04 2200 UNIT MASONRY SYSTEM PAGE 1 PART 1

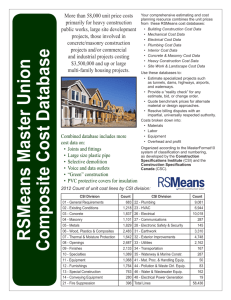

advertisement

04 2200 UNIT MASONRY SYSTEM PAGE 1 PART 1 - GENERAL 1.01 SUMMARY 1.02 A. Section Includes: 1. Concrete Masonry Units (CMU), both standard insulated and non-insulated and split face non-insulated, with integral water proofing agent and without. 2. Reinforcement, Anchorage and Accessories 3. LEED documentation for credits MR4 and MR5. B. Work Installed But Not Furnished Under This Section: 1. Section 05 5000 - Metal Fabrications: Placement of loose steel lintels. 2. Section 04 2200 - Mortar and Masonry Grout: Installation of mortar and grout including grouting of steel door frames and bond beams. C. Related Work Specified Elsewhere: 1. Section 04 2200 - Mortar and Masonry Grout. 2. Section 05 5000 - Lintel installation. 3. Section 07 2100 - Building Insulation: Insulation. 3. Section 07 9200 - Joint Sealers: Rod and sealant at expansion and control joints. 4. Section 13 3419 – Pre-Engineered Metal Building – metal building wall panels over concrete block and furring backup. REFERENCES A. ASTM A641 – Zinc coated (Galvanized) Carbon Steel Wire. B. ASTM C55 - Concrete Building Brick. C. ASTM A153/A153M - Zinc Coating (Hot-Dip) on Iron and Steel Hardware. D. ASTM A951 – Masonry Joint Reinforcement. E. ASTM C140 – Sampling and Testing Concrete Masonry Units. F. ASTM C90 - Load Bearing Concrete Masonry Units. G. ASTM C129 - Non-Load Bearing Concrete Masonry Units. H. 1.03 UL - Underwriters' Laboratories. I MSJC (Masonry Standards Joint Committee) Code – including ACI 530/ASCE 5/TMS 402 Building Code Requirements for Masonry Structures. J. MSJC Specifications – including ACI 530.1/ASCE 6/TMS 602 Specifications for Masonry Structures. QUALITY ASSURANCE A. Perform Work in accordance with MSJC Code and MSJC Specifications. B. Installer: Company specializing in performing the work of this Section with minimum 5 years FPBB129050 MQ-9 FLIGHT TRAINING UNIT HANGAR 04 2200 UNIT MASONRY SYSTEM PAGE 2 documented experience. 1.04 1.05 SUBMITTALS A. Submit product data under provisions of Section 01 3300. B. Submit product data for fabricated wire reinforcement, wall ties and anchors. C. Submit samples under provisions of Section 01 3300. D. Submit manufacturer's certificates under provisions of Section 01 4500 that products meet or exceed specified requirements. E. Submit manufacturer's installation instructions under provisions of Section 01 3300. F. Submit one full size sample of each type of concrete masonry unit; and each color of each type. G. Product Data for Credit MR 4: For products having recycled content, documentation indicating percentages by weight of postconsumer and preconsumer recycled content. Include statement indicating cost for each product having recycled content. H. Product Data for Credit MR 5: Locally extracted and processed materials MOCK-UP A 1.06 All submittals shall be approved prior sample panel construction. B. Materials used for panel shall represent full range of textures, and aggregate for the project. C. Erect face block sample panel of 3 feet x 4 feet size, include specified mortar, in location on site, designated by Owner; facing direct sunlight (South or West-). D. Submit cleaning procedure, and after approval apply to panel. E. When accepted; mock-up will demonstrate minimum standard for the work. F. Mock-up shall remain until project completion, then be removed. REGULATORY REQUIREMENTS A. Conform to UL Classification C-3 (3 hr) for CMU used for 1, 2 and 3 hour fire rated masonry construction. B. Provide certification that all rated CMU meets the requirements for use in UL rated partition and wall systems. Also mark each pallet of CMU as to the hour rating the CMU was manufactured to obtain. All fire resistance ratings shall have been determined in accordance with requirements of ASTM E 119 and ASTM C140 for equivalent thicknesses using the requirements of the National Concrete Masonry Association NCMA TEK 7-1 Fire Resistance Rating of Concrete Block Assemblies. FPBB129050 MQ-9 FLIGHT TRAINING UNIT HANGAR 04 2200 UNIT MASONRY SYSTEM PAGE 3 1.07 1.08 DELIVERY, STORAGE AND HANDLING A. Deliver products to site under provisions of Section 01 6500. B. Store and protect products under provisions of Section 01 6500. C. Accept units on site. Inspect for damage. ENVIRONMENTAL REQUIREMENTS A. General Requirements: 1. Protect masonry units, cementitious materials and sand so that they are not wetted by rain, snow or ground water. 2. Cover tops of masonry at all times when work is not in progress. Cover shall extend a minimum of 2 ft down both sides, and shall be securely held in place. 3. Brick units in excess of 20 g per 30 sq. in. shall be sprinkled with heated water just prior to laying. Water temperature shall be above 70F when units are above 32F. Water temperature shall be above 120F when temperature of units is 32F or below. 4. Grout shall be placed in masonry at a minimum temperature of 70F and a maximum temperature of 120F. Grouted masonry to be maintained above 32F for 24 hr. following placement of grout. B. Construction Requirements (masonry being worked on): 1. Air Temperature 40F to 32F: Heat sand or mixing water to minimum of 70F and maximum of 160F. 2. Air Temperature 32F to 25F: Heat sand and mixing water to minimum of 70F and maximum of 160F. 3. Air Temperature 25F to 20F: Heat sand and mixing water to minimum of 70F and maximum of 160F. Use salamanders or other sources of heat on both sides of wall under construction. Employ windbreaks when wind is in excess of 15 mph. 4. Air Temperature 20F and Below: Heat sand and mixing water to minimum of 70F and maximum of 160F. Provide enclosure and auxiliary heat to maintain air temperature above 32F. Temperature of units when laid shall be not less than 20F. C. Protection Requirements (completed masonry or sections not being worked on): 1. Mean Daily Air Temperature 40F to 32F: Protect masonry from rain or snow for 24 hr. 2. Mean Daily Air Temperature 32F to 25F: Complete cover masonry for 24 hr. 3. Mean Daily Air Temperature 25F to 20F: Completely cover masonry with insulating blankets for 24 hr. 4. Mean Daily Air Temperature 20F and Below: Maintain masonry temperature above 32F for 24 hr. by enclosure and supplementary heat, by electric heating blankets, infrared heat lamps or other approved method. PART 2 - PRODUCTS 2.01 CONCRETE MASONRY UNITS A. Concrete Masonry Units (CMU) shall be normal weight stone concrete units. Provide fire rated units with required face shell thickness as necessary to provide fire ratings called for by the FPBB129050 MQ-9 FLIGHT TRAINING UNIT HANGAR 04 2200 UNIT MASONRY SYSTEM PAGE 4 documents. B Hollow Load Bearing Concrete Masonry Units (CMU): ASTM C90, Grade N, Type I - moisture controlled weight. Hanger entry wing walls to be split face CMU to meet Ft. Drum standards. C. Hollow Non-Load Bearing Concrete Masonry Units (CMU): ASTM C129, Grade N, Type I moisture controlled weight. D. Concrete Brick Units: ASTM C55, Grade N, Type I -moisture controlled of same Grade, Type and Weight as block units. E. Block Masonry Units: Nominal modular face size of 16 x 8 inches x thickness as shown on contract documents. At exterior wall systems of mechanical/sprinkler/electric/common spaces provide plant insulated units of “ICON” or equal. F. Provide integral water repellent in the CMU for hangar entry wing walls added to mix at CMU plant. Rainbloc or equal. ASTM C1384. G. Provide color additive in CMU at wing walls of hangar entries to match siding color and Fort Drum color pallet. 2.03 2.04 REINFORCEMENT AND ANCHORAGE A. Single Wythe Block Unit Joint Reinforcement: Truss type; steel wire, hot dip galvanized to ASTM A641 Class 3 after fabrication, cold-drawn steel wire conforming to ASTM A951, 3/16" side rods with 9 gauge diagonal cross ties. B. CMU Rate Strap Anchors: Factory bent steel shape, 1-1/2" x 24" size x 1/4 inch thick, with a 1 inch 90 degree leg at both ends, galvanized to ASTM A153 B2 finish. C. Interior CMU Ties: corrugated formed sheet metal ties 12 ga x 1 inch x 7-1/2 inch long galvanized to ASTM A153 B2 finish. D. Anchors for CMU to Steel: Steel offset flat bar to be welded to steel and triangle tie 3/16 inch diameter, 4 x 4 inch, stainless steel, ASTM A153 B2 finish. Dur-O-Wall, Inc. D/A 207 with D/A 700 or approved equal. At columns provide anchors 16” O.C. vertically. E. Reinforcing Bars: As specified in Section 03 3100, sizes and spacing as shown on drawings. Include all dowels. FLASHINGS A. SHEET MATERIALS 1. Copper shall conform to ASTM B370 cold rolled. 2. Aluminum Sheet: ASTM B209, .050" or .060” thick; shop pre-coated with Kynar 500 fluorocarbon coating of colors to be selected. 3. Galvanized Steel - ASTM A525 - G90. B. BASE FLASHING 1. Cavity wall flashing to be 3 oz. coated copper. Sheet laminated each side with asphalt coated glass fabric. Copper fabric by York Manufacturing Inc., Copper Armored Sisalkraft by FPBB129050 MQ-9 FLIGHT TRAINING UNIT HANGAR 04 2200 UNIT MASONRY SYSTEM PAGE 5 Fortifiber Corp. of equal. C. LINTEL FLASHING 1. Same as in paragraph 2.04 A above. D. SILL FLASHING – AT WINDOW SILLS 1 2 2.05 A flexible, 40 mil. membrane, consisting of 32 mils. Of pliable and self adhesive rubberized asphalt compound, completely bonded to an 8 mil. high density, cross-laminated polyethylene film, supplied in rolls, inter-wound with silicone coated release paper, width as necessary for the work. Perm-A-Barrier wall flashing by Grace Construction Products, or equal for a fully adhered, self-adhering flashing system. Provide end dams at all flashings ACCESSORIES A. Preformed Control Joints: 1. Regular type, designed for use with standard sash block of PVC material conforming to ASTM D2287 type PVC 654-4. 2. Dur-O-Wal D/A 2002; Ty-Wal PVC001; or equal. B. Building Paper: #15 asphalt saturated felt, ASTM D226. C. Joint Filler: Closed cell neoprene with adhesive one side, conforming to ASTM D1056 Class RE41, oversized 50 percent to joint width; self-expanding; 2-3/4 inches wide. D. Cleaning Solutions: Non-acidic, not harmful to masonry work or adjacent materials. E. Compressible Joint Filler (Soft Joint): Closed cell neoprene, 1/4 inch thick, ASTM D1056 Class RE41, Dur-O-Wall D/A 2010 or equal. F. Horizontal joint reinforcement – hot dipped galvanized ladder type. Dur-O-Wall or equal. Sized to match wall thickness. 2.06 LINTELS: Install loose lintels furnished under Section 05 5000. 2.07 MORTAR: Install mortar furnished under Section 04 2210. PART 3 - EXECUTION 3.01 EXAMINATION A. Ensure that field conditions are in accordance with construction documents and are ready to receive the work of this Section. B. Ensure items provided by other sections of work are properly sized and located. C. Ensure that built-in items are in proper location, and ready for roughing into masonry work. D. Beginning of installation means installer accepts existing conditions. FPBB129050 MQ-9 FLIGHT TRAINING UNIT HANGAR 04 2200 UNIT MASONRY SYSTEM PAGE 6 3.02 3.03 PREPARATION A. Direct and coordinate placement of metal anchors supplied by other specification sections. B. Provide temporary bracing during installation of masonry work. Maintain in place until building structure provides permanent support. COURSING A. Establish lines, levels and coursing indicated. Protect from displacement. B. Maintain masonry courses to uniform dimension. Form vertical and horizontal joints of uniform thickness. C. Lay concrete masonry units in running bond. Course one unit and one mortar joint to equal 8 inches. Form concave mortar joints. 3.04 PLACING AND BONDING A. Lay solid masonry units in full bed of mortar, with full head joints, uniformly jointed with other work. B. Lay hollow masonry units with face shell bedding on head and bed joints. C. Buttering corners of joints or excessive furrowing of mortar joints is not permitted. D. Remove excess mortar as Work progresses. Exercise caution so as not to place mortar on the face of any decorative surfaces of the décor face CMU. Remove immediately. E. Interlock intersections and external corners. F. Do not shift or tap masonry units after mortar has achieved initial set. Where adjustment must be made, remove mortar and replace. G. Perform jobsite cutting of masonry units with proper tools to provide straight, clean, unchipped edges. Prevent broken masonry unit corners or edges. H. Cut mortar joints flush only where cavity insulation is applied or where GWB is to be adhesively applied over CMU surfaces. All other CMU mortar joints shall be tooled to form concave joint, even under special wall finishes. I. Isolate masonry partitions from vertical structural framing members with a movement type control joint. J. Isolate top joint of masonry from horizontal structural framing members and lintels with compressible joint. K. Install rigid insulation affixed to exterior masonry walls in full bed of trowel applied non-asbestos containing adhesive using Karnak 700 with perm rating of one or less, or equal product. Butt all joints tightly. Seal all butted joints in insulation with permanent sealing tape approved by insulation manufacturer with 0 perm rating. Do not use duct tape. Fit boards snugly around wall FPBB129050 MQ-9 FLIGHT TRAINING UNIT HANGAR 04 2200 UNIT MASONRY SYSTEM PAGE 7 ties, columns, flashing, corners and other abutting surfaces and seal all voids or openings with sealant. 3.05 3.06 REINFORCEMENT AND ANCHORAGES -SINGLE WYTHE MASONRY A. Install horizontal joint reinforcement 16 inches oc. B. Place masonry joint reinforcement in first horizontal joints above and below openings. Extend minimum 16 inches each side of opening. C. Place joint reinforcement continuous in first joint below top of walls. D. Lap joint reinforcement ends minimum 6 inches. E. Reinforce joint corners and intersections with strap anchors 16 inches oc. F. Install reinforcing bars vertically or horizontally as shown on the drawings grouting cores and bond beams full. Imbed vertical reinforcement bars in concrete foundation walls. MASONRY FLASHINGS A. 3.07 3.08 3.09 All flashings shall have a positive slope from the cavity to the exterior of the exterior wall to direct water to the exterior of the construction. Do not allow flashing to droop or sag within the cavity which would cause water to pond in the cavity. LINTELS A. Install loose steel lintels over door openings, louver openings and other openings. B. Maintain minimum 6 inch bearing on each side of opening. CONTROL AND EXPANSION JOINTS A. Do not continue horizontal joint reinforcement through control and expansion joints. B. Install preformed control joint device in continuous lengths. accordance with manufacturer's instructions. C. Size control joint in accordance with Section 07900 for sealant performance. D. Form control or expansion joint as detailed by omitting mortar and cutting unit to form open space. Coordinate size and shape with joint type supplied. E. Install joints where shown on drawings or where required by Brick Masonry Institute or Concrete Masonry Association if not shown. Control joints spaced maximum 30 feet on center at exterior locations and 30 feet on center at interior locations. Seal butt and corner joints in BUILT-IN WORK A. As work progresses, install built-in anchors to columns metal door frames, fabricated steel section or metal frames, anchor bolts, plates and other items furnished by other Sections. FPBB129050 MQ-9 FLIGHT TRAINING UNIT HANGAR 04 2200 UNIT MASONRY SYSTEM PAGE 8 3.10 B. Install built-in items plumb and level. C. Bed anchors of metal door frames, metal glazed frames in adjacent mortar joints. Fill voids between frames and CMU solid with grout. Fill adjacent masonry cores with grout minimum 12 inches from framed openings. D. Do not build in materials subject to deterioration. TOLERANCES A. Maximum Variation From Alignment of Columns: 1/4 inch. B. Maximum Variation From Unit to Adjacent Unit: 1/16 inch. C. Maximum Variation From Plane of Wall: 1/4 inch in 10 feet and 1/2 inch in 20 feet or more. D. Maximum Variation From Plumb: 1/4 inch per story non-cumulative; 1/2 inch in two stories or more. E. Maximum Variation From Level Coursing: 1/8 inch in 3 feet and 1/4 inch in 10 feet; 1/2 inch in 30 feet. F. Maximum Variation of Joint Thickness: 1/8 inch in 3 feet. G. Maximum Variation From Cross Sectional Thickness of Walls: 1/4 inch. 3.11 3.12 CUTTING AND FITTING A. Cut and fit for chases, pipes, conduit, sleeves, and ducts. Coordinate with other Sections of work to provide correct size, shape and location. B. Obtain Architect approval prior to cutting or fitting masonry work not indicated or where appearance or strength of masonry work may be impaired. POINTING AND CLEANING A. Cut out any defective joints and holes in exposed masonry and repoint with mortar, matching adjacent work. Fill all holes in joints and CMU block faces and tool. Repair edge and corner chips of CMU block where deemed excessive. B. Dry brush masonry surface after mortar has set at end of each days work and after final pointing. C. Clean exposed unglazed masonry with stiff brush and clear water. D. Apply cleaning to sample wall area of 20 sq. ft. in location acceptable to the Architect, if cleaning by water does not produce satisfactory results. 1. Do not proceed with cleaning until sample area is acceptable to Architect. 2. Follow manufacturer's recommendations. 3. Thoroughly wet surfaces of masonry on which no green efflorescence appears before using cleaning agent. FPBB129050 MQ-9 FLIGHT TRAINING UNIT HANGAR 04 2200 UNIT MASONRY SYSTEM PAGE 9 4. 5. 6. 7. 8. 9. B. 3.13 3.14 Scrub with acceptable cleaning agent. Immediately rinse with clear water. Work small sections at a time. Work from top to bottom. Protect sash, metal lintels, and other materials which may be damaged when masonry is cleaned. Remove green efflorescence in accordance with brick manufacturer's recommendations. Leave work area and surrounding surfaces clean and free of mortar spots, droppings, and broken masonry. PROTECTION OF FINISHED WORK A. Without damaging completed work, provide protective boards at exposed external corners which may be damaged by construction activities. B. Protect sills, ledges, and offsets from mortar drippings or other damage during construction. C. Remove misplaced mortar or grout immediately. D. Protect face materials against staining. SCHEDULES – See drawings and alternates for locations A. Exterior or Interior Partitions and Load Bearing Walls: Single wythe concrete masonry units, reinforced as indicated. B. Interior Fire Walls: One, two, three hour rated walls of CMU at locations identified on Drawings. Build to meet U.L. requirements. ** END OF SECTION ** FPBB129050 MQ-9 FLIGHT TRAINING UNIT HANGAR