06 10 00 Rough Car..

advertisement

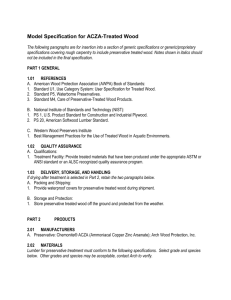

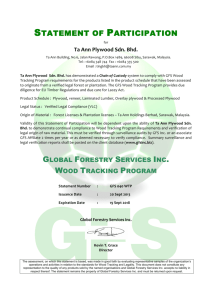

ST. VINCENT COLLEGE SIS AND HERMAN DUPRÉ SCIENCE PAVILION SECTION 06 10 00 - ROUGH CARPENTRY PART 1 - GENERAL 1.01 A. 1.02 A. 1.03 A. RELATED DOCUMENTS Drawings and general provisions of the Contract, including General and Supplementary Conditions and Division 1 Specification Sections, apply to this Section. SECTION SUMMARY Section includes: 1. Plywood a. Plywood, General use. b. Plywood; roof sheathing. c. Plywood; curved sheathing for planetarium outer dome. (ADD#1) 2. Wood Blocking, Nailers, and Grounds. a. Wood blocking in stud space for wall hung casework and base cabinets, including lab casework, tall casework and wood trim. b. Wood blocking in stud space for grab bars and toilet room accessories. c. Wood blocking in stud space for installation of marker boards, chalk boards, bulletin boards, projection screens, and other miscellaneous equipment. d. Wood blocking in stud space for wood base boards, chair rails, moldings, and other wood trim. e. Wood blocking required for installation of windows and skylights. f. Wood blocking required for rooftop equipment, bases and support curbs, roof penetrations. g. Wood blocking where noted on drawings. 3. Rough hardware, lag screws, hangers, bolts, related to Rough Carpentry. 4. Provide any temporary handrails and necessary barricades required for safety precautions. 5. Metal framing anchors. 6. Miscellaneous: a. Fasteners. b. Preservative treated wood. 1) Preservative treated wood for blocking, nailers, grounds in contact with masonry and concrete, including roof and window work c. Building paper. RELATED SECTIONS Related Sections include: 1. 2. 3. Section 01 50 00 - Temporary Facilities; Dust Barricades. Section 03 31 00 - Concrete; Formwork. Section 06 40 00 – Architectural Woodwork. ROUGH CARPENTRY 06 10 00 - 1 (45307035) ST. VINCENT COLLEGE SIS AND HERMAN DUPRÉ SCIENCE PAVILION 1.04 REFERENCES A. Lumber "American Softwood Lumber Standard" PS20. B. Plywood: U.S. Product Standard PSI/ANSI A 199.1 for Construction and Industrial Plywood and American Plywood Association (APA). C. Inspection Agencies 1. 2. 2. 3. 4. 1.06 A. SUBMITTALS Wood treatment data. 1. 2. 3. 4. 1.07 NeLMA - Northeastern Lumber Manufacturer's Association. NLGA – National Lumber Grades Authority. SPIB - Southern Pine Inspection Bureau. WCLIB - West Coast Lumber Inspection Bureau. WWPA - Western Wood Products Association. Preservative-treated wood: provide certification by treating plant stating type of preservative solution and pressure process used, net amount of preservative retained and compliance with applicable standards. Material certificates for dimensional lumber indicating compliance with minimum allowable unit stresses. Indicate species and grade selected for each use and design values approved by the American Lumber Standards Committee's (ALSC) Board of Review. For products receiving a waterborne treatment, include statement that moisture content of treated materials was reduced to levels specified before shipment to Project site. Warranty of chemical treatment manufacturer for each type of treatment. PRODUCT HANDLING A. Delivery and Storage: Keep materials under cover and dry at all times. Protect against exposure to weather and contact with damp or wet surfaces. Stack lumber and plywood, and provide air circulation within stacks. B. Job Conditions: Coordination; Fit carpentry work to other work; scribe and cope as required for accurate fit. Coordinate location of furring, nailers, blocking, grounds and similar supports to allow proper attachment of other work. PART 2 - PRODUCTS 2.01 A. MATERIALS Lumber, General: Factory-mark each piece of lumber with type, ROUGH CARPENTRY 06 10 00 - 2 (45307035) ST. VINCENT COLLEGE SIS AND HERMAN DUPRÉ SCIENCE PAVILION grade, mill and grading agency, except omit marking from surfaces to be exposed with transparent finish or without finish. B. Nominal sizes are indicated, except as shown by detail dimensions. Provide actual sizes as required by DOC PS 20, for moisture content specified for each use. C. Provide dressed lumber, S4S, unless otherwise indicated. D. Provide seasoned lumber with 19% maximum moisture content at time of dressing for lumber; 15% maximum moisture content for plywood. E. Provide lumber graded by an agency certified by the ALSC Board of Review. 2.03 MISCELLANEOUS LUMBER (WOOD BLOCKING) A. Grade: B. Species: 1. 2. 3. 2.04 A. No. 2 or better. Provide one of the following: Douglas Fir or Douglas-Fir-Larch graded, respectively, under WCLIB or WWPA rules. Southern Pine graded under SPIB rules. Hem-Fir (North) NLGA. PLYWOOD Plywood Panels for Signage: exposure to the weather. 1. 2. 3. Exterior type plywood for permanent Exterior grade plywood panels; MDO (Medium Density Overlay) Ext. APA, PSI-83. Size: 4 ft. x 8 ft. x 3/4 inch thick,(1219 x 2438 x 20mm) smooth finish (without grooves), ship lap edges. a. Shop cut ship lap edges and shop prime. Factory primed both sides and edges. B. Plywood Backing Panels: for telephone, data, security and electrical equipment. DOC PS1, Exposure 1, C-D plugged, not less than ½ inch (13mm) thickness. C. Plywood, General: Douglas Fir CD-INT-APA (exterior glue) 4 ft. x 8 ft.(1219 x 2438mm) x thickness required. Square edges. D. Plywood Roof Sheathing: Douglas Fir 3/4" APA Rated Sheathing 32/16, Group 1, Exposure 1, Structural Grade I: : 4 ft. x 8 ft. x 3/4 inches(1219 x 2438 x 20mm) thick. Square edges. (Note: if Contractor wishes to provide nailable insulation as an option to roof sheathing; top layer of sheathing on nailable insulation must be ¾” thick) 1. Plywood for planetarium outer dome to be curved to dimensions shown. (ADD#1) ROUGH CARPENTRY 06 10 00 - 3 (45307035) ST. VINCENT COLLEGE SIS AND HERMAN DUPRÉ SCIENCE PAVILION 2.05 A. MISCELLANEOUS Fasteners: Of size, type, material and finish suited to application shown and complying with applicable standards including FS FF-N-105 and FF-W-92 and ANSI B18.6.1. Provide metal hangers, framing anchors, bridging, tie-downs and hold-downs of size and type recommended for intended use by manufacturer. Hot-dip galvanized fasteners for work exposed to weather, in ground contact, preservative treated wood, and high relative humidity areas; comply with ASTM A 153. 1. 2. 3. 4. 5. B. Nails, brads and staples: ASTM F 1667. Power driven fasteners: NES NER-272. Wood screws: ASME B 18.6.1. Bolts: ASTM A 307, Grade A. Hex nuts: ASTM A 563. Preservative Treated Wood: Preservative pressure treat lumber and plywood with waterborne preservatives to comply with American Wood Preservers Association (AWPA) C2, and with requirements indicated below: 1. 2. 3. Wood for Above-Ground Use: AWPB LP-2. (.25 pound per cu. ft.(4.3kg/cu.m) retention). Wood for ground contact: AWPB LP-22 (.40 pound per cu. ft.(6.36kg/cu.m) retention). Preservative treated wood for sills, sleepers, blocking, furring, stripping and similar items in direct contact with masonry or concrete, including roof and window work. C. Building Paper: Asphalt saturated felt, non-perforated ASTM D 116. 15 lb. weight unless otherwise noted. D. Sill sealer gaskets: closed-cell neoprene foam, ¼ inch (6.4mm) thick, selected from manufacturer’s standard widths to suit width of sill members. PART 3 - EXECUTION 3.01 INSTALLATION, GENERAL A. Discard units of material with defects which might impair quality of work, and units which are too small to use in fabricating work with minimum joints or optimum joint arrangement. Fit rough carpentry to other construction, scribe and cope as needed for accurate fit. B. Set carpentry work to required levels and lines, with members plumb and true to line and cut and fitted. C. Securely attach carpentry work to substrate by anchoring and fastening as shown and as required by recognized standards. D. Countersink nail heads on exposed carpentry work and fill holes. ROUGH CARPENTRY 06 10 00 - 4 (45307035) ST. VINCENT COLLEGE SIS AND HERMAN DUPRÉ SCIENCE PAVILION E. Use common wire nails, except as otherwise indicated. Use finishing nails for finish work. Select fasteners of size that will not penetrate members where opposite side will be exposed to view or will receive finish materials. Make tight connections between members. Install fasteners without splitting of wood; predrill as required. F. Use bolts or screws approved by the Architect to attach wood blocking to metal studs. Countersink fasteners. Fasteners shall be cadmium plated. G. Pre-drill all nail holes in preservative treated lumber. H. For exposed work, arrange fasteners in straight rows parallel with edges of members, with fasteners evenly spaced with adjacent rows staggered. 3.02 A. PLYWOOD SHEATHING Panels shall be installed horizontally, with end joints staggered over supports (face grain across supports). 1. 2. Leave 1/8 inch (3mm)space between panel edge joints. Leave 1/16 inch(1.5mm) space between panel end joints. B. Use minimum 8d nails spaced 6 inches(150mm) along panel edges and 12 inches(300mm) along intermediate supports. (Use ring shanked nails for roof sheathing). C. Cover roof sheathing with building paper, lapped and nailed with aluminum or galvanized roofing nails. D. Roof sheathing installation to meet FM Class 1-60 requirements. 3.02 A. WOOD BLOCKING, NAILERS, AND GROUNDS Provide wherever shown and where required for screeding or attachment of other work. Form to shapes as shown and cut as required for true line and level of work to be attached. Coordinate location with other work involved. 1. 3.03 A. Attach to substrates as required to support applied loading. Countersink bolts and nuts flush with surfaces where required. PROTECTION Protect rough carpentry from weather. If, despite protection, rough carpentry becomes wet, apply EPA-registered borate treatment. Apply borate solution by spraying to comply with EPA-registered label. END OF SECTION ROUGH CARPENTRY 06 10 00 - 5 (45307035)