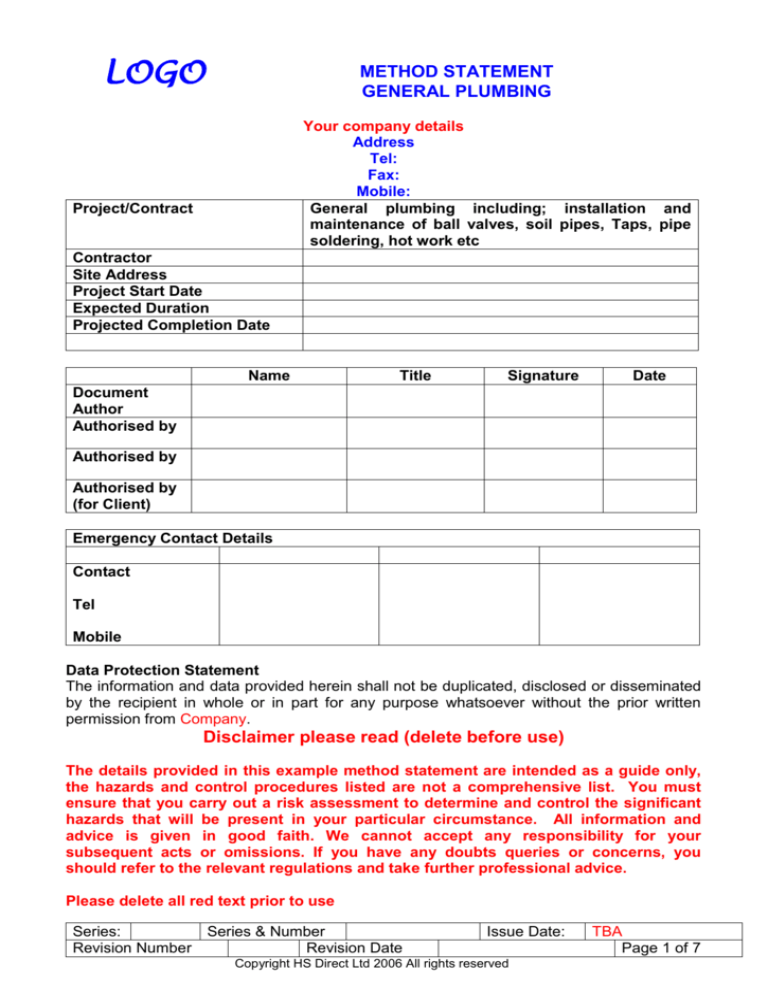

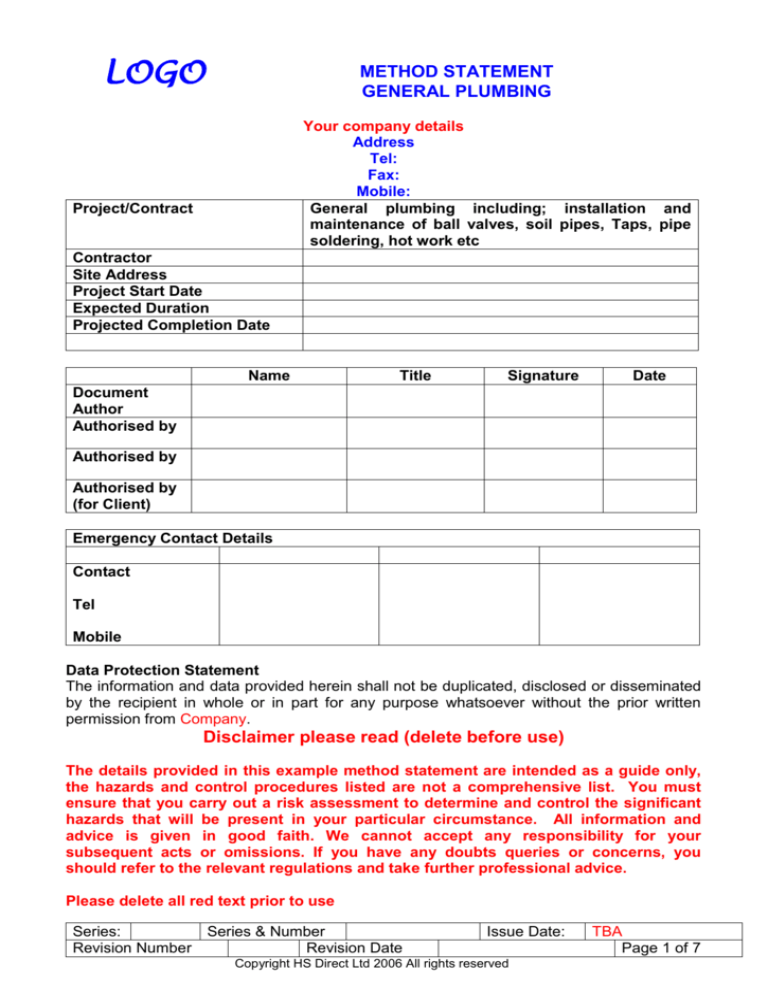

LOGO

METHOD STATEMENT

GENERAL PLUMBING

Your company details

Address

Tel:

Fax:

Mobile:

General plumbing including; installation and

maintenance of ball valves, soil pipes, Taps, pipe

soldering, hot work etc

Project/Contract

Contractor

Site Address

Project Start Date

Expected Duration

Projected Completion Date

Name

Title

Signature

Date

Document

Author

Authorised by

Authorised by

Authorised by

(for Client)

Emergency Contact Details

Contact

Tel

Mobile

Data Protection Statement

The information and data provided herein shall not be duplicated, disclosed or disseminated

by the recipient in whole or in part for any purpose whatsoever without the prior written

permission from Company.

Disclaimer please read (delete before use)

The details provided in this example method statement are intended as a guide only,

the hazards and control procedures listed are not a comprehensive list. You must

ensure that you carry out a risk assessment to determine and control the significant

hazards that will be present in your particular circumstance. All information and

advice is given in good faith. We cannot accept any responsibility for your

subsequent acts or omissions. If you have any doubts queries or concerns, you

should refer to the relevant regulations and take further professional advice.

Please delete all red text prior to use

Series:

Revision Number

Series & Number

Revision Date

Issue Date:

Copyright HS Direct Ltd 2006 All rights reserved

TBA

Page 1 of 7

LOGO

METHOD STATEMENT

GENERAL PLUMBING

Use this page to highlight the significant hazards your staff and others will be

exposed to, also highlight the most important preventative/control measures that

must be taken, HAZARDS and CONTROL MEASURES will be taken from your RISK

ASSESSMENT. You can also highlight quality and environmental issues. The

following are examples; please delete/enter your own

Staff Information Sheet

The following method statement has been developed to provide a safe system of work and

must be adhered to at all times, any significant deviation from this system must first be

authorised by your manager or safety representative. Please read the entire sheet before

beginning, if you have any questions please contact your manager or safety

representative.

The main hazards to your safety and health are;

a)

Injury from slips trips and falls.

b)

Injury from Manual Handling.

c)

Ill health from breathing solder fumes.

d)

Injury to other contractors during works.

e)

Injury from machine and tool hazards.

f)

Fire from hot work.

g)

Working at height.

h)

Possible presence of Asbestos.

Main Preventative Measures you must take;

a)

You must be “competent” to carry out the task.

b)

Barriers and/or warning signs must be placed around the work area where

appropriate.

c)

Fire extinguishers will be on hand during hot work.

d)

Protective heat shields must be used.

e)

Visitors and other members of staff are prohibited from entry unless accompanied

by competent person, all visitors issued with personal protective equipment where

appropriate.

f)

You must read and be familiar with the COSHH Safety Data Sheets for solder.

g)

You must follow all directions given by the project manager or his agents.

h)

Review the asbestos survey before starting work.

Personal Protective Equipment you must wear;

a)

Hard Hat.

b)

Hi Visibility Vest.

c)

Dust Mask.

d)

Safety Glasses.

e)

Overalls.

f)

Gloves.

g)

Safety boots.

Environmental Protection Measures you must take;

a) You must dispose of waste and spoil to the designated area or skip provided for

waste.

Series:

Revision Number

Series & Number

Revision Date

Issue Date:

Copyright HS Direct Ltd 2006 All rights reserved

TBA

Page 2 of 7

LOGO

METHOD STATEMENT

GENERAL PLUMBING

Quality Control

a)

Adhere strictly to the following procedure to ensure quality of service.

b)

If in doubt contact your manager for clarification before proceeding.

Add in other relevant sections such as the items listed below. Your risk assessment

will tell you which control procedures must be in place (Remove any that do not apply

to you)

General Precautions

To be observed by all staff at all times, any deviation from these control procedures

must be authorised by the site foreman or safety representative.

Staff, Training & PPE

Plumbing and maintenance work will be carried out by staff from Company, all staff are time

served plumbers with relevant experience, and hold the following qualifications; List

Qualifications. A site manager will be appointed to each contract he/she will be responsible

for quality and safety. Apprentices and young workers will be supervised and are not

allowed to carry out tasks or operate machinery for which they have not been trained.

All site workers will wear Safety boots, and protective clothing at all times, other items of

PPE such as eye protection, respiratory masks and gloves are available to be worn as and

when necessary.

Preparation & Induction

A risk assessment will be prepared for all maintenance tasks which will be discussed with

members of staff and the building manager, any queries or concerns will be raised with the

contract manager who will ensure it is dealt with. Staff will be inducted onto site by the

building manager and will follow all safety procedures advised by the client.

Welfare

The Client is responsible for providing adequate washing, toilet, drying and refreshment

facilities for Company staff and sub-contractors, Company are responsible for ensuring that

such welfare facilities are maintained in a clean and wholesome manner. This will be your

responsibility when you are the principal contractor, it may be necessary occasionally for

your company to identify suitable local amenities.

First Aid

It is the responsibility of the company to ensure adequate first aid provision for its staff.

Adequate means provision of a trained first aider, suitable first aid equipment and/or the

provision of an appointed person at the minimum.

A trained first aider will be a suitable person who has attended an approved course of at

least 3 days training repeated every 3 years and attended a refresher course every year in

between.

An Appointed Person is a person provided by the employer to take charge of the situation

(e.g. to call an ambulance) if a serious injury/illness occurs in the absence of a first aider.

The Appointed Person can render emergency first aid if trained to do so. Often principal

contractors will ensure sufficient first aid cover for sites under their control

Series:

Revision Number

Series & Number

Revision Date

Issue Date:

Copyright HS Direct Ltd 2006 All rights reserved

TBA

Page 3 of 7

LOGO

METHOD STATEMENT

GENERAL PLUMBING

Access egress

The principal contractor is responsible for providing safe access and egress to the site,

YOUR COMPANY staff will ensure safe access and egress is maintained for themselves and

other contractors in the area they are working in, good standards of housekeeping will be

maintained. YOUR COMPANY will be responsible for safe access and egress when you are

the principal contractor

Material Handling

All materials required for site will be unloaded to a designated unloading and storage area

which will be away from the work area as far as is practicable. This area will be kept tidy to

minimise trip hazards. Materials, as and when required, will be transferred from the storage

area to the work area. All staff will take care when handling materials.

Manual Handling

All staff and contractors have been instructed on the potential dangers of manual handling,

and have received manual handling training. Staff and contractors will not lift items, tools or

equipment beyond their capabilities. Heavy or awkward items will be broken down into

smaller units or dual lifted where this is not possible. It is the responsibility of the site

foreman to identify and control potentially dangerous manual handling situations as they

occur on site on a day to day basis.

Working from Step Ups

The majority of tasks that involve working at height will be carried out using the step up,

before use the floor area should be clear, free from waste and on level ground. The step up

should be checked for any sign of damage before use and if damaged removed from use

immediately.

Working from Step Ladders

The majority of tasks carried out at height involve working below 2 metres from step ladders;

all staff have been made aware of the dangers of working from step ladders and have been

instructed on the safe use of ladders. Staff are required to read and understand HSE leaflet

INDG402 the Safe use of Ladders & Stepladders. Only competent members of staff will be

allowed to work from step ladders and it is the responsibility of the site foreman to ensure

conditions are safe before allowing any ladder work to take place. Only short duration work

will be performed from ladders. Alternative access methods will be used when longer

duration work is required.

Please also see Practical Alternatives to Using Step Ladders Part 1 and Practical

Alternatives to Using Step Ladders Part 2

Contractor/Visitor Safety

YOUR COMPANY will liaise with other contractor’s staff on a day to day basis and ensure

they are aware of the risks present during the works. Staff and contractors will not leave any

area of work in a dangerous condition or with risks to themselves, other contractors, tenants,

or visitors, all tools and equipment will be cleared to secure storage at the completion of

each shift. Scaffold, ladders and any other access to height will be made inaccessible.

Tools and Electrical Equipment

Series:

Revision Number

Series & Number

Revision Date

Issue Date:

Copyright HS Direct Ltd 2006 All rights reserved

TBA

Page 4 of 7

LOGO

METHOD STATEMENT

GENERAL PLUMBING

All items of tools and equipment will be visually inspected on a regular basis defective or

damaged equipment will be removed from service. Electrical tools will be 110V where

possible, sub contractors will not be allowed to bring on to site any damaged or defective

tools, the site foreman is responsible for ensuring all tools and equipment brought onto the

site is fit for purpose.

Solder Flux

Solder flux fumes are potentially dangerous all staff must read and understand the safety

data sheet regarding solder flux. (HSE Publication INDG248 Solder Fume and You). It is

the responsibility of the site foreman to ensure adequate ventilation where soldering is being

carried out.

Method Statements

Describe the task or process you are writing about;

Task Description

This method statement describes the work process for general plumbing and plumbing

maintenance work.

Describe in detail the step by step the tasks or process someone must follow in order

to complete the task safely. Delete any that do not apply to your situation

Preparation

1)

2)

3)

4)

5)

6)

7)

8)

9)

Report to site office and inform site manager of arrival, collect permit to work

where required.

Attend any induction as required by the principal contractor or building manager.

Put on your personal protective equipment.

Take tools and equipment to the work area.

Cordon off work area if required to do so.

Ensure the area to be worked on and the exit points are clear of obstruction and

that safe access and egress is maintained.

Check any electrical or hand tools for damage or faults, faulty or damaged tools

must be removed from service immediately.

Do not leave tools and equipment unattended at any time.

Ensure the work area is left safe at end of each shift and when unattended.

Maintenance/repair work

1)

2)

3)

4)

Liaise with other contractors and facilities manager to isolate water supplies.

Isolate Hot & cold water pipes where necessary.

Drain down the water system where necessary.

When chasing out the walls firstly use the cable/pipe finder to locate any electric

cables or pipe work.

5) Mark the wall for the area to be chased out.

6) On plasterboard walls carefully cut out using a knife or saw.

7) On plaster walls chase out using a Kango power chisel or hand bolster.

Series:

Revision Number

Series & Number

Revision Date

Issue Date:

Copyright HS Direct Ltd 2006 All rights reserved

TBA

Page 5 of 7

LOGO

METHOD STATEMENT

GENERAL PLUMBING

8) If necessary remove any skirting boards by driving the bolster chisel behind the board

and carefully levering it away from the wall (gloves should always be worn)

9) If necessary to take up any floorboards these should first be checked with the

cable/pipe finder to ensure the area below the board is clear.

10) Set the circular saw to 18mm depth and along the length of the board on both sides

through the tennon (on some floors it may be necessary to reset the saw to a

depth of 22mm and take a second cut

11) Using the bolster chisel lever up the board, remove all nails.

12) When taking up carpet and lifting floorboards attention will be paid to the trip hazard

created, do not leave open floorboards and upturned carpets any longer than is

necessary, sufficient warning signs must be posted where there is a risk of other

contractors entering the site.

13) Carry out replacement of parts or repairs.

14) Ensure waste pipes and other plastic pipe work are connected correctly.

15) Where plastic pipe is connected with solvents, staff will follow all safe use instructions.

16) Where solder work has to be carried out, prepare pipe work for solder joints.

17) Obtain the appropriate hot work permit from the facilities manager.

18) Ensure the correct type of fire extinguisher is on hand during hot work.

19) Protect surrounding area with heat shields.

20) Ensure adequate ventilation for solder work.

21) Connect and solder all necessary joints.

22) Check all joints.

23) Liaise with facilities manager to turn water supplies back on.

24) Carry out further checks for water tightness and quality of finish.

25) Chlorinate the system if required and check for successful completion.

26) Request facilities manager to inspect works.

27) Issue certificate of completion and chlorination to facilities manager.

28) Pack tools and equipment and leave area clean and tidy.

29) Maintain fire watch for 30 minutes where hot work has been carried out.

30) Report to site office and sign off permit to work.

Series:

Revision Number

Series & Number

Revision Date

Issue Date:

Copyright HS Direct Ltd 2006 All rights reserved

TBA

Page 6 of 7

LOGO

METHOD STATEMENT

GENERAL PLUMBING

Do you need Assistance with Health & Safety,

Employment Law or Subcontractors?

Our group of companies has 3 “Software as a Service” products offering your business the

support it needs to comply with Health, Safety and Employment law.

Safety First Package:

Online system allowing you to create unlimited Risk Assessments, Method statements

and COSHH assessments

Full support from our Safety consultants 7 days a week

Legal Protection Insurance for HSE Prosecutions, Jury Service and other legal

expenses

Fax to site service, call us and we can have your documents sent directly to your

customer

Workforce Management Package:

Employment contracts and staff handbooks for your employees

A host of forms and paperwork required for dealing with employment matters

Telephone support from our HR consultants

Free insurance against Employment Tribunal and other related court costs and

awards

Manage subcontractors in line with legislation and create a PQQ for them to complete

online

Our systems contain many more features. For a demonstration of our systems please visit

www.hsdirect.co.uk or www.eldirect.co.uk

or call us now on

0800 849 6728

Series:

Revision Number

Series & Number

Revision Date

Issue Date:

Copyright HS Direct Ltd 2006 All rights reserved

TBA

Page 7 of 7