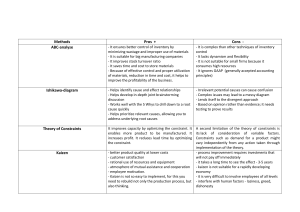

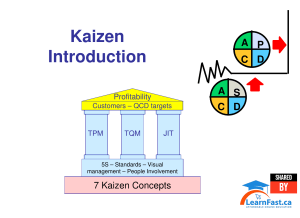

Continuous Improvement (Kaizen) Type of quality system Kaizen is a system that concentrates on small but frequent improvements on every aspect that the production passes. All members of the workforce will be invalid Employees are encouraged to work in Kaizen groups Improvements can take place at any level of the hierarchy Requires highly motivated and committed workforce A vital component of total quality in order to improve the quality of the production process. It Strengthens teamwork through solving problems together as a team. It strengthens bonds between employees and gives a fresh perspective and sense of belonging within the company. It improves leadership skills with team leaders responsible for the organization, coordination and implementation of the event. Improved efficiency, cuts out waste of current processes or procedures ensuring that efficiency across all departments. This eliminates any unnecessary procedures from a work process. Improved best practices as Kaizen is constantly improving and looking for improvement to train new employees and measure current employees performance. It improves employee satisfaction allowing for greatly affected things like productivity, quality of work and retention rates. Advantages of the quality system Change is hard because it means changing an existing system and the management may not agree with changing something that has “worked before so can work again”. Additional training would be required in order to adopt the Kaizen method and to implement the new methods identified. This may interrupt the normal workflow of employees who attend the training. Disadvantages of quality system Toyota – They have used the Kaizen method by slowly and constantly making small and gradual adjustments as to how things are done. Nestlé – They have greatly used kaizen as the food industry is one of the most important firms worldwide. Nestlé have made great improvements in the reduction of waste by lowering the time and materials wasted on their processes. Mayo Clinic- a nonprofit medical practice and medical research group, following the steps of Toyota, was able to help the complex manufacturing operation to improve practices. The industry of medicine is very complex, therefore marginal changes can revolutionize healthcare organizations worldwide. Lockheed Martin- a famous American global aerospace, defense, security and advanced Technologies company. They were able to notably reduce its costs of manufacturing while lowering their defect rate to 3.4 instances per plane; and also lower their order to delivery time from 42 months to just below 22. Another notable accomplishment was in the area of material management, where they were able to reduce the time to move parts from receiving to stock from 30 days to just four hours. Example of scenario where quality system can be implemented. Buy A Bag!!!