surface treatment

advertisement

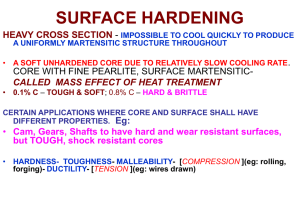

Practical Heat Treatment Training programs on video by the ASM International SURFACE TREATMENT Exercise2 Read the following text of the video film and collect 20 of the most important engineering expressions! 1 01:13 01:46 There are many reasons to perform surface treatments on metal parts. Some of the main reasons are to add stiffness to the part, increase wear resistance, increase fatigue strength, prevent galling; correct a prior surface problem, increase corrosion resistance, increase load-carrying ability, replace lost alloying elements, and simply to increase overall strength. There are four categories of surface treatments.(movie1) They are workhardening, metal alloy build-up, phase change hardening and alloy diffusion. Work Hardening Now, let's talk first about work hardening. Work hardening does several things; it increases the fatigue strength, it minimizes stress corrosion, it increases bending strength, and it increases wear resistance. It does this by imparting compressive stresses and hardness to the surface. 02:08 A very common method of work hardening the surface is shot peening.(Fig.1) In shot peening, hardened steel shot is forced or thrown against the part. This is usually done with the shot being carried in an air blast. Both the size of the shot and its velocity determine how deep the affected layer will be. Typically, the depth of work hardening is between five to ten thousandths of an inch. It is important that the part is not stress relieved and that no grinding or other machining is performed after shot peening. A common misconception about shot peening is that it is a stress relieving process, but it is actually just the opposite. Shot peening is a stress inducing process. It work hardens the surface, which results in compressive stresses. This increases fatigue resistance and minimizes susceptibility to stress corrosion. These are two major reasons for shot peening. The process is most effective on parts that have been prehardened. 03:09 Coining (movie2) tends to be more of a volume work-hardening method than a surface hardening method, but it does harden the surface to a greater extent. In coining, an area of the part is compressed. As we have noted, compressive stresses increase the fatigue strength and the material's resistance to stress corrosion cracking. (Fig.2) Stress corrosion cracking generally occurs when the surface of a part, which is exposed to a specific corrosive medium, is placed in tension. 03:32 Another work hardening method is burnishing. (Fig.3) There are two main types of burnishing; ball burnishing and roll burnishing. Ball burnishing is a process that is performed on crankshafts, where the bearing area joins the counter-weights or where it joins the throws. This area is ball burnished. A hardened ball is forced against the radius and it work hardens the surface in that area. As with other processes, burnishing leaves the treated surface with a net compressive stress. Ball burnishing is generally done in localized areas, to increase the fatigue strength at specific locations of shafts and bolts in materials which are subject to fatigue failure. Roll burnishing has the same effect, but covers a much larger area. To review, work hardening by shot peening, coining or burnishing is applied to the part after all heat treatments have are completed. Parts are not stress relieved or ground 2 afterwards. The processes are used to give the part surface compressive stresses, which improve the resistance of the part to fatigue or stress corrosion damage. 04:40 Metal Alloy Build-Up The second surface treatment we will discuss is Metal Alloy Build-Up. Again, this type of surface finishing is not directly performed during the heat treating process. Metal Alloy Build-Up is used to increase the corrosion resistance of the material, increase its wear resistance and sometimes just to increase the size of the part. 05:00 One such method is called Braze Build-Up. (Fig.4) In this process, an alloy is added to the surface of a part by brazing, and it alone provides the desired properties. Occasionally, the braze alloy is mixed with a ceramic, abrasive resistant material to improve the wear resistance of the layer. This type of build-up is used on low alloy hardenable steels. If the part was heat treated first, the heat from the brazing operation would tend to oversoften the quenched and tempered steel. 05:33 A very similar method is Weld Build- Up. (Fig.5) The difference between the two is that in a weld build-up there is melting of both the weld material and the base metal. In braze build-up only the build-up is melted. An example of weld build-up is a stainless steel welded surface on an alloy steel backing. The stainless layer is added to impart corrosion and oxidation resistance to the underlying alloy steel. Some parts may be hardened and tempered after this treatment is performed, to restore certain properties to the alloy. 06:05 Flame Spraying (Fig.6) is yet another way to build up or add metal to the surface of the part. Here, the metal, either in powder or wire form, is fed into an oxyacetylene or plasma torch. The powder or wire is melted in the gas of the torch and is sprayed onto the part by the force of the gas exiting the nozzle. The liquid metal drops, frees and bonds to the part on contact. Compressed air can be used in some processes to accelerate the particles. This process is often used to build up worn areas of the part. The parts are generally not heat treated after this process. If they are, the flame-sprayed material tends to spall off. Today, there is more and more use of inert gas and vacuum sprayed plasma coatings. These provide better adherence, less oxidation of the coating particles, and a wide variety of coating alternatives. 07:00 Another metal alloy build-up process is Plating. Plating is used generally for three reasons: to change the size of the part, increase the corrosion resistance, or to change the characteristics of the surface. Four different methods of plating are liquid Electrochemical plating, vapor plating, plasma plating and mechanical plating. We will briefly discuss each of these methods. 07:25 Liquid bath electrochemical plating is performed on all types of parts. Chromium, zinc, copper and nickel are metals that are commonly plated on parts for increasing wear and corrosion resistance. Chromium (Fig. 7) is used on heat treated parts to increase their wear resistance in certain areas. Typical uses are bearings and landing gear parts. Nickel (Fig. 8) may be plated on parts to increase corrosion resistance, improve wear, or to act as a base for brazing stainless steels, providing a good joint filler and wetting the surface to be brazed. Zinc (Fig. 9) is plated to provide sacrificial corrosion protection, while copper (Fig. 10) is used to improve the efficiency and performance of electrical connectors, as well as being a primary masking material used in the carburizing and nitriding processes. 3 08:12 09:12 Vacuum or vapor plating (Fig. 11) is one of several physical vapor deposition systems utilizing vacuum technology to vaporize metals and subsequently deposit the vaporized metal onto the substrate or part to be plated. The metal vapor can be obtained by different methods, depending on the metal to be deposited. Evaporation can be accomplished by resistance heating of the metal to its boiling point, by part evaporation, or by electron beam melting. The parts to be plated are fixtured on racks, which are then loaded into the vacuum chamber for processing. Typical materials that are plated are chromium, aluminum and cadmium. Common applications of vacuum or vapor plating, sometimes referred to as vacuum metallising, include the coating of plastic automotive trim with chrome for decorative purposes, aluminum coatings of headlight reflectors (Fig. 12), and cadmium plating of components for corrosion protection without hydrogen embrittlement. Plasma plating, utilizing glow discharge techniques, can be viewed as a modified vapor plating process, wherein the plasma or glow discharge is used to accelerate and improve the efficiency of the plating. This is achieved in several ways; by vaporizing the material to be plated, accelerating the deposition rate, improving the substrate cleaning prior to plating, and by improving the uniformity of the plated layer. One emerging example of this technique is Ion Vapor Deposition of aluminum. The ion vapor deposition process (movie3) is similar in sequence to conventional plating operations, requiring preparation, processing and finishing operations, in order to correctly process parts to be coated. The preparation stage consists of a degreasing operation to remove gross contaminants prior to an aluminum oxide blast treatment, which textures the part surface and removes any solid contaminants. The preparation stage would also include any masking operations required. Suitable low out gassing masking tapes, or metal foils are typical materials used. Part racking or barrel loading operations precede the charging of loads to the IVD vacuum chamber. (movie4) The vacuum vessel is evacuated to a pressure of 8x10-6 Torr to purge the system, prior to vac filling with argon, to 2x10-2 Torr. At this pressure, the parts are subjected to a flow discharge cleaning or sputtering operation. A high negative potential is applied between the parts being coated and the evaporation source. The argon gas in the chamber ionizes and creates a glow discharge around the parts, bombarding them with positively charged ions. (Fig. 13) This ion bombardment of the part surface effects a final cleaning operation prior to coating. The evaporated boat system contained within the vacuum chamber is heated and continuously fed with aluminum wire. The aluminum evaporates and passes through the glow discharge, where it combines with the ionized argon and is transported to the part surface. In this way, pure aluminum is plated on the part surface, providing a uniform, dense, adherent coating. Following the coating operation (Fig.14), parts are removed from the process chamber, and post-treated operations are applied. In order to densify the aluminum coating, the parts are glass bead peened (Fig. 15) using a number ten glass bead. This operation also serves to polish the coating and cosmetically improve its appearance. The primary purpose of this peening operation is to improve the corrosion resistant performance of the coating. It should be noted, however, that the glass bead peening operation also serves as a one hundred percent quality control check on the coated part; any flaw in coating adhesion being highlighted by this operation. The final post-treatment operation 4 is the application of a conventional chromate conversion coating-, which prepares the aluminum surface for finishing and improves the corrosion performance of the coating. The IVD aluminum coating equipment consists of a steel vacuum chamber, a pumping system, a parts racking or barrel tumbling device, an evaporation source and a high voltage power supply. (Fig. 16) The system utilizes conventional vacuum technology components, controlled by a microprocessor-based control system, capable of monitoring system sequencing, system alarms, process timing and datarecording functions. Another example of this type of process is the coating of cutting tools with titanium nitride, to provide a hard, adherent surface coating. Two basic types of processes are available for deposition of titanium nitride coatings: Chemical Vapor Deposition, or CVD, and Physical Vapor Deposition. CVD (Fig.17) requires temperatures in the areas of 1850 oF. In this process, a gaseous metal chloride reacts with hydrogen and nitrogen to form titanium nitride; because of the high temperature of the reaction, and the need to reheat tooling after coating to develop the necessary substrate hardness, some distortion is inevitable. On the other hand, Physical Vapor Deposition, or PVD, can be performed at less than 930'F, a temperature well below that required for the tempering of high speed steels. Several types of PVD systems are available: Evaporative Electron Beam Melting, Cathodic Arc Deposition and Sputter Ion Plating, or SIP. S I P i s a p a t e n t e d p r o c e s s , 5 d e r i v e d f r o m t h e c o a t i n g m e t h o d s u s e d f o r m a n y y e a 6 r s i n t h e s e m i c o n d u c t o r i n d u s t r y . T h e a d v a n t a g e s o f 7 S p u t t e r I o n P l a t i n g c a n b e s t b e s u m m a r i z e d a s f o l l 8 o w s : g o o d p r o d u c t q u a l i t y , e a s e o f e q u i p m e n t m a i n t e 9 n a n c e , a n d h i g h p r o d u c t i v i t y . S I P t i t a n i u m n i t r i d e 10 c o a t i n g s ( F i g . 1 8 ) d e m o n s t r a t e g o o d a d h e r e n c e , h i g h 11 i n t e g r i t y , h i g h h a r d n e s s , a n d a u n i f o r m m i c r o c r y s t a 12 l l i n e s t r u c t u r e . S I P s y s t e m s a l s o p r o v i d e r e p l i c a t i 13 o n o f t h e s u b s t r a t e s u r f a c e f i n i s h a n d a n e x c e l l e n t 14 g o l d c o l o r . B e c a u s e o f t h e s i m p l i c i t y o f c o n s t r u c t 15 i o n , S I P e q u i p m e n t t e n d s t o o f f e r a h i g h u p t i m e a n d 16 m i n i m u m m a i n t e n a n c e . P e r h a p s t h e m o s t i m p o r t a n t ; i 17 t p r o v i d e s u n i f o r m c o a t i n g o f c o m p o n e n t s o f d i f f e r e 18 n t s i z e s a n d s h a p e s i n a s i n g l e w o r k l o a d . Th e SI P pr oc es s 19 (Fi g. 19 ) uti liz es a gl o w dis ch ar ge to fre e tit an iu m fro m a lar ge tit an iu m tar ge t. Tit an iu m at o ms re act wi th nit ro ge n to for 20 m tit an iu m nit rid e. Tit an iu m nit rid e is att ra cte d to th e w or kp iec es, w hi ch ar e po sit iv el y ch ar ge d. Th e pr oc es s is pe rfo 21 rm ed in a ch a m be r un de ra so ft va cu u m of nit ro ge n an d ar go n, an d ab ou t 10 0 mi cr on s pr es su re. Th e va cu u m is ac 22 hi ev ed usi ng m ec ha ni cal pu m ps, eli mi na tin g th e ne ed for dif fu sio n pu m ps, co ldtra ps or cr yo ge ni c pu m pi ng sy ste ms . Th e 23 w or k to be co ate d is fir st cle an ed usi ng de gr ea ser s, aci d an d ba se, rin se s an d ult ras on ic dr yi ng , ta nk s. (Fi g. 20 ) Th e w or 24 k su rfa ce m ust be ox id efre e for go od co ati ng ad he re nc e. W he n cle an ed , pa rts ar e lo ad ed on a sta tio na ry fix tur e, w hi ch is lo 25 we re d int o th e co ati ng ch a m be r. (Fi g. 21 ) W ith th e w or kl oa d in pl ac e, th e co ati ng ch a m be r is ev ac ua te d an d a 26 lo w he ate d to ap pr ox im ate ly 50 0' wi th ex ter na l he ate rs. Th is ste p en su res re m ov al of an y m ois tur e or tra ce hy dr oc ar bo ns th 27 at mi gh t be pi ck ed up by th e fix tur e or pa rts aft er cle an in g. (m ov ie 5) In th e ne xt ste p, ar go n is int ro du ce d int o th e ch a 28 m be r an d th e w or k is ne ga tiv el y ch ar ge d to 50 0 V olt s. Io ni ze d ar go n bo m ba rd s th e w or kp iec es, sp utt er cle an in 29 g th e su rfa ce of th e pa rts to be co ate d. Th is ste p re m ov es ox id es or co nt a mi na tio n, as su rin g a go od bo nd . O nc e th e co 30 ati ng te m pe rat ur e is re ac he d, th e bi as on th e w or kp iec e is re ve rse d, so th at th e gl o w dis ch ar ge oc cu rs on th e tit an iu 31 m so ur ce. Th e ins id e wa lls of th e ve ss el ar e th or ou gh ly lin ed wi th tit an iu m to pr ov id ea lar ge , un ifo rm so ur ce for co ati ng . 32 Ar go n io ns bo m ba rd th e tit an iu m lin in g to rel ea se tit an iu m at o ms , w hi ch ar e th en de po sit ed on to th e po sit iv el y ch 33 ar ge d w or kp iec es. (Fi g. 22 ) W he n nit ro ge n is ad de d, a tit an iu m nit rid e co ati ng is for m ed . 16:50 Lastly, there is Mechanical Plating. Mechanical Plating is a method of plating parts by tumbling or burnishing the parts in an environment where the plating material, in powder or plate form, is mechanically forced against the part. In this way, by repeated contact between the parts and the plating material, the plating material mechanically bonds to the part. 34 17:13 Phase Change Hardening Hardening of the surface can also be done by locally heating just the surface. This is called Phase Change Hardening. (movie 6) Phase Change Hardening increases the hardness of the surface to a controlled depth below the surface. Carbon steels, alloy steels, cast iron and some tool steels are often treated by this method. What is Phase Change Hardening? It is a method by which the metal is heated through the surface to form austenite at a specific depth, and then cooled to form martensite. The four common methods of heating for Phase Change Hardening are: induction, flame, electron beam, and laser beam. Let's look at these processes more closely: 17:55 Induction hardening (movie7) is a non-contact hardening process. The work is heated by causing an electrical current to flow in the surface of the part by close proximity to a high frequency induction field. The lower the frequency, the deeper the heating. The higher the frequency, the more shallow the heating. Heating is very rapid (Fig.23) and tends to follow the surface of the part. Often, a round coil can be placed around a small gear that has teeth on the outer diameter and the heating will follow the contour of the teeth. The length of time that the current is induced in the part, plus the power density used, determines how high a temperature the part reaches. To develop shallow cases, for example, five to ten thousandths of an inch deep, the base material may act enough as a heat sink to fully harden the material to martensite. For deeper cases, such as 18 to 20 thousandths of an inch or more, it is common to quench the part in oil, polymer solution, or water. Heating times are very short, and usually measured in seconds. As a result, pieces can be heated one at a time very efficiently. Induction hardening has been used, for example, for hardening automobile axles and camshafts. Here's an example (movie8) of how camshaft lobes are selectively hardened with induction heating. The camshaft is first loaded into a specially designed induction coil. Then, the part is rotated for heat uniformity. (Fig.24) Notice how the lobes slowly heat up to a reddish-orange color. Finally, the camshaft is unloaded with the aid of a robotic ripper, is placed in a quench chamber, a hood is lowered to collect and contain fumes generated by the quenching operation, and the camshaft is quenched to attain the desired hardness in the lobe sections. In this next scene, a bar is loaded into the induction scanner. Watch as the coil moves along the bar, progressively heating and then quenching the bar. Notice how the bar is rotated for heat uniformity and is supported to help control distortion. To rapidly heat a specific area of a steel part to austenitizing temperature, flux concentrators (movie9) are attached to the inductor. These are made from ferritic powder or silicon electrical steel. The flux concentrator compresses and directs the magnetic flux lines through the surface of the parts to be heated. Concentrators can be used to tailor the heating pattern to a particular part geometry. These are often used in combination with coils, specifically conformed to a gear profile. (Fig.25) 20:37 In flame hardening (Fig.26), the part surface is heated with a flame-head burner. The flame is produced by oxygen, mixed with either acetylene mixed gas, or hydrogen. The surface is brought to a high enough temperature to form austenite and then the part is quenched by a liquid spray, or air hardened if the material is an air hardening metal. Flame hardening is one of the oldest and simplest methods for hardening specific areas of a particular part. For instance, this crane wheel (movie10) is flame hardened where it comes into contact with the rail. A part this size would be very difficult and expensive to harden any other way. Occasionally, the inside diameter may be hardened to provide a bearing surface. Flame hardening can also be used to harden the inside diameter of a part if the bore is large enough to accept the flame heads. Forged wheels are annealed and pre-hardened and tempered prior to flame hardening. 35 21:39 Another method of surface phase change hardening of steel uses an electron beam (Fig.27) to heat the surface by a high energy stream of electrons. A beam of high speed electrons, very similar in principle to the beam of electrons in a TV set, but with much higher energy, is focused on the surface of the part. This beam focuses several kilowatts of power in a spot less than one quarter of an inch in diameter. As a result, the surface at that spot is heated almost instantly to the austenitizing temperature. (Fig.28) The beam is moved electronically in a pattern to heat a broad area of the surface. Because the surface is heated to only a few thousandths of an inch deep, the unheated material underneath cools the surface fast enough to harden the part as the beam moves. Although the surface can be quickly heated in a very fine and controlled pattern, the system must be programmed to avoid overheating. Also, electrons are very easily scattered at normal atmospheric pressure. Because of this, electron beams must be close to the part and the part must be normally in a high vacuum chamber. In spite of this, processing times can be very short, with high precision. One example is the hardening of the roll on an automatic typewriter. The roll is placed in a chamber and rotated under the beam. The beam hardens the surface of the roll in a spiral pattern with no distortion. 23:09 Laser hardening is similar in principle to electron beam, except that the beam is high energy light. There is no special chamber required. The light energy heats the surface to the austenitising range, and the part self quenches. The unique part of the process is that the energy beam can be directed into almost totally inaccessible areas using mirrors. (Fig.29) By rotating the mirror and controlling the beam it is possible to harden areas of a part that would be very difficult to harden any other way. Since it is light energy, shiny surfaces must be coated black to absorb the energy for good efficiency. One example would be a clutch on an automatic transmission that is laser hardened on the back of the clutch. There are many variations of these local heating processes. Alloys can be made by diffusing coatings with the heat source, for example. The key is that heat is very locally applied to heat only a portion of the outer surface. The heat source does not need to be a point source of beam. For example, in rotation hardening, the rim of a part or the teeth of a gear are hardened by placing the part into the salt bath only as deep as it needs to be hardened, rotating it in the bath. (Fig.30) As the part is rotated, the rim is heated and can be hardened by quenching. This process is similar to flame hardening, and is used to give the part wear- or load-carrying capabilities. (movie11) The rest of the part can be left in a softer condition for further machining, or for toughness and ductility of the overall part. 24.45 To summarize, we have discussed four different methods of phase change hardening: Flame hardening is used for deep hardening. The process uses simple equipment, is portable, and requires a lot of experience. The second method is induction hardening. It can rapidly provide a contoured case, is energy efficient, case properties are easily controlled, and the process can automatically treat large numbers of similar parts in sequence. Electron beam hardening, as a third method, can be used to provide a very intricate surface hardened pattern, even on very tiny parts. The fourth method, laser hardening, is similar to electron beam, except that it can be done in air, and the beam can be directed by mirrors. Both electron beam and laser hardening can produce hard surfaces with no distortion. 36 25:38 Alloy Diffusion The next category of surface treatment we will discuss is surface hardening by alloy diffusion. The three most common alloy diffusion surface treatments are nitriding, carburizing and carbonitriding. All of these involve adding nitrogen, or carbon, or both, to aid in the hardening of the surface. 25: 58 Nitriding involves absorption of nitrogen into the surface of the steel. The steel is heated to a temperature range between 800 oF and 1050 oF. Today, there are three methods used to nitride. These are salt bath, gas, or ion, also known as plasma nitriding. Most materials nitrided are alloy steels, however, tool steels, nickel-based alloys, stainless steels, and even titanium are successfully nitrided. The key to successful nitriding is the conversion of nitrogen to a form that can be absorbed into the metal. Air is 80% nitrogen. However, that is molecular nitrogen, also known by its chemical formula, N2; that is, two atoms of nitrogen, combined to form a molecule. Nitrogen in this form is not readily soluble in iron or other materials. When the nitroge n molec ule is split into its two indepe ndent atoms, it can be absorb ed. In the atomic form, it is also called "nasce nt" nitroge n. Atomi c, or nascen t, nitroge n is obtain ed by decom positio n of 37 ammo nia gas, NH3, at the surfac e of the work, by the follow ing reactio n: two molec ules of ammo nia, plus heat, gives two atoms of nitroge n, plus three molec ules of hydrog en. (Fig.3 1) The nitroge n, in this atomic form, diffuse s into the surfac e of the steel. Nitrog en atoms, that do not diffuse , join to form nitroge 38 n molec ules, and are swept away in the effluen t gas. The depth that is achiev ed during the proces s at a consta nt temper ature is depen dent upon time. The depth of the case is related to some consta nt for the temper ature used, times the square root of time. Now, what this means is that if you can get five 39 thousa ndths of an inch case in four hours, with everyt hing else equal, you will get approx imatel y ten thousa ndths of an inch in sixteen hours. To double the case, you have to go four times the length of time. The hardne ss of the case (Fig.3 2) obtain ed during the nitridi ng proces s is depen dent upon 40 the micros tructur e that you start with, and the alloy that you're nitridi ng. Materi als that contai n alumin um and chromi um form very hard nitride s. Iron forms fairly hard nitride s, but iron nitride s are very brittle, and tend to spall, or chip, off. When nitroge n is absorb ed by steel, two distinc t zones can be 41 created in the case. (Fig.3 3) At the surfac e, iron and other strong nitride formin g eleme nts, such as chromi um, readily form high nitroge n compo unds in a very thin layer at the surfac e. This layer has been called the white layer, or compo und zone, and is normal ly betwee n two ten thousa ndths and 42 one thousa ndth of an inch thick. The second re-ion is the diffusi on zone, which contai ns less nitroge n. The depth of this layer contin ues to build as the metal is held at temper ature. We will revisit this subject shortly , but first let's discus s the differe nces in the three nitridi ng proces ses. The three main nitridi ng 43 proces ses; salt bath, gas, and ion, differ in the way that they create atomic nitroge n, but all share the fact that the purpos e is to make nitroge n availa ble for absorp tion in the metal. 29:27 In salt nitriding, the parts are immersed in a bath containing nitrogen compounds. These chemically decompose and release nitrogen to the surface. In earlier days, the compounds were cyanide salts. Today, formulations without cyanide have replaced the older compounds. The salt bath compounds also contain some carbon, which is also transferred to the surface. 29:54 The salt and gas treatments which provide carbon in addition to nitrogen form a special class of nitriding, known as Nitrocarburising. The gas nitriding process uses ammonia gas to release atomic nitrogen to the metal. The surface of the metal, especially iron, acts as a catalyst to break ammonia into its component parts. Some of the atomic nitrogen is absorbed, but most reforms into molecular nitrogen. This process is relatively simple in principle, but is rather difficult to control in practice. This is because the atmosphere does not become stable relative to the work. It also is affected by the surface area, or number of parts, put in a given vessel. To make it simple, a large excess of ammonia is used. This results in excess nitrogen absorbed, with an excessive white layer. This white layer must then be removed because of its brittleness. Some improvements have been made over years of experience to control this build-up. In the flow process, the concentration of ammonia is reduced in the second half to two thirds of the cycle. This is usually done by increasing the amount of alreadydissociated ammonia. When this is done, the nitrogen diffuses into the case, reducing the white layer. However, if the white layer is to be completely removed, it must be done by grinding the part after nitriding. 44 31:25 The third major nitriding process is called ion nitriding or plasma nitriding. (Fig.34) These names were given to the process because of the way atomic nitrogen is Generated and transferred to the part surface. Ion nitriding is carried out in a vacuum chamber. (Fig.35) Ordinary nitrogen is introduced and the pressure is held at between one and ten Torr. Remember, normal atmospheric pressure is 760 Torr. A voltage potential of about 450 Volts is applied between the inside of the vessel and the work support on which the parts are placed. This causes the parts to be negatively charged. They become the cathode in the electrical circuit formed. The high voltage causes the nitrogen to be positively ionized, which allows them to be absorbed into the part surface. Nitrogen ions move to the negative part surface, pick an electron, and diffuse into the surface. The ionization process and electron recombination cause a re-ion in the gas near the part surface to glow with a bluish-purple color (Fig.36), which is why the process is also known as a glow discharge process. This ionization process is very efficient. The nitrogen in the -as is readily transferred to the part, meaning that very little nitrogen is required for nitriding. In addition, the surface is cleaned during nitriding, by a process known as sputtering. This means that metal, such as stainless steel, can easily be nitrided. The oxide, which is always present on stainless steels, is very stable at nitriding temperatures. In ion nitriding, this oxide is removed by sputtering, allowing the nitrogen to penetrate the surface. In gas, or soft, nitriding the oxide would need to be chemically removed, or mechanically blasted. Also, because the process is electrical in nature, the white layer composition and thickness can be easily controlled and even eliminated. The ion nitriding process is growing in importance for other reasons, the major ones of which are summarized (Fig.37) here: all steels are nitrided in the hardened condition; most materials can be used directly after nitriding with only minimum finishing; these materials usually do not need quenching, therefore, and are gas- or air-cooled from the nitriding temperature. Other comparisons will be made after we have finished discussing carburizing. 34:00 Carburizing, which, as one might guess, is the process of adding carbon to metal, is also a diffusion process. It differs from nitriding in two basic ways: First, the temperature is in the austenite field, between 1500 and 1900 oF. The higher the temperature, the faster the carbon diffuses into the metal. The longer the time in the furnace, and the higher the temperature, the deeper the case. These relations are well known and are usually plotted as straight lines on a logarithmic plot, as shown here. (Fig.38) The graph says, for example, that if we hold steel at 1700 oF for ten hours, we can predict the depth that carbon will be diffused into the steel. The second difference from nitriding is re ate to the process parameters. Since carburizing is carried out at the austenitizing temperature, the part can be quenched to hard martensite. The maximum attainable hardness of steel parts is a function of the carbon content, reaching a maximum at about 0.8% carbon. The depth below the surface at which the carbon is about 0.3 to 0.4%, hardens to approximately 50 Rockwell C hardness (HRC). This depth is commonly referred to as the affected case depth. The carbon profile is controlled by the concentration of the carbon at the surface and the rate of diffusion at the temperature used. A typical profile is shown (Fig.39), along with the hardness that resulted after quenching. Carburizing is a very attractive process. The hardened depth can be reached much faster than in nitriding. The atmosphere is also very close to equilibrium. This means that the carbon at the surface can be predicted by measuring the composition of the gas, as we will discuss shortly. 45 Just as in nitriding, carburizing can be done in different ways. These all relate to the method of getting the carbon to transfer to the surface of the part. There are five main commercial processes. These are: liquid, pack, gas, vacuum, and ion or plasma carburizing. 36:25 Liquid carburizing is done in a molten salt bath containing salts that liberate carbon. Usually chlorides are added. Other metal salts are there to control the fluidity and fume in the bath. Here the released carbon, and a little bit of nitrogen, is absorbed in the steel part during this process. 36:44 In pack carburizing (Fig.40), the parts are surrounded by a carbon-containing material in a suitable container. Typically, charcoal and coke are used, and mixed in with the charcoal and coke is an activator such as barium carbide, which releases carbon dioxide when heated. Carbon dioxide reacts with carbon in the charcoal and coke to form carbon monoxide. Carbon gets from the solid charcoal and coke to the surface of the part via the carbon monoxide. Two molecules of carbon monoxide release one carbon atom to the surface of the face centered cubic austenite, and the carbon atoms diff-use inward to form the case. The pack carburizing process was the first carburizing process developed. Because it is labor intensive and dirty, much pack carburizing has been replaced by gas carburizing. 37:35 In gas carburizing, the parts are heated to austenite in an atmosphere that contains carbon monoxide, carbon dioxide, nitrogen, hydrogen, water vapor, and enriching gases such methane or propane. In almost all cases, gas carburizing, is done with an endothermic atmosphere as the carrier gas (Fig.41). This is a generated atmosphere that is approximately 38% nitrogen, 40% hydrogen, 20% carbon monoxide, 1% carbon dioxide and 1% water vapor maximum, and extremely minute amounts of oxygen. A similar type of endothermic atmosphere can be generated in the furnace by cracking methanol and adding nitrogen. It is the carbon monoxide to carbon dioxide ratio. and the hydrogen to water vapor ratio, that determine the carbon potential in the atmosphere. The higher these ratios, the more carbon that will be absorbed into the steel, until the carbon's saturated level of austenite is reached, which varies with temperature. Here is a practical application of carburizing and hardening an AISI 8620 steel shaft, 1.25 inch in diameter by 8 inches long (Fig.42). The drawing specifies that only a 1.5 inch length, at the center of the bar should be carburized, to a depth of one tenth of an inch. After carburizing, the shafts are to be quenched in oil. To prevent carburization in other sections. the 1.5 inch length is masked, and the remainder of the bar is copper plated to a thickness of 5 thousandths of an inch. Final surface carbon content is specified to be in the range of 0.80 to 1%. Due to the large depth of case required, 1700 oF is selected as the optimum carburizing temperature. Sixteen hours at this temperature will produce the required case depth of approximately one tenth of an inch. (Fig.43) Parts are properly spaced and stacked vertically in the baskets. Baskets are then placed on trays for processing through a pusher carburizing furnace (movie12). A schematic of a typical pusher furnace is shown here (Fig.44), including loading vestibule, carburizing section, and quench chamber. The next figure (Fig.45) depicts the zones of temperature and carburizing potential atmospheres which will provide the case depth and approximate surface carbon percent. The dew point temperature for the mixing of endothermic carrier gas and enriching gas should be approximately 16 oF inside the furnace. Slight modifications are made at the charge and discharge ends of the furnace, including temperature and atmosphere, to provide an optimum carbon percent gradient from the part surface to the core. The carbon is very sensitive to the changes in the carbon dioxide, water vapor and oxygen in the atmosphere. These are also related to each other through the chemical reactions going on in the atmosphere. As a result, the surface carbon can be controlled very closely by measuring one or more of these variables. Carbon dioxide can be measured with high accuracy using an infrared analyzer. Water vapor is measured by a dew point analyzer. Oxygen is measured by a solid state oxygen probe inserted into the hot furnace. All of these can be used to generate an electrical signal for controlling the carbon potential in the atmosphere. 46 41:19 Similar to nitrocarburizing and nitriding, carbonitriding is a modified gas carburizing process, rather than a form of nitriding. The modification consists of introducing ammonia into the gas carburizing atmosphere. This adds nitrogen to the carburized case as it is being produced. The nitrogen serves several useful purposes: First, nitrogen in the case lowers the austenite transformation temperature. Very low carbon steels can be carbonitrided at temperatures as low as 1450 oF. Second, nitrogen increases the hardenability of the case. A slower, oil, quench can be used instead of water quenching. This minimizes distortion. And, lastly, nitrogen retards softening during tempering. A hardened core can be softened without excessive softening of the case. One problem is that nitrogen tends to lower the martensite finish temperature, retaining austenite. Ammonia additions, therefore, must be kept to a minimum. Gaseous carbonitriding has rapidly replaced salt bath cyaniding. Cyanide is a toxic chemical, and is very difficult to dispose of under EPA regulations. 42:37 Vacuum carburizing is a modified gas carburizing process, in which the carburizing is carried out at pressures less than atmospheric. (Fig.46) A typical pressure is between 50 and 300 Torr. The advantage of this method is that the surface of the metal stays very clean, due to the vacuum, making it easier to transfer carbon to the surface (Fig.47). Natural gas, which is methane or CH4, or propane C 3H 8, provides carbon by decomposing at the temperature of carburizing. These are not equilibrium reactions as in gas carburizing (Fig.48). Instead, the surface is raised to the saturation level of carbon in austenite very rapidly. To achieve the proper surface hardness, the carburizing step is followed by a diffusion step. In this step, the furnace is evacuated to remove the carburizing gas. Diffusion causes the carbon to diffuse into the steel, reducing the surface concentration and increasing the case depth. By repeating the steps of carburizing to saturation or boosting, then diffusing, any desired carbon profile can be achieved. (Fig.49) Similar to the atmosphere carburizing process, curves have been developed to relate total boost time, diffusion time, surface carbon and case depth for various temperatures (Fig.50). To ensure a uniformity of carburizing, various methods of introducing the gas and causing it to move about have been developed. In atmosphere carburizing, this is done with fans, when, in vacuum processing, fans are generally not practical. 44:16 Another vacuum process for carburizing is ion or plasma carburizing (Fig.51). This process is, in principle, identical to ion nitriding, except that the temperature is higher, and the ions consist of carbon generated from ionizing propane or methane. Like in the other ion processes, the purpose of the ionizing is to accelerate carbon transfer. The electrical attraction of the positive, carbon-bearing ions to the negative workpieces, also promotes uniformity. These two factors result in an improvement over vacuum carburizing and also over atmosphere, in that very uniform carbon profiles can be achieved everywhere on the part at pressures even lower than in vacuum carburizing,. The pressure used in ion carburizing is usually much less than 10 Torr, and typically about 3 Torr. The ion carburizing process uses a boost and diffuse method, similar to vacuum carburizing, to generate case depth and control surface carbon. In addition, the throwing power of carbon into the surface is enhanced by increasing the current density so this variable can be controlled. Pressure in the vessel affects the thickness of the ionized layer, known as the glow scene, allowing the ions to be made uniform around the contours of the part (Fig.52). As pressure is increased, the -low scenes become thinner and closer to the part surface (Fig.53). As a result, holes and gear teeth can be uniformly carburized by increasing the pressure. 45: 47 54 The questions may be asked: why carburize?; or, how does one determine which process to use? There are many factors to consider in answering these. First there are the part properties to be achieved. If one needs very high strength, it may only be possible to achieve this with carburizing. For examp le, this curve was develo ped to compa re carburi zing and nitridi ng case depths for a highly loaded gear (Fig.5 4). Practic ally speaki ng, if case depth exceed s about 40 thousa ndths of an inch, it is no longer possibl e to use nitridi ng, becaus e of the slow diffusi on of nitroge 48 n. Of course, one could redesi gn the gear, to reduce tooth stresse s, allowi ng to some extent the use of shallo wer case depths which might then permit nitridi ng. Nitridi ng, becaus e it does not involv e quenc hing transfo rmatio n, is capabl e of produc ing very low distorti on. On the other hand nitridi ng 49 usuall y require s more expens ive materi als, which are more difficu lt to machi ne or grind. In summ ary, the proces s selecti on is a series of interac tive steps, involvi ng materi als selecti on to achiev e engine ering proper ties, includi ng the design itself. The selecti on must then be weigh ed against 50 the produc tion consid eration s, which again impact upon the quality issues import ant to the end user of the part. In closing (movie13), we tried to provide an overview of the many processes available to improve the surface properties of parts. These fall into four major categories, which can be further subdivided into specific processes. The choice of a process depends upon the properties required, the production requirements, and the environment in an individual production plant. We have not attempted, in this short program, to provide all the details of each process, but rather, have attempted to give a clearer picture of the choices available, and their major difficulties. (Fig.55) 51