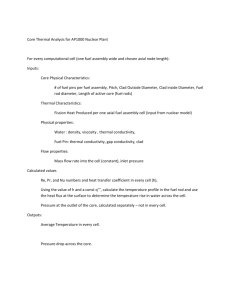

Fuel rod quality characteristic

advertisement