Manishupdated - Food Tech Innovation Portal

advertisement

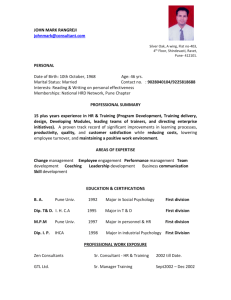

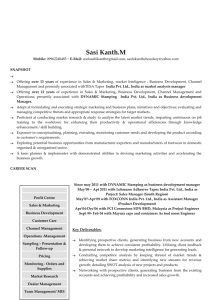

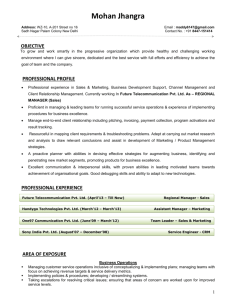

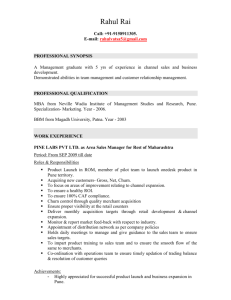

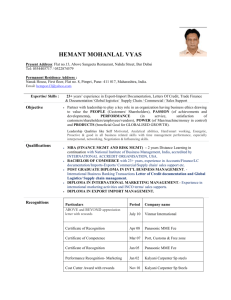

MANISH KUMAR M ANTWAL GMC Angan 7/113 Sector CDC Chikhali Pradhikaran, Purnanagar MIDC Chinchwad Pune-19 India +91 9225609478 PROFESSIONAL PROFILE M. Tech (Food Science) with 14 years’ qualitative experience in Project management, business development and sales, Production Operations, Process Engineering, R&D, Quality, with reputed organisations in the Food and allied industry. MBA (International Business) with specialisation in International Marketing from Institute of International Business & Research, Pune. Abilities to work as efficient team member. Good understanding of the unit operations and Unit process used in food processing. Effective communicator with excellent analytical, planning and interpersonal skills. AREAS OF EXPOSURE & EXPERTISE Business Development Devise and execute strategic plans for achieving sales targets and ensure profitability. Proactive business plans for key customers Identify & explore new markets and tap profitable business opportunities to augment market share. Monitor competition and devise effective counter strategies. Production Operations Develop production plans & schedules, arrange resources and ensure achievement of pre-set targets as per budgeted parameters. Streamline processes and plan capacities as per market demand. Process Engineering Develop processes for manufacture of food products and establish process parameters. Conduct trials, identify deviations & make relevant modifications to stabilise products. Implement HACCP to prevent contamination in the food processing chain. R&D Handle product and process development of starch derivatives. Supervise products and their ingredient composition as per predefined specifications. Quality Supervise quality of raw material/ finished products to ensure adherence to quality norms. Conduct regular audits to identify poisonous compounds & ensure NIL contamination of products. Facilitate implementation of Kaizen, TQM etc. as well as adherence to GMP. ORGANISATIONAL EXPERIENCE Presently at Triple Pee Solutions Pvt Ltd as Head of systems (Oct’07-Till to date) Management Consulting firm in processed food industry. Involved into Project, Process and product development on new business Management and planning of Team of Engineers and technologists for each project Execution of Technology and process Selection, Vendor Identification, Technical Feasibility, Layouts for plant and machinery, Utility working for respective projects Heading the product development from ideation, Formulation development, Process defining, and Scale up trials at Lab level as well as plant level Heading team of QMS and FSMS system development for HACCP, BRC V6 for respective projects Successfully executed following projects o Ice Cream Project 1T per Hrs o o o o Noodles Project 1T/Hr Tortilla Chips Porject 1T/Hr Non Gelatine Based Jelly depositing line Project 600kg/hr Instrumental in Successful product development from ideation to Project Execution Industrial non cocoa butter based Chocolate products, Ice Cream toppings, Non Gelatin based deposited jelly, At International Flavors and Fragrances India Ltd, India as Business development Manager (May’05Till to Sep2007) The company is a market leader in flavours with over 2.0 billion sales globally with a market share of 12% global. Acquire critical market information and contribute effectively to target setting process. Build a growing relationship with major accounts like Heinz, AMUL, Novartis, Shaw Wallace (Now UB) and Coca Cola etc and win major business with them. Gather information on the policies, practices, culture, ventures of the account through its key personnel. Devise business strategies for short term penetration and long term gains with the customers Use the techno commercial knowledge to help the customer take major decisions. Achieve sales target and collection targets and control DSO within limits. Discuss with the team about market trends, document market information and use them for mutual benefit of customers and Company Participate in small group activities and problem solving exercises with functional / cross functional teams and make continuous improvements of the job processes. Instrumental in winning 25% new business of the assigned budget for the year 2006. At Mini Bakeries Ltd., Nairobi, Kenya as Production Manager (Sep’01-Jul’03) The company is a market leader in bakery & confectionery products with over 22 manufacturing sites in East Africa. Developed sales and marketing strategies Built lasting relationship with clients. Identified market needs and converted it to viable business opportunity. Spearheaded production operations with a team of 50 personnel. Distinction of consistently exceeding production & sales targets across the assignment. Instrumental in planning operations as per market requirements. Instrumental in reducing quality defects through successful implementation of GHK practices. Received appreciation from management for excellent performance. At Makson Foods Pvt. Ltd, Surendranagar, India as QA & Product Development In-Charge (SEP’00– Aug’01) The company is a leading co-packer in the confectionery industry, for multinationals like Nestle, Proctor & Gamble, Hindustan Lever etc. for hard-boiled candies. Managed QA for the HLL co-packing unit. Instrumental in designing the procedure for incident management and recall Designed a format for maintaining CCP records and monitoring trend analysis Essayed the chief role as Technical Secretary of HACCP team that implemented the HACCP system Also undertook initiatives to develop corrective & preventive action system to facilitate processing and resolution of consumer’s complaints a traceability system for manufacture of liquid glucose. Commenced career at Chh Shahu Institute of Business Education and Research, Kolhapur, India as Lecturer (Jul’99-Aug’00) The institute is one of the leading educational institutes in western Maharashtra under Shivaji University Kolkapur. As lecturer for food technology department ,conducted regular teaching as well as practical classes for the Bachelors degree course ACADEMIC CREDENTIALS M.Tech (Food Science) from Marathwada Agricultural University, Parbhani in 1999. Secured CGPA of 9.19 / 10. Received the Best Student Awards from CFTRI, Mysore & Marathwada University in 1998. B.Tech (Food Science) from Marathwada Agricultural University, Parbhani in 1997. Secured CGPA of 9.04 / 10. ACADEMIC TRAINING Undertook the summer training project at Dohler India Pvt Ltd., Pune (Jun’04-Aug’04) as part of the MBA program: Conducted the project as member of the team that implemented ERP applications. Developed & established Standard Operating Procedures for the Customer Order, Purchase and Operations modules and obtained integrated results. Passport Details: DATE OF BIRTH: 15th November’1975 Passport no. Z2640928 valid till 04/07/2023, issued at Pune