Chapter 3 Recommendations for the New Biomass Stoves Initiative

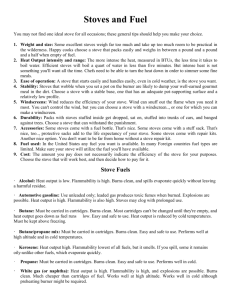

advertisement