engines

advertisement

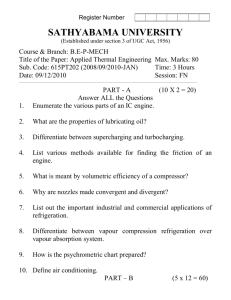

ME210 THERMAL ENGINEERING - I Objective of the Course: To familiarize students with the working of Compressors and reciprocating piston engines and to enable them to develop a deep appreciation of the concepts of thermodynamics and fluid mechanics underlying in the design and development of these machines. UNIT - I Introduction : Introduction, Comparison of Air Standard and Actual Cycles, Actual and FuelAir Cycles Of IC Engines, Classification - Working principles, Valve and Port Timing Diagrams. Engine systems – Fuel Carburetor, Fuel Injection System, Ignition, Cooling and Lubrication. Introduction to Fuels –Conventional and Alternate fuels-Characteristics. UNIT - II Combustion in S.I Engines : Normal Combustion, Importance of flame speed, pre-ignition and knocking, anti knock additives, combustion chamber, types. Combustion in C.I. Engine: Stages of combustion – Delay period and its importance – Diesel Knock– Need for air movement, suction, compression and combustion induced turbulence. UNIT – III Performance of I.C Engines : Measurement of cylinder pressure, fuel Consumption, air intake, exhaust gas composition, Brake power – Determination of frictional losses and indicated power – Performance test – Heat balance sheet. UNIT – IV Reciprocating Compressors : Classification and working principle, work of compression with and without clearance. Volumetric efficiency, Isothermal efficiency and isentropic efficiency of reciprocating air compressors. Multistage air compressor and inter cooling – working of multistage air compressor. UNIT - V Centrifugal compressors : Principle of operation – velocity and pressure variation. Energy transfer-impeller blade shape-losses, slip factor, power input factor, pressure coefficient velocity diagrams, power. Axial Flow Compressors - Mechanical details and principle of operation – velocity triangles and energy transfer per stage degree of reaction, work done factor - isentropic efficiency. Polytrophic efficiency. TEXT BOOKS 1. John B. Hey Wood” “Fundamentals of I.C. Engines”, 2nd ed., Mc.Graw-Hill, 1988. 2 GANESAN V., “Internal Combustion Engines”, 2nd ed., TMH. 2007. REFERENCE BOOKS 1. Sarkar B.K, “ Thermal Engineering”, Tata McGraw-Hill, 1998. 2. R.YADAV, “Thermal Engineering” , Central Book Depot, 1995. 3. Mathur R.P., and Sharma, “Internal Combustion Engines”, 8th ed., Dhanpath Rai & Sons, New Delhi, 1996. UNIT-I ENGINES (i) (ii) (iii) Heat Engine E.C Engines (External Combustion Engines) I.C Engines (Internal Combustion Engines) Engine: An engine is a device which transforms one form of energy into another form. (or) The machine which does this job of energy conversion is called an engine Heat Engine: Heat engine is a device which transforms the chemical energy of a fuel into thermal energy and utilizes this thermal energy to perform useful work. The most widely used ones are the reciprocating internal combustion engine. The gas turbine and the steam turbine. The reciprocating internal combustion engine enjoys some advantages over the steam turbine due to the absence of heat exchanges in the passage of the working fluid. Absence of heat exchanges results in a considerable mechanical simplicity and improved efficiency of the internal combustion engine. Heat Engine IC Engine Rotary Reciprocating Wankel Opencycle Gasoline diesel Engine gas turbine engine engine EC Engine Reciprocating steam engine Rotary stirling stem closedcycle engine engine gas turbine Reciprocating internal combustion engine components work at an average temp. which is much below the maximum temperature of the working fluid in the cycle. In internal combustion engine, thermal efficiency can be obtained with moderate maximum working pressure of the fluid. Disadvantage: Problem of vibration caused by the reciprocating components and also, it is not possible to use a variety of fuels in these engines. Only liquid (or) gaseous fuels of given specification can be efficiently used. Reciprocating internal combustion engines have been found suitable for use in automobiles, motor-cycles and scooters, power boats, ships, slow speed air craft, locomotives and power units of relatively small output. External combustion engines are those in which combustion takes place outside the engine. Ex: Steam engine (or) a steam turbine. Internal combustion engines combustion takes place within the engine. Ex: Gasoline (or) diesel engine. In Case of I.C Engine analysis, there are three types of cycles as follows a) Air standard cycles b) Fuel-Air cycles c) Actual cycles About Air standard cycles : The accurate analysis of I.C Engine process is very complicated. In order to understand them it is advantageous to analyze the performance of an idealized closed cycle that closely approximates the real cycle. Following assumptions are lying under the air standard cycles The working medium is assumed to be a perfect gas and follows the relation PV=mRT There is no change in the mass of the working medium. All the processes that constitute the cycle are irreversible Heat is assumed to be supplied from a constant high temperature source and not from chemical reactions during the cycle Some heat is assumed to be rejected to a constant low temperature sink during the cycle It is assumed that there are no heat losses from the system to the surroundings The working medium has constant specific heats throughout the cycle. About Fuel-Air cycles: By air-standard cycle analysis, it is understood how the efficiency is improved by increasing the compression ratio. However the analysis could not bring about the effect of air-fuel ratio on thermal efficiency. The fuel-air cycle analysis takes into account the following: The actual composition of cylinder gases: The cylinder gas contains fuel, air, water vapor and residual gas. The variation in specific heat with temperature: Specific heats increase with the increase of temperature. The effect of dissociation: the fuel and air do not completely combine chemically at high temperatures and this leads to presence of CO,H2,H and O2 at equilibrium conditions The variations in the number of molecules: The number of molecules present after combustion depend upon fuel-air ratio and upon pressure and temperature of the combustion. There is no chemical change in either fuel or air prior to the combustion Subsequent to combustion, the charge is always in chemical equilibrium There is no heat exchange between the gases and the cylinder walls in any process. The burning takes place instantaneously(constant volume). Actual cycles: The actual cycles for internal combustion engines differ from air standard cycles in many respects. The actual cycle efficiency is much lower than the air-standard efficiency due to various losses occurring in the actual engine operations. The losses are mainly due to The working substance being a mixture of air and fuel vapour or finely atomized liquid fuel in air combined with the products of combustion left from the previous cycle. The change in the chemical composition of the substance The variations of specific heats with the temperature The progressive combustion rather than instantaneous combustion. The heat transfer to and from the working medium. Time loss factor Heat loss factor Exhaust blow down Gas exchange process or pumping loss Engine Main Components: (i) Cylinder: It is a cylindrical vessel (or) space in which the piston makes a reciprocating motion. (ii) Piston: It is a cylindrical component fitted into the cylinder forming the moving boundary of the combustion system. (iii) Combustion Chamber: The space enclosed in the upper part of the cylinder, by the cylinder head and the piston top during the combustion process. (iv) Inlet Manifold: The pipe which connects the intake system to the inlet value of the engine and through which air (or) air-fuel mixture is drawn into the cylinder is called the inlet manifold. (v) Exhaust Manifold: The pipe which connects the exhaust system to the exhaust value of the engine and through which the products of combustion escape into the atmosphere is called the exhaust manifold. (vi) Inlet and exhaust Valves: Regulating the charge coming into the cylinder and for discharging the products of combustion from the cylinder. (vii) Spark Plug: It is a component to initiate the combustion process in Spark Ignition (SI) engines and is usually located on the cylinder head. (viii) Connecting rod: It interconnects the piston and the crankshaft and transmits the gas forces from the piston to the crankshaft. (ix) Crankshaft: In converts the reciprocating motion of the piston into useful rotary motion of the output shaft the crankshaft is enclosed in a crankcase. (x) Piston Rings: Piston rings, fitted into the slots around the piston, provide a tight seal between the piston and the cylinder wall thus preventing leakage of combustion gases. (xi) Gudgeon Pin: It forms the link between the small end of the connecting rod and the piston. (xii) Camshaft: The camshaft and its associated parts control the opening and closing of the two values. The camshaft is driven by the crankshaft through timing gears. (xiii) Cams: These are made as integral parts of the camshaft and are designed in such a way to open the values at the correct timing and to keep them open for the necessary duration. (xiv) Fly Wheel: The net torque imported to the crankshaft during one complete cycle of operation of the engine fluctuates causing a change in the angular velocity of the shaft. In order to achieve a uniform torque an inertia mass in the form of a wheel is attached to the output shaft and this wheel is called the fly wheel. Nomenclature: (i) Cylinder Bore (d): The nominal inner diameter of the working cylinder is called the cylinder bore and is designed by the letter ‘d’. (ii) Piston area (A): The area of a circle of diameter equal to the cylinder bore is called the piston area and is designated by the letter ‘A’ (iii) Stroke (L): The nominal distance through which a working piston moves between two successive reversals of its direction of motion is called the stroke and is designated by the letter ‘L’. (iv) Dead Centre: The position of the working piston and the moving parts which are mechanically connected to it, at the moment when the direction of the piston motion is reversed at either end of the stroke is called the dead centre. There are two dead centres in the engine as (a) Top dead centre (T.D.C) (b) Bottom dead centre (B.D.C) (a) Top Dead Centre (TDC):It is the dead centre when the piston has long distance from the crankshaft. It is designated as TDC. It is also called as Inner Dead Centre (IDC). (b) Bottom Dead Centre (BDC): It is the dead centre when the piston has shortest distance to the crankshaft. It is designated as BDC. It is also called as the Outer Dead Centre (ODC) (v) Displacement (or) Swept Volume (VS) or Stroke Volume: The nominal volume swept by the working piston when it is travelling from one dead centre to the other dead center is called the displacement volume. VS A L d 2 L 4 (vi) Clearance Volume (VC): The nominal volume of the combustion chamber above the piston whent it is at the top dead centre is called the clearance volume. (vii) Compression Ratio (r): It is the ratio of the total cylinder volume when the piston is at the bottom dead centre, VT to the clearance volume VC. VT VC VC VS VC VS 1 VC r Classification of internal Combustion engines Classification based on i) Cycle of operation a) Otto cycle b) Diesel cycle ii) Types of fuel a) Petrol, Gasoline, kerosene b) Diesel c) LPG, Natural gas d) Solid fuel e) Dual fuels iii) Method of charging a) Naturally aspirated engines b) Super charged engines iv) Type of ignition a) Spark ignition i) Battery ignition ii) Magento ignition b) Comp ignition v) Type of cooling a) Air cooling b) Water cooling vi) Cylinder a) In-line engine b) V-engine c) Opposed cylinder engine d) Radial engine e) X-type engine f) M-type engine g) U-type engine vii) Application of engines a) Transportation b) Marine c) Power-plant d) Space applications Working of a 4-Stroke spark Ignition engine: TDC Top Dead Centre BDC Bottom Dead Centre Vc Clearance Volume SP Spark Plug For Horizontal engine IDC Inner Dead Centre ODC Outer Dead Centre Stroke: Movement of piston from one dead centre to other dead centre. For a 4-stroke engine we get only one power stroke. For a 4-stroke crank speed – 2 revolutions degrees (360+360=7200) For two movements of a piston getting one power stroke is good. The diagram is Value Timing Diagram (VTD) Working of a 4-stroke compression ignition engine same as Spark Ignition (SI) engine but spark plug is replaced as fuel injector. It discharges diesel and it combusts itself due to high pressure. Diesel has low self ignition temperature than petrol. SI – Petrol – Quantity Governing (can control) CI – Diesel – Quality Governing. The compression ratio for SI 6-10 CI 10-20 CI is costlier & weightier We can regulate power in CI by regulating the quantity of diesel. SI by regulating the quantity of fuel. Four – Stroke spark Ignition engine: In a four-stroke engine, the cycle of operations is completed in four strokes of the piston or two revolutions of the crankshaft. During the four strokes, there are five events to be completed. (i) Suction (ii) Compression (iii) Combustion (iv) Expansion (v) Exhaust Each stroke consists of 1800 of crankshaft rotation and hence a four-stroke cycle is completed through 7200 of crank rotation. The cycle of operation for an ideal four-stroke SI engine are (i) Suction (or) Intake Stroke (ii) Compression Stroke (iii) Expansion (or) Power Stroke (iv) Exhaust Stroke (i) Suction (or) Intake Stroke: Suction, stroke 0 1 starts when the piston is at the top dead centre and about to move downwards. The inlet value is open at this time and the exhaust is closed. (ii) Compression Stroke: The charge taken into the cylinder during the suction stroke is compressed by the return stroke of the piston 1 2 during this stroke both inlet and exhaust values are in the closed position. A spark plug located on the cylinder head burning takes place the fuel is converted into heat energy producing a temperature rise of about 20000C (2 3). (iii) Expansion (or) Power Stroke: The high pressure of the burnt gases forces the piston towards the BDC, stroke 3 4 with both the inlet and exhaust values remaining closed. (iv) Exhaust Stroke: At the end of the expansion stroke the exhaust value opens and the inlet value remains closed. The piston moves from the bottom dead centre to top dead centre (stroke 5 0). (ANIMATION) Four-Stroke compression Ignition engine: The Four-stroke CI engine is similar to the Four-stroke SI engine but it operates at a much higher compression ratio. The compression ratio of an SI engine varies from 6 to 10 while for a CI engine it is from 16 to 20. Due to the high compression ratio employed, the temp. at the end of the compression stroke is sufficiently high. The ideal sequence of operation for the four-stroke CI engine is as follows: (i) Suction Stroke: Air alone is inducted during the suction stroke during this stroke intake valve is open and exhaust value is being closed. (ii) Compression Stroke: Air inducted during the suction stroke is compressed into the clearance volume. Both values remain closed during this stroke. (iii) Expansion Stroke: Fuel injection starts nearly at the end of the compression stroke. Heat is assumed to have been added at constant pressure. Both values remain closed during the expansion stroke. (iv) Exhaust Stroke: The piston travelling from BDC to TDC pushes out the products of combustion. The exhaust value is open and the intake value is closed during this stroke. Working principles of four stroke and two stroke engines (i) In Four-stroke engines, there is one power stroke for every two revolutions of the crankshaft. (ii) (iii) (iv) (v) There are two non-productive strokes of exhaust and suction which are necessary for flushing the products of combustion from the cylinder and filling it with the fresh charge. If this purpose could be served by an alternative arrangement, without the movement of the piston, it is possible to obtain a power stroke for every revolution of the crankshaft (increases) the o/p of the engine. However, in both SI and CI engines operating on four-stroke cycle, power can be obtained only in every two revolution of the crankshaft. Since, both SI and CI engines have much in common, it is worth while to compare then based on important parameters like basic cycle of operation, fuel induction, compression ratio etc. Two-Stroke engine: (i) The suction and exhaust could be served by an alternative arrangement, especially without the movement of the piston then there will be a power stroke for each revolution of the crankshaft. (ii) In such an arrangement, theoretically the power o/p, of the engine can be doubled for the same speed compared to a four-stroke engine. (iii) In two-stroke engines the cycle is completed in one revolution of the crankshaft. (iv) The main difference between two-stroke and four-stroke engines is in the method of filling the fresh charge and removing the burnt gases from the cylinder. (v) In the four-stroke engine these operations are performed by the engine piston during the suction and exhaust stroke respectively. (vi) In a two-stroke engine the filling process is accomplished by the charge compressed in crankcase (or) by a blower. (vii) The induction of the compressed in charge moves out the product of combustion through exhaust parts. Therefore, no piston strokes are required for these two operations. (viii) Two strokes are sufficient to complete the cycle, one far compression the fresh charge and the other far expansion (or) power stroke. ACTUAL INDICATOR DIAGRAM FOR A TWO STROKE CYCLE PETROLENGINE The actual indicator diagram for a two -stroke cycle petrol engine is shown in suction is shown by the line 1 -2-3, i.e. from the instant transfer port pens (TPO) and transfer port closes (TPC). We know that during the suction stage, the exhaust port is also open. In the first half of suction stage, the volume of fuel -air mixture and burnt gases increases. This happens as the piston moves from I to 2 (i.e. BDC). In the second half of the suction stage, the volume of charge and burnt gases decreases. This happens as the piston moves upwards from 2 to 3. A little beyond 3, the exhaust port closes (EPC) at 4. Now the charge inside the engine cylinder is compressed which is shown by the line 4-5. At the end of the compression, there is an increase in the pressure i n s i d e t h e e n g i n e cylinder. Shortly before the end of compression (i.e. TDC) the charge is ignited (IGN) with the help of spark plug. The sparking suddenly increases pressure and temperature of the products of combustion. But the volume, practically, remains constant as shown by the line 5-6. The expansion is shown by the line 6-7. Now the exhaust port opens (EPO) at 7, and the burnt gases are exhausted into the atmosphere through the exhaust port. It reduces the pressure. As the piston is moving towards BDC, therefore volume of burnt gases increases from 7 to 1. At 1, the transfer port opens (TPO) and the suction starts. Fig Two-Stroke Engine (ANIMATION) Description Basic cycle SI Engine Otto cycle (or) constant volume heat addition cycle. CI Engine Diesel cycle (or) constant pressure heat addition cycle. Fuel Gasoline, a highly volatile fuel, self-ignition temp. is high. Diesel oil, a non-volatile fuel self-ignition temp. is comparatively low. Introduction A gaseous mixture of fuel and Fuel is injected directly into the of fuel air is introduced during the suction stroke. A carburetor is necessary to provide the mixture. combustion chamber at high pressure at the end of the compression stroke. A fuel pump and injector and necessary. Load Control Throttle controls the quantity of mixture introduced. The quantity of fuel is regulated in the pump. Air quantity is not controlled. Ignition Requires as ignition system with spark plug in the combustion chamber. Primary voltage is provided by a battery or a magneto. Compression 6 to 10 upper limit is fixed by ratio antiknock quality of the fuel. Self-ignition occurs due to high temp. of air because of the high compression. Ignition system and spark plug are not necessary. Speed Due to light weight and also the homogeneous combustion, they are high speed engines. Due to heavy weight & also due to heterogeneous combustion, they are low speed engines. Thermal efficiency Because of lower CR, the max. value of thermal efficiency that can be obtained is lower. Because of higher CR, the max. value of thermal efficiency that can be obtained as higher. Weight Lighter due to lower peak pressures. Heavier due to higher peak pressures. 16 to 20 upper limit is limited, by weight of the engine. Comparison of Four Stroke and Two-Stroke Cycle Engines. Four-Stroke Engine The thermodynamic cycle is completed in four strokes of the piston or in two revolutions of the crankshaft. Thus, one power stroke is obtained in every two revolutions of the crankshaft. Two-Stroke Engine The thermodynamic cycle is completed in two strokes of the piston or in one revolution of the crankshaft. Thus one power stroke is obtained in each revolution of the crankshaft. Because of the above, turning moment is not so uniform and hence a heavier fly wheel is needed. Because of the above, turning moment is more uniform and hence a lighter fly wheel can be used. Again, because of one power stroke for two revolutions, power produced for some size of engine is less, or for the same power the engine is heavier and bulkier. Because of one power stroke for every revolution, power produced for same size of engine is more (or) far the same power the engine is lighter and more compact. Because of one power stroke in two revolutions lesser cooling and lubrication Because of one power stroke in one revolution greater cooling and lubrication requirements. Higher rate of wear and requirements. Lower rate of wear and tear. The four-stroke engine contains values and value actuating mechanisms to open and close the values. Because of the heavy weight and complicated value mechanism, the initial cost of the engine is more. Volumetric efficiency is more due to more time for induction. tear. Two-stroke engines have no values but only parts. Because of light weight and simplicity due to the absence of value mechanism, initial cost of the engine is less. Volumetric efficiency is low due to lesser time for induction. Thermal efficiency is higher; part load efficiency is better than two-stroke cycle engine. Thermal efficiency is lower; part load efficiency is poor compared to a fourstroke cycle engine. Used where efficiency is important, viz, in cars, buses, trucks, tractors, industrial engines, aero planes, power generation etc.,. Used where low cost, compactness and light weight are important, viz, in mopeds, scooters, motor cycles, hand sprayers etc.,. In Four-stroke we have valve mechanism. Costlier In two-stroke we have port mechanism. Cheaper. Valve Timing Diagram: A valve timing diagram is a graphical representation of the exact moments, in the sequence of operations, at which the two valves (i.e. inlet and exhaust valves) open and close as well as firing of the fuel. It is, generally, expressed in terms of angular positions of the crankshaft. Here we shall discuss theoretical valve timing diagrams for four stroke and two stroke cycle engines. Fig: Theoretical valve timing diagram 1. Theoretical valve timing diagram for four stroke cycle engine The theoretical valve timing diagram for a four -stroke cycle engine is shown Inthis diagram, the inlet valve opens at A and the suction takes place from A to B. The crankshaft revolves through 180 0 and the piston moves from T.D.C. to B.D.C. At B, the inlet valve closes and the compression takes place from B to C. The crankshaft revolves through 1800 and the piston moves from B.D.C. to T.D.C. At C, the fuel is fired and the expansion takes place from C to D. The crankshaft revolves through 1800 and the piston again moves from T.D.C. to B.D.C. At D, the exhaust valve opens and the exhaust takes place from D to E. The crankshaft again revolves through 1800 and the piston moves back to T.D. C. 2. Theoretical Port timing diagram for two-stroke cycle engine . The theoretical Port timing diagram for a two-stroke cycle engine is shown. In this diagram, the fuel is fired at A and the expansion of gases takes place from A to B. The crankshaft revolves through approximately 1200 and the piston moves from T.D.C. towards B.D.C. At B, the valves open and suction as well as exhaust take place from B to C. The crankshaft revolves through approximately 120 0 a n d t h e p i s t o n m o v e s f i r s t t o B.D.C and then little upwards. At C. both the valves close and co mpression takes place from C to A. The crankshaft revolves through approximately 1200 and the piston moves to T.D.C ACTUAL VALVE TIMING DIAGRAM FOR A FOUR S T R O K E C Y C L E P E T R O L ENGINE: In the valve timing diagram, as shown we see that the inlet valve opens before the piston reaches TDC o r i n o t h e r w o r d s , w h i l e t h e p i s t o n i s s t i l l m o v i n g u p b e f o r e t h e beginning of the suction stroke. Now the pi ston reaches the TDC and the suction stroke starts. The piston reaches the BDC and then starts moving up. The inlet valve closes, when the crank has moved a little beyond the BDC This is done as the incoming charge continues to flow into the cylinder although the piston is moving upwards from BDC Now the charge is compressed (with both valves closed) and then and temperature) push the piston downwards with full force and the expansion or working stroke takes place. Now the exhaust valve opens before the piston again reaches BDC and the burnt gases start leaving the engine cylinder. Now the piston reaches BDC and then starts moving up, thus performing the exhaust stroke. The inlet valve opens before the piston reaches TDC to start suction stroke. This is done as the fresh incoming charge helps in pushing out the burnt gases. Now the piston again reaches TDC, and the suction stroke starts. The exit valve closes after the crank has moved a little beyond the TDC. This is done as the burnt gases continue to leave the engine cylinder although the piston is moving downwards. It may be noted that for a small fraction of a crank revolution, both the inlet and outlet valves are open. This is known as valve overlap. PORT TIMING DIAGRAM FOR A TWO-STROKE CYCLE PETROL ENGINE In the port timing diagram, as shown we see that the expansion of the charge( a f t e r i g n i t i o n ) s t a r t s a s t h e p i s t o n m o v e s f r o m TDC towards BDC. F i r s t o f a l l , t h e exhaust port opens before the piston reaches BDC and the burnt gases start leaving the cylinder. After a small fraction of the crank revolution, the transfer port also opens and the fresh fuel -air mixture enters into the engine cylinder. This is done as the fresh incoming charge helps in p u s h i n g o u t t h e b u r n t g a s e s . N o w t h e p i s t o n r e a c h e s BDC a n d t h e n s t a r t s m o v i n g upwards. As the crank moves a little beyond BDC, first the transfer port closes and then the exhaust port also closes. This is done to suck fresh charge through the transfer port and to exhaust the burnt gases through the exhaust port simultaneously. Now the charge i s c o m p r e s s e d w i t h both ports closed, and then ignited with the help of a spark p l u g before the end of compression stroke. This is done as the charge requires some time toignite. By the time the piston reaches TDC, the burnt gases (under high pressure and temperature) push the piston downwards with full force and expansion of the burnt gases takes place. It may be noted that the exhaust and transfer ports open and close at equal angles on either side of the BDC position. CARBURETTOR : The carburetor is a device for *atomizing and**vaporizing the fuel and mixing it with the air in the varying proportions to suit the changing operating conditions of the engine. The process of breaking up and mixing the fuel with the air is called carburetion. There are many types of the carburetors in use, but the simplest form of the carburetor is shown in fig. It consists of a fuel jet located in the centre of the choke tube. A float chamber is provided for maintaining the level of the fuel jet located in the centre of the choke tube. A float chamber is provided for maintaining the level of the fuel in the jet is controlled by a float and lever which operates its needle valve. The fuel is pumped into the float chamber and when the correct level of the fuel is reached, the float closes the needle valve, and shuts off the petrol supply. The suction produced by the engine draws air through the choke tube. The reduced diameter of the choke tube increases the velocity of air and reduces the pressure. The high velocity and low pressure in the tube facilities the breaking up of the fuel and its admixture with the air. A throttle valve controls the flow of the mixture delivered to the engine cylinder. Fig: Carburettor FUEL PUMP The main object of a fuel pump in a diesel engine is to deliver a fuel to the i n j e c t o r w h i c h s p r a y s t h e f i n e l y d i v i d e d p a r t i c l e s o f t h e f u e l s u i t a b l e f o r r a p i d combustion. T h e simplified sketch of a fuel pump is shown. It consist of a plunger which moves up and down in the barrel by the cam and spring a r r a n g e m e n t p r o v i d e d f o r pushing and lowering the plunger respectively. The fuel oil is highly filtered by means of felt-pack filter before entering the barrel of the pump. The upper end part of the plunger is cut away in a helix shaped piece forming a groove between the plunger and barrel, which is the most important one. Therefore, the amount of fuel delivered and injected into the engine cylinder depends upon the rotary position of the plunger in the barrel. Figure (b) and (c) shows how the top part of the plunger is designed so that the correct amount of fuel is delivered to the injector. When the plunger is at the bottom of its stroke as shown ill Figure (b), the fuel enters the barrel through the inlet port. As the plunger rises, it forces this fuel up into the injector, until the upper part cut away comes opposite the sill port. Then the fuel escapes down the groove and out through the sill port so that injection ceases, as shown in Figure (c). The plunger can be made to rotate in the barrel and therefore more fuel is injected. When the plunger is rotated so that the groove is opposite to the sill port, no fuel at all is injected and thus the engine stops Classification of injection systems The injection systems can be classified as follows (1) Air injection systems (2) Solid injection systems Air injection systems In this system, fuel is forced into the cylinder by means of compressed air. This system is little used nowadays, because it requires a bulky multi-stage air compressor. This causes an increase in engine weight and reduces the brake power output further. One advantage that is claimed for the air injection system is good mixture of fuel with the air with resultant higher mean effective pressure. Another is the ability to utilize fuels of high viscosity which are less expensive than those used by the engines with solid injection systems. These advantages are off-set by the requirement of a multistage compressor thereby making the air- injection system obsolete. Solid injection system In this system the liquid fuel is injected directly into the combustion chamber without the aid of compressed air. Hence, it is also called airless mechanical injection or solid injection system. Solid injection system can be classified into four types. (1) Individual pump and nozzle system (2) Unit injector system (3) Common rail system Individual pump and nozzle system The details of the individual pump and nozzle system are shown in fig. (a) an (b).In this system ,each cylinder is provided with one pump and one injector. In this arrangement a separate metering and compression pump is provided for each cylinder. The pump may be placed close to the cylinder as shown in fig. (a) or they may be arranged in a cluster as shown in fig.(b). The high pressure pump plunger is actuated by a cam, and produces the fuel pressure necessary to open the injector valve at the correct time. The amount of fuel injected depends on the effective stroke of the plunger. Figure in pending Unit injector system The unit injector system is one in which the pump and the injector nozzle are combined in one housing. Each cylinder is provided with one of these unit injectors. Fuel is brought up to the injector by a low pressure pump, where at the proper time, a rocker arm actuates the plunger and thus injects the fuel into the cylinder. The amount of fuel injected is regulated by the effective stroke of the plunger. The pump and the injector can be integrated in one unit as shown in Fig. (c) Figure in pending Common Rail System In the common rail system, fig.(d), a HP pump supplies fuel, under high pressure, to a fuel header. High pressure in the header forces the fuel to each of the nozzles located in the cylinders. At the proper time, a mechanically operated (by means of a push rod and rocker arm) valve allows the fuel to enter the proper cylinder through the nozzle. The pressure in the fuel to enter the proper cylinder through the nozzle. The pressure in the fuel header must be that, for which the injector system was designed, i.e., it must enable to penetrate and disperse the fuel in the combustion chamber. The amount of fuel entering the cylinder is regulated by varying the length of the push rod stroke. A high pressure is used for supplying fuel to a header, from where the fuel is metered by injectors (assigned one per cylinder). Figure in pending INJECTOR OR ATOMISER The injector or atomiser is also an important part of the diesel e n g i n e w h i c h breaks up the fuel and sprays into the cylinder into a very fine divided particles. Figure s h o w s t h e t y p e o f a n i n j e c t o r i n w h i c h f u e l i s d e l i v e r e d f r o m t h e p u m p a l o n g t h e horizontal pipe connected at A. The vertical spindle of the injector is spring loaded at the top which holds the spindle down with a pressure of 140 bar so that the fuel pressure must reach this value before the nozzle will lift to allow fuel to be injected into the engine cylinder. The fuel which leaks past the vertical spindle is taken off by means of an outlet pipe fitted at B above the fuel inlet pipe Fig: Fuel Injector BATTERY IGNITION SYSTEM: BASIC IGNITION SYSTEM(BATTERY) Fig: Battery ignition system for a six-cylinder engine Introduction The electrical discharge produced between the two electrodes of a spark plug by the ignition system starts the combustion process in a spark ignition engine. The function of the ignition system is to initiate this flame propagation process. Energy requirements for ignition An ignition process obeys the law of conservation of energy. Hence, it can be treated as a balance of energy between (i) That provided by an external source (ii) That released by chemical reaction and (iii)That dissipated to the surroundings by meaning of thermal conduction convection and radiation. The spark energy and duration : With a homogeneous mixture in the cylinder, spark energy of the order of 1 kv and a duration of a few micro-seconds would suffice to initiate the combustion process. Energy requirements for ignition : An ignition process obeys the law of conservation of energy. Hence, it can be treated as a balance of energy between (i) That provided by an external source (ii) That released by chemical reaction and (iii)That dissipated to the surroundings by meaning of thermal conduction, convection and radiation. The spark energy and duration : With a homogeneous mixture in the cylinder, spark energy of the order of 1MJ and a duration of a few micro-seconds would suffice to initiate the combustion process. Ignition System : A conventional ignition system should provide sufficiently large voltage across the spark plug electrodes to effect the spark discharge. Further, it should supply the required energy for the spark to ignite the combustible mixture. Conventional ignition system should take these factors [optimum spark timing varies with engine speed inlet manifold pressure & misture composition] into account to provide the spark of proper energy. Spark – Ignition System : Air is a poor conductor of electricity an air gap in an electric circuit act as a high resistance. But when a high voltage is applied across the electrodes of a spark plug it produces a spark across the gap. When such a spark is produced to ignite a homogeneous air-fuel mixture in the combustion chamber of an engine it is called the spark-ignition system. The ignition systems are classified depending upon how the primary energy for operation the circuit is made available as: (i) Battery ignition systems (ii) Magneto ignition systems (i) It should provide a good spark between the electrodes of the plugs at the correct timing. (ii) It should function efficiently over the entire range of engine speed. (iii)It should be light, effective and reliable in service. (iv) It should be compact and easy to maintain. (v) It should be cheap and convenient to handle. (vi) The interference from the high voltage source should not affect the functioning of the radio & television receives inside an automobile. Battery Ignition System : Most of the modern spark –ignition engines use battery ignition system. Battery – 6 or 12 volt battery Ex: Passenger cars, light trucks, some motorcycles & large stationary engines are fitted with battery ignition system. The essential components of the system are : (i) Battery (ii) Ignition switch Primary side of the ignition coil (iii)Ballast resistor (iv) Ignition coil (v) Contact breaker (vi) Capacitor (vii) Distributor Secondary side of the ignition coil (viii) Spark plug Battery Storage Battery : To provide electrical energy for ignition Cell connections for 12 volt battery Two types of batteries are used for spark-ignition engines (i) The lead acid battery (ii) The alkaline battery The former is used in light duty commercial vehicles and the later on heavy duty commercial vehicles Ignition switch : Battery is connected to the primary winding of the ignition coil through and ignition switch and ballast resistor with the help of the ignition switch the ignition system can be turned on or off. Ballast resistor : A ballast resistor is provided in series with the primary winding to regulate the primary current. Ignition Coil : Ignition coil is the source of the ignition energy in the conventional ignition system Secondary coil consists – 21,000 turns, 38-40 gauge enameled wire Primary winding, located outside the secondary coil -> 200-300 turns 20 Guage wire Resistance – 1.15 Figure is required At low speed the amount of spark produced are low for H.T magneto efficient system & it produces many starting troubles the weight is also very high. Difference between battery ignition & magneto ignition system : Battery Magneto ignition Battery is required & hence there will be a problem of discharge Battery is not required & hence there is no problem of discharge More maintenance required Less maintenance Charge flows form battery to the primary circuit Magneto generates the electric charge Good spark is available at plugs even at low speed Spark is poor at the starting & lower speed At correspondingly higher ranges of speed the performance will be reduced At correspondingly higher speed ranges performance will Occupies more space Occupies less space Used in cars & UCV (light commercial vehicles) In racing cars & two wheelers Contact Breaker : This is a mechanical device for making and breaking the primary circuit of the ignition coil usually tungsten and each point has a circular flat fact of about 3mm dia. Capacitor : The construction of the ignition capacitor is the same as that of every electrical capacitor. Distributor : The function of the distributer is to distribution the ignition surges to the individual spark plugs in the correct sequence and at the correct instants in time. There are two types of distributors, the brush type and the gap type. Spark Plug: The spark plug provides the 2 electrodes with a proper gap across which the high potential discharges to generate a spark and ignite the combustible mixture within the combustion chamber. Spark plugs are usually classified as hot plugs or cold plugs depending upon the relative operating temp range. The type of spark plug used in an engine depends on the particular requirements. Operation of a battery ignition system: The source of the ignition energy in the battery ignition system is the ignition coil. This coil stores the energy in its magnetic field and delivers it at the instant of ignition (Firing pt) in the form of a surge of high voltage current (ignition pulse) though the high tension ignition cables to the correct spark plug. Storage of energy in the magnetic field is based on an inductive process as a result of which we also designate the ignition coil as an inductive storage device. The schematic diagram of a conventional battery ignition system for a four-cylinder engine. Limitations : (i) The primary voltage decreases as the engine speed (increases) due to the limitations in the current switching capability of the breaker system. (ii) Time available for build-up of the current in the primary coil and the stored energy (decreases) due to the dwell period becoming shorter. (iii)Because of the high source impedance (about 500K ) Lubrication: Lubrication is the art of admitting a lubrication (oil, gases) between two surfaces that are in contact & in relative motion. Types of lubrication system 1. Mist lubrication system’ 2. Wet – sump lubrication system 3. Dry – sump lubrication system Basic components of wet sump lubrication system: Fig Splash Lubrication Dry-sump lubrication system: Fig: Dry Sump Lubrication Properties of lubrication i) Viscosity ii) Flash & Fire points iii) Cloud & Pour points iv) Oiliness & Film strength v) Corrosiveness vi) Detergency vii) Stability viii) Foaming Types of liquid cooling systems: 1. Thermo psyphon system 2. Forced circulation cooling system 3. Evaporating cooling system 4. Pressure cooling system Advantages of liquid – Cooling system 1. Compact design & smaller frontal area. 2. Fuel consumption is rather lower when compared to air cooled ones. 3. Uniform cooling of the parts particularly engine barrel & head because of jacketing & thus ensuring lower temperature at valve seats. 4. Insulation of cooling system is not necessary . Limitations: 1. This is a dependent system where water circulation has to be ensured by additional means. 2. Power absorbed by the pump for circulation is considerable & effects the power output of the engine. 3. In case of failure of cooling systems there will be severe damage in the system. 4. Cost is also considerably high. 5. System requires considerable maintenance also. Advantages of air – cooled system: 1. Design of the engine become simpler has no water jacket air required & they are cheaper to renew in case of accidents. 2. Less maintenances problems because of absence of cooling pipes, radiator etc. 3. No damage of leakage of the cooling. 4. No freezing trouble & no cold starting trouble. 5. Higher power to weight ratio. 6. Installation is easy. Limitations: 1. Limited to only small & medium power range. 2. Suitable in cases where ambient temperature are lower. 3. Cooling is not uniform 4. More aerodynamic noise. 5. SFC is slightly higher. 6. Lower maximum allowable compression rations. Comparison of Air Cooling and Water Cooling Systems: Air Cooling Systems Water Cooling Systems The design of the system is simple and The design of this system less costly. complicated and more costly. is The mass of the cooling system (per The mass of the cooling system (per b.p. of the engine) is very less. b.p. of the engine) is much more. The fuel consumption (per b.p. of the The fuel consumption (per b.p. of the engine) is more. engine) is less. Its installation and maintenance is very Its installation and maintenance is easy and less costly. difficult and more costly. There is no danger of leakage or There is no danger of leakage or freezing of the coolant. freezing of the coolant. It works smoothly and continuously. If the system fails, it may cause serious Moreover it does not depend on nay damage to the engine within a short coolant. time. COOLING SYSTEMS FOR I.C. ENGINES We have already discussed, in the last article, the adverse effects of overheating of an I.C. engine and characteristics of the cooling system adopted. The following two systems are used for cooling the I.C. engines these days: 1. Air cooling system: The air cooling system, as shown , is used in the engines of motor cycles, scooters, aeroplanes and other stationary installations. In countries wit h cold climate, this system is also used in car engines. In this system, the heat is dissipated d i r e c t l y t o t h e a t m o s p h e r i c a i r b y c o n d u c t i o n t h r o u g h t h e c yl i n d e r w a l l s . I n o r d e r t o increase the rate of cooling, the outer surface area of the cylinder and c ylinder head is increased by providing radiating fins and flanges. In bigger units, fans are provided to circulate the air around the cylinder walls and cylinder head. Fig: Air Cooling 2. Water cooling system (Thermosyphon system of cooling). The water cooling system as shown , is used in the engines of cars, buses, trucks etc. In this system, the water is circulated through water jackets around each of the combustion chambers, cylinders, valve seats and valve stems. The water is kept continuously in motion by a centrifugal water pump which is driven by a V-belt from the pulley on the engine crank shaft. After Fig: Thermosyphon system of cooling passing through the engine jackets in the cylinder block and heads, the water is passed through the radiator. In the radiator, the water is cooled by air drawn through the radiator by a fan. Usually, fan and water pump are mounted and driven on a common shaft. After p a s s i n g t h r o u g h t h e r a d i a t o r , t h e w a t e r i s d r a i n e d a n d d e l i v e r e d t o t h e w a t e r p u m p through a cylinder inlet passage. The water is again circulated through the engine jackets.