Design And Implementation Of A Bill Of Materials

advertisement

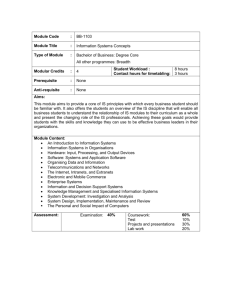

Design And Implementation Of A Bill Of Materials Processing System (A Case Study Of Emenite Nig Ltd, Enugu) 1 TABLE OF CONTENTS Title page i Certification ii Dedication iii Acknowledgement iv Abstract v Table of contents vii CHAPTER ONE INTRODUCTION 1 1.1 Background of the study 1 1.2 State of the problem 2 1.3 Purpose of the study 3 1.4 Aims and objectives 3 1.5 Scope of study 5 1.6 Limitations of study 5 1.7 Assumptions 6 1.8 Definition of terms 7 2 CHAPTER TWO LITERATURE REVIEW 8 CHAPTER THREE 3.1 Description and analysis of existing system 15 3.2 Fact finding method used 17 3.3 Organization structure 19 3.4 Objectives of Existing system 21 3.5 Input, Process and Output Analysis 22 3.6 Information Flow Diagrams 26 3.7 Problems of the Existing System 27 3.8 Justification of the New System 28 CHAPTER FOUR 4.1 Design of the New System 30 4.2 Input Specification and design 30 4.3 Output specification and design 32 4.4 File Design 34 4.5 Procedure chart 36 3 4.6 System flow chart 38 4.7 System requirements 40 CHAPTER FIVE 5.1 Implementation 42 5.2 Program Design 45 5.3 Program Flowchart 48 5.4 Pseudo code 54 5.5 Source Program: Test Run 59 CHAPTER SIX Documentation 60 CHAPTER SEVEN 7.1 Recommendation 62 7.2 Conclusion 64 Bibliography 65 4 TABLE OF CONTENTS Title page i Certification ii Dedication iii Acknowledgement iv Abstract v Table of contents vii CHAPTER ONE INTRODUCTION 1 1.1 Background of the study 1 1.2 State of the problem 2 1.3 Purpose of the study 3 1.4 Aims and objectives 3 1.5 Scope of study 5 1.6 Limitations of study 5 1.7 Assumptions 6 1.8 Definition of terms 7 CHAPTER TWO LITERATURE REVIEW 8 CHAPTER THREE 3.9 Description and analysis of existing system 15 3.10 Fact finding method used 17 3.11 Organization structure 19 5 3.12 Objectives of Existing system 21 3.13 Input, Process and Output Analysis 22 3.14 Information Flow Diagrams 26 3.15 Problems of the Existing System 27 3.16 Justification of the New System 28 CHAPTER FOUR 4.8 Design of the New System 30 4.9 Input Specification and design 30 4.10 Output specification and design 32 4.11 File Design 34 4.12 Procedure chart 36 4.13 System flow chart 38 4.14 System requirements 40 CHAPTER FIVE 5.6 Implementation 42 5.7 Program Design 45 5.8 Program Flowchart 48 5.9 Pseudo code 54 5.10 Source Program: Test Run 59 CHAPTER SIX Documentation 60 CHAPTER SEVEN 6 7.3 Recommendation 62 7.4 Conclusion 64 Bibliography 65 CHAPTER ONE INTRODUCTION 1.1 BACKGROUND OF THE STUDY The use of traditional approach in problems solving has really left some loopholes in life and this has encourage the introduction of computers in various fields of work including production in terms of keeping of bill of materials in production and most recently reordering of sales. The Bill-of-material processing system has been in existence in many organizations though in a traditional approach. Introducing the computer system will greatly improve materials requirement planning in the following aspects. (a) Reliability (b) Validity (c) Accuracy (d) Appropriate storage of data (e) Timeliness The above factors are due to the fact that the computer possesses some great features, and advantages over traditional approach. 7 1.2 STATEMENT OF THE PROBLEMS No doubt that the use of traditional system has created a lot of problems in production of roofing sheets at EMENITE. The quantity and amount of materials and sub-assembly needed to produce a product cannot be traceable because of glaring disadvantages stated below. Poor information storage method: The use of office files and file cabinets is not a good form of information storage. Insecurity of data because it is prone to vandalization and unauthroised accessibility Duplication of data in various departments because of the nature of work needed It takes a long time in accessing records in the manual system (filing system) due to the nature of the job. It is not always good for materials to finish unnoticed, so the re-ordering of materials are not made as and when due. The introduction of the computer system will help eliminate these problems to an extent. 1.3 PURPOSE OF THE STUDY This project is generally towards eradication of all the deformities and curb hookups of the manual method of bill-of- 8 materials processing, thus developing a new system to handle the jobs involved in the processing of Bill-of-material electronically. 1.4 AIMS AND OBJECTIVES In an organization whether manufacturing or not manufacturing where the competitors and the objectives of the organization are at the top of the scale of preference especially the meeting of the standard in the market, there is always a focus on the organizational goal which might not be the goals of the sub-system to avoid sub-optimality, working towards a divisional or individual benefits. The aims of this work include the following; (1) To work towards the elimination of ineffective modes of operation; it centers on the user having a good atmosphere for work thereby minimizing stress. (2) The objective from the initiator of the proposal is generally towards combating al the aims and the problems being discovered on the existing system, which are listed under problem of study. (3) Safeguarding of information through effective monitoring of access is the filing system (database). (4) Knowing when materials are almost out of stock, in order to make an order so as not to show the production pace of the labourers. 9 1.5 SCOPE OF STUDY The scope of this project work covers all the areas of bill-ofmaterials processing systems, which include the cost of individual material responsible for production, the stock control or inventory areas, and every other necessary areas. The storage of records, which have different fields that could be expanded a little to form files. These file five rooms for editing, updating and retrieval of information when needed. Some of these fields are item description, quality, total requirement, re-ordering point, labour cost, overhead cost, profit, lower cost, etc. This project is focused on the entire information recorded on Bill-of-material processing for EMENITE NIGERIA LIMITED, EMENE, ENUGU STATE. 1.6 LIMITATIONS The constraints that were highly against this study are as follows: (1) Time Lag: the fact that the duration of the project work was little; the researcher would only cover little scope. The time for the researcher to combine academic works and project writing is also another limiting factor. (2) Financial constraints: The researcher’s low financial backbone really affected the project writing. This stopped the researcher 10 from traveling wide to industrialized areas like Lagos so as to meet with bigger companies instead of EMENITE. 1.7 ASSUMPTIONS Sequel to insufficient information, the following assumptions were made: The recording of Bills-of-materials has not been made Hardware for the installation of the program or software is procured already The people to use the systems are in the industry already. 1.8 DEFINITION OF TERMS (1) Traditional Approach: The system of use of files, file jackets and file cabinets in the storage of records i.e. the manual way of storage of information. (2) Record: Facts of a particular material and any other thing used in production. (3) Field: An item of data within a record. It is made up of a number f character. (4) Hardware: The physical component of a computer system e.g. keyboard. 11 (5) Software: The program in the hardware of the computer that instructs the system on steps to take in executing a giving task. (6) File organization: The process or the way of arranging and maintaining files that are used for keeping of records. (7) Flowchart: This is a diagrammatical representation of procedures taken in executing a given task. 12 *** INSTRUCTIONS *** Please Read The Below Instructions Carefully. ****************************** HOW TO ORDER THIS COMPLETE MATERIAL If you want to order the complete materials (Chapter One to Five, Including Abstract, References, Questionnaires, Proposal (where applicable)) of the above mentioned topic, please visit www.freeplace.org and click on “Order” (i.e. www.freeplace.org/order) ****************************** HOW TO BECOME OUR PARTNER To become our partner, visit www.freeplace.org and click on partnership. ****************************** TERMS OF USE This Material is for Academic Research Purposes only. On no account should you copy this material word for word. Copying this material “Word for Word” is against our “Terms of Use”. That you ordered this material shows you have agreed Our ‘Terms of Use’. ****************************** 13 Better is not good enough, the best is yet to come! Endeavour to be the best!! 14