IZMIR INSTITUTE OF TECHNOLOGY

advertisement

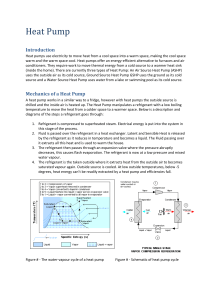

IZMIR INSTITUTE OF TECHNOLOGY Department of Mechanical Engineering Heat Pump Experiment 2014 – 2015 Fall Thermodynamics & Heat Transfer Laboratory 1. INTRODUCTION 1.1. Aims of Heat Pump Apparatus: a) To demonstrate the performance of a heat pump in both heating and cooling modes. b) To demonstrate the process of air conditioning. 1.2. Objectives: To achieve an understanding of the Second Law of Thermodynamics as applied to a heat pump in both heating and cooling modes. 1.3. Experiments: a) Production of heat balance for a heat pump; In this experiment, it will be shown that the total energy transferring into and out of the system is zero. b) Verification of the Second Law of Thermodynamics; The actual and ideal system calculations will be compared. c) Study of the performance of a heat pump Apparatus; Performance of ideal and actual systems will be calculated. 1 2. THEORETICAL OPERATION This apparatus uses water as a source and air as a sink in heating mode, and water as a sink and air as a source in cooling mode. In cooling mode, heat pump can be named as air cooler. Figure 1 shows the theoretical circuit of apparatus in heating mode, drawing energy from the circulating water and delivering it to the air. The compressor delivers refrigerant under pressure and at high temperature to the refrigerant-to-air heat exchanger, where heat is transferred to the air and the refrigerant condenses in the process. The refrigerant then passes through a restriction tube to the low pressure side of the circuit and to the refrigerant-to-water heat exchanger where it evaporates, taking up heat from the circulating water. It then returns to the compressor. Figure 1: Flow diagram in heating mode Note: Energy flows in watts. 2 Figure 2 shows the theoretical circuit in cooling mode. The direction of flow is now reversed. The refrigerant passes from the compressor to the refrigerant-to-water heat exchanger, where it gives up heat to the cooling water, subsequently passing through the reducing valve to the refrigerant-to-air heat exchanger, where it evaporates, and extracting heat from the air. When the apparatus acts in cooling mode, the air is sometimes cooled to below the dew point and condensate is deposited. Figure 2: Flow diagram in cooling mode 3 3. CALCULATION Notation TERM SYMBOL UNITS Diameter of Discharge Duct D m Flow Rate of Discharge Air V m3 / s Flow Rate of Circulating water L L/h Density of Air at Discharge a kg / m 3 Pitot tube Velocity Heat Hl mmH 2 O Maximum Velocity in Discharge Duct U m/ s Mean Velocity in Discharge Duct U m/ s Pa N / m2 Dry Air ml kg.s 1 Condensate at Discharge m2 kg.s 1 Circulating Water m3 kg.s 1 Air at Inlet T1 K Air at Discharge T2 K Circulating Water at Inlet T3 K Circulating Water at Discharge T4 K Compressor-Heat Pump Discharge/Cooler Inlet T5 K Compressor-Heat Pump Inlet/Cooler Discharge T6 K Refrigerant to Water Heat Exchanger-Heat Pump Discharge T7 K Refrigerant to Water Heat Exchanger-Heat Pump Inlet T8 K Refrigerant to Air Heat Exchanger-Heat Pump Inlet T9 K Pressures Barometric Pressure Mass Flow Rates Temperatures 4 Refrigerant to Air Heat Exchanger-Heat Pump Discharge T10 K Refrigerator Compressor EC Watts Fan EF Watts Specific Heat of Water CW J / kg 0C Specific Heat of Air at Constant Pressure CP J / kg 0C Specific Enthalpy of Water Vapor hv J / kg Specific Enthalpy of Condensate hW J / kg Dry Air Entering Conditioner Q1 J /s Water Vapor Entering Conditioner Q2 J /s Dry Air Leaving Conditioner Q3 J /s Water Vapor Leaving Conditioner Q4 J /s Condensate Q5 J /s Circulating Water at Inlet Q6 J /s Circulating Water at Outlet Q7 J /s Radiation and Stray Losses Q8 J /s Power Input Heat Quantities Enthalpy Flow Rates Psychometric Data Relative Humidity at Inlet Density of Saturated Water Vapor at Inlet w kg / m 3 Density of Dry Air at Inlet a kg / m 3 Specific Humidity at Inlet Ideal Heat Pump Power Input W J /s Input From Cold Source q2 J /s Output to Hot Sink ql J /s 5 In both heating and cooling modes, apparatus is operating as a reversed heat engine or heat pump, since the ultimate effect is to transfer heat from one reservoir to another, normally at higher temperature, using mechanical energy (work). To evaluate the efficiency of the reversed heat engine, it is compared with the theoretical reversible or Carnot engine, which is shown together with its temperature enthalpy diagram in figure 3. This engine takes in heat isothermally at temperature Q1, and rejects it isothermally at a higher temperature Q2. The intervening processes are termed ‘adiabatic’ and ‘isentropic’. Figure 3: The ‘ideal’ reversible engine. The ‘coefficient of performance’ of the machine, when operating as a heat pump, is defined as: CPH q2 W (1) q1 W (2) And when operating as a refrigerator: CPR These equations also apply to a real machine operating between the same temperature limits, but the numerical values will be less than those corresponding to the ideal reversible engine for which: 6 CPH MAX CPR MAX 2 2 1 1 2 1 (3) (4) Note that in all cases: CPH CPR 1 (5) These equations indicate that, as the temperature difference between the cold source and the hot sink is reduced, the coefficient of performance should increase; a given expenditure of work permits the transfer of an increasing quantity of heat from the lower to the higher temperature. In a real machine, such as the unit fitted in this apparatus, the efficiency is less than ideal for several reasons, of which the most important are: a) Electrical and mechanical losses in the refrigerator motor and compressor. b) The imperfection (irreversibility) of the refrigeration cycle itself. c) The necessity for temperature differences between refrigerant and air, and between refrigerant and water, as a result of which the refrigerant cycle operates between substantially wider temperature limits than those applicable to the water and air forming the source and sink. d) Electrical and mechanical losses in the circulating fan. 7 Figure 4: The energy diagram of the apparatus. The machine is shown diagrammatically in figure 4, which shows the various energy flows through the system boundary. They are defined as below: Enthalpy of dry air entering conditioner Q1 m1CPT1 (6) Enthalpy of water vapor entering conditioner Q2 m1 hv (7) Enthalpy of dry air leaving conditioner Q3 m1C P T2 Enthalpy of water vapor leaving conditioner 8 (8) Q4 m1 m2 hv (9) Q5 m2 hw (10) Enthalpy of condensate Enthalpy of circulating water at inlet Q6 m3T3CW (11) Enthalpy of circulating water at outlet Q7 m3T4 CW (12) Radiation and stray losses Q8 Electrical input to fun EF The steady flow energy equation for the system may then be written: Q6 Q7 EC EF Q3 Q4 Q5 Q1 Q2 Q8 (13) The first term represents the heat supplied to the system from the circulating water. The second term represents the electrical power input. The algebraic sum of these terms is equated with the increase in enthalpy of the air and water vapor passing through the system, together with the stray losses to the surroundings. The steady flow equation applies equally, with appropriate changes of sign, when the machine is operating as a cooler. When operating in heating mode, the coefficient of performance may be defined in two different ways. 9 1. The overall of external coefficient is: CPH E Q3 Q4 Q5 Q1 Q2 EC EF (14) The value for an ideal machine operating between the same mean temperatures is: CPH MAX 1 T1 T2 2 1 T1 T2 1 T3 T4 2 2 (15) The performance of the basic heat pump is not identical with the overall performance since the energy supplied to the circulating fan is not chargeable to the heat pump proper and appears in the discharge air in which the fan and motor are reversed. 2. This leads to an internal coefficient: CPH 1 Q3 Q4 Q5 E F Q1 Q2 EC (16) This may be compared with an ideal performance based upon the temperature difference across the heat pump circuit: CPH 1 T10 T10 T8 (17) Similarly, two different criteria may be recognized when the machine is operating as a cooler: Q1 Q2 Q3 Q4 Q5 E C E F (18) CPR MAX 1 T1 T2 2 1 1 T1 T2 T3 T4 2 2 (19) CPR E Compared with the ideal: and; 10 CPR 1 Q3 Q4 Q5 E F Q1 Q2 EC (20) Compared with the ideal: CPR MAX T10 T8 T10 (21) In this case the thermal equivalent of the power supplied to the fan reduces the overall cooling effect, since it is transferred to the cooled air on its way to the discharge duct. The air flow through the conditioner is measured by means of a pitot tube mounted in the centre of the discharge duct. The pressure of the air at this point is effectively equal to that of the atmosphere, Pa , and its density a is given by the gas equation: Pa a RT1 (22) The velocity U , corresponding to a velocity head H 1 (in mmH 2 O ), as measured by the pitot tube is given by: aU 2 2 9.81H 1 (23) H1T2 Pa (24) Combining these two equations: U 75.04 The mean velocity in the duct may be calculated by traversing the pitot tube across a horizontal and vertical diameter and integrating to obtain the total flow. Such a calibration for the present apparatus gives a value: U 0.96U (25) 11 The volumetric rate of flow in the duct, diameter D, is given by: V D 2 4 0.96 75.04 H 1T2 Pa (26) or, for D 0.073 m: V 0.3014 H 1T2 Pa (27) The corresponding mass rate of flow is: m1 0.00105 H 1 Pa T2 (28) The specific humidity of the air entering the conditioner is related to the relative humidity Φ as measured by the whirling hygrometer by the equation: W a (29) where W and a are the densities respectively of saturated water vapor and of air at inlet conditions. The value of the former, together with the enthalpies of steam and water, may be read from steam tables. 12 4. REPORT FORMAT A brief description of what should be included in each of these sections is included below. Introduction: Your introductory paragraphs must include: - Objective: A single, concise statement of the major objective of the lab, - Procedure: Include the information necessary to allow someone to repeat what we did. Observations and Results: Calculations will be made for heat pump and air cooler modes. 1. Calculate mass flow rates of air and water in kg/s. 2. Calculate enthalpy flow rates (Q1, Q2, …., Q8) 3. Calculate the following coefficient of performance: o The overall of external coefficient for real and ideal cases. o The overall of internal coefficient for real and ideal cases. o Write your comments on the results. 4. Show the energy balance of the system: o Electrical energy to compressor motor o Electrical energy to fan motor o Heat from circulating water o Heat to/from air o Heat from condensed water vapour o Heat to/from surroundings. 13