04 20 00 (04200)

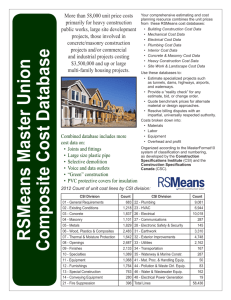

advertisement

SECTION 04 20 00 UNIT MASONRY PART 1 GENERAL 1.01 SUMMARY A. Section Includes: 1. B. Types of masonry work required include: a. Standard Concrete Masonry Units b. Stone Trim Units c. Mortar and Grout d. Reinforcing Steel e. Masonry Joint Reinforcement f. Required Masonry Ties and Anchors Products installed, but not furnished, under this Section include the following: 1. Steel Lintels for unit masonry, furnished under Section 05 50 00, - Metal Fabrications. 2. Hollow-metal frames in unit masonry openings, furnished under Section 08 11 13 - Steel Doors and Frames. 1.02 REFERENCES A. ASTM International Publications: 1. A82 “Standard Specification for Steel Wire, Plain, for Concrete Reinforcement” 2. A185 “Standard Specification for Steel Welded Wire Reinforcement, Plain, for Concrete” 3. A307 "Standard Specification for Carbon Steel Bolts and Studs, 60 000 PSI Tensile Strength" 4. A496 “Standard Specification for Steel Wire, Deformed, for Concrete Reinforcement” 5. A497 “Standard Specification for Steel Welded Wire Reinforcement, Deformed, for Concrete” 6. A615 "Standard Specification for Deformed and Plain Billet-Steel Bars for Concrete Reinforcement" 7. A951 “Standard Specification for Masonry Joint Reinforcement” 8. C90 “Standard Specification for Loadbearing Concrete Masonry Units” 9. C140 "Test Methods of Sampling and Testing Concrete Masonry Units and Related Units" 10. C144 “Standard Specification for Aggregate for Masonry Mortar” 11. C270 “Standard Specification for Mortar for Unit Masonry” 12. C404 “Standard Specification for Aggregates for Masonry Grout” 13. C476 “Standard Specification for Grout for Masonry” ▪ SECTION 04 20 00 (04200) - UNIT MASONRY ▪ ▪ PAGE 1 ▪ FILE: 533583295 2011, Marriott International, Inc. REVISED: 04/01/11 CFRST SPECMSTR-NEW BUILD 14. C641 “Standard Test Methods for Mastics and Coatings Used With Thermal Insulation” 15. C1314 “Standard Test Method for Compressive Strength of Masonry Prisms” 16. D226 “Standard Specification for Asphalt-Saturated Organic Felt Used in Roofing and Waterproofing” 17. D2287 “Standard Specification for Nonrigid Vinyl Chloride Polymer and Copolymer Molding and Extrusion Compounds” 18. E119 "Standard Test Methods for Fire Tests of Building Construction and Materials" 19. E514 "Test Method for Water Penetration and Leakage through Masonry" B. C. Joint American Concrete Institute (ACI) / American Society of Civil Engineers (ASCE) / The Masonry Society (TMS) Publications: 1. ACI 530-1/ASCE 6/TMS 602 “Specification for Masonry Structures” 2. ACI 530/ASCE 5/TMS 402 “Building Code Requirements for Masonry Structures” National Concrete Masonry Association (NCMA) Publications: 1. "Tek" Bulletins 1.03 PERFORMANCE REQUIREMENTS A. Provide unit masonry that develops 2150psi net-area compressive strengths at 28 days. Determine compressive strength of masonry from net-area compressive strengths of masonry units and mortar types according to Tables 1 and 2 in ACI 530.1/ASCE 6/TMS 602. B. Determine net-area compressive strength of masonry by testing masonry prisms according to ASTM C1314. C. Fire Resistance Ratings: Where indicated, provide materials and construction which are identical to those of assemblies with fire-resistance ratings determined by testing in compliance with ASTM E119 by a recognized testing and inspecting organization, by equivalent concrete masonry thickness, or by another means, as acceptable to authorities having jurisdiction. 1.04 SUBMITTALS A. Product Data: Submit manufacturer's product data for each type of masonry unit, accessory, and other manufactured products, including certifications that each type complies with specified requirements. B. Cold-Weather Procedures: Detailed description of methods, materials, and equipment to be used to comply with cold-weather requirements. 1.05 QUALITY ASSURANCE A. Unit Masonry Standard: Comply with ACI 530.1/ASCE 6/TMS 602, "Specifications for Masonry Structures", except as otherwise indicated. 1. B. Revise ACI 530.1/ASCE 6 to exclude Sections 1.5; Parts 1.6-A.1.b and 1.6-A.1.c; an d Part 3.3-E. Fire Resistance Ratings: Where indicated, provide materials and construction which are identical to those of assemblies with fire-resistance ratings determined by testing in compliance with ASTM E119 by a recognized testing and inspecting organization, by equivalent concrete masonry thickness, or by another means, as acceptable to authority having jurisdiction. ▪ SECTION 04 20 00 (04200) - UNIT MASONRY ▪ ▪ PAGE 2 ▪ REVISED: 04/01/11 CFRST SPECMSTR-NEW BUILD FILE: 533583295 2011, Marriott International, Inc. C. Single Source Responsibility for Masonry Units: Obtain exposed masonry units of uniform texture and color, or a uniform blend within the ranges accepted for these characteristics, through one source from a single manufacturer for each different product required for each continuous surface or visually related surfaces. D. Single Source Responsibility for Mortar Materials: Obtain mortar ingredients of uniform quality, including color for exposed masonry, from one manufacturer for each cementitious component and from one source and producer for each aggregate. E. Prism Test: For each type of wall construction indicated, per ASTM C1314. 1.06 DELIVERY, STORAGE, AND HANDLING A. Deliver masonry materials to project in undamaged condition. B. Store masonry units on elevated platforms in a dry location. If units are not stored in an enclosed location, cover tops and sides of stacks with waterproof sheeting, securely tied. If units become wet, do not install until they are dry. C. Store cementitious materials on elevated platforms, under cover, and in a dry location. Do not use cementitious materials that have become damp. D. Store aggregates where grading and other required characteristics can be maintained, and contamination avoided. E. Store masonry accessories, including metal items, to prevent deterioration by corrosion and accumulation of dirt. F. Deliver preblended, dry mortar mix in moisture-resistant containers designed for lifting and emptying into dispensing silo. Store preblended, dry mortar mix in delivery containers on elevated platforms, under cover, and in a dry location or in a metal dispensing silo with weatherproof cover. 1.07 PROJECT/SITE CONDITIONS A. Protection of Work: During construction, cover tops of walls, projections, and sills with waterproof sheeting at end of each day's work. Cover partially completed masonry when construction is not in progress. 1. Extend cover a minimum of 24 inches down both sides and hold cover securely in place. 2. Where one wythe of multi-wythe masonry walls is completed in advance of other wythes, secure cover a minimum of 24 inches down face next to unconstructed wythe and hold cover in place. B. Do not apply uniform roof loading for at least 12 hours after building masonry walls or columns. C. Do not apply uniform roof or floor loading until the masonry has cured to the extent that it will safely support the intended load, a minimum of 12 hours after building masonry walls or columns. D. Do not apply concentrated loads until the masonry has cured to the extent that it will safely support the intended load, a minimum of 3 days after building masonry walls or columns. E. Staining: Prevent grout, mortar, and soil from staining the face of masonry to be left exposed or painted. Immediately remove grout, mortar, and soil that come in contact with such masonry. 1. Protect base of walls from rain-splashed mud and from mortar splatter by means of coverings spread on ground and over wall surface. ▪ SECTION 04 20 00 (04200) - UNIT MASONRY ▪ ▪ PAGE 3 ▪ FILE: 533583295 2011, Marriott International, Inc. REVISED: 04/01/11 CFRST SPECMSTR-NEW BUILD 2. Protect surfaces of window and door frames, as well as similar products with painted and integral finishes, from mortar droppings. 1.08 COLD AND HOT WEATHER PROTECTION A. Cold-Weather Requirements: Do not use frozen materials or materials mixed or coated with ice or frost. Do not build on frozen subgrade or setting beds. Remove and replace unit masonry damaged by frost or by freezing conditions. Comply with cold weather construction requirements contained in ACI 530.1/ASCE 6/TMS 602. B. Remove masonry damaged by freezing conditions. C. Cold Weather Construction: When the ambient temperature is within the limits indicated, use the following procedures: D. 1. 40 to 32 deg F: Heat mixing water or sand to produce mortar temperatures between 40 and 120 deg F. 2. 32 to 25 deg F: Heat mixing water and sand to produce mortar temperatures between 40 and 120 deg F. Heat grout materials to produce grout temperatures between 40 and 120 deg F. Maintain mortar and grout above freezing until used in masonry. 3. 25 to 20 deg F: Heat mixing water and sand to produce mortar temperatures between 40 and 120 deg F. Heat grout materials to produce grout temperatures between 40 and 120 deg F. Maintain mortar and grout above freezing until used in masonry. Heat masonry units to 40 deg F if grouting. Use heat on both sides of walls under construction. 4. 20 deg F and Below: Heat mixing water and sand to produce mortar temperatures between 40 and 120 deg F. Heat grout materials to produce grout temperatures between 40 and 120 deg F. Maintain mortar and grout above freezing until used in masonry. Heat masonry units to 40 deg F. Provide enclosures and use heat on both sides of walls under construction to maintain temperatures above 32 deg F within the enclosures. Cold-Weather Protection: When the mean daily temperature is within the limits indicated, provide the following protection: 1. 40 to 25 deg F: Cover masonry with a weather-resistant membrane for 48 hours after construction. 2. 25 to 20 deg F: Cover masonry with insulating blankets or provide enclosure and heat for 48 hours after construction to prevent freezing. Install wind breaks when wind velocity exceeds 15 mi./h. 3. 20 deg F and Below: Provide enclosure and heat to maintain temperatures above 32 deg F within the enclosure for 48 hours after construction. E. Cold-Weather Cleaning: Use liquid cleaning methods only when air temperature is 40 deg F and above and will remain so until masonry has dried out, but not less than 7 days after completion of cleaning. F. Hot-Weather Requirements: Protect unit masonry work when temperature and humidity conditions produce excessive evaporation of water from mortar and grout. Provide artificial shade and wind breaks and use cooled materials as required. 1. Comply with hot weather construction requirements contained in ACI 530.1/ASCE 6/TMS 602. 2. When ambient temperature exceeds 100 deg F, or 90 deg F with a wind velocity greater than 8 mph, do not spread mortar beds more than 48 inches ahead of masonry. Set masonry units within one minute of spreading mortar. ▪ SECTION 04 20 00 (04200) - UNIT MASONRY ▪ ▪ PAGE 4 ▪ REVISED: 04/01/11 CFRST SPECMSTR-NEW BUILD FILE: 533583295 2011, Marriott International, Inc. PART 2 PRODUCTS 2.01 CONCRETE MASONRY UNITS A. Avendra, LLC Preferred Manufacturers: 1. B. C. D. None Approved Manufacturers: 1. Oldcastle Architectural Inc. (800-899-8455) 2. Approved Substitution. General: Comply with referenced standards and other requirements indicated below applicable to each form of concrete masonry unit required. 1. Provide special shapes where required for lintels, corners, jambs, sash, control joints, headers, bonding and other special conditions. 2. Provide square-edged units for outside corners, unless Drawings. indicated otherwise on the Concrete Masonry Units: Provide units complying with characteristics indicated below for grade, type, face size, exposed face and, under each form of block included, for weight classification: 1. Size: a. 2. Unless noted otherwise, provide manufacturer's standard units with nominal face dimensions of 16" long x 8" high (15-5/8" x 7-5/8" actual) x thickness indicated. Exposed Faces: a. Manufacturer's Standard Gray Color and Texture b. Color and Texture as selected by Owner’s Representative from Manufacturer's Standard Colors c. Face Finish: 1) 3. Smooth Hollow Loadbearing Block: ASTM C90, and as follows: a. Weight Classification: Medium weight, minimum compressive strength of 2000 psi (net area). 2.02 FIRE RATINGS: Where fire ratings on masonry walls are shown on the Drawings, the Contractor shall make certain that the fire-resistant units to be used qualify for the ratings. 2.03 MORTAR AND GROUT MATERIALS A. Colored Cement Product: Packaged blend made from masonry cement and mortar pigments, all complying with specified requirements, and containing no other ingredients. 1. Avendra, LLC Preferred Manufacturers: a. 2. None Approved Manufacturers: a. LeHigh Cement Co. (800-523-5488) b. Cemex (800-245-1705) c. Custom Building Products (800-272-8786) ▪ SECTION 04 20 00 (04200) - UNIT MASONRY ▪ ▪ PAGE 5 ▪ FILE: 533583295 2011, Marriott International, Inc. REVISED: 04/01/11 CFRST SPECMSTR-NEW BUILD d. LaFarge Corporation (800-336-2490) e. Essroc, Italcementi Group (800-245-1717) 3. Formulate blend as required to produce color indicated or, if not indicated, as selected from manufacturer’s standard colors. Use cement with synthetic iron oxide pigment only. 4. Aggregate for Mortar: ASTM C144; except for joints less than 1/4 inch thick, use aggregate graded with 100 percent passing the No. 16 sieve. a. White-Mortar Aggregates: Natural white sand or ground white stone. b. Colored-Mortar Aggregates: Natural-colored sand or ground marble, granite, or other sound stone; of color necessary to produce required mortar color. B. Aggregate for Grout: ASTM C404. C. Grout for Unit Masonry: Comply with ASTM C476 for grout for use in construction of reinforced and nonreinforced unit masonry. Use grout of consistency indicated or, if not otherwise indicated, of consistency (fine or coarse) at time of placement which will completely fill all spaces intended to receive grout. Minimum compressive strength shall be 2,500 psi in 28 days. 1. Use fine grout in grout spaces less than 2" in horizontal direction, unless otherwise indicated. 2. Use coarse grout (maximum 3/8" aggregate) in grout spaces 2" or more in least horizontal dimension, unless otherwise indicated. D. Mortar Color: See Exterior Finish Index. E. Water: Potable F. Cold Weather additives shall NOT be used. 2.04 JOINT REINFORCEMENT, TIES AND ANCHORING DEVICES A. General: Comply with ASTM A 951. B. Materials: Comply with requirements indicated below for basic materials and with requirements indicated under each form of joint reinforcement, tie and anchor for size and other characteristics: 1. Mill Galvanized Steel Wire: ASTM A82 for uncoated wire and with ASTM C641 for zinc coating of class indicated below: a. 2. Hot-Dip Galvanized, Carbon Steel Wire: ASTM A82 with ASTM A153 for zinc coating of class indicated below: a. C. Class 1 (0.40 oz. per sq. ft. of wire surface). Class B-2. Joint Reinforcement: Provide welded-wire units prefabricated with deformed continuous side rods and plain cross rods into straight lengths of not less than 10', with prefabricated corner and tee units, and complying with requirements indicated below: 1. Width: Fabricate joint reinforcement in units with widths of approximately 2" less than nominal width of walls and partitions as required to provide mortar coverage of not less than 5/8" on joint faces exposed to exterior. 2. Wire Size for Side and Cross Rods: #9 Gauge 3. For single-wythe masonry, provide type as follows with single pair of side rods: ▪ SECTION 04 20 00 (04200) - UNIT MASONRY ▪ ▪ PAGE 6 ▪ REVISED: 04/01/11 CFRST SPECMSTR-NEW BUILD FILE: 533583295 2011, Marriott International, Inc. a. D. Truss design with continuous diagonal cross rods spaced not more than 16" o.c. Anchor Section: Sheet metal plate, with screw holes tope and bottom and with raised, ribstiffened strap stamped into center to provide slot between strap and plate for connection of wire tie, of overall size and thickness indicated below: 1. Size: Plate and strap size: 1-1/4" wide for plate, 5/8" for strap x lengths indicated below. Slot clearance formed between face of plate and back of strap at maximum rib projection: 1/32" + diameter of wire tie. 2. Plate and Strap Lengths: 5" and 3-5/8", with both sides of plate stiffened by ribs. 3. Thickness: 0.0747" (14 Gauge) 2.05 REINFORCING STEEL A. General: Provide reinforcing steel complying with requirements of referenced unit masonry standard and this article. B. Steel Reinforcing Bars: Material and grade as follows: 1. Billet steel complying with ASTM A615, Grade 60. C. Deformed Reinforcing Wire: ASTM A496. D. Plain Welded Wire Fabric: ASTM A185. E. Deformed Welded Wire Fabric: ASTM A497. 2.06 ACCESSORIES A. Premolded Control Joint Strips: Material as indicated below, designed to fit standard sash block and to maintain lateral stability in masonry wall. Size and configuration as indicated. 1. Polyvinyl Chloride Complying with ASTM D2287, General Purpose Grade, Designation PVC-63506. a. Avendra, LLC Preferred Manufacturers: 1) b. None Approved Manufacturers: 1) "AA2000-2001 Blocktite"; Hohmann & Barnard, Inc. (800-645-0616) 2) "Rapid Poly-Joint"; Dur-O-Wal, A Dayton Superior Company (800-323-0090) B. Bond Breaker Strips: Asphalt-Saturated Organic Roofing Felt Complying with ASTM D226, Type I (No. 15 Asphalt Felt) C. Reinforcing Bar Positioners: Wire units designed to fit into mortar bed joints spanning masonry unit cells with loops for holding reinforcing bars in center of cells. Units shall be formed from 0.187-inch steel wire, hot-dip galvanized after fabrication. 1. Provide units with either two loops or four loops as needed for number of bars indicated. 2. Avendra, LLC Preferred Manufacturers: a. 3. None Approved Manufacturers: a. “D/A 811”; Dur-O-Wal, A Dayton Superior Company (800-323-0090) b. “D/A 816”; Dur-O-Wal, A Dayton Superior Company (800-323-0090) c. “#RB Rebar Positioner”; Hohmann & Barnard, Inc. (800-645-0616) ▪ SECTION 04 20 00 (04200) - UNIT MASONRY ▪ ▪ PAGE 7 ▪ FILE: 533583295 2011, Marriott International, Inc. REVISED: 04/01/11 CFRST SPECMSTR-NEW BUILD d. D. Flashings: 1. E. Refer to Section 07 62 00 (07620) – Sheet Metal Flashing & Trim for flashing materials. Flashing Termination Drip Plates 1. Approved Manufacturers: a. F. “#RB-Twin Rebar Positioner”; Hohmann & Barnard, Inc. (800-645-0616) “Foam-Tite Seal Model No.FTSA”; Hohmann & Barnard, Inc. (800-645-0616) Anchor Bolts: Provide steel bolts wit hex nuts and flat washers complying with ASTM A307, Grade A, hot-dip galvanized to comply with ASTM C153, Class C, in sizes and configuration indicated. 2.07 MORTAR AND GROUT MIXES A. General: Do not use admixtures, including coloring pigments, air-entraining agents, accelerators, retarders, water repellent agents, anti-freeze compounds or other admixtures, unless otherwise indicated. 1. Do not use calcium chloride in mortar or grout. B. Mixing: Combine and thoroughly mix cementitious, water and aggregates in a mechanical batch mixer; comply with referenced ASTM standards for mixing time and water content. C. Mortar for Unit Masonry: Comply with ASTM C270, Proportion Specification, for types of mortar required, unless otherwise indicated. D. 1. Use Type S mortar. 2. For masonry below grade, in contact with earth, and where indicated, use Type - S. 3. For reinforced masonry and where indicated, use Type - S. 4. For exterior, above-grade, load-bearing and non-load-bearing walls and parapet walls; for interior load-bearing walls; for interior non-load-bearing partitions; and for other applications where another type is not indicated, use Type - S. 5. For mortar parge coats use Type N. Grout for Unit Masonry: Comply with ASTM C476. 1. Use grout of type indicated or, if not otherwise indicated, of type (fine or coarse) that will comply with Table 1.15.1 in ACI 530.1/ASCE 6/TMS 602 for dimensions of grout spaces and pour height. 2. Proportion grout in accordance with ASTM C476, Table 1 or paragraph 4.2.2 for specified 28-day compressive strength indicated, but not less than 2000 psi. 3. Provide grout with a slump of 8 to 11 inches as measured according to ASTM C143. 2.08 SOURCE QUALITY CONTROL A. Brick Tests: For each type and grade of brick indicated, units will be tested according to ASTM C67. B. Concrete Masonry Unit Tests: For each type of concrete masonry unit indicated, units will be tested according to ASTM C140. ▪ SECTION 04 20 00 (04200) - UNIT MASONRY ▪ ▪ PAGE 8 ▪ REVISED: 04/01/11 CFRST SPECMSTR-NEW BUILD FILE: 533583295 2011, Marriott International, Inc. PART 3 EXECUTION 3.01 EXAMINATION A. B. Examine conditions, with Installer present, for compliance with requirements for installation tolerances and other conditions affecting performance. 1. Verify that foundations are within tolerances specified. 2. Verify that reinforcing dowels are properly placed. 3. Proceed with installation only after unsatisfactory conditions have been corrected. Before installation, examine rough-in and built-in construction to verify actual locations of piping connections. 3.02 INSTALLATION - GENERAL A. Do not wet concrete masonry units. B. Cleaning Reinforcing: reinforcing. C. Thickness: Build cavity and composite walls, floors and other masonry construction to the full thickness shown. Build single-wythe walls (if any) to the actual thickness of the masonry units, using units of nominal thickness indicated. D. Build chases and recesses to accommodate items specified in this Section or in other sections of the Specifications as shown or required. Provide not less than 8" of masonry between chase or recess and jamb of openings, and between adjacent chases and recesses. E. Leave openings for equipment to be installed before completion of masonry work. After installation of equipment, complete masonry work to match work immediately adjacent to the opening. F. Cut masonry units using motor-driven saws to provide clean, sharp, unchipped edges. Cut units as required to provide continuous pattern and to fit adjoining work. Use full-size units without cutting where possible. 1. G. Before placing, remove loose rust, ice and other coatings from Use dry cutting saws to cut concrete masonry units. Select and arrange units for exposed unit masonry to provide a uniform blend of colors and textures. 3.03 CONSTRUCTION TOLERANCES A. Comply with tolerances in ACI 530-1/ASCE 6/TMS 602 and the following: 1. Variation from Plumb: For vertical lines and surfaces of columns, walls and arises do not exceed 1/4" in 10', or 3/8" in a story height not to exceed 20'. For external corners, expansion joints, control joints and other conspicuous lines, do not exceed 1/4" in any story or 20' maximum, nor 1/2" in 40' or more. For vertical alignment of head joints, do not exceed plus or minus 1/4" in 10'. 2. Variation from Level: For bed joints and lines of exposed lintels, sills, parapets, horizontal grooves and other conspicuous lines, do not exceed 1/4" in any bay or 20' maximum, nor 1/2" in 40' or more. For top surface of bearing walls, do not exceed 1/8" between adjacent floor elements in 10' or 1/16" within width of a single unit. 3. Variation of Linear Building Line: For position shown in plan and related portion of columns, walls and partitions, do not exceed 1/2" in any bay or 20' maximum, nor 3/4" in 40' or more. ▪ SECTION 04 20 00 (04200) - UNIT MASONRY ▪ ▪ PAGE 9 ▪ FILE: 533583295 2011, Marriott International, Inc. REVISED: 04/01/11 CFRST SPECMSTR-NEW BUILD 4. Variation in Mortar Joint Thickness: Do not exceed bed joint thickness indicated by more than plus or minus 1/8", with a maximum thickness limited to 1/2". Do not exceed head joint thickness indicated by more than plus or minus 1/8". 3.04 LAYING MASONRY WALLS A. Lay out walls in advance for accurate spacing of surface bond patterns with uniform joint thicknesses and to accurately locate openings, movement-type joints, returns and offsets. Avoid the use of less-than-half-size units at corners, jambs and wherever possible at other locations. B. Lay-up walls to comply with specified construction tolerances, with courses accurately spaced and coordinated with other work. C. Bond Pattern: Lay exposed masonry in the bond pattern shown or, if not shown, lay in running bond with vertical joint in each course centered on units in courses above and below. Lay concealed masonry with all units in a wythe in running bond or bonded by lapping not less than 2". Bond and interlock each course of each wythe at corners. Do not use units with less that nominal 4" horizontal face dimensions at corners or jambs. D. Stopping and Resuming Work: In each course, rack back 1/2-unit length for 1/2-running bond or 1/3-unit length for 1/3 running bond; do not tooth. Clean exposed surfaces of set masonry, wet clay units lightly (if required) and remove loose masonry units and mortar prior to laying fresh masonry. E. Built-in Work: As construction progresses, build-in items specified under this and other Sections of these Specifications. Fill in solidly with masonry around built-in items. F. 1. Fill space between hollow metal frames and masonry solidly with mortar, unless otherwise indicated. 2. Where built-in items are to be embedded in cores of hollow masonry units, place a layer of metal lath in the joint below and rod mortar or grout into core. 3. Fill cores in hollow concrete masonry units with grout 24” under bearing plates, beams, lintels, posts and similar items, unless otherwise indicated. Build non-load-bearing interior partitions full height of story to underside of solid floor or roof structure above, unless otherwise indicated. 1. Install compressible filler in joint between top of partition and underside of structure above. 2. At fire-rated partitions, install firestopping in joint between top of partition and underside of structure above to comply with Division 07 Section "Firestopping." 3.05 MORTAR BEDDING AND JOINTING A. Lay solid masonry units and brick units with completely filled bed and head joint; butter ends with sufficient mortar to fill head joints and shove into place. Do not slush head joints. B. Lay hollow concrete masonry units with full mortar coverage on horizontal and vertical face shells. Bed webs in mortar in starting course on footings and in all courses of piers, columns and pilasters, and where adjacent to cells or cavities to be reinforced or filled with concrete or grout. For starting course on footings where cells are not grouted, spread out full mortar bed including areas under cells. C. Maintain joint widths shown, except for minor variations required to maintain bond alignment. If not shown, lay walls with 3/8" joints. D. Cut joints flush for masonry walls which are to be concealed or to be covered by other materials, unless otherwise indicated. ▪ SECTION 04 20 00 (04200) - UNIT MASONRY ▪ ▪ PAGE 10 ▪ REVISED: 04/01/11 CFRST SPECMSTR-NEW BUILD FILE: 533583295 2011, Marriott International, Inc. E. All exposed joints shall be well-tooled to a concave or rodded profile, unless otherwise indicated. 1. Provide raked joints at all vertical scores in scored brick units. Strike to match concave or rodded profile of horizontal joints. 2. Rake-out expansion joints and joints indicated on Drawings to receive sealant. F. Mortar joints shall be struck at a consistent time interval when mortar is at the same medium stiff consistency in order to minimize color variations. G. Remove masonry units disturbed after laying; clean and reset in fresh mortar. Do not pound corners or jambs to shift adjacent stretcher units which have been set in position. If adjustments are required, remove units, clean off mortar and reset in fresh mortar. H. Collar Joints: After each course is laid, fill the vertical longitudinal joint between wythes solidly and with mortar for the following masonry work: 1. All exterior walls, except cavity walls, and interior walls and partitions. I. Use continuous horizontal joint reinforcement installed in horizontal mortar joints for bond tie between wythes. Install at not more than 16" o.c. vertically. J. Corners: Provide interlocking masonry unit bond in each course at corners, unless otherwise shown. K. Intersecting and Abutting Walls: Unless vertical expansion or control joints are shown at juncture, provide same type of bonding specified for structural bonding between wythes and space as follows: 1. Provide individual metal ties at not more than 24" o.c. vertically. 3.06 MASONRY JOINT REINFORCEMENT A. General: Provide continuous masonry joint reinforcement as indicated. Install longitudinal side rods in mortar for their entire length with a minimum cover of 5/8" on exterior side of walls. Lap reinforcing a minimum of 6". B. Cut or interrupt joint reinforcement at control and expansion joints, unless otherwise indicated. C. Reinforce walls with continuous horizontal joint reinforcing, unless specifically noted to be omitted. D. Provide continuity at corners and wall intersections by use of prefabricated "L" and "T" sections. Cut and bend reinforcement units as directed by manufacturer for continuity at returns, offsets, column fireproofing, pipe enclosures and other special conditions. E. Space continuous horizontal reinforcement as follows: F. 1. For multi-wythe walls (solid or cavity) which are structurally bonded by masonry headers or individual wire ties, space horizontal reinforcement 24" o.c. vertically. 2. For single-wythe walls, space reinforcement at 16" o.c. indicated. 3. For parapets, space reinforcement at 8" o.c. vertically, unless otherwise indicated. vertically, unless otherwise Reinforce masonry openings greater than 1'-0" wide, with horizontal joint reinforcement placed in 2 horizontal joints approximately 8" apart, immediately above the lintel and immediately below the sill. Extend reinforcement a minimum of 2'-0" beyond jambs of the opening, except at control joints. ▪ SECTION 04 20 00 (04200) - UNIT MASONRY ▪ ▪ PAGE 11 ▪ FILE: 533583295 2011, Marriott International, Inc. REVISED: 04/01/11 CFRST SPECMSTR-NEW BUILD 1. In addition to wall reinforcement, provide additional reinforcement at openings as required to comply with the above. 3.07 ANCHORING MASONRY WORK A. General: Provide anchor devices of type indicated. B. Anchor masonry veneers to concrete and masonry backup with masonry-veneer anchors to comply with the following requirements: 1. Fasten anchors to concrete and masonry backup with metal fasteners of type indicated. 2. Embed connector sections and continuous wire in masonry joints. Provide not less than 2 inches of air space between back of masonry veneer and face of sheathing. 3. Locate anchor sections to allow maximum vertical differential movement of ties up and down. 4. Space anchors as indicated, but not more than 16 inches o.c. vertically and 24 inches o.c. horizontally with not less than 1 anchor for each 3.5 sq. ft. of wall area. Install additional anchors within 12 inches of openings and at intervals, not exceeding 36 inches, around perimeter. 3.08 CONTROL AND EXPANSION JOINTS A. General: Provide vertical and horizontal expansion, control and isolation joints in masonry where shown. Build-in related items as the masonry work progresses. B. Control Joint Spacing: If location of control joints is not shown, place vertical joints spaced not to exceed 30’-0” o.c. for concrete masonry wythes if reinforced, or 20’-0” o.c. if not reinforced. Locate control joints at points of natural weakness in the masonry work. C. Build-in non-metallic joint fillers where indicated. 3.09 LINTELS A. Provide masonry lintels where shown and wherever openings of more than 2'-0" for block size units or more than 1'-0" for brick size units are shown without structural steel or other supporting lintels. B. Provide minimum bearing of 8" at each jamb, unless otherwise indicated. 3.10 FLASHING OF MASONRY WORK A. General: Provide concealed flashing in masonry work at, or above, shelf angles, lintels, ledges and other obstructions to the downward flow of water in the wall so as to divert such water to the exterior. Prepare masonry surfaces smooth and free from projections which could puncture flashing. Place through-wall flashing on sloping bed of mortar and cover with mortar. Seal penetrations in flashing with mastic before covering with mortar. Extend flashings through exterior face of masonry and turn down to form drip. 1. Refer to Division 07 Specification Sections for flashing materials. B. Extend flashing the full length of lintels and shelf angles and minimum of 4" into masonry each end. Extend flashing from exterior face of outer wythe of masonry, through the outer wythe, turned up a minimum of 4", and through the inner wythe to within 1/2" of the interior face of the wall in exposed work. Where interior surface of inner wythe is concealed by furring, carry flashing completely through the inner wythe and turn up approximately 2". At heads and sills, turn up ends not less than 2" to form a pan. Extend flashing on exterior to 1/4 inch past wall surface. Do NOT cut flush with wall. C. Install flashing to comply with manufacturer's instructions. ▪ SECTION 04 20 00 (04200) - UNIT MASONRY ▪ ▪ PAGE 12 ▪ REVISED: 04/01/11 CFRST SPECMSTR-NEW BUILD FILE: 533583295 2011, Marriott International, Inc. D. Install weep holes in the exterior widths of the head joints of the first course of masonry immediately above embedded flashings. Space 24" o.c. unless otherwise indicated. 3.11 REPAIRING, POINTING AND CLEANING A. Remove and replace masonry units which are loose, chipped, broken, stained or otherwise damaged, or if units do not match adjoining units as intended. Install new units to match adjoining units and install in fresh mortar or grout, pointed to eliminate evidence of replacement. B. Pointing: During the tooling of joints, enlarge any voids or holes, except weep holes, and completely fill with mortar. Point-up all joints including corners, openings and adjacent work to provide a neat, uniform appearance, prepared for application of sealants. C. Final Cleaning: After mortar is thoroughly set and cured, clean masonry as follows: 1. Remove large mortar particles by hand with wooden paddles and non-metallic scrape hoes or chisels. 2. Test cleaning methods on sample wall panel. Leave 1/2 panel uncleaned for comparison purposes. Obtain Owner’s Representative approval of sample cleaning before proceeding with cleaning of masonry. 3. Protect adjacent stone and non-masonry surfaces from contact with cleaner by covering them with liquid strippable masking agent, polyethylene film or waterproof masking tape. 4. Clean concrete unit masonry to comply with masonry manufacturer's directions and applicable NCMA "Tek" bulletins. 3.12 PROTECTION A. Provide final protection and maintain conditions in a manner acceptable to Installer, which ensures unit masonry work being without damage and deterioration at time of substantial completion. END OF SECTION ▪ SECTION 04 20 00 (04200) - UNIT MASONRY ▪ ▪ PAGE 13 ▪ FILE: 533583295 2011, Marriott International, Inc. REVISED: 04/01/11 CFRST SPECMSTR-NEW BUILD