Stress Analysis of a Chicago Electric 4½ Angle Grinder

by

Khalid Zouhri

A Project Submitted to the Graduate

Faculty of Rensselaer Polytechnic Institute

in Partial Fulfillment of the

Requirements for the degree of

MASTER OF MECAHNICAL ENGINEERING

Approved:

_________________________________________

Dr.Ernesto Gutierrez-Miravete, Thesis Adviser

Rensselaer Polytechnic Institute

Troy, New York

October, 2009

(For Graduation May 2010)

© Copyright 2009

by

Khalid Zouhri

All Rights Reserved

Table of Contents

1. Problem Statement ...................................................................................................................... 3

1.1. Photos of the Device, Subassembly, and Components ............................................................ 3

1.2. Given and Measured Data ....................................................................................................... 9

1.1.1. Given Data ............................................................................................................................ 9

1.1.2. Measured Data .................................................................................................................... 10

1.1.3. Schematic Drawing .............................................................................................................. 15

2. Force Analysis ............................................................................................................................ 15

2.1.1. Free Body Diagram of Shaft ................................................................................................ 15

2.1.2. Gear Force Calculations: ...................................................................................................... 16

2.1.3. Shaft Force Calculations: ..................................................................................................... 17

2.1.4. Shear Force and Bending Moment Diagrams ...................................................................... 19

3. Stress Analysis ........................................................................................................................... 20

3.1.1. Bending Stress and Bending Factor of Safety ...................................................................... 20

3.1.2. Wear Stress and Bending Factor of Safety ........................................................................... 22

.

Table of Figures

Figure 1: Chicago Electric Angle Grinder ........................................................................................... 3

Figure 2: Complete Component Assembly .......................................................................................... 4

Figure 3: Bevel Pinion in Gear Casting Subassembly ........................................................................ 4

Figure 4: Bevel Gear in Gear Casing Subassembly ............................................................................ 5

Figure 5: Component Subassembly without Gear Casing .................................................................. 5

Figure 6: Shaft with Bevel Pinion Gear Removed .............................................................................. 6

Figure 7: Shaft with Bevel Pinion Gear .............................................................................................. 6

Figure 8: Bevel Pinion ......................................................................................................................... 7

Figure 9: Components in Position ....................................................................................................... 7

Figure 10: SolidWorks Model Assembly ............................................................................................ 8

Figure 11: SolidWorks Assembly Exploded ....................................................................................... 8

Figure 12: Components Analyzed Exploded...................................................................................... 9

Figure 13: ME-2 Rockwell Hardness Testing System ...................................................................... 10

Figure 14: Hardness Testing for Shaft .............................................................................................. 10

Figure 15: Hardness Testing for Bevel Pinion .................................................................................. 11

Figure 16: Pinion Close-up with Reference Lines ............................................................................ 14

Figure 17: Schematic Drawing .......................................................................................................... 15

Figure 18: Free Body Diagram of Shaft ............................................................................................ 15

Figure 19: Pinion- Bevel Schematic .................................................................................................. 16

Figure 20: Force Analysis 2-D Planes ............................................................................................... 17

Figure 21: Load, Shear Force, and Bending Moment Diagrams ....................................................... 19

Table of Tables

Table 1: Manufacturing Specifications ............................................................................................... 9

Table 3: Hardness Testing Results .................................................................................................... 11

Table 4: Hardness Conversion Chart ................................................................................................ 12

Table 5: AGMA Strength Graph for Gears ...................................................................................... 13

Table 6: Gear and Shaft Information ............................................................................................... 14

1. Objective

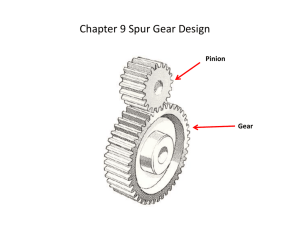

The purpose of this Engineering Project for this semester is to do stress analysis of mechanical device Chicago

Electric 4.5 inch angle grinder ITEM 91223-1VGA. The grinder utilizes spiral bevel gears whose output angular

velocity (ω) is 11,000 rpm. The first component I'm going to analyzed it’s the spiral bevel pinion gear (Figure 8).

This pinion gear is directly coupled to the rotor shaft of the electric motor and supplies torque to the

accompanying spiral bevel gear which is closed coupled to the output shaft. The pinion gear is held onto the

end of the rotor shaft by a nut which forces the pinion against one of the two shaft bearings (Figure 7). The

second component I decided to analyze is the rotor shaft of the electric motor (Figure 6).

1.1

Photos of the Device, Sub assembly, and Components

Figure 1: Chicago Electric Angle Grinder

Figure 2: Complete Component Assembly

Figure 3: Bevel Pinion in Gear Casting Sub assembly

Figure 4: Bevel Gear in Gear Casing Subassembly

Figure 5: Component Subassembly without Gear Casing

Figure 6: Shaft with Bevel Pinion Gear Removed

Figure 7: Shaft with Bevel Pinion Gear

Figure 8: Bevel Pinion

Figure 9: Components in Position

1.2 Given Data

In Table 1 below [2], manufacturing specifications are given.

Manufacturing Specifications

Angular Velocity

11,000 rev/min

Horse Power

½ hp

Voltage

110 volts

Frequency (AC)

60 Hz single Phase

Power

570 watts

Amperage

4.5 amps

Table 1: Manufacturing Specifications

1.2 Key Resource

For proper analysis, certain measurable data needed to be collected

The material used in the angle grinder it's unknown we need to do Rockwell Hardness Testing System

Machine to get the data for shaft and bevel gear

Compare the data with hardness conversation chart to get data for the material

Solids Works to do 3D Model

Cosmos to do stress analysis

1.3 Project deadline

project proposal draft posted due 9/25............done

Also, please prepare a brief presentation of your proposed work (6 slides)........Done

First Progress Report due no later than 10/16!

Second Progress Report due no later than 11/6!

Also, please prepare a brief yet comprehensive presentation of progress on your work to date (10 minutes

long; 6-12 slides).

Final Draft due no later than 11/27!

Final Report due no later than 12/11!

Also get prepare a brief yet comprehensive presentation of your work (10 minutes long; 6-12 slides).

Figure 10: SolidWorks Model Assembly

Figure 11: SolidWorks Assembly Exploded

Figure 12 : Components Analyzed Exploded

1.2

1.2.1

Given and Measured Data

Given Data

In Table 1 bellow [2], manufacturing are given.

In Table 1, all specifications are given by the manufacturer except horsepower. Knowing that for single phase

armature motors, one hp is generated by 720 watts. Assuming that the most efficiency expected out of a single phase

motor is approximately 70%, 60% is used in this analysis.

hp

1.2.2

570 w 3

hp

720 w 4

Measured Data

For proper analysis, certain measurable data needed to be collected. The material used in the angle grinder

was unknown; therefore it was necessary to perform hardness testing to gather useful material data. The

shaft and bevel pinion gear were easily accessible by the Rockwell Hardness Testing Machine. This made

the process more reliable in that the integrity of the material was not compromised by forcefully removing

the components from the remaining subassemblies. The bevel gear was completely isolated from its main

subassembly. This ensured no cutting of material or extended surface hardening from clamping and pulling.

The shaft was permanently fixed to its immediate subassembly. Luckily the shaft was just long enough to

get true readings without similar structural compromises as the bevel gear.

Figure 13: ME-2 Rockwell Hardness Testing System

Before the hardness test could begin, proper surface preparation needed to be performed to ensure proper

results. Three readings were done on the shaft as well as the bevel in different locations to and an average

hardness number. The location of testing on the material was also changed to get a variety of readings and to

also not get tainted results from nearby surface hardening created by testing. The hardness testing operation can

be seen below.

It is imperative to note that the material will be much harder on the tooth of the gear rather than in the

makeup material. There was no way to test the hardness of the material directly on the tooth without risking

safety for the holder. The reading, however, was done as close as possible to the side of the tooth without

risking the ball sliding down the face of the tooth.

Table 2: Hardness Testing Result

Using the hardness conversation chart [2] and the information from Shigley’s Mechanical Engineering

Design in Table 5 [3], material grade and tensile strength can be determined .grade1 used for limiting case

material, steel.

Table 3: Hardness Conversion Chart

Figure 4: AGMA Strength Graph for Gears

Tensile Strength Calculation

S t 77.3H b 12,800 psi

S tpiniom 77.3 * 294 12,800 psi 35.526kpsi

S tpiniom 77.3 * 294 12,800 psi 35.526kpsi

Calculations of Diametric Pitch

P

Np

d

Np =13 Teeth

Pt

Np

d

13

d=20.0mm (outside diameter) as shown in figure

teeth / mm 0.65teeth / mm

20

17.

Equation below was used to calculate pitch.

Before the normal diametral pitch can be determined, the helical angle “ψ” needed to be

determined. In the illustration below, lines were added and a protractor was used to measure ψ.

Figure 16: Pinion Close-up with Reference Lines

By using the reference lines the angle ψ was measured to be 40 degree.

To get normal diametral pitch;

Pn

Pn

Pt

cos

0.65

teeth / mm 0.8485teeth / mm

cos 40

Pitch diameter;

dp

N

13teeth

15.32mm

Pn 0.8485teeth / mm

Table 5: Gear and shaft information

1.2.3

Schematic Drawing

Figure 17: Schematic Drawing

2. Force Analysis

1.1. Free Body Diagram of Shaft

Figure 18: Free Body Diagram of Shaft

1.2. Gear Force Calculations:

Figure 19: Pinion- Bevel Schematic

tan 1 (

PinionTeet h

)

Bevelteeth

tan 1 (

PinionTeet h

) 22.1

Bevelteeth

22.1

90 22.1 67.9

t 2 3.25mm cos(22.1 ) 3.011mm

t 3 3.25mm sin( 22.1 ) 1.222mm

These thicknesses represent the location of the pitch point and are illustrated above in Figure 19.

Distance from bearing D to horizontal pitch point location P is:

9.5 mm is from outside of bevel pinion to far side of bearing

Bearing is 7 mm wide so half of bearing is 3.50

DP( x) 19.5 (3.011mm 3.50mm) 13mm

Distance from bearing D to horizontal pitch point location P is:

DP( y )

20 mm

1.222 mm 8.78mm

2

d p 8.78mm 2 17.56mm( pitchdiameter)

t

WBP

t

WBP

60,000 hp

*d *n

3

60,000 hp

4

74 .2 N

*17 .56 mm *11,000 rpm

r

t

WBP

WBP

tan() cos( )

a

t

WBP

WBP

tan() sin( )

r

WBP

74.2N tan 20 cos22.1 25.02N

a

WBP

74.2N tan 20 sin 22.1 10.16N

W 10 .16 i 25 .02 j 74 .2k N

W ABS(W ) 78.96N

1.3. Shaft Force Calculations:

Taking the moment around D:

Figure 20: Force Analysis 2-D Planes

(x-y) plane :

M D Fcy 136 .5mm 10.16 N 8.78mm 25.02 N .13mm 0

Fcy 1.73N (change direction ) 1.73N

Fx W a FDX

0

FDx 10.16N

Fy W r FDy Fcy 0

FDy 26.75N

(x-z ) Plane:

M D W t 13mm Fcz .136 .5mm 0

Fcz 7.07N (change direction ) 7.07N

Fz W t FDZ FCZ 0

FDZ 81.27N

1.73 j 7.07 K N

F

c

FC ABS ( FC ) 7.28 N

F D {10 .16i 26 .75 j 81 .3K}N

FD ABS ( FD ) 86 .2 N

1.4. Shear Force and Bending Moment Diagrams

Figure 21: Load, Shear Force, and Bending Moment Diagrams

23

3. Stress Analysis

Bending Stress and Bending Factor of Safety

Dynamic Factor (Kv)

Assume quality number is 6. Transmission accuracy level number (Qv) could be taken as the

quality number. Qv = 6.

Kv (

A 200 .V B

)

A

A 50 56(1 B) ifB 0.25(12 Qv )

B 0.25 * (12 6)

2

3

2

3

0.8254

A 50 56(1 0.8254) 59.77

*d p *np

V

60

V

*17.56 mm *11,000 rev / min

Kv (

60

10,113 .8 mm sec 10.114 m sec

59 .77 200 10 .114 m / sec .8254

)

1.59

59 .77

Overload Factor (Ko)

Assuming uniform loading, so Ko = 1.

Size Factor Ks.

From Table 14-2 [5], Yp (13T) is 0.261

Face width 6.5 mm →6.5 mm/25.4 mm/in= 0.2559 in.

P = 0.8485 Teeth/mm = 21.552 Teeth/in

Ks

Ks

1

F Y 0.0535

1.192 (

)

This is for standard units

kb

P

1

F Y 0.0535

0.2559 in * 0.261 0.0535

1.192 (

)

1.192 * (

)

0.907

kb

P

21.552 T / in

24

K H Cmf 1 Cmc * (C pf *C pm Cma*Ce )

Assume uncrowned so (load correction factor) Cmc=1

F 10.00

C pf

In (Pinion Proportion factor) Cpf;

F

6.5mm

0.025

0.025 0.0120

10 * d

10 *17.56 mm

Cpm ( pinion proportion modifier)=1.0

Cma(Mesh alignment factor)

Cma A BF CF 2

Using table 14.9 [6] , Value for A,B,C are as follows ( Commercial,Enclosed units);

A=0.127

B=0.0158

C .930 10 4

Cma 0.127 0.0158 0.2559 .930104 *.25592 .1310

Ce( Mesh alignment correction factor )1

K H Cmf 1 1* (0.0120*1 0.1310*1) 1.143

Rim Thickness factor Kb=1 due to consistent thickness of gear.

Speed Ration mG;

mG

N G 32T

2.46

13T

NP

Load Cycle factor (Yn) using 13T for pinion and life cycle 10

25

YN ( P) 1.3558* N p 0.0178 1.3558* (108 ) 0.0178 0.977

From Table 14-10 [7] and a reliability of 0.90, KR (YZ) = 0.85;

From Figure 14-6 [8], The YJ(P) = 0.21

KT (Temperature Factor) Temperature is less than 250 °F so K T = 1

Brinell hardness number 294

St (Allowable Bending Stress for Hardened Steels) for 294 Brinell.

Grade 1:

St (0.533 H B 88.3)MPa (0.533 * 294 * 88.3) 245 MPa

Sc ( Contact fatigue strength ) for brinell and grade 1.

S c (2.22 H B 200 )Mpa (2.22 * 2.94 200 ) 852 .7Mpa

Pinion Tooth bending stress

p W t K0 Kv ks *

P KH KB

*

F

Yj

p 16.7ibf *1*1.59 * .907 *

21.552 T / in 1.143 *1

*

11040 psi 76.1Mpa

0.2559 in

.21

Bending fatigue factor of safety for pinion;

S t * YN

S F ( P)

p KT K R

245 MPA * .977

3.7

S F ( P )

76

.

1

Mpa

*

1

*

.

85

p 76.1MPa

S F ( P) 3.7

26

4. Reference:

[1] Manufacturing Specifications link,

http://www.harborfreight.com/cpi/ctaf/displayitem.taf?Itemnumber=43471

p/english/gear/myset/spiral.html

[2] Hardness conversion chart,

http://www.carbidedepot.com/formulas-hardness.htm

[3] AGMA Strength Graph for Hardened Steels,

Budynas, R., Nisbett, K., Shigley’s Mechanical Engineering Design. 8th Ed. McGraw Hill,

New

York NY, 2008. pp 727

[4] Reliability Assumption,

Budynas, R., Nisbett, K., Shigley’s Mechanical Engineering Design. 8th Ed. McGraw Hill,

New

York NY, 2008. Table 6-5, pp 285

[5] Parameters for Marin Surface Modification Factors,

Budynas, R., Nisbett, K., Shigley’s Mechanical Engineering Design. 8th Ed. McGraw Hill,

New

York NY, 2008. Table 6-2, pp 280

[6] Lewis Form Factor,

Budynas, R., Nisbett, K., Shigley’s Mechanical Engineering Design. 8th Ed. McGraw Hill,

New

York NY, 2008. Table 14-2, pp 718

27