Station: NTPC- Simhadri

advertisement

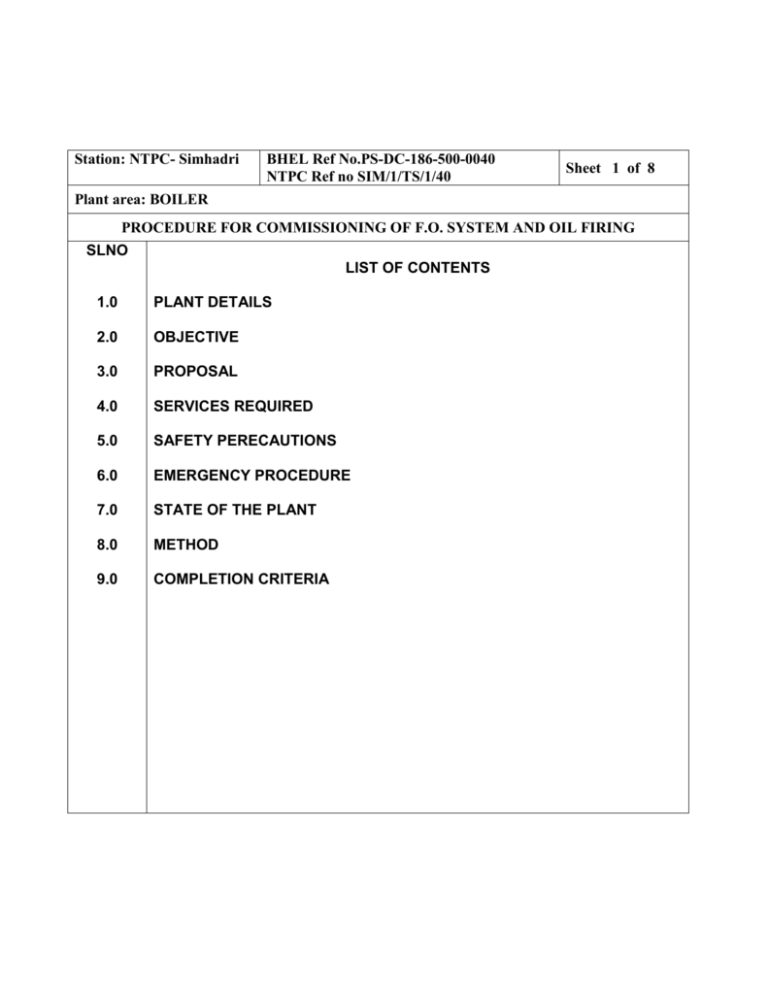

Station: NTPC- Simhadri BHEL Ref No.PS-DC-186-500-0040 NTPC Ref no SIM/1/TS/1/40 Sheet 1 of 8 Plant area: BOILER PROCEDURE FOR COMMISSIONING OF F.O. SYSTEM AND OIL FIRING SLNO LIST OF CONTENTS 1.0 PLANT DETAILS 2.0 OBJECTIVE 3.0 PROPOSAL 4.0 SERVICES REQUIRED 5.0 SAFETY PERECAUTIONS 6.0 EMERGENCY PROCEDURE 7.0 STATE OF THE PLANT 8.0 METHOD 9.0 COMPLETION CRITERIA Station: NTPC- Simhadri BHEL Ref No.PS-DC-186-500-0040 NTPC Ref no SIM/1/TS/1/40 Sheet 2 of 8 Plant area: BOILER PROCEDURE FOR COMMISSIONING OF F.O. SYSTEM AND OIL FIRING SL.NO 1.0 STATUS PLANT DETAILS The Light / Heavy Oil Firing System consists of the following 1.1 Air cooled Oil Gun Assembly 1.2 LDO Supply & Return Trip Valves 1.3 Corner Trip nozzle (Air, Oil & Steam) Valves 1.4 High energy arc ignitor assembly 1.5 Discriminating Scanner Assembly 1.6 Fuel Oil Heaters 1.7 Fuel oil lines from HFO/LDO Pump to Burners 1.8 Atmoising steam line from Aux. PRDS to burners 1.9 HFO Steam Tracing Lines 1.10 Pressure Filters are provided before HFO Heating Station and HFO Trip Valves 1.11 Plant Completion List to be prepared at site prior to commissioning of oil firing system for mechanical, electrical and C&I areas. 1.12 Ref. Drg. No. TP-DG-186-104-3751 (3 Sheet) for the schematic of Oil Firing System Signatures NTPC BHEL Station: NTPC- Simhadri BHEL Ref No.PS-DC-186-500-0040 NTPC Ref no SIM/1/TS/1/40 Sheet 3 of 8 Plant area: BOILER PROCEDURE FOR COMMISSIONING OF F.O. SYSTEM AND OIL FIRING SL.NO STATUS 2.0 OBJECTIVES 2.1 To Commission Fuel Oil System and make it available for Boiler Light up and operation. 3.0 PROPOSALS 3.1 The Commissioning of Fuel Oil System (LFO/HFO) will be carried out as per following proposals. 3.2 Commissioning of LFO System (LFO Firing) 3.3 Commissioning of HFO System (HFO Firing) (Testing Schedules PS-DC-186-500-008 & PS-DC-186-500-0039 to be referred for oil flushing & Aux. PRDS System) 4.0 SERVICES REQUIRED 4.1 Availability of Manpower with required tools for attending to any leak 4.2 Availability of operating personnel to co-ordinate /carry out the activities 4.3 Availability of lighting arrangements near Fuel oil heaters and in fireman’s floor in all oil elevations 4.4 Availability of portable fire fighting equipment 4.5 Availability of L.T. Power Supply 4.6 Availability of Aux. Steam, Light Oil and Heavy Oil 4.7 Availability of Service water / Service air (For LFO atomisation) Signatures NTPC BHEL Station: NTPC- Simhadri BHEL Ref No.PS-DC-186-500-0040 NTPC Ref no SIM/1/TS/1/40 Sheet 4 of 8 Plant area: BOILER PROCEDURE FOR COMMISSIONING OF F.O. SYSTEM AND OIL FIRING SL.NO STATUS 5.0 SAFETY PRECAUTIONS 5.1 Debris in and around Lube oil heater and Fireman’s floor to be removed. 5.2 Approach/Stair Case/Platform where ever required are made available 5.3 Sign boards to be displayed at strategic location to indicate that Oil System is charged and oil burners are ‘ON’. 6.0 PROPOSALS 6.1 First Aid Kit shall be made available 6.2 The test team should know about the procedure to be adopted in case of damage to machinery or injury to personnel connected to the activity 6.3 The Test Team should be well aware of procedures to be adopted in case of any abnormality 7.0 STATE OF THE PLANT 7.1 Hydraulic Test, Steamblown and oil flushing of LDO/HFO and atomising steam line completed. (Refer procedure PS-DC-186500-0008) 7.2 The Fuel Oil Burner Assembly with Scanners and Ignitors are erected as per required drawing. (Oil Gun ‘K’ & KK dimension, scanner orientation & Ignitor Advance / Retract mechanisation checked) 7.3 Steam tracing lines are erected and terminated to suitable outlet point. Signatures NTPC BHEL Station: NTPC- Simhadri BHEL Ref No.PS-DC-186-500-0040 NTPC Ref no SIM/1/TS/1/40 Sheet 5 of 8 Plant area: BOILER PROCEDURE FOR COMMISSIONING OF F.O. SYSTEM AND OIL FIRING SL.NO STATUS 7.4 Power supply system to scanner, ignitor and trip and corner nozzle valve solenoids are commissioned and available for operation. 7.5 Require local/remote I&C input are made available. (List to be prepared at site) 7.6 Filter elements in the system are erected in position 7.7 Corner station are steam blown and corner nozzle valves and burner flexible hoses are reerected. 7.8 Trial run of LDO/HFO Pumps through pump RC completed. 7.9 Steam blowing of LDO, HFO, Atomising Steam Line from Pump House to Ring Header completed. 7.10 Steam Tracing lines are completed. 7.11 24 V DC, 220 V Dc supply with UPS are in charged condition 7.12 Dry simulation of FSSS System for LDO/HFO oil elevation (ABLDO & CD-HFO) completed with required permissives and interlocks (List to be prepared at site) 7.13 Scanners and ignitors are mounted as per drawing. 7.14 Trial run of ID/FD Fans System and Scanner Air fans completed and released for normal operation of plant 7.15 Trial run of APH and availability of ESP to be ensured 7.16 Boiler cleared for light up (Refer to Boiler O&M for other preparatory checks to be made prior to light up) Signatures NTPC BHEL Station: NTPC- Simhadri BHEL Ref No.PS-DC-186-500-0040 NTPC Ref no SIM/1/TS/1/40 Sheet 6 of 8 Plant area: BOILER PROCEDURE FOR COMMISSIONING OF F.O. SYSTEM AND OIL FIRING SL.NO STATUS 7.17 Boiler expansion constraints are removed and ensured for free expansion. Expansion Trans erected at pre-determined locations. (Refer to Quality Plan for locations) 7.18 Availability of instruments and service air to be ensured 7.19 Boiler filled upto normal operating level 7.20 Ash handling system erected and provides required sealing at all required locations / areas. 8.0 Method 8.1 Start ID/FD/APH Systems as per normal start up procedure. (Respective Testing Schedules or O&M to be referred) and establish required furnace draft (Around –5 to –10 mmwc) 8.2 Depending on the availability of SCAPH, it can be charged (SCAPH charging is optional during trial light up of IFO burner, which is done to prove the burners) 8.3 Start the LDO Pump and ensure charging up to fireman’s floor 8.4 Adjust the boiler airflow and windbox DP to the required level 8.5 Put the RC valve operation of LFO Pump on ‘auto’ 8.6 Give command for “start” of LFO burners and watch for flame establishment 8.7 Once the flame is established, ensure a. Oil combustion is proper and b. Flame scanner pick up the flame. 8.8 After few minutes of operation, trip the burner and observe and ensure that shutdown sequence take place as envisaged. Signatures NTPC BHEL Station: NTPC- Simhadri BHEL Ref No.PS-DC-186-500-0040 NTPC Ref no SIM/1/TS/1/40 Sheet 7 of 8 Plant area: BOILER PROCEDURE FOR COMMISSIONING OF F.O. SYSTEM AND OIL FIRING SL.NO STATUS Repeat the above procedure for other LFO Oil Guns 8.9 HFO Firing 8.10 Start ID/FD/APH Systems as per normal start up procedure. (Respective Testing Schedules or O&M to be referred) and establish required furnace draft (Around –5 to –10 mmwc) 8.11 Charge SCAPH and raise the air temperature to around 600C. 8.12 Adjust the boiler airflow and windbox DP to the required level 8.13 Charge 8.14 Start any one of the HFO Pump and after charging HFO Heater, charge HFO line up to boiler and put under short recirculation first and then long recirculation for raising HFO temperature. 8.15 After attaining FIFO firing temperature (around 1150C -- 1200C), give command for HFO burner “start”. Watch the flame establishment. 8.16 Once the flame is established, ensure a. Oil combustion is proper and c. Flame scanner pick up the flame. 8.17 After few minutes of operation, trip the burner and observe and ensure that shutdown sequence take place as envisaged. 8.18 Repeat the above procedure for other HFO Oil Gun, in that elevation a. b. Atomising Steam System and Steam Tracing System Signatures NTPC BHEL Station: NTPC- Simhadri BHEL Ref No.PS-DC-186-500-0040 NTPC Ref no SIM/1/TS/1/40 Sheet 8 of 8 Plant area: BOILER PROCEDURE FOR COMMISSIONING OF F.O. SYSTEM AND OIL FIRING SL.NO STATUS 8.19 Oil Gun, in other elevations are commissioned on similar lines as explained above. 8.20 With the Commissioning of LFO/HFO System, boiler is ready to commence all pre-commissioning activities, such as alkali boilout, steam blowing, safety valve floating, steam dumping etc. 9.0 COMPLETION CRITERIA 9.1 Commissioning of F.O. System and Oil Firing completed by carrying out the proposal, given in Section 3.0. Signatures NTPC BHEL PROCEDURE FOR COMMISSIONING OF F.O. SYSTEM AND OIL FIRING