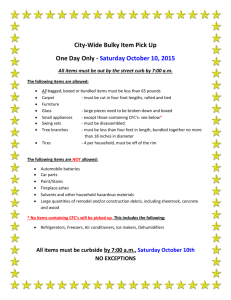

1 Essential Uses and Sale of MDI-ODS to Other

advertisement