Chapter IV-A - CLSU Open University

advertisement

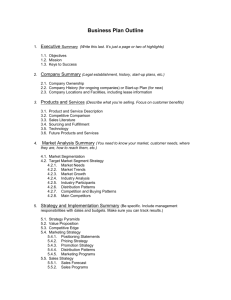

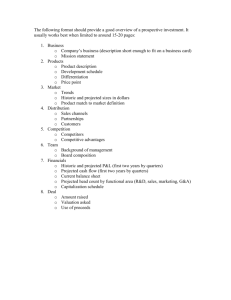

105 Project Feasibility Studies Most projects need feasibility studies before these could be started. This feasibility study will show the following major aspects or parts: 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. The Executive Summary Project Background and History Management and Personnel Feasibility Marketing Feasibility Technical (Production) Feasibility Financing Feasibility Financial Feasibility Socio-economic Feasibility Project Implementation and Timetable Conclusion In order for you to prepare your own feasibility study I have prepared a sample which I said earlier in this module, so that you will have a model. You have to gather the data needed for each major aspect. Once the data are available, these should be analyzed and interpreted so that these will serve as information. Based on these informations, formulation of recommendations and conclusions will be possible. A useful project study covers the various important phases of a project: organization and management, marketing, technical taxation and financing. Financial projections which estimate the profitability and cash requirements of a project should also be included. Components of Feasibility Studies in General A. The Executive Summary B. Project Background and History C. Management, Proponents, Personnel and Organization 1. Management complement and supporting professional firms a. During the pre-operating period b. During the operating period 2. Proponents a. Owners b. Project originators, promoters, founders 3. Personnel or Work Force a. During the pre-operating period b. During the operating period 4. Organization – Operating Period a. Form of business organization b. Internal organization structure 5. Project implementation time table D. Marketing 106 Demand – customers Supply Pricing Marketing Program a. Distribution channels and sales b. Promotions 5. Project sales opportunity 1. 2. 3. 4. E. Production Facilities and Product 1. 2. 3. 4. 5. Product specifications Product process Productive capacity and production schedule Physical facilities Production inputs F. Taxation and Legal Aspects 1. Taxation a. Tax provisions affecting the industry b. Tax exemptions c. Tax schemes 2. Legal aspects affecting the project or industry G. Financing – Sources of financing 1. Internal sources 2. External sources H. Financial Estimates and Analyses 1. Financial estimates a. Projected Income Statement b. Projected Cash Flow Statement c. Projected Balance Sheet d. Assumptions, Schedules, Supporting calculations 2. Financial Analyses a. Return on investment b. Sales volume and sales price Sensitivity tests I. Social Desirability 1. Specific project contribution to the country’s economy or society a. Contribution to government reserves b. Contribution to foreign exchange reserves c. Contribution to the growth of related industries d. Contribution to households e. Contribution to workforce 2. Social rates of return New Manufacturing Project Outline of a Project Study Report A. Project Summary 1. Brief description of the project 107 2. Summary of the findings and conclusions regarding the: a. b. c. d. e. f. g. h. Project timetable and status Management aspects Marketing aspects Technical aspects Taxation aspects Financing aspects Financial aspects Social aspects B. Project Timetable and Status Actual or target dates or periods for: 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. General project planning Incorporation Preparation of engineering specification Building construction Selection of machinery supplies Arrival of machinery Installation of machinery Trial run Start of normal production Start of selling operations C. Management Aspects 1. Management during the pre-operating period a. Project originators b. Project promoters; managers c. Firms or persons involved or to be involved in marketing, engineering, and other studies d. Management during the construction period 2. Management during the operating period a. Type of business organization b. Internal organization 1.) Statements of functions of each unit 2.) Organization chart c. Owners – citizenship of owners, and percentage of their respective holdings d. Management personnel 1.) Duties, and time to be devoted to the project 2.) Requirements 3.) Recruitments 4.) Compensation 5.) Staffing – qualifications e. Labor 1.) Skills required 2.) Number required for each skill 3.) Sources of labor force for each type of skill 108 4.) Recruitment program 5.) Labor training program 6.) Compensation a.) Prevailing rates b.) Legal rates c.) Rates intended for the project - starting rates and provisions for annual increases 7.) Facilities for laborers a.) Housing b.) Transportation c.) Medical and dental care d.) Recreation and other fringe benefits 8.) Effect of labor laws on the above items e.) Government managers, if any – arrangement and fees f.) Professional firms to be hired – law, accounting, engineering and others D. Marketing Aspects 1. Demand a. Consumption for the past years 1.) Regional markets 2.) Types of consumers 3.) Types of market 4.) Major firm-users b. Projected consumption for the next 5 years 1.) Quantity, broken down into: a.) Regional markets b.) Types of consumers c.) Types of markets d.) Major firm-users 2.) Methods used and factors considered in preparing the above projections 3.) Comparison of the projections with that of: a.) Government offices b.) Trade associations c.) International organizations d.) Other private parties 2. Supply a. Supply for the last 5 years 1.) Imported a.) Form b.) Country of origin c.) Firm-importers d.) Brands 2.) Locally-produced a.) Province of origin b.) Firm producers c.) Brands b. Projected supply for the next five years 109 1.) Imported a.) Form b.) Country of origin c.) Firm-importers d.) Brands 2.) Locally-produced a.) Province of origin b.) Firm producers c.) Brands c. Factors affecting trends in past and future supply 1.) Regarding competing products a.) Development of new competing products b.) Improvement in quality or decrease in cost and in price 2.) Regarding importations a.) Tax-free importation by certain entities 3.) Regarding local production a.) Capacities b.) Percentage utilization of the capacities 1.) Maintenance policies 2.) Obsolescence or prolonged breakdown of plant machinery 3.) Shipping interruptions 4.) Financing available for working capital 3. Prices a. Comparison of the following: 1.) Cost of importation 2.) Cost of production of existing firms 3.) Projected cost of production of the project 4.) Importers’ and local producers’ selling prices 5.) Distributors’, wholesalers’ and retailers’ prices b. c. d. e. Tariff protection assumed or expected for the project Domestic transportation costs Effects of different laws Price to be adopted by the project 4. Marketing Program a. Present and expected marketing practices of competitors b. Proposed marketing program for the project c. Explanation for any material deviations, covering the following: 1.) Terms of sale 2.) Channels of distribution 3.) Promotions 4.) Packaging 5. Projected sales quantity a. Expected annual volume b. Sales contracts E. Technical Aspects 1. Product 110 a. Description and specifications of the product including weight, size, and physical and chemical properties b. Principal uses c. Tests for the product d. Assurance that the products will be of the expected quality and quantity 2. Manufacturing process a. Description of the process, flow chart, and normal duration of the process b. Proof of reliability and superiority of the process, alternative processes considered, and factors used in determining the process to be employed c. Licensing agreement d. Processes used in existing plant e. Processes being developed 3. Plant size and production schedule a. Rated annual and daily plant capacity, at a given number of shifts per day, and number of operating days per year. b. Desirability of the selected capacity; alternative plant rated capacities considered; minimum economical plant size; factors used in determining plant size c. Provisions made in the location, layout, machinery design and structures for expansion d. Expected annual production volume for the next five years 4. Machinery a. Specifications and functions; rated capacities and balancing; engineering firm which prepared the specification b. Availability of spare parts and repair service c. Selection of supplier, including bidding procedures, and evaluation of bids d. Quotations from suppliers e. Reliability of the suppliers and machinery guarantees f. Delivery, payments, and other arrangements with the suppliers 5. Plant location a. Plant location; location map b. Desirability of the location, in terms of distance to sources of raw materials and markets, tie-in with transportation facilities and utilities, weight-bearing capacity of the site, and other factors c. Alternative locations considered, and factors used in determining the locations 6. Plant layout a. b. c. d. e. Description of the plant layout Effect of the layout on the materials flow Treatment of materials handling and storage in the layout Tie-in with transportation facilities Provisions for expansion 7. Structures a. Buildings – area, specifications, and built-in utilities as materials handling and airconditioning facilities b. Other structures as piers c. Land improvements – roads within the compound, drainage facilities, fence 8. Raw materials 111 a. Specifications or description (physical and chemical) b. Proof of reliability and superiority of the raw materials selected c. Alternative raw materials considered, factors used in selecting raw materials, and tests made d. Raw materials used in other plants and new raw materials being studied or developed e. Quantity required every year, materials balance f. Availability, continuity of supply, current and prospective sources, and transportation facilities g. Supplier - reliability, and arrangements as to delivery and payments h. Mineral resources – adequacy of technical studies on the extent of deposits, and quality i. Current and prospective cost of raw materials; terms of any long-term contracts 9. Utilities a. Electricity, fuel, water, steam and supplies 1.) Uses 2.) Quantity required 3.) Utilities balance 4.) Availability 5.) Source 6.) Reasons for the choice of source 7.) Reliability of the source 8.) Alternative sources considered 9.) Cost b. Electricity 1.) Maximum or peak power demand in KW c. Fuel – average consumption per hour d. Water 1.) Quantity required 2.) Average consumption per hour of raw and softened/treated water for process, cooling, sanitary, and general utilities 3.) Water treatment 4.) Storage and distribution e. Steam 1.) Maximum steam demand – pound per hour at specified pressure and temperature 2.) Average steam consumption – pound per hour 10. Waste disposal a.) b.) c.) d.) e.) f.) g.) h.) Description and quantity of the waste to be disposed of Description of the waste disposal method selected Reliability and superiority of the method Alternative methods considered, and factors used in the selection Methods used in other plants Methods being developed Cost of waste disposal Clearance form the proper authorities or compliance with legal requirements F. Taxation Aspects 1. Taxes affecting the project 112 2. Project design used so that the project will fall under a lower alternative tax rate 3. Tax exemptions to be availed of by the project G. Financing Aspects 1. Sources of financing for the project a. Sources selected, for both long-term and short-term financing b. Alternative sources considered and factors used in determining the selected sources 2. Amount and terms of financing for each source selected a. b. c. d. e. f. g. Type of financing (stocks, bonds, loans, etc.) Use of proceeds Currency of financing Amount Security Repayment period Interest or dividend rate 3. Status of the from each source a. Actual release already made – amounts and dates b. Applications already approved – but corresponding funds not yet released – assurance of release of funds, and expected date c. Applications pending d. Applications still to be made 4. Financing of contingencies and seasonal peaks in working capital a. Contingencies – provision made for the financing of contingencies, as overrun in construction costs or delay in start of normal operations b. Seasonal peaks in working capital – provision made for the financing of seasonal increases in working capital, as in the case of a project solely oriented to the manufacture of Christmas items H. Financial Aspects 1. Major assumptions used as on: a. b. c. d. e. f. g. h. i. j. Project timetable Sales volume Plant capacity Plant location Raw materials to be used Income tax rates Tariff rates Tax exemptions to be enjoyed by the project Foreign exchange rate General price level 2. Financial statements a. Projected Income Statement b. Projected Cash Flow Statement c. Projected Balance Sheet 3. Financial analyses 113 a. Break-even point 1.) Profit break-even point – volume and selling price 2.) Cash break-even point – volume and selling price 3.) Debt service sales volume b. Capital recovery and earnings 1.) Cash payoff period 2.) Accounting rate of return 3.) Discounted cash flow rate of return c. Others I. Social Desirability of the Project 1. Government revenues a. Gross increase in government revenues, in terms of taxes and duties to be paid by the project, during both the pre-operating and operating period b. Decrease in government revenues due to the setting-up of the project, as loss in tariff duties on goods currently imported, but to be subsequently produced by the project 2. Foreign exchange reserves a. Gross in the international reserves in terms of the dollar earnings or dollar savings capability of the project b. Decrease in the international reserves, due to the dollar cost of the project, as salaries of foreign technicians, CIF cost of the imported raw materials, royalties, cost of imported machinery, and fees to engineering consultants 3. Related industries – development of related industries – other projects which may be developed subsequently to supply the raw material requirement of the project, or to further process the products of the project. 4. Consumers – possible decrease in the retail price of the goods 5. Employees a. Number of persons to be employed, broken down into local and foreign, and into the various skills required b. Total wage bill c. Training of workers 6. Social rate of return – discounted cash flow basis With these outlines you have a clear picture of what should be gathered before you can prepare a project feasibility study. Project Feasibility Studies Elements of Project Feasibility Study according to Dr. Ernesto Franco 1. Marketing Study 1. Importance of Marketing Study 114 This provides data bases needed in the execution of the technical, management, financial and economic portions like: a. Annual quantity or volume of products to be sold b. Selling prices c. Marketing program 2. Setting Sales Quantity or Volume a. Demand consumption or usage of product; or sales quantity. Past demand such as total importations and local production plus year-end inventories b. Consumption – surveys of consumers of firm-users c. Importation – from government entities, embassies, customs information d. Local Production – situation of local supplier or manufacturer through industry survey to know about competition. e. Local production and implementation f. Past period to be covered in study is 5 to 10 years 3. Projected Demand – historical data can be used for projecting future demand. Methods commonly used: a. b. c. d. e. Executive opinion poll Derived demand Market indicators Arithmetical geometric curve Time series analysis 4. Projected Supply – total importation and local production a. b. c. d. e. f. g. h. i. j. k. Product substitute Importations Local production Prices Cost of transportation Importers’ or suppliers’ selling price Distributors’ and retailers’ price Cost of importation Cost of transportation Importers’ and manufacturers’ prices Cost of product vs. competition 5. Marketing Practices and Program a. b. c. d. e. f. Terms of sale Distribution Transportation Packaging Brand Names Promotions 6. Marketing Plan Statement of Facts a. b. c. d. e. Basic assumptions Problems and opportunities Objectives Program Budget 115 f. Volume and profit-profile less projection 2. Engineering/Technical and Production Studies Elements of this Study 1. Choice of Technology 2. Plant size and Production schedule 3. Machinery and Equipment a. b. c. d. Origin of machinery Projected output of plant Availability of spare parts and repair services Quotations from suppliers, machinery guarantees, delivery conditions, payment terms e. Landed cost and installed cost of imported machinery and equipment 4. Raw Materials and Supplies a. Volume b. Source 5. Design Requirements a. Plant Location 1. Availability and accessibility of raw materials 2. Utilities 3. Cost of transportation 4. Distance to markets 5. Availability of skilled and unskilled labor 6. Investments, taxes 7. Available land with good topography 8. Waste disposal utilities b. Plant Layout 1. Meet capacity requirements 2. Quality and safety – with minimum material handling 3. Effective space usage 4. Smooth work flow 5. Safety and sanitation c. Structures 1. Design of building and facilities 2. Materials 3. Construction scheme and cost 4. Roads 5. Drainage 6. Power and pump houses d. Utilities 1. Water – quality and sources 2. Process steam 3. Power requirement e. Waste Disposal 1. Quantity of waste materials 116 2. Manner of disposal, cost and recycling 6. Manpower Requirements a. b. c. d. Number needed plus skills required Sources Salaries and wages Position titles, minimum qualifications and number of personnel for each position 7. Environmental Study a. b. c. d. e. Soil quality Sufficiency of water Adequate drainage Adequate sunlight Right climate 3. Organization/Management/Institutional Studies Four parts of this study: 1. 2. 3. 4. External Linkages Internal Organizations Management Plan Personnel