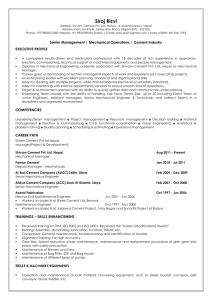

SANTOSH KUMAR SINGH

advertisement

SANTOSH KUMAR SINGH E-Mail: santosh_singh_30@rediffmail.com / Mobile: 91-9910037402 In quest of senior level assignments in Project Management, Erection & Commissioning, Maintenance & Operations for Dry Process Cement Plant Projects with an organisation of repute. CAREER AT GLANCE A Mechanical Engineer with an experience of 17 years in EPC project management, Project finance planning and control, erection & commissioning, operations & maintenance of equipment in the dry process cement plant and team management. A keen strategist & implementer aiming at achieving timely project completion, profit and business growth objectives & turnaround for increase in top line and bottom line in rapid change environments. Adept in managing erection & commissioning activities involving resource planning, in-process inspection, team building and co-ordination with internal / external departments. Effectively conceptualized and completed various operations pertaining to maintenance repair, modification and executing project with high degree of safety. Demonstrated excellence in setting priorities, develop a work schedule, monitor progress towards goals, and track details/data/information/activities. Expertise in managing various operations as per the set parameters & standards as well as experience of developing procedures for operational excellence. An effective communicator with excellent skills in building relationships. Possess strong analytical, problem solving and organisational abilities. EMPLOYMENT SCAN 1. Presently Working with ATS Engineering Company Private Limited – Since May 2011 to till date. Working as “Head Marketing & Project Control”. 2. Devi Constructions, Hyderabad - Since July’09 to March 2011. President Projects for Cement Plant Projects. 3. ETA STAR International LLC, Angola - Aug’08 to Jun’09 Planning Manager & Promoted as Project Head Execution (Green field Cement Plant Project). 4. Andhra Cements Limited, Hyderabad - Apr’07 to Jun’08 General Manager Projects (Cement Plant Expansion from 3000 TPD to 6000 TPD) & Split grinding unit as Unit head in Vizag. 5. Lafarge Surma Cement, Bangladesh - Jul’05 to Mar’07 Manager Mechanical (HOD) – (Green Field Cement Plant Project). 6. May 1996 to June 2005: Mangalam Cement Limited, Kota Rajasthan (Up gradation Project with Operation & Maintenance). CORE COMPETENCIES: Project Management Managing activities right from the conceptualisation stage to the execution; involving finalization of technical specifications, store management & inventory control, scheduling, progress monitoring, site management, manpower planning, etc. Establishing project review, monitoring and status reporting procedures to accurately report progress of the project to the stakeholders and end user clients. Handling activities involving working out various requirements & monitoring overall project operations for ensuring timely completion. Coordinating projects for the set-up standards with accountability for strategic utilisation & deployment of available resources to achieve organisational objectives. Managing preventive and predictive maintenance schedules of equipment to minimize stoppages in critical production areas. Reviewing the development related procedures for ensuring compliance with various standards. Maintenance / Troubleshooting Planning and effecting predictive & preventive maintenance schedules for equipment in the dry process Cement plant to increase machine up time & equipment reliability. Implementing maintenance schedules and carrying out periodic checks to ensure performance of equipment and maintaining requisite documents for the same. Identifying areas of bottlenecks / breakdowns and taking steps to rectify the equipment through application of trouble shooting tools like root cause analysis. Maintaining and ensuring stringent adherence to quality standards, norms & practices, identifying gaps and taking corrective action. Installation & Commissioning Commissioning of heavy industrial static & dynamic weighing systems, batching systems, loading systems and other related equipment as well as conducting tests & inspections to ensure operational effectiveness of plant & utilities. Carrying out overhauling work of equipment, modifications, and major repairs to improve equipment efficiency by faultfinding. Involving in installation, vibration performance trials, system layouts and checks of main and auxiliary machinery and preparing documents for the same. Process Enhancement Identifying scope for: Planning, implementing & monitoring of technological changes to enhance productivity. - Modifications in equipment, process flow, working practices, consumables, power, etc. for controlling & reducing conversion cost per unit produced. Implementing various techniques for cycle time reduction, entailing identification of opportunities, energy audits, analysis of data, conduction of tests and implementation & post audits. Team Management Leading, mentoring & monitoring the performance of the team members to ensure efficiency in process operations and meeting of individual & group targets. Creating and sustaining a dynamic environment that fosters development opportunities and motivates high performance amongst team members. Key Projects Executed: Up gradation of cement plant for Ball Mill, Vertical Raw Mills, like close circuiting of Circuit, up gradation of complete conveying system, up gradation of Pre heaters, etc. Project “Green Field” from erection to commissioning of the plant having capacity of 3600 TPD Clinker production in Lafarge Surma Cement in Bangladesh as HOD Mechanical. Up gradation Project of 3000 TPD to 6000 TPD Plant in Andhra Cements Limited as GM Project. Erection and commissioning of Andhra Cement Project as hear consultant in 5 months Efficiently worked as head Project Execution in ETA STAR for green field Project of 4200 TPD in Angola. Managed production in full capacity of the plant after commissioning. Handled the department as HOD Mechanical and made complete setup for planning and execution department (With Maximo, JDE, MS Project & Primavera setup) in Lafarge Surma Cement. Mangalam Cement Ltd, Kota, Rajasthan (A dry process plant of 4200 TPD capacity -- B.K Birla group). Completed green field project in Lafarge Surma Cement Ltd. Bangladesh, Plant with 3600 TPD - Friction drive Kiln as HOD Mechanical Department. Notable Attainments across tenure: Accomplished project execution and successful commissioning, operation and maintenance in Lafarge Surma Cement with a team of Trainee technicians and trainee engineers only. New processes developed in Mangalam Cement Limited.: ISO 9001:2000, System documentation and implementation Development of Preventive maintenance System and implementation. Implementation of Complete Project planning & execution methodology in ETA STAR. Streamlined complete Plant process and maintenance system revived and corrected, to get rated output with the equipment in Andhra Cements Limited. Other accomplishments: I. Cost effective maintenance with minimum downtime hours in Mangalam Cement Limited. II. Achieved full rated capacity of Plant production after commissioning in Lafarge Surma Cement. III. Project execution with in a shortest period in Andhra Cements Limited. Implemented systems like ISO, TPM, Training to Workman and Engineers to get continual improvement in the working system and to adopt best practices in organization. Special increment in salary was declared, just after three months of joining and special bonus of handsome amount within six months of Joining in Andhra Cements Limited for Achieving Record production and fastest project implementation. SEMINARS ATTENDED Safety Project Management Project Management Tools ACADEMIC CREDENTIALS 1995 B.E. (Mechanical) from Regional Engineering College, Silchar. Secured 1st class Honours with 70%. PERSONAL DOSSIER Date of Birth: Present Address: Languages Known: 15th December 1971 H40 Second Floor, Sushantlok III, Sector 57, Gurgaon – 122001 Haryana (India) Mobile – 09910037402. Hindi, English Current CTC: Appx. 29.4 Lacs Per year with additional bonus (0.5% of company’s turnover). Salary Expectation: Negotiable (As per company Standard salary pattern).