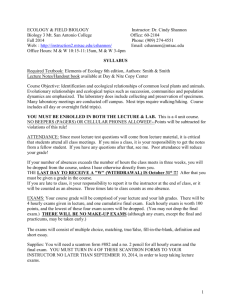

ME 350 Mechanical Design I

advertisement

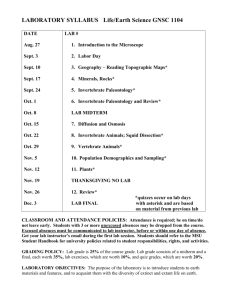

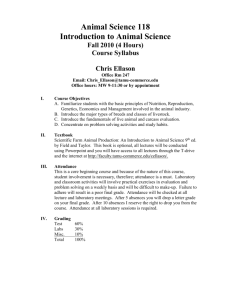

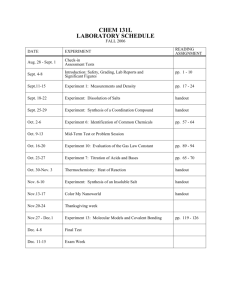

VM350 Design and Manufacturing II Syllabus and General Course Information Fall 2009 Course Information Lectures Time: Monday 10:00~11:40 and Friday 8:00~9:40 Location: Dong Zhong Yuan 2-103 Design Lab Time: TBA Location: TBA Instructors Name: Prof. Qiaode Jeffrey Ge (葛巧德) Office: N203 Law School Building E-mail: Jeff.Ge@gmail.com Office Hours: 1-2pm, Monday and Friday TA Name: TBA Textbook Mechanical Engineering Design by J.E. Shigley and C.R. Mischke, McGraw-Hill Design of Machinery by R. L. Norton, McGraw-Hill Online References (not to be purchased) 1. Machinery Handbook 2. ASM Materials Handbook 3. www.machinedesign.com 4. Fundamentals of Design, A.H. Slocum, 2007 Course Description This course will cover the basics of mechanism and machine design. Specific topics will include kinematics, dynamics, mechanism synthesis, design and selection of machine components, and actuators. This is a project-based course where students will work in teams to complete project. Prerequisites VM 250 Design and Manufacturing I is a pre-requisite for this course. You are expected to have (i) a basic working knowledge of elementary mechanics such as statics, dynamics and strength of materials, (ii) basic machine shop skills (i.e., lathe, mill, drill, etc.) and (iii) working knowledge of a commercial CAD program – IDEAS, Unigraphics, ProEngineer or AutoCAD (preferably unigraphics). VM350 General Course Information Course Objectives The goal of this course is to provide each student an understanding of (a) basic principles of mechanical design, (b) methods of synthesis and analysis of machine components and systems, and (c) relate engineering knowledge to real-world engineering problems. At the end of the course, students should be able to do the following in either a team setting or individually. 1. Identify standard mechanical and electromechanical components and systems and explain how they work. 2. Basic kinematic and kinetostatic analysis of mechanical systems. 3. Design a mechanism or machine to satisfy given motion (or other performance) requirements. Identify design tradeoffs in concept and detail design from the perspectives of functionality, manufacturability, design effort, and available resources. 4. Derive predictive models to analyze, evaluate and optimize mechanical systems. In particular, evaluate kinematic, static and dynamic performance of a mechanical system using modeling, simulation and virtual prototyping methods. 5. Test and evaluate simple machine systems and components for performance and failure. 6. Apply appropriate selection criteria to choose standard machine components such as gears, bearings, springs, motors, sensors and controllers. 7. Be able to create solid models and engineering drawings, suitable for communication to a professional machine shop. 8. Select appropriate materials and manufacturing processes based on geometry and tolerances. 9. Build, assemble and test mechanical and electromechanical systems using standard machine shop tools and mechatronics facility. 10. Understand the characteristics of common sensors and be able to read a sensor datasheet. 11. Understand the characteristics and models of various electromechanical actuators (brushed dc motor, brushless dc motor, and stepper motor). Be able to read and understand an actuator data sheet. Fall 2009 VM350 Page 2 VM350 General Course Information Date Topic Sept.7 Sept.11 Chapter Course Overview Introduction to Mechanical Design Handout 1: Norton Sept. 14 Power Transmissions-Power Screws Sept. 18 Power Transmissions-Power Screws 8-1: Shigley 8-2: Shigley Sept. 21 Power Transmissions-Belts Sept. 25 Power Transmissions-Belts 17: Shigley 17: Shigley Sept. 28 Motors Oct 2 Holiday 2-16: Norton Oct. 5 Oct. 9 Motors Transmission Support-Bearings 2-16: Norton 11: Shigley Oct. 12 Oct. 16 Transmission Support-Bearings Introduction to Mechanisms, Kinematic Diagrams Degree of Freedom 11: Shigley 2: Norton Oct. 19 Oct. 23 Four-bar Linkages, Grubler’s Criteria Linkages: Position Analysis 2: Norton 4,5: Norton Oct. 26 Linkages: Velocity and Acceleration Analysis (Xu) 6,7: Norton Oct. 30 Exam #1 Nov. 2 Joining Methods-Fasteners 8: Shigley Nov. 6 Joining Methods-Fasteners 8: Shigley Nov. 9 Intro to Mechatronic System Design Nov. 13 Sensors Nov. 16 Sensors and Signal Conditioning Electronics Nov. 20 Actuators and Drivers Nov. 23 Nov. 27 Introduction to Gears and Gear Kinematics Gear Trains 13: Shigley 13: Shigley Nov. 30 Dec. 4 Gear Geometry and Manufacturing Spring 14: Shigley 10: Shigley Dec. 7 Dec. 11 Cams Exam II Review HW Assignment Team Selection Form Sept.11 8: Norton Dec. 14~18 Exam II NOTE: Fall 2009 This is intended only as a rough outline and adjustments may be necessary to accommodate the expertise level of the class. VM350 Page 3 VM350 General Course Information Course Format and Policies Lecture Cooperative Learning methods will be used during this course. These methods depend heavily on teamwork. Students will be assigned to groups of three to four that will work together the entire semester. It is expected that the students within a team will work together on homework, projects and inclass activities. Students are requested to sit together with their team mates in class to help facilitate them working together on in-class activities. It is expected that each team during the semester will experience some conflict. What is important is that the teams deal with this conflict in a positive and constructive manner. Teams having problems working together should make every effort to resolve them by themselves. If that doesn’t work, see the course instructor for help. Students who consistently fail to pull their weight can as a last resort be fired with permission of the instructor and unanimous vote of the remaining team members. Firing a student is a serious procedure and should not be taken lightly. Please consult the course instructor for the procedure. Students repeatedly carrying the load for their teammates can as a last resort quit with permission from the instructor. Students who either are fired or quit must find another group with three members willing to unanimously take them on. Design Labs The design labs are two hours long and the format will vary for each. The focus of these design labs will be on the projects and in class exercises. Some of the period will be used to hand out, explain and discuss the projects. Time will be available for student groups to work on in class exercises and project (design, analysis, building, etc). All projects will be tested and evaluated during the design labs. Since the projects are an integral part of the course attendance at the design labs is required. This period will also be used for clarification of course material, problem solving and questions on homework and exams. Homework and Projects Homework will be assigned in class and project descriptions will be handed out in the design labs. Both homework and projects are to be completed by your class team and cooperation among everyone in the class is encouraged. This is the time to learn. However, you are not allowed to possess, look at, use or in anyway derive advantage from the existence of solution (paper or apparatus) prepared in prior years whether these solutions were former students’ work or copies of solutions that had been made available by the instructors. Violation of this policy will be considered violation of the honors policy and will be filed with the Honor’s Council. Penalties may be imposed on homework, project reports and exams for lack of neatness, legibility or clear organization of your work. On each assignment, put the names and roles of the participating group members on the outside. If a student’s name appears on a solution set, it certifies that he/she has participated in solving the problems. Students whose names do not appear on a solution set will receive zeros. Exams There will be two exams given. Exams are to be completed individually and students are not allowed to work together on the exams. For each exam the students are expected to sign the Honor Code. Since the course material builds upon previous material all exams will be comprehensive. You may use your textbook for the exam but it will be closed notes. Make-up exams will be given only in exceptional cases (determined by the instructor). If you have a conflict with the exam day you must see Fall 2009 VM350 Page 4 VM350 General Course Information the instructor BEFORE the exam so that arrangements for a make-up exam may be made. Once the exam has started no make-up exams will be granted and the missed exam will receive a zero score. Grading Policy Projects: 40% Exam 1: 20% Exam 2: 20% Homework, Quizzes and In-class Activities: 20% Total 100% Projects and in-class activities will be submitted and graded as a team grade. The exams, group and participation evaluation will be graded on an individual basis. Machine Shop Usage It is expected that you have received machine shop training during VM 250 and are certified to use the machines in the machine shop. If you do not have this certification then it is your responsibility to gain it as soon as possible since it will be needed for completion of the projects. Incomplete machine shop training will not be accepted as an excuse for your projects. If you do not have this training, please inform the course instructor immediately so that arrangements can be made for training. The machine shop is a highly used resource in the department and shop time is very valuable. Missing a machine-shop time slot will be considered a serious offense. There will be a 5% penalty accessed your team project for each two-hour machine-shop slot missed. In addition, there will be a 2 point penalty (out of 100) applied to the final course grade total of the offending individual for every two-hour machine-shop time slot missed. If missing machine-shop slots becomes habitual, machine shop privileges will be revoked. Additional Reading There are many other texts that have the same scope as Shigley & Mischke that you may want to consult K.S. Edwards and R.B. McKee, Fundamentals of Mechanical Component Design, McGraw-Hill R.C. Juvinall and K.M. Marshek, Fundamentals of Machine Component Design, Wiley (1991) M.F. Spotts, Design of Machine Elements (6th ed.), Prentice Hall (1985). A.D. Deutschman, W.J. Michels and C.E. Wilson, Machine Design: Theory and Practice, Macmillan (1975). R.M. Phelan, Fundamentals of Mechanical Design (3rd ed.), McGraw-Hill (1970). Finally, for both fun and enlightenment, I recommend: M.J. French, Invention and Evolution: Design in Nature and Engineering, Cambridge University Press (1988). H. Petroski, Design Paradigms: Case Histories of Error and Judgment in Engineering, Cambridge University Press (1994). H. Petroski, To Engineer is Human: The Role of Failure in Successful Design, St. Martin’s Press Fall 2009 VM350 Page 5