Módulo: Mecanizado (MEC)

advertisement

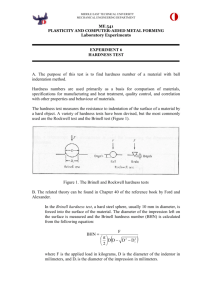

AF_FM01_ Fabricació Mecànica. Ferrous Materials. Guia del Professor CONTENTS 1. Objectives 2. Use of materials and advice for teachers 3. Methodology 4. Assessment 5. Other considerations 6. Solutions to the proposed activities Activity 1.3 Types of Cast Irons Activity 1.4 Questions ( 1 to 20) Activity 2.3 Questions (21 to 40) Activity 3.2 Questions (41 to 60) 7. Transcriptions of the videos about hardness tests. The BRINELL hardness test The ROCKWELL hardness test (Scale C) The VICKERS hardness test 1. Objectives The objectives (general and/or specific) of this Formative Activity are: Know the English words related to ferrous materials in order to understand written texts about these topics. Know the different types of ferrous materials, understanding the relation between their properties and their chemical composition, and identifying their place in the Iron-Carbon diagram. Identify the different constituents of steels and iron castings in an iron-carbon diagram. Learn about Hardness: what it is, how it is measured, what relation it has with Strength... 2. Use of materials and advice for teachers This Formative Activity about Ferrous materials consists of 3 units: 1. Ferrous materials: Iron, Steel and Iron Castings. Composition and Properties. 2. The Iron-Carbon diagram. 3. Physical properties of ferrous materials: Hardness and Strength. Units must be imparted in the given order. 3. Methodology Each Unit has been planned to be imparted in 3 hours. In each Unit there is an activity related to the topic, that students could do at home as homework if they haven't got enough time to finish it in class (it's estimated that an extra time of 40 minutes at home will be needed to finish each activity). Some of the activities have to be done using a computer, sometimes because they are on-line activities or sometimes because students will need an on-line translator to do their work. Each activity have to be done individually. AF_FM01_ Fabricació Mecànica. Ferrous Materials. / Guia del professor 1 4. Assessment The assessment depends on the learning outcomes that you have planned with this activity. If you follow the whole Formative Activity (3 Units) with your students you will have 3 marks (one per Unit) and you could do an exam at the end of the Formative Activity; the final mark could be: Final Mark (FM) = 30% U1 + 30% U2 + 15% U3 + 25% Exam Since this Formative Activity could be included in many Formative Units, you can assign a weight to the final mark (FM) in respect to the Formative Unit curriculum, total number of hours of the Formative Unit, etc. 5. Other considerations These materials have been developed for use with the upper level of vocational training students. 6. Solutions to the proposed activities Activity 1.3 Types of Cast Irons WHITE /waɪt/ : White cast iron ... Composition Fe > 90%, C = 1.8 – 3.6% , Si = 0.5 – 2% . It's the hardest. Its hardness is about 450 BHN (Brinell Hardness Number) . Carbon is in form of cementite (Fe3C) due to a low Si content and a fast cooling. Its fracture has a white appearance due to cementite in its micro structure. It is hard but brittle. It has good wear resistance. GRAY /ɡreɪ/ : Grey cast iron ... Composition Fe > 90%, C = 2.5 – 4% , Si = 1 – 3% . It's the most widely used cast material in weight. Its microstructure has Carbon in form of graphite flakes. Its fracture has a grey appearance due to its graphite micro structure. Its compressive strength is comparable to steels but has less shock resistance. MALLEABLE /ˈmælɪəbəl/: Malleable cast iron ... Composition Fe > 90%, C = 2 – 2.6% , Si = 1.1 – 1.6% . It starts as a white cast iron and then is heat treated (malleablizing). Its microstructure has Carbon in the form of spheroidal and isolated particles of graphite. During the heat treatment carbide particles develop towards a stable spherical form. It has been replaced by ductile cast iron, because ductile is cheaper and better. DUCTILE /ˈdʌktaɪl/: Ductile cast iron ... Composition Fe > 90%, C = 3 – 4% , Si = 1.8 – 2.8% , S < 0.03% , P < 0.1%. It is called also Nodular cast iron. Its microstructure has Carbon in the form of spheroidal particles of graphite. Tiny amounts of Mg or Ce slow down the growth of graphite precipitates. It is possible to cast parts with large sections. Activity 1.4 Questions AF_FM01_ Fabricació Mecànica. Ferrous Materials. / Guia del professor 2 1 Which is the most common metal on Earth? (Take a look at IRON definition) a) Aluminum b) Iron c) Oxygen d) Silicon 2 An alloy is composed by 97% Fe and 3% C. This alloy is a … a) Cast Iron b) Iron c) Steel d) None of the above. 3 An alloy is composed by 99.0 kg Fe and 1.00 kg C. Which is the Carbon content in weight percent (Carbon, wt%)? a) 0.01% b) 1.00% c) 1.01% d) 99% 4 Previous alloy is a … a) Cast Iron b) Iron c) Steel d) None of the above. 5 An alloy is composed by 50.0 kg Fe and 0.500 kg C. Which is the Carbon, wt%? a) 0.01% b) 0.99% c) 1.00% d) 50% 6 Previous alloy is a … a) Cast Iron b) Iron c) Steel d) None of the above. 7 With 30kg of pure Iron, what's the maximum amount of Carbon needed to form a steel? a) 0.02 kg b) 0.06 kg c) 0.61 kg d) 2.00 kg 8 Which is the main element to make a ferrous product? a) Al b) C c) Cast Iron d) Fe 9 Which are the two elements necessary to make a cast iron? a) Carbon and Graphite b) C + Fe c) Fe + Iron d) Iron and Steel 10 Which are the two elements necessary to make a steel? a) Carbon and Graphite b) C + Fe c) Fe + Iron d) Iron and Steel 11 Which sentence is correct? a) Steel has less Carbon than Cast iron e) Steel b) Cast iron has less Carbon than Steel 12 Name the three different allotropes of pure iron at atmospheric pressure. Alpha iron (a-iron) , gamma iron (g-iron) and delta iron (d-iron) 13 Which allotrop is ferromagnetic? a) Alpha Iron b) Beta Iron c) Gamma Iron d) Delta Iron 14 What is the melting point of pure iron?. Express the result in ºC, ºF and K. 1540ºC = 2800ºF = 1810 K (rounded in multiples of 10) 15 What does the acronym BCC mean?. a) Body-Carbon Centered b) Body-Centered Carbon c) Body-Centered Cubic 16 What does the acronym FCC mean?. a) Face-Carbon Centered b) Face-Centered Carbon c) Face-Centered Cubic 17 How many degrees does room temperature represent? Express the result in ºC, ºF & K. 20ºC = 68ºF = 293 K (rounded in multiples of 1) 18 Which crystal structure has pure iron at room temperature?. a) ABC b) BCC c) FCC d) SC 19 Which crystal structure has gamma iron? a) ABC b) BCC d) SC c) FCC 20 Which crystal structure has pure iron at 1500ºC?. a) ABC b) BCC c) FCC AF_FM01_ Fabricació Mecànica. Ferrous Materials. d) SC / Guia del professor 3 Activity 2.3 Questions 21. What is the name of the solid solution of carbon in alpha iron? a) Austenite b) Cementite c) Ferrite d) Ledeburite e) Pearlite 22. What is the name of the solid solution of carbon in gamma iron? a) Austenite b) Cementite c) Ferrite d) Ledeburite e) Pearlite 23. Which is the crystal structure of austenite? a) ABC b) BCC 24. What is Fe3C? a) Austenite b) Cementite c) FCC d) SC c) Ferrite d) Ledeburite e) Pearlite c) Ferrite d) Ledeburite e) Pearlite 26. What is the name of the eutectoid? a) Austenite b) Cementite c) Ferrite d) Ledeburite e) Pearlite 25. What is the name of the eutectic? a) Austenite b) Cementite 27. Ledeburite is a structure that consists of ... a) Austenite+Cementite b) Austenite+Ferrite c) Cementite+Ferrite 28. Pearlite is a structure that consists of ... a) Austenite+Cementite b) Austenite+Ferrite c) Cementite+Ferrite 29. Find the letter (in diagram) and the maximum amount of carbon for solid austenite. Solid austenite is located in g region, its maximum amount of carbon is 2.1%C. 30. Find the letter (in diagram) and the maximum amount of carbon for solid ferrite. Solid ferrite is located in e and n regions. Its maximum amount of carbon is 0.1%C. 31. Find the letter (in diagram) and the carbon content for cementite. Cementite is located in d region, its carbon content is equal to 6.7%C. 32. Find the letter (in diagram) and the carbon content for ledeburite. Ledeburite is located at letter B , its carbon content is equal to 4.3%C (It's the eutectic point). 33. Find the letter (in diagram) and the carbon content for pearlite. Pearlite is located at letter A , its carbon content is equal to 0.8%C (It's the eutectoid point). 34. What is the minimum melting temperature of steel? What is the %C at this point? The minimum melting temperature of steel is 1360ºC and its carbon content is 2.1%C . 35. What is the minimum melting temperature of cast iron? What is the %C at this point? The minimum melting temperature of cast iron is 1150ºC and its carbon content is 4.3%C . 36. What is the maximum temperature for Ferrite? The maximum temperature for Ferrite is 1540ºC (melting point of pure iron). 37. What is the maximum temperature for Ledeburite? The maximum temperature for Ledeburite is 1150ºC. 38. What is the maximum temperature for Pearlite? The maximum temperature for Pearlite is 730ºC . 39. Which phases are present with 2%C at 1000 K? a) Austenite+Cementite b) Austenite+Ferrite 40. Which phase is present with 6.7%C at 1500 K ? a) Austenite b) Cementite c) Ferrite AF_FM01_ Fabricació Mecànica. Ferrous Materials. c) Cementite+Ferrite d) Ledeburite e) Pearlite / Guia del professor 4 Activity 3.2 Questions Name three different tests for measuring hardness. Brinell, Rockwell and Vickers. What is the difference between the Rockwell A and Rockwell C tests?. The difference is the weight used: 60 kg in Rockwell A and 150 kg in Rockwell C test. In which test is a 10 mm-diameter steel ball used? A 10mm-diameter steel ball is used in Brinell test. What is the difference in the indent between Rockwell C and Vickers tests. Rockwell C use a 120º diamond cone while Vickers use a 136º diamond pyramid. Is it possible to know the mechanical strength of a steel by measuring its hardness? Yes, it is possible because there is a direct relation between strength and hardness. What is the problem of the tensile strength test?. The tensile test is a destructive test so the metal is destroyed by the test. What is an indenter? Tell the different shapes of indenters described in the text. An indenter is a hard material that is forced into the metal surface. Ball, Cone, Pyramid. Do Rockwell B and Brinell tests use the same indenter in shape and dimensions? No, both use a ball but its diameter is 1.6 mm in Rockwell B test and 10 mm in Brinell test. Which hardness tests measure the depth of penetration of the indenter on the sample? Rockwell tests do. What is the test that uses the highest load to determine hardness? The highest load is used in Brinell test. Which type of hardness test is more suitable for cast irons? The most suitable test for measuring hardness in cast irons is the Brinell test. Why do you think Brinell test is not suitable to measure hardened steels? Because the indenter used is also made out of hardened steel, and it could be deformed. What supposes an advantage of the Brinell test related to the Rockwell test? The Brinell test measures hardness over a much larger area than the Rockwell test. What is the relation between the hardness measured and the mechanical strength? The more the hardness of a sample is, the more the mechanical strength is. Which test measures the diagonal length of the indent?. The Vickers test measures the length of the diagonals of the square indent. Which hardness test is a one-step test? The Rockwell test because they measure the depth of the penetration of the indent. What values are equivalent to 550 HV in Rockwell C and Brinell scales? 550 HV = 52.3 HRC = 517 BHN (approximate equivalent values for steels) Pearlite has a hardness about 40 HRC . What is the equivalent to Vickers scale? 40 HRC = 392 HV (approximate equivalent values for steels). Martensite has a hardness of about 65 HRC. What is the equivalent to Vickers scale? 65 HRC = 830 HV (approximate equivalent values for steels). What values are equivalent to 209 BHN in Rockwell B and Vickers scales? 209 BHN = 95 HRB = 220 HV (approximate equivalent values for steels). AF_FM01_ Fabricació Mecànica. Ferrous Materials. / Guia del professor 5 7. Transcriptions of the videos about hardness tests. THE BRINELL HARDNESS TEST MaterialsScience2000 HOCHSCHULE KARLSRUHE The Brinell Hardness Test Using the Brinell method the hardness of a turbo charger housing is to be measured. 0:10 First of all the tester has to make himself familiar with the testing machine. 0:14 A monitor and the control panel are positioned in the upper part of the machine. These are used to select and program different testing methods. Below the control panel a microscope lens with the digital camera under the indenter are installed. These two elements are connected to each other and retake towards the test piece as required. It is also possible to select an exchange the indenter, so different methods of hardness testing can be conducted on the same testing machine. 0:47 The support table can be adjusted in height, so the test piece can be positioned at the correct distance to the microscope lens and the indenter. 0:56 After becoming familiar with the machine, let's start the experiment. 1:05 The principle of the Brinell hardness test is to press a hard spherical indenter with an exactly defined force onto the test piece, then evaluate the surface area of the indentation. 1:19 The tester selects a suitable spherical indenter and inserts it into the holding device of the testing machine. 1:33 Next he puts the turbocharger housing onto the support table, retakes the microscope lens into vertical position, and adjusts the correct height of the test piece. After bringing the test piece surface into focus, he selects the exact spot where the hardness test is to be made. 1:52 By pushing the start button the hardness test procedure begins. The testing machine retakes the lens back to its resting position and places the spherical indenter carefully on the test piece surface. Gradually and shock free the test force rises to its specified value. 2:09 After maintaining the test force for a certain time the intenter automatically lifts off again and the microscope lens pans back to its former position. 2:20 The indentation can now clearly be seen on the monitor. 2:24 With the control knob, the tester places 4 measuring lines on the edges of the indentation to measure its diameter. 2:35 That's it! The testing machine can now calculate the Brinell hardness. The hardness value is defined as test force F in the old unit kilopond, divided by the area of the indentation A in square millimeters. The result is displayed on the bottom left hand corner of the screen and amounts to 250. AF_FM01_ Fabricació Mecànica. Ferrous Materials. / Guia del professor 6 THE ROCKWELL HARDNESS TEST (Scale C) MaterialsScience2000 HOCHSCHULE KARLSRUHE The Rockwell hardness test scale C In this video we will show how the Rockwell hardness test works using a gear wheel. 0:13 The basic idea of this test method is to measure the permanent depth of indentation of a hard indenter under a test force. 0:20 In the process variant scale C a rounded cone made out of diamond is used as an indenter. 0:27 In step 1 the diamond cone is pressed onto the test piece surface with a minor force of 10 kilo ponds. The depth of indentation under this preliminary load is the reference point. 0:38 In step two the test force is increased by 140 kilo ponds, which is acting as the major force. This means that an overall force of 150 kilo ponds is now acting on the indenter and this force is held for a certain time. 0:54 In step 3 the major force is removed again well the minor force still acting, the permanent increase in depth of indentation e is measured. 1:05 This is how the Rockwell hardness is calculated Rockwell hardness HRC is equal to 0.2 minus permanent depth of indentation e in millimeters times 500. 1:18 Let's take a look at how the test is carried out in practice. The tester selects the conical diamond indenter and installs it in the testing machine. 1:37 Then he picks up the gear wheel and puts it on the support table. 1:40 After rotating the microscope lens to its vertical position he can adjust his test piece. As soon as a focused image can be seen on the screen the surface of the test piece is in the correct height. The test can start. 1:59 In modern testing machines the Rockwell hardness test is fully automated. That's why the Rockwell hardness test is used so often in automated production lines. 2:09 That's it. The Rockwell hardness of a gear wheel is 55 HRC. This result is displayed on the screen. THE VICKERS HARDNESS TEST MaterialsScience2000 HOCHSCHULE KARLSRUHE The Vickers Hardness Test The hardness of a compressor wheel for a turbocharger is to be measured using the Vickers method. The main principle of this hardness testing method is to press a pyramid-shaped diamond indenter with an exactly defined force onto the test piece, and then to evaluate the surface area of the indentation. 0:30 First the tester has to prepare his testing machine. He takes the Vickers indenter with the four sided pyramid and inserts it into the mounting device at the testing machine. 0:49 He then places the compressor wheel on the support table, and retakes the microscope lens into its working position. With a hand wheel, he adjusts the height of the support table until the test piece surface is displayed in focus on the screen. Next he moves the test piece around on the support table until the right spot for the hardness test is displayed. 1:12 Now that everything's been prepared, let's begin with the test. After pushing the start button, the diamond pyramid pans down and carefully touches the test piece surface. The test force slowly increases to its specified value. 1:28 After holding the test force constant for a certain time, the indenter lifts again, pans back, and the microscope lens resumes its former position. 1:40 This is the magnified indentation on the display screen. With the control knob the tester now places 4 measuring lines at the corners of the indentation, doing that he can easily measure the length of the two diagonals. 1:53 Finally, he only has to push the input key. The Vickers hardness value will then be calculated automatically. It is equal to the test force F in the old unit kilopond, divided by the area of the indentation A in square millimeters. The Vickers hardness of our compressor wheel is displayed on the bottom left hand corner of the screen and amounts to 125.