277_Lab04_Retentive_Info

advertisement

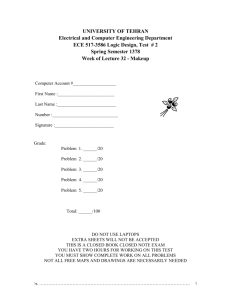

EET 277, Lab 4 Retentive Information Name: _______________________ In PLCs some information is retentive and some is only temporary. Retained information will remain set unless it is changed or the CPU battery dies. In RSLogix all Outputs, Binary Storage Bits (B3 File), Counters, Word Storage (N7 File) and Sequencers are retentive. In terms of latching an output there are 2 common ways of doing it. You can use a Software-Latch or a Latched Output. Care should be taken when using latched output instructions on physical outputs because if the program stops at an unexpected time the outputs will be latched on start-up. 1) Write and run the PLC program below using the following Inputs and Outputs: Start= I/0 (NO), Stop1=I/1(NC), Stop2=I/2 (NC), Output1=O/1, Outout2=O/2 Software Latch Latching instructions a) Is there a difference in the operation of Output1 and Output2 aside from which Stop buttons turn it off ? b) When Outputs 1 and 2 are on, unplug the PLC for 5 seconds, and plug it back in. Are either of the outputs on when power is resumed? 4) When would Latched Outputs NOT be good to use? 5) When would Latched Outputs or bits be helpful? 6) In The case of Rung 0, would the output turn on if any of the wires or switches failed? 7) In Rung 2, would the circuit turn off the Output if the Stop Switch or its wiring failed? 8) How should safety switches be wired into a system? EET 277, Lab 4 Retentive Information 9) Execute the Program below: 10) Increment the Counter to 9, Allow the RTO to time to about 9 seconds but not to time out, and press input 2. Note the conditions of the outputs. a) Disconnect the PLC from the communications cable and unplug it. (Note: Do not hit “Retry” on the computer screen until the PLC is reconnected in a later step). b) Wait 1 minute then power the PLC. Note that the Outputs should not have changed state. c) Press I/0 and note that O/0 should turn on because the Counter is now at 10. 11) Now connect the PLC to the computer and tell RSLogix to re-try the connection. Note that the counter should be at 10 and the RTO at 10s. Were the RTO and the counter retentive? 12) Now, with the PLC on-line figure out how to reset the counter and the RTO. Note that the Image tables would be helpful. Record how you managed this below: 13) Program the LogixPro Dual Compressor to allow motor 1 (O/0) to run if the Selector Switch is in Position A (I/4), the Stop (I/0) is closed and Start button (I/1) is pressed. Seal-in the Start Button. If the motor has been on for 24 hours total time (total time), stop the motor, flash the CI indicator (O/3) every 2 seconds, and do not allow the motor to be re-started until the Selector switch is moved to position B (I/6) and Stop is pressed 3 times. Use a Retentive timer (as an hour timer) and a counter to track the number of hours. You will need a second counter as a reset-counter. Only allow the motor to run if the selector switch is in Pos A (I/4). If you do not have a LogixPro disk yet, use the I/O above and your imagination. Note that you do not have to wait 24 hours for the counter to finish. You can use the data tables to change the accumulated values in the counters and timers. Any accumulated value greater than the Preset value will cause a timer or counter to be “done.” Demonstrate your Program___________________