PBL - heuserportfolio

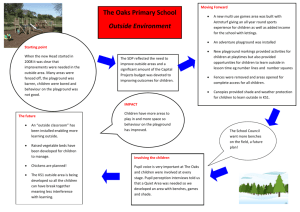

advertisement

PROJECT OVERVIEW Name of Project: Subject/Course: 7th Grade Project Lead the Way Other subject areas to be included, if any: Web 2.0 used in PBL: Duration: 3 weeks Playground Design Teacher(s): Mr. Heuser Grade Level: 7th Other subject areas – math, science, and art connect with this project, but those classes do not participate, this is strictly a PLTW project. Web 2.0 tools used: Wordle to put together a collage of all different playground equipment Prezi to put together the playground presentation after completion Project Idea Summary of the issue, challenge, investigation, scenario, or problem: Students will work as a group to develop a design proposal for a playground that will be built at an elementary school. Students must research, design, and fabricate a model of the playground and follow the steps of the PLTW design process along the way. Students will complete a design brief, decision matrix, and rough sketches before creating a 3D model of their playground on Autodesk Inventor. The group will then make models or prototypes on Inventor, which is then followed by a scale model constructed in the class using the tools and equipment. After completion of the scale model, the students will present their playground and other design materials to the class and parents on curriculum night. Driving/Essential Questions Why are teams of people used to solve problems?, Why is it important to follow the design process when creating a solution to a problem?, What is the difference between a model, a mockup and a prototype? Content and technology Standards to be addressed: Write number and standard A.8.2 Explain the need for and application of knowledge and skills from other disciplines when engaging in technological activities. B.8.3 Identify potential sources of failure in a system; such as, defective parts, maintenance needs, a large number of complex components, or use in applications beyond its original purpose. C.8.5 Explain the value of technical knowledge and teamwork in the development of a device or process. D.8.4 Explain why people must think about how a new technology might affect other people, societies, and the ecosystem in which we live. A.8.1 Use common media and technology terminology and equipment B.8.5 Record and organize information C.8.4 Demonstrate self-motivation and increasing responsibility for their learning D.8.1 Participate productively in workgroups or other collaborative learning environments © 2008 Buck Institute for Education 1 T+A st 21 Century Skills to be explicitly taught and assessed (T+A) or that will be encouraged (E) by project work, but not taught or assessed: E T+A Collaboration: Student must work together in a team/group to plan, design, and build a playground model. Group roles will be assigned as to who will design what parts of the playground, who will bring what materials for the model, who will build what of the model, and what parts of the presentation will they give. Critical Thinking: Students will have to research playgrounds for specific ages, locations, temperatures, materials, and other useful information for their design. They must complete a design brief, decision matrix, process chart, 3D models, and working model of their designs. They must then present their information to the class, and explain their playground including why/where they got their designs from. Presentation: The presentation must share all items of the design packet, all Inventor assemblies, the use of multimedia, and a display and explanation of their model by all group members. Other: Cross-Cultural: examples of playgrounds from other countries/places Career Readiness: practicing problem solving skills Creativity: Students will have the freedom of designing their own playground. Technology: The students will use Inventor to construct the 3D models of the playground items, Word to complete the design template packets, and PowerPoint to create the presentation. E Presentation Audience: Group: Culminating Products and Performances Individual: As a group, the students will develop the design of their overall playground. They will determine what items to include, assign duties, and construct the model together in class. Upon completion, the students will develop their presentation and present all of their final items as a group to the class, and then share their materials on curriculum night which is open to the school and community. Individually, students will sketch drawings and a final sketch of their assigned or selected playground piece. They will design individually their piece on the 3D modeling software Autodesk Inventor. The student will be given certain roles in the construction of the playground design and certain roles in the creation of the presentation. Class: X School: X Community: X Experts: X Web: Other: (experts are the instructors) © 2008 Buck Institute for Education 2 PROJECT OVERVIEW Entry event to launch inquiry, engage students: Assessments: If a checkmark is made in one of the following boxes, an assessment piece MUST be provided. Quizzes/Tests Formative Assessments (During Project) Summative Assessments Practice Presentations Journal/Learning Log X Notes Preliminary Plans/Outlines/Prototypes X Checklists Rough Drafts X Concept Maps Online Tests/Exams Other: Written Product(s), with rubric: Other Product(s) or Performance(s), with rubric: __________________________________________________ _3D Model files + Scale Model _________________________________________________ (End of Project) X Oral Presentation, with rubric X Peer Evaluation Multiple Choice/Short Answer Test Self-Evaluation Essay Test Other: . Resources Needed Reflection Methods On-site people, facilities: Instructor, Computer Lab with Autodesk Inventor, Shop with saws, tools, etc. Equipment: Band Saw, Belt Sander, Palm Sander, Glue gun, Scissors, Computer, Inventor, tape measure Materials: Dowels, misc. wood, plywood, tape, string, pencils, paint, other misc. desired materials Community resources: Pictures of existing playgrounds in community (Individual, Group, and/or Whole Class) Journal/Learning Log X Focus Group Whole-Class Discussion X Fishbowl Discussion Survey Other: © 2008 Buck Institute for Education 3 PROJECT TEACHING AND LEARNING GUIDE Project: Playground Design Project Course/Semester: 7th grade PLTW Knowledge and Skills Needed by Students (Learning Targets) to successfully complete culminating products and performances, and do well on summative assessments I can create a 3D model of an object To be able to do this I must learn and understand that: - Simple geometric shapes are combined and joined to create a representation of an object. - Three-dimensional computer modeling uses descriptive geometry, geometric relationships, and dimensions to communicate an idea or solution to a technological problem. I will show I can do this by creating a 3D model of my playground item and creating it in an .ipt file I can create a decision-making matrix. To be able to do this I must learn and understand that: - It’s important to follow the design process when creating a solution to a problem. - Decision matrix’s are a tool used to make decisions based on logic and not opinion I will show I can do this by creating a decision making matrix of my different designs for my playground I will Demonstrate the ability to produce various annotated working drawings of a 3D model. To be able to do this I must learn and understand that: - What purpose do annotations serve in an assembly drawing - What is the difference between a part file (.ipt), an Scaffolding / Materials / Lessons to be Provided by the project teacher, other teachers, experts, mentors, community members I will provide instructional PowerPoints for the students on how to create .ipt files using Inventor. I will give relevant demonstrations to the students on how to create similar playground items, and will do so through the use of instructional technologies such as a laptop with Autodesk Inventor and a projector to display the image so that all students can see. I will provide and instructional PowerPoint for the students on how to create a decision making matrix. I will go through a few examples of how to create one, and how ideas are weighed evenly against one another through the use of criteria and constraints. Students will understand decisions are made using analysis and logic. I will provide instructional PowerPoints for the students on how to create a drawing file (.idw) and how to complete the dimensions, titles, and annotations. Students will watch a demonstration done by the instructor on how to do all of these things prior to beginning and understand the importance of an © 2008 Buck Institute for Education 4 assembly file (.iam), and a working drawing (.idw) I will show I can do this by creating a drawing file (.idw) that displays all of my playground files with dimensions, titles, and annotations. I will assemble the product using the CAD modeling program. To be able to do this I must learn and understand that: - What is the difference between a part file (.ipt), an assembly file (.iam), and a working drawing (.idw) - How do assembly constraints differ from geometric and numeric constraints I will show I can do this by creating an assembly file (.iam) that will show all of my parts put together to make my final playground design item I will understand why teams of people are used to solve problems. To be able to do this I must learn and understand that: - teams of people are used to solve problems on a regular basis - Teamwork requires constant communication to achieve the goal at hand I will show I can do this by successfully completing the project assigned and all group members have completed their playground portion and contributed to the presentation. orthographic projection and how it displays multiple views of a 3D model. I will provide the students with PowerPoint presentations on how to successfully create an assembly file and how all of the constraints in an assembly work together to make a final product. The students will watch a number of different demonstrations that show all of these constraints and when is an appropriate time to utilize all of these tools. I will provide the students with a PowerPoint presentation on how to work as a team and how to be successful using teamwork and that each individual has strengths and weaknesses they bring to the table when working in a group. Students will understand how to utilize the skills and talents that each person in their group has in order to complete the assignment according to the project guidelines. © 2008 Buck Institute for Education 5 P R O J E C T Project: Playground Design Project M O N D A Y C A L E N D A R Start Date: 10/31/11 T U E S D A Y W E D N E S D A Y T H U R S D A Y F R I D A Y PROJECT WEEK ONE Objective- Anticipatory Objective- Anticipatory Set and outline of Set and outline of project project Objective – Students will begin their playground designing and research Activity- Principal will come in and read the project overview to the class, and the instructor will pick groups. Activity- Principal will come in and read the project overview to the class, and the instructor will pick groups. Activity – Students will complete their design brief to outline the project. Students will also brainstorm ideas and begin to research different playground ideas and themes Assessment- none Assessment- none Assessment – Playground Design Brief Objective- Students will start to develop their own ideas Activity- Students will each design 3 different designs of their desired playground item. The group will then weigh each design through a Decision Matrix Assessment- Sketches that are graded in the rubric, and the Decision Matrix sheet Objective – Students will get a refresher of Autodesk Inventor Activity – Students will complete a few mini practice sessions of Autodesk Inventor (not graded) before beginning to design, assemble, and create a drawing file of their playground item. Assessment – Students will create an assembly file and drawing file of their playground which is graded in part of the rubric © 2008 Buck Institute for Education 6 PROJECT WEEK TWO Objective – Students will complete their Autodesk files Objective – Students will complete their Autodesk files Objective – Students will learn proper shop safety Objective – Students will create a prototype of their model Objective – Students will create a prototype of their model Activity – Students will complete their Autodesk Inventor files of their playground. Activity – Students will complete their Autodesk Inventor files of their playground. Assessment – Students will create an assembly file and drawing file of their playground which is graded in part of the rubric Assessment – Students will create an assembly file and drawing file of their playground which is graded in part of the rubric Activity – Students will complete the one day walk through of the shop of how to appropriately use the saws, sanders, and other misc. equipment. These students have already gone through it, but safety is a priority and must be done again. Activity – Students will work collaboratively as a group to complete their playground model that will be a replica of their Inventor files. Activity – Students will work collaboratively as a group to complete their playground model that will be a replica of their Inventor files. Assessment – see Rubric Assessment – see Rubric Assessment - none PROJECT WEEK THREE Objective – Students will create a prototype of their model Objective – Students will create a prototype of their model Objective – Students will create a PowerPoint presentation. Activity – Students will work collaboratively as a group to complete their playground model that will be a replica of their Inventor files. Activity – Students will work collaboratively as a group to complete their playground model that will be a replica of their Inventor files. Activity – Students will work collaboratively as a group to complete a PowerPoint presentation that displays all of their work completed and Objective- Students will present all of their items to the instructor Objective- Students will present all of their items to the instructor Activity- Groups will share playground, PowerPoint, drawings, and Inventor files Activity- Groups will share playground, PowerPoint, drawings, and Inventor files © 2008 Buck Institute for Education 7 Assessment – see Rubric Assessment – see Rubric share their steps they used to complete the assignment. Assessment- see grading rubric Assessment- see grading rubric Assessment – see Rubric and Design Process Chart. Playground Design Brief Client: Designer: Problem Statement: Design Statement: © 2008 Buck Institute for Education 8 Constraints: Deliverables: © 2008 Buck Institute for Education 9 Playground Decision Matrix 1. In the criteria boxes, list the criteria from your design brief. 2. Under the ideas boxes, put your three ideas and your partner’s three ideas – label the sketches A, B, C, D, E, and F. 3. Evaluate the design idea for all criteria, giving each a value between 1 and 4. 1 means the design doesn’t meet the criteria; 4 means that this is the best possible solution to the problem for this specific need. 4. If your criteria is a question, use 1 if the answer is no and 2 if the answer is yes. 5. When you finish evaluating your sketches, add the numbers across and put your answer in the Total column. 6. The design with the highest total is your Best Solution. Criteria Ideas Totals A Designed by: © 2008 Buck Institute for Education 10 B Designed by: C Designed by: D Designed by: E Designed by: F Designed by: © 2008 Buck Institute for Education 11 Playground Design Process Solution A log for following all of the steps of the Design Process Design Process Step Student Work at This Step: 1: Define the Problem 2: Brainstorm © 2008 Buck Institute for Education 12 3: Research 4: Develop Ideas 5: Choose Best Idea 6: Model or Prototype 7: Test and Evaluate 8: Improve Design 9: Communicate Results © 2008 Buck Institute for Education 13 Conclusion – Reflection Piece – to complete individually, then discussed in class 1. What specific tasks were you responsible for? 2. What was the most challenging part of this design experience? 3. Which stage of the design process was most difficult for you and why? 4. The seven resources of technology are listed below. Give an example of how you used each resource to solve the playground design problem. Capital (Money or Value) Time Information Materials People Energy Tools and Machines © 2008 Buck Institute for Education 14 Project Playground Design and Fabrication Rubric Elements Thumbnail Sketches Pencil Drawing – Orthographic Views Working Drawing and Playground Specification Sheet 3D Modeling Drawing – Annotated Orthographic Views Working Drawing of Assembled Playground Weight 5 Points 4 Points 3 sketches are completed on the provided paper. All designs are unique and are completed in pencil. All views (top, front, and side) of playground are drawn on graph paper in pencil. The drawing includes dimensions and annotations as necessary. All views (top, front, and side) of playground meet all specifications as indicated on both working drawing and Playground Specification Sheet. All orthographic and isometric views are shown in the proper location with proper dimensions identified. 2 sketches are completed on the provided paper. All designs are unique and are completed in pencil. One or two views of playground drawn on graph paper in pencil. The drawing is missing some dimensions and annotations. 1 sketch is completed on the provided paper. 3 Points Duplicate sketch(es) are completed on any paper available; directions are not followed. 2 Points Thumbnail sketches are not provided. 1-0 Points The top and front views of playgrond are drawn on graph paper with pencil. No dimensions or annotations are included. The top or front view of playground is drawn on graph paper with pencil. No dimensions or annotations are included. The orthographic view pencil drawings are excessively incomplete or are missing. The playground meets most specifications as indicated on both the working drawing and the Playground Specification Sheet. Most orthographic and isometric views are shown in the proper location with some dimensions in error. Several specifications are not met as indicated on both the working drawing and the Playground Specification Sheet. Orthographic and isometric views are shown, but with an error in either proper location or proper dimensions. The playground fails to meet more than half of the specifications indicated on both the working drawing and the Playground Specification Sheet. Either the Playground Specification Sheet or the .idw file of the playground is incomplete. Orthographic and isometric views contain many errors. The orthographic and isometric views are excessively incomplete or are missing. The playground is printed and assembled correctly. The playground is printed and assembled, contains few errors. The playground is partially assembled with some errors. The playground is not completely assembled and includes many errors. The playground is excessively incomplete or is missing. Total © 2008 Buck Institute for Education 15 The final product exactly matches the final design. A slight difference exists between the final product and the final design. The group has successfully and thoroughly put together a multimedia presentation that meets all required criteria in the playground design specification sheet The group has successfully and thoroughly put together a multimedia presentation that meets most required criteria in the playground design specification sheet Team members use tools and machines safely and as instructed most of the time. Playground Model Communication Tool/ Machine Use Team members always use tools and machines safely and as instructed. A significant difference exists between the final product and the final design, but an attempt was made to follow the design. The group has successfully and put together a multimedia presentation that meets all required criteria in the playground design specification sheet, but does not show understanding Team members require some prompting to use tools and machines safely and as instructed. A significant difference exists between the final product and the final design. No apparent attempt was made to follow the design. The groups presentation is subpar in information, not all group members participate, and does not answer all required information in the Playground Specification Sheet. The playground model is excessively incomplete or is missing. Team members require repeated reminders to use the tools and machines safely and correctly. Team members do not use tools and machines safely or as instructed. The student shows little to no evidence of communication or cooperation. © 2008 Buck Institute for Education 16 Problem 1.5.9 Playground Design Introduction Your school’s Board of Education has contacted your class and asked if you will design a new playground for the elementary school. Your class will work as a team to sketch and design using the design process, a solution for the playground. You will present your solution to a representative from the committee. Teamwork is essential in order to finish in time and present your solution. A team is a group of individuals, each with an expertise, who are brought together to benefit a common goal. The benefits of working in a team are that 1. More ideas can be pursued. 2. The workload is shared. 3. More work can be accomplished. Make sure your group completes all stages of the design process. One of your biggest constraints is time; you must be prepared to present your design solution by _______________________. (Record the date that your teacher provides.) Procedure In this activity your class will work as an engineering design team. You will use your knowledge of the design process, engineering tools, the Internet, and teamwork to communicate and work with your partners to solve the playground problem. Make at least one entry in your GTT notebook for every class period. Identify all of your research sources, and sketch all of your ideas in your GTT notebook. 1. Define the problem by completing the Playground Design Brief as a class. List the constraints presented by your teacher, the playground committee representative, and the constraints your team decides to include. For example, your team (class) may decide the playground should have an African theme or should be color-coded for age-appropriate play areas. 2. As you complete each step in the Design Process, describe the steps that you took on the Playground Design Process Solution chart. 3. Brainstorm with your classmates as to how you can complete this problem given your resources and constraints. 4. Research by taking a tour of an existing playground, online, or by asking elementary-aged students what types of playground equipment they like. 5. Develop ideas by breaking into smaller groups. Each group will design and complete a specific part of the playground. Each student will sketch 3 thumbnail sketches that follow the criteria established by the class and follow the guidelines presented in the Engineering Notebook Sketching Example Document. © 2008 Buck Institute for Education 17 6. You will present your ideas to your group for suggestions to help improve designs. A project manager may be assigned and will work with each group. The best designs will be chosen to develop further. Use the Decision Making Matrix form to help determine the best design ideas. 7. Use your 3D modeling software to create computer models. Print a working drawing. 8. Include files of each assembly with balloons and a parts list. 9. Make prototypes of the playground equipment using the supplies provided by your teacher. 10. Continually test and evaluate your design solutions as you model and prototype. Have elementary-aged students look at your designs and give you input on how they may want that piece of equipment to look, act, or work. 11. Improve your designs. Update all drawings and discuss any changes and why they were made during the presentation. 12. Communicate the results to the playground committee representatives who come and listen to your presentation. All students should be involved in the presentation, some speaking, some helping with technology, and some helping with room organization. All students should be available during a question and answer time following the presentation. The following items should be included in your presentation: Explain the problem. Review the constraints. Explain the research that was conducted. Show and explain initial design sketches. Explain why an idea was chosen to pursue or why it wasn’t pursued. Show and explain working drawings of 3D Computer model. Show and explain Tech Card model. Explain the method of testing and evaluating the models. Explain changes made to initial CAD drawings and why these changes were made. Questions? Presenters should: Present in a logical order. Maintain good eye contact with the audience. Use good voice projection. Practice and be well prepared to present. © 2008 Buck Institute for Education 18 Mr. Heuser’s Workshop Safety Rules I. II. III. IV. V. VI. VII. VIII. IX. X. XI. General Lab Safety Rules Hand Tools Safety Table Saw Safety Jointer Safety Drill Press Safety Band Saw Safety Wood Lathe Safety Surface Planer Safety Miter Saw Safety Router Table Safety Portable Power Tools Safety I. General Lab Safety Rules The following are general safety rules to be observed throughout the lab at all times by everyone. Activities in the Woods Lab are not hazardous to those who know safe practices and observe them. A clean, well organized lab is directly related to overall lab safety. 1. “Horseplay” has no place in the lab. There is no running in the lab 2. Loud talking or shouting is prohibited because of the danger of startling a person into making an involuntary movement while operating a machine. 3. The lab floor should be free of wood scraps, sawdust, and tools. Do not block doorways or aisles with wood or projects. 4. Mental alertness is closely associated with safety. Keep your mind and your eyes on the task at hand. Do not talk to others while operating any machinery. 5. The operator must know the machine and how to operate it safely before using. 6. Take good care of each machine so that it stays in perfect working order. Allow each machine to attain full operating speed before using. 7. When the power to a machine is turned off and the blade is slowing down, never attempt to slow the blade down or rotating part with a stick, board or hand. 8. Never place tape measures, rules, tools, pieces of lumber or any other article on a machine while in operation. © 2008 Buck Institute for Education 19 9. Check every machine set-up carefully before turning on the power. When possible, make test cuts on scrap before cutting and possibly ruining good stock. 10.Always use protective guards and safety devices whenever possible. 11.In most cases, there should be only be one operator per machine. It is hazardous to permit other students or spectators to crowd around the operator of a machine. 12.Never use any tool or machine unless you have received instruction and have passed a safety test. 13.Report all injuries, however slight, to the instructor for treatment. If the injury requires medical attention, the injured person must be accompanied to the hospital or physician and an accident report must be completed. 14.Long sleeves must be rolled up above the elbow. Remove neck ties and loose jewelry. Loose, floppy, unbuttoned clothing is not permitted 15.If it is ever necessary to get the operator’s attention while running a machine, approach from the front, speak in a normal tone while gesturing with the hands. 16.Always examine the board for nails, wire fencing, loose knots, splinters, stones, concrete, bullets, old paint and varnish, etc., before feeding into a machine. 17.Always utilize the best light available when working in the lab. 18.Never load a machine beyond capacity. A machine that slows down noticeably as stock is being fed into it, is indicating that it is being run beyond safe limits. 19.Do not use tools or machines for purposes other than the purpose for which they were designed. 20.Obey all safety rules. When in doubt consult your instructor 21.Listen to and learn how each machine sounds when running properly. Odd or unusual sounds indicate a problem; report these to the instructor immediately. 22.Do not leave a machine that is running. 23.Even after passing safety tests on the machines, the student should consult the instructor before executing special setups. The instructor will double-check the set-up before allowing the student to proceed. 24.Students are allowed to operate power equipment in the lab ONLY when the instructor is present and permission has been granted. 25.Do not hurry or rush work when operating machinery. Students have a tendency to hurry up toward the end of each class period. Avoid this tendency, it increases your possibility of committing a careless accident. 26.Develop the habit of keeping hands off knives, blades, and cutters when making machine adjustments. Major adjustments are to be made only when the machine is no longer running and the electrical cord has been disconnected from the power supply. 27.When changing blades, knives, cutters, and so on, disconnect the machine(unplug) from the power supply. © 2008 Buck Institute for Education 20 28.Do not pile lumber or place projects in passageways or aisles. Never block exits from the lab. 29.If machines, tools or equipment need repairs, unplug the machine and immediately report this fact to the instructor. 30.Never oil or clean a machine while that machine is in motion 31.Dull blades, knives, cutters, bits, etc., are dangerous. Report to instructor 32.Use a shop brush to remove shavings, chips, and pieces of wood from beds and other parts of machinery even if the machine is not running. 33.Learn the location of fire-extinguishers. Read the instructions and learn how to operate extinguishers. Familiarize yourself with the type of extinguishers located in the lab. 34.Know where the first aid cabinet is located and get familiar with it. 35.No student should leave class at any time for any reason without permission of the instructor 36.The instructor has the right to take such action that they deem necessary in cases when a student’s attitude and actions regarding safety do not meet these standards. II. Hand Tools Safety 1. When using any edged tool, avoid pulling the tool toward yourself. Push the tool away from the body. 2. Burred (mushroomed) head on such tools such as chisels, punches, hammers, and nail sets should be ground off before they are used. 3. Split, broken, or loose handles on hand tools such as files and hammers are dangerous and should never be used. 4. Never use a file or rasp without a wooden handle. 5. Sharp edged tools such as scribes and chisels should never be carried in a pocket. 6. Wrenches, with badly worn, chewed, and spread openings are prone to slippage and should never be used. 7. No tool should be placed on a bench or sill with the sharp edge(s) projecting. 8. The hands should be kept away from the screwdriver point. 9. When driving nails, the eyes should be kept above the flying nail level. The nail should be held near the head when starting. (Hit the right nail) 10.Tools with exposed edges or points should not be left where they may be stepped on, sat on, or bumped into. 11.Tools should be kept sharp and used for the purpose for which they were intended. ∙Machinist hammers should not be used as carpenter’ hammers and vice versa. ∙Screwdrivers should not be used as or for chisels ∙Wrenches should not be used as hammers ∙Pliers should not be used when a wrench is needed © 2008 Buck Institute for Education 21 ∙Pliers, taped or not taped should never be used on live electric circuits ∙Use the correct tool for the job 12.Adjustable wrenches should always be used with the jaws facing the directions of pull thereby eliminating slippage which in turn produces the skinning or mashing of knuckles. 13.Never throw tools to a fellow student 14.Never use dull tools 15.Put tools away carefully to avoid falling in tool cabinets 16.Use tools properly 17.Use vises or clamps to hold work before using hand tools. Never hold free hand or have a fellow student serve as your vise. 18.Do not use handle extending devices(pipe) on wrenches. III. Table Saw Safety 1. Be sure you have witnessed a class demonstration by the instructor. 2. Be sure the instructor give you permission and observes you the first time you run any of the table saws. 3. You must pass a safety test on the table saw before operating them. 4. Always use a properly adjusted splitter or spreader guard in connection with the rip saw to prevent a dangerous “Throwback.” 5. Do not stand directly behind or in line with a circular saw blade while it is in operation. 6. Do no allow saw blade to extend more than ¼” above the stock being cut. 7. Avoid reaching over the saw blade to remove sawed pieces. 8. A helper taking stock from the saw is never to pull on stock being ripped unless he gets a signal to do so from the operator. When given the signal the helper or “tail man” guides the stock slowly and keeps it straight. 9. Rip no stock unless one edge has been jointed and the jointed edge has been placed against the rip fence. 10.Never push stock with hand between ripping fence and blade when distance between fence and saw blade is less than 4 inches. 11.Use push stick to advance stock when distance between blade and fence is less than 4 inches. Caution. Exercise extreme care and go slowly when using push stick. 12.When distance between blade and fence is less than thickness of push stick, back piece out carefully and push down sharply on end extending in front of table. Turn stock end for end and repeat operation © 2008 Buck Institute for Education 22 13.Never saw “free hand”, i.e. without using the fence or miter gauge. 14.Do not use rip fence for crosscutting 15.There is a cross-cutting or miter gauge for each side of crosscut saw. Be sure you are using the correct one. 16.Only the operator is to advance stock through the saw, make adjustments or turn the power on or off. Only when operator is in trouble should anyone else shut off the power. 17.Be sure all adjustments are tight and that rip fence or miter gauge is fastened securely. 18.Do not use a saw blade that is dull or in need of set. 19.Use proper saw blade for all work. (rip, crosscut, dado) 20.Never make adjustments while saw is running. 21.Students must never lower pieces of stock down over the saw without permission from instructor. This operation is sometimes performed when cutting openings in rails from drawer fronts. Use a crosscut saw for this purpose to prevent throwback. 22.Consult the instructor for special set-ups on table saw. IV. Jointer Safety 1. This is potentially the most dangerous piece of equipment in the shop, use it with extreme care. 2. Never remove the guard. Test the guard before starting the machine to insure it moves easily out of the way as stock is passed over blades. 3. Be sure you have witnessed a class demonstration by the instructor. 4. Be sure the instructor gives you permission and observes you the first time you run the jointer. 5. You must pass a safety test on the jointer before operating the machine. 6. Check knives to see if they are correctly set and are sharp. Dull knives are dangerous. 7. Depth of cut varies with the width and hardness of the stock. Do not take too heavy a cut. Several light cuts will produce better results than a single heavy cut. Consult instructor when in doubt. 8. Always use pushblock when jointing flat surfaces. 9. Consult instructor before jointing short or small stock. 10.Hold stock firmly against the table and fence to avoid kickback. 11.Special set-ups must be checked by the instructor before machine is put into operation. © 2008 Buck Institute for Education 23 12.When operating the jointer stand with feet apart, left foot forward, and press right leg or hip against machine. 13.Use an assistant when jointing the edge or face of long pieces. 14.When jointing surfaces keep concave surfaces against the table. 15.Keep guard in place except for rabbetting and chamfering. Its operation should be fully automatic. 16.Never adjust the fence when the machine is in motion. 17.To avoid injury when jointing an edge, hold face of stock firmly against the fence by pushing in a horizontal direction. 18.Make certain no one is standing directly behind the jointer while in operation. 19.Never joint the end of a board without consulting your instructor. 20.Run stock through with the grain, not against it. 21.Do not plane stock shorter than 10”, narrower than 1” or thinner than ½”. 22.Special care should be used when jointing knotty stock. 23.Do not plane old lumber as it may contain nails. 24.Do not use jointer to remove paint from boards. 25.Know where your hands are at all times. Do not attempt to operate the jointer with wet or sweating hands. Stock Sizes for Safer Jointer Operation Depth of cut: Surfacing = 1/32” maximum Hardwoods = 1/16” maximum Softwoods = 1/8” maximum Stock Size: Width = 1” minimum Length = 10” minimum Thickness = ½” minimum V. Drill Press Safety 1. Use only properly sharpened drills and bits. 2. Fasten drill or bit securely into chuck. Tighten by turning chuck key. 3. Always clamp work that is being drilled or use a fence. Use Vee blocks and clamps when drilling round stock. 4. Keep long hair and loose clothes away from spindle and drill bit. 5. Never reach around the drill when it is running. 6. Avoid forcing or feeding the drill to fast. In heavy drilling in hard material retract drill periodically to extract shavings and cool drill bit. 7. Never use wiping rages around a drill bit. Debris may be wiped away with a brush. © 2008 Buck Institute for Education 24 8. Run drill at proper speed for size of drill or bit. Consult instructor. 9. Change speeds only when drill is stopped. 10.Always be sure machine is stopped before leaving. 11.Never brush table with hands. VI. Band Saw Safety 1. Be sure you have witnessed a class demonstration by the instructor. 2. Be sure the instructor gives you permission and observes you the first time you operate any of the band saws. 3. You must pass a written safety test on the band saws before operating them. 4. Check adjustments of the blade by moving the wheels by hand. 5. Adjust top guide to within ¼” of the work. 6. Before cutting, determine that blade travels freely between side guides and makes light contact with guide bearing. 7. Do not twist the blade or force it to cut sharp curves. This tends to crystallize the blade and snap the blade in two. 8. A cracked or partially broken blade will saw, for a short time, with a noticeable knock or kick. Stop the saw and report this condition to the instructor. 9. Always saw through stock whenever possible. When necessary to back out of a cut, go slowly, being sure that you do not pull blade away from guides. 10.Always use special jig(vee block) for sawing cylindrical stock. 11.Consult instructor before sawing small or irregular pieces on the band saw. 12.Replace a worn throat plate because chips of wood may fall through and be caught between blade and lower wheel causing blade to break. 13.If blade breaks, step away from it quickly and shut power off. Do not touch blade until both wheels have stopped. 14.The operator and spectators should not stand in line with band saw blade. 15.Resawing usually requires a special guide. Consult instructor. 16.Keep hands and fingers away from front of blade. Use extreme care when sawing small pieces. 17.Use only correct blade. Small diameter circles require very narrow blades. 18.If blade has improper set(cuts to one side but not the other) tell the instructor. VII. Wood Lathe Safety 1. Be sure you have witnessed a class demonstration on the wood lathe. © 2008 Buck Institute for Education 25 2. 3. 4. 5. 6. Be sure the instructor gives you permission and observes you the first time you operate the lathe. You must pass a written safety test before operating the lathe. Use the correct cutting tool for the cutting operation. Be sure tools are sharp. Never attempt to measure stock with calipers while the stock is turning. Be sure the tool rest is 1/8” above vertical center and 1/8” away from the stock. Rotate stock by hand to determine proper clearance before turning on power. 7. Always keep two hands on the lathe cutting tool during cutting operations. 8. Lubricate the dead center with soap or wax to avoid burning stock 9. When turning a faceplate, be sure faceplate is securely in position before turning “on” power. 10.Center cylindrical stock- unbalanced stock may be thrown from the lathe at high speed. 11.Never slow down moving stock with the hand. Wait until the lathe comes to a complete stop before checking measurements. 12.Be sure you use sound stock or properly glued stock for turning stock. 13.Be sure to use correct spindle speeds for all turning operations. 14.When polishing or applying finish with a rag, be sure to hold it tightly to avoid being wrapped around the revolving stock. 15.Observers should never stand directly behind the revolving stock. Observers should stand beside the headstock or tailstock portion of the lathe. 16.Do not take too heavy a cut with the cutting tools. VIII. Surface Planer Safety 1. Be sure that the knives are sharp and are securely and accurately mounted before using the planer 2. Never plane stock which might contain nails, staples, wires, or bullets! 3. Never place small tools or metal pieces on the machine table. 4. Always stop the machine before attempting to dislodge a “stuck” workpiece or clear away loose chips from the table. 5. Do not force stock through the planer if the rollers fail to pull stock through as intended. Shut machine “off”, wait until blades stop, lower table and extract stock. 6. Do not exceed the maximum cut (normally 1/8”) for which the machine was designed. 7. Do not position fingers under the front column tie rod at any time while machine is in operation. When feeding stock into the planer, pay close attention to hand position-move your hands back away from the blades whenever they get as close as three inches to the tie rod. © 2008 Buck Institute for Education 26 8. Do not plane stock that is shorter than the distance between the feed and delivery rolls. 9. On a single surface planer one face must be made flat on the jointer. This face should be next to the bed. 10.Always place the thick end of the stock into the planer first. 11.The depth of cut is regulated by the width and hardness of the stock. Consult the instructor until you have gained experience. 12.Keep hands on top of the board and hold board flat on in-feed table when starting out to avoid chance of mashing fingers between board and table. 13.Never stand directly behind work being planed, nor allow spectators to do so. 14.Never push stock into the planer with body. A kickback might be serious. 15.Never reach over machine for anything and avoid contact with rolls, gears and belts. 16.Do not look into in-feed end of surfacer when machine is running. Splinters and other material might be thrown back. 17.Avoid brushing dust, shavings and dirt from machine with your hands. Use a brush. 18.Always feed boards of uniform thickness side by side; one of a different thickness may kick back. 19.Consult instructor before doing special work on the planer. 20.Use a helper to take long pieces out of planer. 21.Always rotate which side is being planed through the planer – i.e. if you plane one face of the stock, flip it over and plane the other face next time through. Stock Sizes for Safe Operation of Surface Planer Depth of Cut: Hardwoods = 1/16” maximum Softwoods = 1/18” maximum Stock Size: Width = 12” maximum Length = 12” minimum Thickness = 3/8” minimum IX. Miter Saw Safety 1. Be sure you know how to operate this saw. It is very safe if operated properly but very dangerous if not. Read and understand operation directions. 2. Keep saw blade sharp- make sure that before use that the blade is not dull. 3. Never attempt to adjust the saw’s set-up until the blade has come to a complete stop. 4. Adjust guard down to material for all operations. © 2008 Buck Institute for Education 27 5. 6. 7. 8. 9. Do not attempt to rip thin or short pieces. Always make sure that cutting table is locked and secured before cutting. Do not “cross” your arms to cut a workpiece. Keep your hand on the power until blade is returned to starting position. Do not attempt to remove any scrap pieces until blade is completely stopped. X. Router Table Safety 1. Be sure you have witnessed a class demonstration by the instructor. 2. Before replacing or adjusting the bit, always make sure that the router is unplugged. 3. Before using the router, always make sure that the chuck is securely tightened. 4. When adjusting or replacing bit lock in the locking mechanism. 5. Be sure that work space is clear of debris and dust- use a brush to clear work space. 6. Never stand directly in front or in line with the router. 7. Always use a push stick on thin or narrow stock. 8. Never place your hands directly over router when pushing through router. 9. Do not leave machine still running when done. 10.Never touch router bit with hand when immediately done with operation – it will be warm, and could possibly burn you. XI. Portable Power Tools Safety: A. Saws 1. Adjust saw correctly before starting to saw. 2. Always have a firm hold on the saw using both hands. 3. Unplug saw when changing blades. 4. Always start saw and allow blade to reach maximum speed prior to moving into cut 5. Be sure telescoping guard is working properly. This is only held out of the way when making a pocket cut. 6. Always use sharp blades. © 2008 Buck Institute for Education 28 7. Be sure saw is properly grounded at frame and the cord is in good condition. 8. Use a saw guide whenever possible. 9. Be sure saw blade has stopped before laying saw down. 10. Pay attention to what lies directly underneath the stock to be cut. Do not cut through bench tops, cords, or human extremities while operating the saw. B. Belt Sanders 1. Clamp stock to be sanded 2. Be sure sander belt is stopped before setting machine down. Do not lay it on its side. 3. Use the proper abrasives for the stock to be sanded 4. Do not use a worn or ragged belt. 5. Belts are designed to travel in one direction. 6. Be sure belt “tracks” in a straight line and does not travel left or right before applying to stock. 7. Use both hands to control and guide the belt sander while operating . 8. Move sander continuously in line with the grain of the stock. 9. Do not sand against pointed corners 10. Be sure cord is not in the way of your work. C. Drills 1. Be sure the drill is grounded and the cord is in good condition. 2. Assume a firm footing when drilling 3. Do not lock drill in the “on” position. 4. Be sure drill is stopped before setting down 5. Reduce pressure when protruding through stock to prevent torque being placed on drill body. 6. See Drill Press for other rules that may apply. © 2008 Buck Institute for Education 29 Woodworking I Safety Contract I, _______________________________ have read each and every safety rule above; I have successfully passed a safety exam; and I thoroughly understand the importance of safety in the woods lab. Further, I understand that failure to abide completely by these safety rules, increases the risk of injury to myself and others. Therefore, I agree to abide by each and every safety rule while working in the woods lab. I also understand that failure to abide by these rules may result in a lower grade in the course Woodworking I. Signature:_____________________________________ Date:__________ Parent Signature: ______________________________ Date: __________ © 2008 Buck Institute for Education 30 © 2008 Buck Institute for Education 31