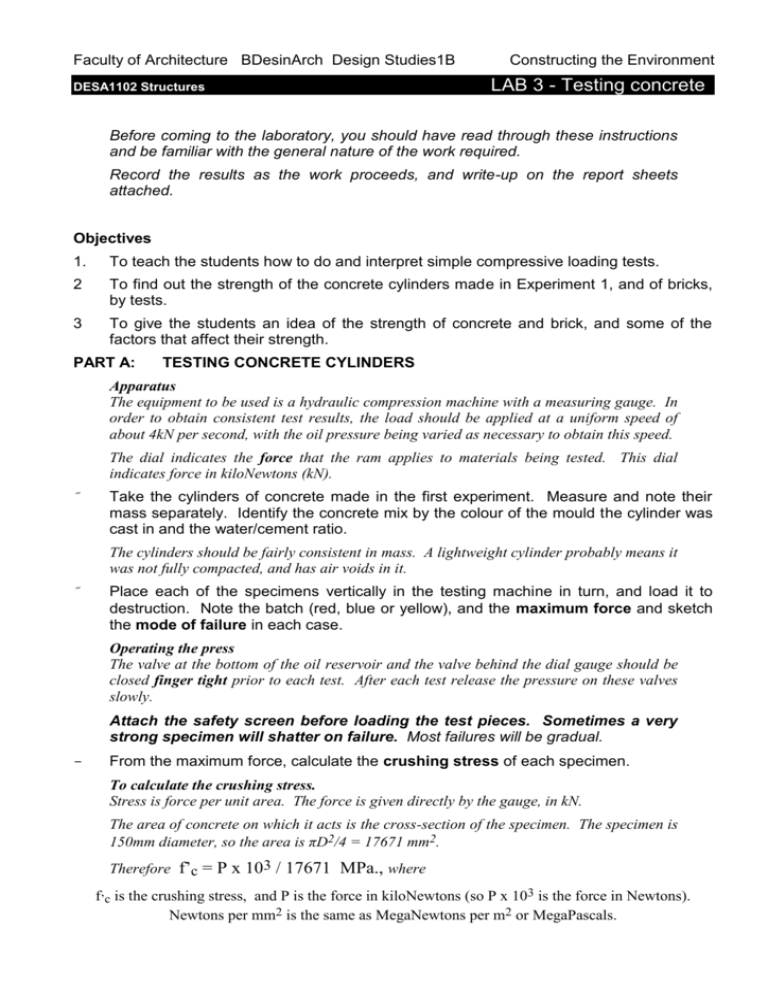

Experiment 2 - Strength of concrete and bricks

advertisement

Faculty of Architecture BDesinArch Design Studies1B DESA1102 Structures Constructing the Environment LAB 3 - Testing concrete Before coming to the laboratory, you should have read through these instructions and be familiar with the general nature of the work required. Record the results as the work proceeds, and write-up on the report sheets attached. Objectives 1. To teach the students how to do and interpret simple compressive loading tests. 2 To find out the strength of the concrete cylinders made in Experiment 1, and of bricks, by tests. 3 To give the students an idea of the strength of concrete and brick, and some of the factors that affect their strength. PART A: TESTING CONCRETE CYLINDERS Apparatus The equipment to be used is a hydraulic compression machine with a measuring gauge. In order to obtain consistent test results, the load should be applied at a uniform speed of about 4kN per second, with the oil pressure being varied as necessary to obtain this speed. The dial indicates the force that the ram applies to materials being tested. This dial indicates force in kiloNewtons (kN). ˝ Take the cylinders of concrete made in the first experiment. Measure and note their mass separately. Identify the concrete mix by the colour of the mould the cylinder was cast in and the water/cement ratio. The cylinders should be fairly consistent in mass. A lightweight cylinder probably means it was not fully compacted, and has air voids in it. ˝ Place each of the specimens vertically in the testing machine in turn, and load it to destruction. Note the batch (red, blue or yellow), and the maximum force and sketch the mode of failure in each case. Operating the press The valve at the bottom of the oil reservoir and the valve behind the dial gauge should be closed finger tight prior to each test. After each test release the pressure on these valves slowly. Attach the safety screen before loading the test pieces. Sometimes a very strong specimen will shatter on failure. Most failures will be gradual. - From the maximum force, calculate the crushing stress of each specimen. To calculate the crushing stress. Stress is force per unit area. The force is given directly by the gauge, in kN. The area of concrete on which it acts is the cross-section of the specimen. The specimen is 150mm diameter, so the area is πD2/4 = 17671 mm2. Therefore f’c = P x 103 / 17671 MPa., where f’c is the crushing stress, and P is the force in kiloNewtons (so P x 103 is the force in Newtons). Newtons per mm2 is the same as MegaNewtons per m2 or MegaPascals. Faculty of Architecture - DESA 1102, Design Studies, Structures Lab3 RECORD ALL THE RELEVANT INFORMATION ABOUT THE DIFFERENT CONCRETES AND TESTS ON THE ATTACHED LABORATORY REPORT SHEETS. Before filling out the report, make sure you know all the results of your group’s work. Ask your colleagues if necessary. PART B: TESTING BRICKS AND BRICK PIERS ˝ (a) Crushing tests. The crushing strength of a brick is tested by laying it flat between the plates of the testing machine, and loading it at a uniform, slow rate. ˝ Carry out this crushing test: (i) on each of two single bricks, and (ii) on each of two already-made piers, each three bricks high. - Record the maximum crushing force, and observe the mode of failure in each case. Make sketches showing how the test pieces failed. Compare the results of the bricks and the “walls”. What can be the reason for the difference? - Determine the mean crushing strength in megapascals (MPa) in each case. The crushing strength (compressive strength) is found by dividing the force needed to cause the brick to fail (P, the maximum force it can resist) by the cross-sectional area (A) of the brick in contact with the bearing plate of the machine fb = P/A. Note that the size of the face of the bricks in contact with the bearing plate must be measured before the bricks are tested. Before leaving the laboratory, properly clean all the equipment. Place the broken concrete iand brick in the wheelbarrow and bins provided and deposit it in the industrial waste bin outside.