view

advertisement

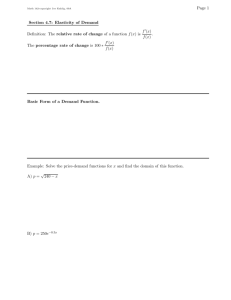

Subject Group of Mechanical and Intelligent System Engineering 27202 Solid Mechanics and Materials Winter Description and rationale: It is very important for the design of mechanical products to choose the most suitable material. The deformation of materials is roughly divided into two regions i.e., elasticity and plasticity, and these deformations lead to fractures of materials. Therefore, the deformation mechanism of the elasticity and plasticity should be well understood from both macroscopic and microscopic point of view. This course aims to understand some basic theories for the elastic and plastic deformation, which are based on the historical continuum theory, and also to understand the fracture mechanism from the microscopic point of view. Keywords: method elasticity, plasticity, tensor, continuum mechanics, finite element method, boundary element Pre-requisite: none Expected students: master and doctoral Instructors: Dr Hiroyuki KATO (hkato@eng.hokudai.ac.jp) Dr Katsuhiko SASAKI (katsu@eng.hokudai.ac.jp) Course outline: The course is divided into two parts (2 sections); elasticity and plasticity. The responsible instructor of each section is Dr. Kato for elasticity (1-8) and Dr. Sasaki for plasticity (9-15). Part 1. 2. 3. 4. 5. 6. 7. 8. 1: Elasticity Basics of linear elasticity 1: tensor descriptions of stress, strain, and Hooke's law Basics of linear elasticity 2: Hooke's law, the equilibrium in stress components, compatibility in strain Conservative equations in elasticity: the equation of continuity, the strain energy function Method of Airy's stress function: plane stress problem, complex stress function Variational principle of elasticity Approximation method of boundary value problem 1: fundamentals of finite element method Approximation method of boundary value problem 2: fundamentals of finite element method Approximation method of boundary value problem 3: Boundary element method Part 2: Plasticity 9. Outline of plastic deformation: true stress, true strain, incompressibility, Bauschinger effect 10. Yield criterion (1): initial yield stress, yield function, von Mises’s yield criterion 11. Yield criterion (2): Tresca’s yield criterion, plane, equivalent stress 12. Constitutive modelling for plasticity (1): stress invariant, deviatoric stress, incremental strain theory 13. Constitutive modelling for plasticity (2): theory of plastic potential, plastic flow, associate flow rule 14. Constitutive equation for creep deformation 15. Introduction of damage mechanics for next step Grading: 20%: class participation 30%: Assignments (4-5 assignments are required during the term) 50%: Final exam Textbooks and references: 1) Handout made by the course instructor will be delivered. 2) References are shown below. *Finite Element Method: O.C. Zienkiewicz, R.L. Taylor, and J.Z. Zhu, Elsevier. *Engineering plasticity -theory and application to metal forming processes-: R. A. C. Slater, Macmillan. *Mathematical theory of elasticity: I.S.Sokolnikoff, 2nd, McGraw-Hill Book Co., 1956. *available at the library 7/2008