Arvind Rajput

advertisement

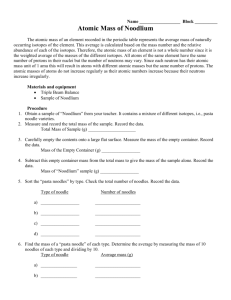

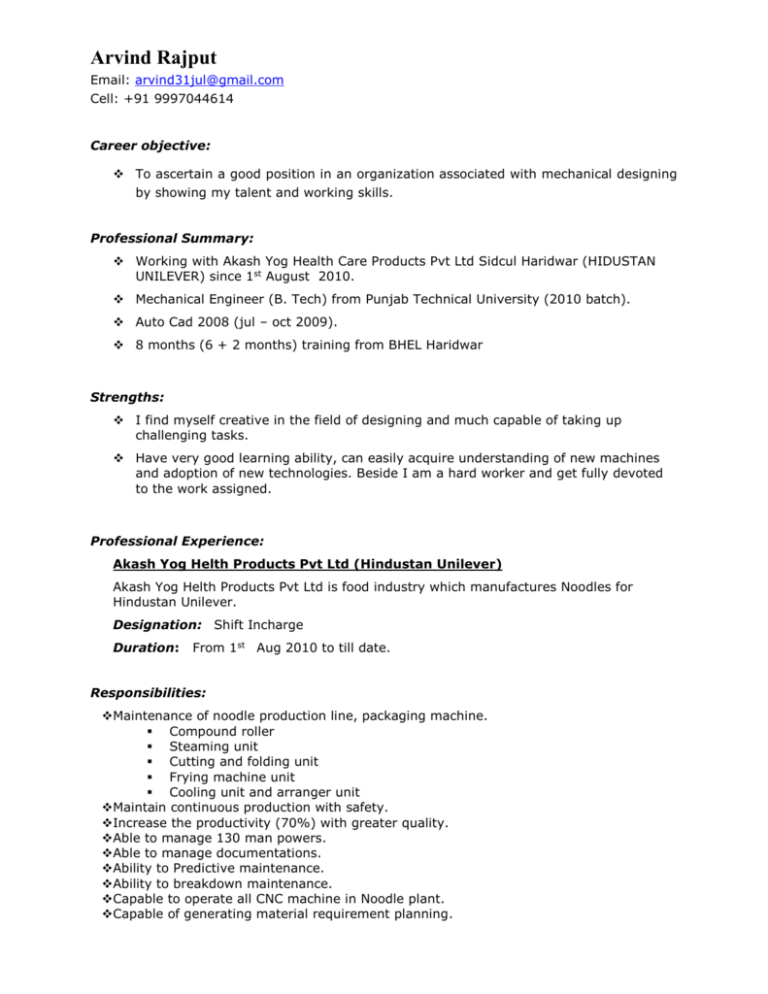

Arvind Rajput Email: arvind31jul@gmail.com Cell: +91 9997044614 Career objective: To ascertain a good position in an organization associated with mechanical designing by showing my talent and working skills. Professional Summary: Working with Akash Yog Health Care Products Pvt Ltd Sidcul Haridwar (HIDUSTAN UNILEVER) since 1st August 2010. Mechanical Engineer (B. Tech) from Punjab Technical University (2010 batch). Auto Cad 2008 (jul – oct 2009). 8 months (6 + 2 months) training from BHEL Haridwar Strengths: I find myself creative in the field of designing and much capable of taking up challenging tasks. Have very good learning ability, can easily acquire understanding of new machines and adoption of new technologies. Beside I am a hard worker and get fully devoted to the work assigned. Professional Experience: Akash Yog Helth Products Pvt Ltd (Hindustan Unilever) Akash Yog Helth Products Pvt Ltd is food industry which manufactures Noodles for Hindustan Unilever. Designation: Shift Incharge Duration: From 1st Aug 2010 to till date. Responsibilities: Maintenance of noodle production line, packaging machine. Compound roller Steaming unit Cutting and folding unit Frying machine unit Cooling unit and arranger unit Maintain continuous production with safety. Increase the productivity (70%) with greater quality. Able to manage 130 man powers. Able to manage documentations. Ability to Predictive maintenance. Ability to breakdown maintenance. Capable to operate all CNC machine in Noodle plant. Capable of generating material requirement planning. Project undertaken: Continuous noodle production line and packaging machine. Duration Team size Tools/Machines Used : : : Role Functional Area : : sep 2010- till date 68 compound roller, continuous roller, steam section Unit. cutting and folding unit, dividing unit, frying unit, cooling unit, arranger, packaging machine, coding machine, taping machine project engineer to maintain noodle production line and packaging machines Description: In this project I gained experience of maintenance as well as production of noodle production line and their assembly. Assembled compound roller where maida formed into sheet. Next unit continuous rolling machine reduces the thickness of sheet up to desired level (1.2mm). combing unit where threads (80 threads in one noodle) of Maida is formed and it allowed to go in steaming unit (95 C at 0.2 bars) were noodles row (6) cooked. Cutting and folding unit create a part noodle and divided into separate noodle. Frying unit is responsible for frying (up to temperature of 140 C) the noodle and cooling unit is cooling the noodle after that arranger is arrange the noodle and allowed to go in packaging machine (4 nos ) where packaging is done. Software proficiency: Relevant software Auto Cad 2008 Other MSWord, Power Point, Excel, MS DOS, Windows 98, 2K, XP Certificates: Auto Cad 2008 (2D & 3D) from U-Tech education centre. Academic Qualification: B.Tech (Mechanical Engineering) with 68.5% from Shaheed Bhagat Singh College Of Engineering And Technology, Ferozepur (PTU) in 2010 Higher Secondary Examination from CBSC Board in 2005. Matriculation passed from CBSC Board in 2002. Academic Project Undertaken: 1. General Awareness Of Steam Turbine Manufacturing Including NC Technology Organization : BHEL Haridwar Duration Team size Tools/Machines Used : : : Role Functional Area : : 6 months (Jul - Dec 2009) 2 Lathe and Horizontal Boring Machine (NC Machine), Balancing Machine, Alignment Machine, Gas Welding Machine, Cranes Leaner Electricity Production Description : In this project I gained hands on experience on Lathe and Horizontal Boring Machine which are based on NC technology. I also learned the basic design of a steam turbine and working its different parts including front and rear bearing pedestal. In NC Department of BHEL I tried some hands on coding in developing program for cutting operations that are used to build in G-Coding and M-Coding. 2. Bicycle Powered Grass Cutting Machine. Duration Team size Tools/Machines Used : : : Role Functional Area : : 3 months (Mar - May 2010) 4 Welding Machine, balance equalizer, Alignment Machine, Load Impact Machine and other Tools Designer, producer, adviser and tester Ground Cleaning Description : This bicycle power grass cutting machine has a superseded electrical source with bicycle paddles for providing the required energy and therefore it results into saving of substantial amount of electricity that could be wasted if used ordinary grass cutting machine. It also saves man power because of its simple construction and low weight. Personal Profile: Name Arvind Rajput Father’s Name H.S.Rajput Date Of Birth Nationality Marital Status Languages known Permanent Address 31 Jul 1987 Indian Unmarried English, Hindi P-132 Shivalik Nagar BHEL Haridwar, U.K.-249403 Alternate Ph No. +91 9897986941 (mob) Alternate e-mail id 31jularvind@gmail.com Declaration : I hereby declare that the information furnished above is true to the best of my knowledge. Place: Date: Arvind Rajput