale 1=lowest value/quality

5=highest value/quality

Basic Math (Calculus, Differential Equations)

Basic Sciences (Physics, Chemistry)

Problem Solving Skills

Computer Programming/Numerical Methods

General Software Applications

Special Software Applications (Process Simulations, etc)

Basic Chemical Engineering (Thermo, Trans, Kinetics)

Experimental/Research Methods and Analysis

Process Design and Economics

Process Control

Optimization

VALUE

3.46 1.37

4.11 .88

4.55 .78

3.43 1.40

3.85 1.03

2.89 1.26

3.76 1.09

3.79 .94

3.48 .87

2.86 1.24

3.21 1.13

QUALITY

3.78 .91

3.79 .88

4.20 .67

3.21 .83

3.22 .89

3.43 .88

4.17 .66

3.60 .78

3.38 .86

3.61 .92

3.03 .81

Engineering Electives

Communications (Speech and Writing)

Environmental, health and safety considerations

Ability to learn independently

Multidisciplinary Teamwork/Leadership

Professional and Ethical Responsibilities

2.86 1.14

3.82 1.09

4.55 .74

3.93 .86

4.45 .91

4.55 .74

4.21 .82

2.86 .85

3.89 .92

3.93 .75

3.36 .95

4.03 .82

3.90 .72

3.62 .90

Knowledge of Contemporary and Global Issues

3.59 .87

2.62 .90

Model Development

Rate your preparation for employment or graduate school, in comparison with your peers using the following

scale: 3=Better prepared 2=About average 1=Not as well prepared

Results = 2.55 .57

General Comments:

Negatives: weak team skills and speaking skills, grad school peers (foreign) more knowledgeable in science, no

coop experience, lack coop experience

Positives: eng electives allow greater breadth of skills; better than most non-chem E's; teachers willing to help; just

as good or better than RPI& WPI; better written and oral tech comm skills; independent study key to success; great

practical prep; practical sr lab - great prep for designing equip and responding to unplanned situations; as well or

better prepared than highly qualified and talented peers; high expectations of faculty pushed students to stand on

their own two feet; 3 work experiences while at Uconn gave me an advantage; comparable prep to peers from RPI &

WPI

The most important component of my Uconn Education

Summary Oral & Written communication - 12 respondents

Teamwork - 10 respondents

Lab & Unit operations - 6 respondents

Independent Study - 5 respond

Faculty Interactions - 4 respondents

Problem Solving - 3 respondents

Elective Classes - 3 respondents

Co-op - 2 respondents

Tools/skills that you wish you had received

Summary Computer skills/software applications - 7 respondents

Communications - 6 respondents

Design projects/independent research - 4 respondents

Flexibility/work study opportunities - 3 respondents

Business - 3 respondents

Experimental Design/Statistical Analy - 2 respondents

Other - 6 respondents

Would you recommend UConn Chemical Engineering to friends, relatives, etc.?

28 respondents answered yes...

2 respondents answered no....

market for Chem E's in the New England area was small - Uconn's program was small

market for Chem E's is quite small in area

Program Objectives/ Mission Statement Additions & Suggestions

Suggestions:

provide a foundation for life-long learning

responsible care/ process safety management, provide students w/ knowledge concerning industry standards toward safety

there is a need in the marketplace for engineers skilled in new process development in both plastics and chemicals...consider

adding process development to mission statement or goals and curriculum

more flexible curriculum so students can co-op more easily

chemical engineers receive an education in multiple disciplines (mechanical, controls, electrical, financial) in order to

effectively design production equipment

provide educational tools to produce chemical engineering graduates that can improve and create chemical processes

regarding safety, health, and the environment

a graduate described as such is worthless to a company. A graduate must be well-rounded. Though the graduate can think

critically, does he/she have common sense? Too many graduates do not have common sense.

maybe a note of its versatility & application to other fields

produce graduates who will have the capability of demonstrating their leadership that will influence positive change & the

sustainability of this discipline w/in their immediate environments (academia, industry) & w/in society as a whole

their should be some more emphasis on computer-related technology as well

chance for students to pursue more projects that pertain to their goals/ career objectives; more interactive means to achieve

their goals and yours for the education to be of more value to future employers and administrators

I feel that the department needs to strive more vigorously to attain program goal #3. In particular, exposing students more to

new and emerging technologies today and in the future.

Developmental History of Current

Program Educational Objectives

1995 Objectives

The goal of the undergraduate program is to prepare men and

women to enter the challenging fields spanning the spectrum of

activities that require the talents of chemical engineers. The first

two years of the curriculum are similar for all branches of

engineering and are designed to give sound knowledge of basic

principles in mathematics, physics, chemistry and

communications skills, to provide a broad exposure to the

humanities and social sciences, and to introduce engineering

design. In the last two years this knowledge is expanded and

complemented by courses in chemical engineering, chemistry, and

other relevant disciplines. The students build on their knowledge

of underlying chemical engineering principles, to increase their

understanding of the design and operation of chemical processes,

to reinforce their problem solving skills, and to develop an

appreciation of relevant safety, environmental, social, and

economic issues.

Engineering science and design are integrated throughout the

curriculum, as are computer applications. The classroom and

laboratory experiences in the curriculum enable students to...

pursue successful careers in industry, government,

consulting, or toDec

continue

on to graduate work.

'99 Objectives

Flexibility

is

provided

in

the

curriculum

byinallowing

The Dept....prepares students for productive

careers

this

studentsdynamic,

to select

two chemical

and three

versatile,

evolving

discipline.engineering

Upon graduation,

students

will have learned skillscourses

in criticalduring

thinking,their

analytical

professional-requirement

last two

problem

solving,

and communication

necessary for

in

years. The

overall

program objectives

aresuccess

to help

diverse careers in the chemical process industries, sustainable

students

attain fundamental

knowledge;

developand

fuels, biotechnology,

pharmaceuticals,

advanced materials,

skills in analysis

and design, teamwork, and oral and

environmental

protection.

Program

written Objectives:

communication necessary for a successful

1.

Produce

graduates

who think

critically and can

define,

career;

and

to acquire

an appreciation

and

capability

formulate and solve technical problems by effectively applying

for

life-long

learning.

scientific, mathematical, engineering and computational tools and

principles.

2. Develop teamwork habits and communication skills necessary

for technical achievement in the modern industrial world.

3. Expose students to technology in emerging and

interdisciplinary fields and produce graduates who can design

and conduct independent research as well as analyze and interpret

data in those fields.

4. Promote a sense of commitment, service, professional ethics,...

June '00 Objectives

As printed in

section B.2

Sept '99 Objectives

The mission of the undergraduate program is to prepare our

graduates for productive careers in the ever changing and evolving

fields requiring the talents of chemical engineers... ...Flexibility in

the curriculum allows students to gain real world experience through

voluntary participation in the co-op program.

Program Objectives

1.Students will be able to participate in one semester of co-op work

experience without creating “course sequencing” problems in their

senior year.

2.Our students will be able to communicate effectively.

3. Our students will be able to apply design principles in a variety

of areas.

Mar '00 Objectives

The Department of Chemical Engineering at the University of

Connecticut prepares students for productive careers in this versatile,

dynamic, evolving discipline. Upon graduation, students will have

learned skills in critical thinking, problem solving, and

communication necessary for success as practicing chemical

engineers or in graduate studies. Particular strengths of the

department lie in the areas of biotechnology, advanced materials,

computer applications and environmental protection.

Program Objectives:

I. Produce graduates who are able to adapt to and become

successful, lifelong contributors to the ever-changing discipline of

chemical engineering.

II. Promote a sense of commitment, professional ethics and

responsibility in students and forge life-long mutually supportive

relationships among graduates, academia, industry, and the greater

society.

B3. Program Outcomes and Assessment

The Department prides itself in trying to provide an excellent education and preparation for aspiring engineers. To

this end, the Department implemented a formal process for continual program outcome assessment and improvement

in the spring 2000.

Program Outcomes:

The following list of program outcomes has been developed by the faculty to support the program objectives

described in section 2. This list was also developed with ABET Criterion 3 in mind and using alumni input from the

Spring 2000 Alumni Survey. A detailed list of specific student learning outcomes associated with each of the

program outcomes, the ABET criteria satisfied by each, where each learning outcome is placed in the curriculum,

and the assessment methods used for each is included in a B3 -Table 1 at the end of this section. A mapping of

program outcomes to individual CHEG courses is provided in B3 - Table 2 at the end of this section.

1.

Produce graduates who think critically and can define, formulate and solve technical problems and design

chemical processes by effectively applying scientific, mathematical, engineering and computational tools and

principles. (Satisfying ABET criteria a, c, e & k)

2.

Expose students to technology in emerging and interdisciplinary fields and produce graduates who can design

and conduct an experimental program as well as analyze and interpret data in traditional and emerging fields.

(Satisfying ABET criteria a, b, c, e, f, h, i, j, & k)

3.

Produce graduates with teamwork habits and communication skills necessary for technical achievement in the

modern industrial world. (Satisfying ABET criteria d & g)

4.

Provide curricular and extracurricular student experiences that present a holistic view of engineering actions and

their consequences, encourage student/faculty and student/industry interactions, and present opportunities for

personal development. (Satisfying ABET criteria f, h, i & j)

Program Outcome 1 includes all fundamental and core courses of the program (with the exception of senior unit

operation laboratories) and satisfies Abet criteria a,c,e and k. Experimental design and data analysis fit well with our

strong desire to provide students more opportunities to explore emerging and interdisciplinary areas, and were

included in Outcome 2. Outcome 2 also requires that students apply fundamental concepts to solving new and

interdisciplinary problems and understand professional and ethical responsibility, the need for life-long leaning and

the impact of this technology in today's rapidly changing world (encompassing Abet criteria a, b, c, e, f, h, i, j, & k).

Communication and teamwork, highly valued and closely related skills, were placed in the 3rd program outcome

(Abet criteria d & g). These skills represented by Outcomes 1, 2, and 3 are necessary to satisfy Program Objective

I, "Produce graduates who are able to adapt to and become successful, lifelong contributors to the ever-changing

discipline of chemical engineering".

Desirable non-technical traits such as educational breath and an understanding of ethics and responsibility (Abet

criteria f, h, i, & j) are included in Outcome 4. Outcomes 2 and 4 support the achievement of Objective II, "Promote

a sense of commitment, professional ethics and responsibility in students and forge life-long mutually supportive

relationships among graduates, academia, and industry".

A mapping of Program Outcomes to Criterion 3 ABET requirements is shown in the table below.

B3- Table 3

Mapping Program Outcomes to Criterion 3 Requirements

a

b

c

d

e

f

g

Program Outcome 1

1-1 problem solving

1-2 design

1-3 interdisciplinary prob solving

1-4 use computing tools

Program Outcome 2

2-1 exposed to tech in emerging fields

2-2 lab safety, equip op, exper design

2-3 use statistical methods

2-4 conduct independent research

2-5 incorporate lab into lecture courses

X

X

X

h

i

j

k

X

X

X

X

X

X

X

X

X

X

X

X

X

X

Program Outcome 3

3-1 posses written and oral comm skills

3-2 gain confidence in comm ability

3-3 work in teams

Program Outcome 4

4-1 societal impact of engin practices

4-2 profession and ethical responsibility

4-3 make infomed career choices

4-4 participate in prof organizations

4-5 broad backgr in humanities, soc sci

4-6 appreciation for life-long learning

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

Process to Achieve Program Outcomes:

Each program outcome (and its associated Abet criteria) is described by a detailed list of learning outcomes that are

linked to specific courses and/or other activities in the program. For example, Program Outcome 2, "Expose

students to technology in emerging and interdisciplinary fields and produce graduates who can design and conduct

an experimental program as well as analyze and interpret data in traditional and emerging fields" is supported by the

following learning outcomes:

2-1 Students will be exposed to technology in emerging and interdisciplinary fields and successfully apply chemical

engineering principles in solving problems relevant to these fields (Abet a, c, e ). Students will also understand

the professional and ethical responsibility, the need for life-long leaning and the impact of new technology in

today's rapidly changing world. (Abet f, h, i, j)

2-2 Students will demonstrate lab safety and a knowledge of equipment operation, identify independent and

dependent variables and the range of variables to be measured and will be able to gather, analyze and interpret

data and test theories (Abet b & k)

2-3 Students will use statistical methods to estimate and interpret error in experimental data, extract key

results/parameters from data, and perform a regression analysis on data (Abet b & k)

2-4 Students will conduct independent research by performing a literature search, designing or specifying

experimental equipment, determining appropriate analytical techniques, specifying experimental runs and

procedures, and collecting and analyzing data (Abet b, i & k)

2-5 Students will have increased comprehension of lecture material and will gain experience in designing and

conducting experiments (Abet b & k).

Each of these learning outcomes is linked to specific courses and activities in the program (see B3- Tables 1 & 2 at

the end of section B3). For instance, Outcome 2-3 is linked with Cheg 237W and 239W (senior unit operation labs).

A set of clearly defined “course objectives” that coincide with specific learning outcomes are developed at the

beginning of the semester for each undergraduate course offered that semester. The course objectives are written by

each instructor and presented to the students at the beginning of the semester, along with a list of assessment methods

(exams, homework, labs, design projects, etc.) and expected level of achievement. Students receive a passing mark

in a class after demonstrating an acceptable level of achievement in all learning outcomes.

Student graduation is dependent on meeting all curricular and GPA requirements set out by the department, school

and university. The degree program requires that each student to complete a total of 134 applicable credit hours and

earn at least a 2.0 (on a 4.0 basis) for all calculable Upper Division work (work in excess of the first 60 credits

earned). Details of student performance requirements were given in section B1 of this report.

Specific engineering curriculum requirements that must be met are those shown in the Plan of Study (section B1) and

described in detail in section B4 of this report. Table 1 in Appendix IA summarizes the basic-level curriculum in

chemical engineering. Table 2 Appendix IA contains a summary of course and section size. Course syllabi are

contained in Appendix IB. A complete reference listing specific requirements for graduation as a chemical engineer

is provided in the “Chemical Engineering Guide to Course Selection” found in Appendix 3.

An explanation of transfer admissions policies and procedures to validate credit for courses taken elsewhere are

presented later in this section.

Data Used to Demonstrate Program Outcome Achievement:

B3- Table 4 summarizes the data sources used to demonstrate program outcome achievement.

B3- Table 4

Assessor

Students

Individual

Faculty

Alumni

Advisory

Board

Data Gathered to Demonstrate Outcome Achievement

Data Source

Resulting Data

1. End of Course Surveys (EOC) 1. Student Level of Achievement on each

course objective

2. EBI Survey

2. Comprehensive rating of all components

of students education

3. Senior Exit Survey

3. Info regarding post grad plans, likes and

dislikes of dept, etc

1. HW, quizzes, lab reports, etc

1. grades

2. End of Course Surveys

2. Student level of achievement on each

course objective

3. Year End Course Summary

3. Proposed changes in course content,

Forms

teaching style, course objectives

1. Alumni Surveys

1. Rating of all components of alumni's

education, current employer/position,

relative prep for career compared to

fellow employees, etc

1. Advisory Board Meeting

1. Rating of student level of achievement

on the job

2. Informal discussion

2. "

"

"

"

Responsibility

1.Students/course

instructor

2.Students/ Assist

Dept Head

3.Students/ Dept

Head

Individual Faculty

Admin Assist/

Assist Dept Head

Dept. Head

Using student learning outcomes (i.e. course objectives) stated in the course syllabi presented at the start of the

semester, students and instructors complete an End of Course Survey to assess student level of achievement. Level

of achievement is judged according to the scale: 1=not acceptable, 2= below expectations, 3=meets expectations,

and 4=exceedes expectations. An explicit set of definitions for "not acceptable", "below expectations", etc. is

provided on the survey form to insure that students and instructor evaluate performance using a common basis. An

example survey is given at the end of this section.

Both student and instructor survey results are compiled in a Year End Course Summary Form. This form is

compiled by the instructor and contains the instructor’s interpretation of the results and recommended changes to

course objectives, course content, and/or teaching methods needed to correct deficiencies or shortcomings. An

example “Course Summary Form” is included at the end of this section.

In addition to monitoring “course objective achievement”, a Senior Exit Survey is conducted yearly by the

department head just prior to graduation. During the survey students are asked to provide input on all aspects of the

program, including advising, co-op/summer internship opportunities, the curricula, the instructors, extracurricular

activities, and their employment/grad school choices. Seniors are also asked to fill out a standardized survey (EBI)

offered by Educational Benchmarking, Inc. that covers similar material. Results from the senior exit and EBI

surveys are attached at the end of this section.

The Alumni Survey (shown at the end of section B2) and information gathered from recruiters and the advisory

board are also used in evaluating program outcome achievement.

Faculty discussion is also an important component in determining program outcome achievement. The

undergraduate program is often a topic of discussion among the faculty. This past academic year (Spring 2000) the

Department initiated a formal process involving year-end discussions of student outcome achievement and program

assessment and modification. These and other informal meetings lead to a critical discussion of our program with

questions such as: How does this course fit into the overall program? Is this course necessary? Are the courses

being taught in the most effective manner? Are there new mechanisms for presenting the material that may be more

effective? Is the workload reasonable and coordinated? What do students like about our courses? And, what do

students dislike about our program? The diverse background of the faculty also contributes to this discourse; faculty

from different universities have experienced various programs and can suggest alternative techniques, syllabi, etc. to

improve our program. A faculty that is critical of itself and demands only the best in the undergraduate program is

perhaps the best way of ensuring that the educational goals are met.

Program Improvement Process

The formal program improvement process, initiated in the spring of 2000, occurs yearly. Components of the process

are the alumni survey, the end of course surveys, the year end course summary forms, the senior exit survey, the EBI

survey, the advisory board meeting, and a series of faculty meetings culminating in recommendations for the

following year. A schematic of the "Program Improvement Process" is shown below and described in the following

narrative.

Schematic of the "Program Improvement Process"

Program

Improvement

Report

Undergraduate

Program

Assessment

Faculty Meeting

Senior Exit Survey

& EBI Survey

Alumni Survey,

Advisory Board Input,

& Informal Input

"Fundamentals"

Area Report

"Core"

Area Report

"Integration"

Area Report

"Electives"

Area Report

ENGR 166, CHEG 203,

math, phys, chem

End of Course Surveys &

Year End Course Summary

CHEG 211, 212,

223, 224, 251

End of Course Surveys &

Year End Course Summary

CHEG 237W, 239W,

243, 247

End of Course Surveys &

Year End Course Summary

CHEG 245, 256, 261,

283, 285, 295, 299

End of Course Surveys &

Year End Course Summary

Input from all sources mentioned above are gathered from September to May. At the end of the spring semester in

May, small groups of faculty meet to review and discuss the end of course survey and year end course summary

forms pertaining to their educational “area”. Four “areas” have been identified. They are the “fundamentals” area,

covering freshman and sophomore level courses, the “core” area, including thermodynamics, transport, kinetics, and

unit operations courses (junior level required courses), the “integration” area, covering senior level design, control,

and laboratory courses, and the “electives” area, covering all undergraduate electives. During "area" meetings, the

faculty assess weaknesses in their area and recommend changes in individual courses or the program to remedy these

weaknesses. Four reports are generated from these meetings to summarize and document the finding. An example

report from the "Core" area meeting is contained at the end of this section. The reports are then presented at the

“Undergraduate Program Assessment” faculty meeting (attended by all faculty).

Following the “area” meetings, a “Undergraduate Program Assessment” faculty meeting is held to discuss program

improvements in light of all the data gathered during the year, including alumni survey, senior exit survey, EBI

survey (if available), advisory board input, and “area reports”. Data from these sources are summarized,

program improvements discussed, and recommendations approved during the meeting. Minutes of the meeting are

taken to document all material discussed and a final "Program Improvement" report is generated. A copy of this

report is provided at the end of this section and a summary of actions to be implemented in the academic year 20002001 given in B3- Table 6.

99-00 Assessment Data

Data collected from the end of course surveys, senior exit survey, and EBI survey in the spring of 2000 are presented

at the end of this section. Data from the alumni survey for that same period was presented at the end of section 2 of

this report. A brief summary of this data, discussion, and suggested actions follows. Note: One half a year of data

is insufficient to determine "outcomes attainment" with a high level of certainty. The real value of the

assessment process will only become visible over time.

End of Course Surveys

Results: Course surveys show student level of achievement ranging from “acceptable” to “above expectations” in

90% of all course objectives from both the student and instructor perspectives. Learning outcomes that were below

acceptable were, for the most part, due to overstatement of the outcomes, for example one outcome stated that

“students will be proficient at using ASPEN” after only five ASPEN labs. One notable exception was that students

rated themselves slightly less than acceptable (2.6) performance in verbal and written communication in CHEG

239W.

Discussion: From these results, the majority of learning objectives, and hence Program Outcomes 1, 2, and 4, are

being successfully achieved. Some weakness in verbal and written communication was expressed (Outcome 3). A

few of the learning objectives are overstated.

Suggested Action: Add more verbal and written communications into the curriculum, particularly in the junior year

(responsibility of the "core area" faculty and the Department Head). Overstated objectives will be corrected

(responsibility of the individual faculty)

Senior Exit Survey

Results: The senior exit survey revealed that 70% of all seniors had participated in CHEG 299 (elective Independent

Study) and that the majority said it helped them in choosing their post graduate career path. Only 21% participate in

coop and 67% participate in summer internships. Over half of the respondents expressed a desire for more flexibility

in the curriculum so that a co-op would only set them back one semester, rather than two. Students also requested

better “advertisement” of summer internship positions. Concerning the curriculum, “Design” was sited as the most

useful course, however it felt that two semesters of design were unnecessary. Other curricular issues include a desire

for fewer, but greater in depth experiments in the senior lab and better preparation in the statistical treatment of data.

The senior survey of our 2000 graduates also showed that over 90% were employed or attending graduate school,

reflecting well on the preparation our students receive.

Discussion: High level of participation in CHEG 299 is desirable and has been achieved (Outcome 2 and 4). High

level participation in co-op is desirable but not been achieved (Outcome 4). Therefore the faculty agree that more

flexibility should be permitted in the senior curriculum (affecting Outcome 4). It was agreed that reducing the

number of senior level core CHEG requirements would provide more flexibility. Better advertisement of summer

"engineering" positions is requested (also affecting Outcome 4). Lab equipment and experiment upgrades could

incorporate students request for fewer, more "in depth" labs (Outcome 2). Lack of statistics "ability" can be

addressed many ways without adding a statistics class to the curricular requirements (Outcome 2).

Suggested Action: The existing senior level Design sequence, CHEG 241 (3 cr) and 242 (3 cr) should be changed

to a new single 4 credit Design course, CHEG 243. This action will require that certain "design" elements be

incorporated into CHEG courses earlier in the curriculum, specifically ENGR 166, CHEG 203, and CHEG 224

(responsibility of the "core" and "integration" area faculty, the individual course instructors of 166, 203, 224, and

243, and the Dept. Head)

Summer Internship and permanent jobs should be advertised on our web page. Future development could lead to

links between our page and selected industries for use by both students and alumni (responsibility of Doug Cooper or

Web Developer).

Chemical Engineering lab renovations will consolidate the two kinetics and two control experiments into one kinetics

and one control experiment (responsibility of Rich Kozel, C. Erkey, and D. Cooper). Faculty will advise their

students seeking a strong background in statistics to take STAT 243 as an elective (responsibility of all faculty).

EBI Survey

Results: The EBI survey rates a wide array of components of the educational program with a response range of one

(very dissatisfied) to seven (very satisfied) with 4 being neutral. B3- Table 5 shows average student ranking of "EBI

defined" factors distributed into the four chemical engineering "Outcomes". The only EBI factor that received an

average rating less than 4 was "Satisfaction with Career Services & Job Placement" (Outcome 4, factor 3). In

comparison with the other 52 schools participating in the EBI survey, the only factor rated significantly differently

by our students was "Satisfaction with Fellow Students" (Outcome 3, factor 1). For this factor, our rating was 17%

less than the average of all schools.

Discussion: It is not apparently clear to us why students are dissatisfied with their fellow students. Class

"personalities" tend to vary widely from year to year. Therefore, the faculty felt it best to not try and correct this

problem unless it persists for several years (affecting Outcome 4). The student's dissatisfaction with Career Services

was echoed in the Senior Exit Survey and affects Outcome 4.

Suggested Action: Closely monitor "Level of Satisfaction with Fellow Students" over the next few years to see

whether dissatisfaction is truly a manifestation of the program or just a whim of the class (responsibility of the

Assistant Department Head). Advertise job opportunities on the CHEG web page as stated above.

Alumni Survey

Results: Alumni, in response to the question “Rate your preparation for employment or graduate school, in

comparison with your peers using the following scale: 3=Better prepared 2=About average 1=Not as well

prepared “ rated themselves as average or better prepared (average of all respondents was 2.55 .57). Alumni

offered positive comments regarding their training, for example "better prepared in oral and written technical

communications"; ".independent study was key to my success", "practical senior lab was great prep for designing

equip and responding to unplanned situations", "high expectations of faculty pushed students to stand on their own

two feet". In evaluating specific components of their education, training in “knowledge of contemporary issues”

was rated as the weakest point (2.6) on a scale of 1=lowest quality to 5= highest quality. Most other components

received a score of 3 or above. Alumni cited communication, problem solving, teamwork, and ability to learn

independently as the most important skills required for success upon graduation. Other alumni survey results were

presented in section B2.

Discussion: Alumni feel that they are well prepared for employment as chemical engineers upon graduation with the

exception of "knowledge of contemporary issues" (affecting Outcome 4). Faculty have only recently (in the past 3 or

4 years) started stressing this point, primarily in CHEG elective classes. Therefore the alumni filling out the survey

accurately reflected the teaching at the time.

Suggested Action: Offer more elective classes and include ample discussion of global and societal issues

(responsibility of Department Head and individual faculty)

B3- Table 5

CHEG Student Avg

Rating

EBI Survey Results as Pertaining to

Chemical Engineering Outcomes

6

4

2

0

1

2

3

4

factor 1

factor 2

factor 3

factor 4

factor 5

CHEG Outcomes

EBI Factor Definition Mapped into CHEG Outcomes

Outcome 1-"Produce grads who think critically and can define, formulate and solve technical problems..."

Factor 1 - Satisfaction with Major Courses (grades/ accessibility/ responsiveness/ size/ availability)

Factor 2 - Satisfaction with Computer Resources (quality/ availability/ remote access/ training)

Factor 3 - Degree of system Design & Problem Solving (Design/ interpret/ identify/ analyze/ solve problems)

Factor 4 - Degree that Major Design Experience Built on Previous Course Work and Skills

Factor 5 - Degree that Major Design Experience Addresses Issues (economic/ env/ ethical/ health & safety/ etc)

Outcome 2- "Expose students to technology in emerging and interdisciplinary fields and produce graduates who..."

Factor 1 - Satisfaction with the Breadth of the Curriculum (technology, practical experience)

Factor 2 - Degree of Understanding Ethical Responsibilities and Global Impact of Engineering solutions

Factor 3 - Degree that Laboratory Facilities Aided in Learning/ Use of Modern Engineering Tools

Outcome 3- "Produce graduates with teamwork habits and communication skills necessary for technical...."

Factor 1 - Satisfaction with Fellow Students (Academic Quality/ Team Work/ Camaraderie)

Factor 2 - Oral and Written Communication Skills

Outcome 4- "Provide curricular and extracurricular student experiences that present a holistic view of eng..."

Factor 1 - Satisfaction and Instruction and Interaction in Major Courses

Factor 2 - Satisfaction with Extracurricular Activities (Team experiences/ Organization Activities/ Leadership Op)

Factor 3 - Satisfaction with Career Services & Job Placement (Assistance/ No and Quality of Companies/ Alumni)

Factor 4 - Overall Satisfaction with the Engineering Program

Advisory Board and Employer Input

Results: Almost all of our students who have participated in co-op or summer internship are offered permanent jobs

with these employers after graduation. Informal conversations with employers and the continued support from our

advisory board and other industrial affiliates indicate a high level of employer satisfaction with our graduates. These

include managers and executives from Uniroyal, CYRO, CYTECH, Dow, Rogers, and Olin, just to name a few.