Specifications - Gilson Engineering Sales

advertisement

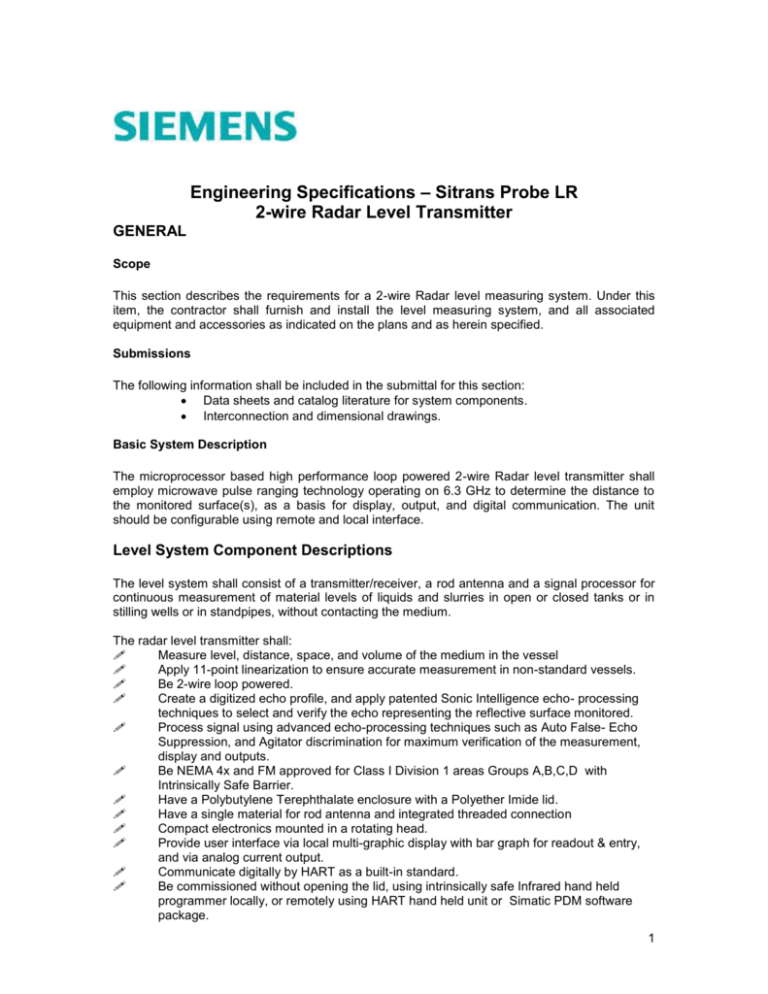

Engineering Specifications – Sitrans Probe LR 2-wire Radar Level Transmitter GENERAL Scope This section describes the requirements for a 2-wire Radar level measuring system. Under this item, the contractor shall furnish and install the level measuring system, and all associated equipment and accessories as indicated on the plans and as herein specified. Submissions The following information shall be included in the submittal for this section: Data sheets and catalog literature for system components. Interconnection and dimensional drawings. Basic System Description The microprocessor based high performance loop powered 2-wire Radar level transmitter shall employ microwave pulse ranging technology operating on 6.3 GHz to determine the distance to the monitored surface(s), as a basis for display, output, and digital communication. The unit should be configurable using remote and local interface. Level System Component Descriptions The level system shall consist of a transmitter/receiver, a rod antenna and a signal processor for continuous measurement of material levels of liquids and slurries in open or closed tanks or in stilling wells or in standpipes, without contacting the medium. The radar level transmitter shall: Measure level, distance, space, and volume of the medium in the vessel Apply 11-point linearization to ensure accurate measurement in non-standard vessels. Be 2-wire loop powered. Create a digitized echo profile, and apply patented Sonic Intelligence echo- processing techniques to select and verify the echo representing the reflective surface monitored. Process signal using advanced echo-processing techniques such as Auto False- Echo Suppression, and Agitator discrimination for maximum verification of the measurement, display and outputs. Be NEMA 4x and FM approved for Class I Division 1 areas Groups A,B,C,D with Intrinsically Safe Barrier. Have a Polybutylene Terephthalate enclosure with a Polyether Imide lid. Have a single material for rod antenna and integrated threaded connection Compact electronics mounted in a rotating head. Provide user interface via local multi-graphic display with bar graph for readout & entry, and via analog current output. Communicate digitally by HART as a built-in standard. Be commissioned without opening the lid, using intrinsically safe Infrared hand held programmer locally, or remotely using HART hand held unit or Simatic PDM software package. 1 Product Specification RADAR LEVEL TRANSMITTER – ROD / HORN ANTENNA Service Service: Fluid: Operating Pressure: Process Temperature: Humidity: Installation Drawing: Application: As noted As noted, turbulent surface As noted minus 40 to 80oC (minus 4°F to 176°F) 10 to 90% As noted Level and volume monitoring in Closed tanks / Open Wet wells Performance Range: Accuracy: Repeatability: Fail-safe: Sensor Measuring Principle: Frequency: 0.3 to 20 m (1.3 to 65’) +/- 10 mm or +/- 0.1% of the range, whichever is greater +/- 5 mm mA and “reading” programmable high, low or hold, or user selectable upon Loss of Echo (LOE) condition Pulse-based microwave 6.3 GHz Closed Tank Type: Mounting: Pressure Rating: Antenna: Blanking: Single construction Rod Antenna with integrated threads hermetically sealed 1 ½” Maximum 3 bar at 80oC (43.5 psig at 176°F) di-electric rod with integral threads in Polypropylene 0.3 M Open Wet wells / tanks Type: Mounting: Pressure Rating: Antenna: Blanking: Single construction Rod Antenna with integrated threads hermetically sealed 1 ½” Maximum 3 bar at 80oC (43.5 psig at 176°F) di-electric rod with integral threads in Polypropylene 0.3 M Transmitter Power supply: Enclosure: Ingress protection: Ambient Temp: Display: mA O/P: Communication: Loop powered with 24 VDC at maximum 550 Ohms Polybutylene Terephthalate enclosure and Polyether Imide lid with 2 x ½” NPT cable entries NEMA 4X or IP 67 -40°C to 80°C (-40°F to 176°F) Alpha numeric and Multi-graphic LCD display with bar graph (for level) 4 – 20 mA into 550 Ohms maximum at 24 Vdc Built-in HART Infrared hand programmer link HART hand held unit and/or SIMATIC process device manager (PDM) software package 2 Approvals: Radio approval FCC Intrinsically Safe with approved barrier Additional Equipment The following additional equipment shall be available at additional cost. Infrared hand programmer for local instrument access and configuration. HART hand held unit or software package SIMATC process device manager (PDM) for instrument access and configuration using PC. Manufacturer: Siemens – Milltronics The local factory trained representative of the selected equipment shall have a website containing manuals for the equipment being supplied, training videos covering key features and basic configuration of the instrument, and list frequently asked questions with troubleshooting guidelines. This website shall list local contacts with name, address, telephone number and e-mail addresses. Installation: All equipment shall be installed, configured, interconnected, and commissioned by qualified persons, in accordance with the manufacturer’s instructions and guidelines, and in compliance with all governing regulations and accepted engineering practices. Warranty: The manufacturer shall warrant the equipment described herein, to be free of defects in materials and workmanship, for a period of thirty (30) months from the date of shipment from the supplier, or twenty four (24) months from the date of initial equipment start up, whichever is earlier. The manufacturers liability shall be limited to the repair or replacement of the materials supplied, free of charge F.O.B. the manufacturer’s facility. Alternatively, at its option, the manufacturer may elect to refund the purchase price. Other limitations may apply. Refer to the “Terms and Conditions of Quotation or Sale”, provided by the equipment manufacturer for complete warranty details. 3