Кулюкин А.Н. Программа «On-line» для диспетчеров ЦУП

advertisement

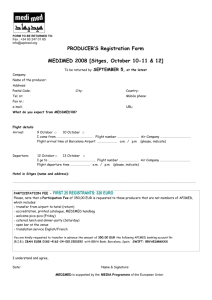

Кулюкин А.Н. Программа «On-line» для диспетчеров ЦУП «Основные системы самолета А 319/320/321» ЦПАП ОАО «Аэрофлот» 1 INTRODUCTION A318/319/A320/A321 GENERAL The A320 family is a short to medium range twin engine transport aircraft. The fuselage is a double bubble construction giving a single aisle and seating up to 185 passengers in two rows of three seats. The flight deck is designed for two pilot operation and two observer seats are installed. The A320 was developed and is assembled by AEROSPATIALE, Airbus Industries, Toulouse France. The A320 program was launched in 1984. Maiden flight was completed February 1987 and the first Aircraft entered service in April 1988. The A320 Family is certified for two different engine types: A318/319/320/A321 powered with CFM 56-5A A318/319/320/A321 powered with IAE V2500 The A320 family is available in a stretched version named A321 and a shorter version named A319. DESIGN CRITERIA The design criteria for the primary structure is 48000 flights. The aircraft is approved for 24000 flights and the threshold for initial structure inspection is 20000 flights based on average flight time of 1.25 hour. Landing gear design criteria is 60000 cycles. The Cabin Pressure system operates on Max Differential Pressure of 8.06 PSI. Max relief valve pressure is 8.40 PSI Max usable fuel in the two tank version is 15609 LTR (12487 KGS). In the three tank version 23859 LTR (19087 KGS) based on a fuel density of 0.800 and with additional space for 2% thertnal expansion. 2 HIGHLIGHTS The A 320 belongs to the "New Generation" aircraft where most of the latest technology has been utilized. FADEC Each of the Engines is controlled by a Full Authority Digital Engine Controller providing power management, indications and engine limitation among other duties. Pilot control is achieved by means of electrical power levers on the pedestal. ECAM Aircraft system monitoring is now achieved by a Electronic Centralized Aircraft Monitoring system where system page is automatically displayed in case of failure. EFIS The cockpit is equipped with Electronic Flight Instrument System, consisting of six CRT indicators. CFDS A Centralized Fault Display System uses the Multifunction Control and Display Units (MCDU) as access keyboard to perform check and trouble shooting of various computers in most of the systems in the aircraft. Sidestick The conventional control column is replaced by two sidesticks for control of the aircraft. MCDU Two Multifunction and Display Units are used as interface for the Flight Management System and for access to the CFDS. 3 Composite materials of different kind are used in a great extend, specially for flight control surfaces. Fly By Wire The conventional cables for the flight control surfaces are replaced by wires, only the Stabilizer and the Rudder are backed-up by cable runs. EFCS The aircraft is equipped with a Electrical Flight Control System controlled by Digital computers. Autobrakes The Landing Gear is equipped with Auto brake system and Carbon brakes. The system includes electronic control of Nose gear steering and brakes. 4 5 6 COCKPIT LAYOUT The Cockpit is designed for a "TWO PILOT " operation. Athird occupant fold-able and slidable seat is located on the rear right panel. It is a "CLASS COCKPIT" that means there are 6 CRT's installed which give information about the aircraft systems and the flight situations. The windows can be opened and they function as a emergency exit. COCKPIT PRESENTATION GENERAL The cockpit is equipped with adjustable seats for two crew members, a third occupant seat and depending of configuration a folding seat for a fourth occupant. Various furnishings and equipment are fitted in the cockpit for the comfort, convenience and safety of the occupants. OVERHEAD PANEL The controls of most aircraft systems are located on the overhead panel. The overhead panel is divided into two main sections: - a FWD section including the system panels. - an AFT section mainly comprising the circuit breaker panel. GLARESHIELD The Flight Control Unit (FCU), includes the Electronic Flight Instrument System (EFIS) controls, and is used for control and monitoring of the Auto Flight System (AFS). It is located on the glareshield. The "Master Caution" and the "Master Warning" lights are also Located on the glareshield. 7 MAIN INSTRUMENT PANEL Six interchangeable Cathode Ray Tubes are Located on the main instrument panel. Two of them are dedicated to the ECAM. The others are two Primary Flight Displays and two Navigation Displays. Stand-by instruments and landing gear controls are also located on the main instrument panel. 8 9 CENTER PEDESTAL Several control panels are located on the center pedestal as shown on the screen. The mainly control panels are: - thrust levers and thrust reverser levers, - pitch trim wheels, - flaps and slats control, - brakes controls, - MCDUs. SIDE CONSOLES The side sticks and nose wheel steering handles are mounted on the side consoles. The side consoles provide documentation stowage, oxygen masks and communication devices. 10 11 EIS: EIS ARCHITECTURE EFIS - ECAM The EFIS are displayed on identical display units (DUs). The EFIS DUs are controlled through the EFIS control panels. The ECAM pages are displayed on identical display units (DUs). The ECAM DUs are controlled through the ECAM control panel. DMC DMC : Display Management Computer. The Display Management Computers process data in order to generate codes and graphic instructions corresponding to the image to be displayed. Note the particular role of DMC 3 which can be switched instead of DMC 1 or DMC 2. Each DMC can process three displays : PFD, ND and upper or lower ECAM display. FWC FWC: Flight Warning Computer. The Flight Warning Computers monitor the aircraft systems. These computers are the heart of the ECAM system. Each FWC generates all warning messages to be displayed and supplies the attention getters. It also computes the flight phases and provides aural warnings. SDAC SDAC: System Data Acquisition Concentrator. The System Data Acquisition Concentrators receive various signals from the aircraft systems and send them to 12 the FWCs and DMCs. The SDACs acquire most of the signals used to display system pages and used by the FWCs to generate amber warnings. INPUTS The inputs received by the FWC are used to elaborate red warnings. Inputs corresponding to red warnings or essential information are delivered to the FWC. Various items of information which do not correspond to a warning are directly given to the DMCs. Various items of information for systems like engines, fuel, navigation are directly sent to the DMCs. The inputs received by the SDACs are used to elaborate amber warnings. Inputs corresponding to amber warnings are delivered to the SDACs for acquisition. These signals will then be sent to the FWC to generate warnings. 13 14 15 A319/A320/A321 general Engine Maximum weights (kg) Operation limits Model M anuf. Type MTOW MLW MZFW A31 9-111 CFM CFM56-5B5 61000 57000 A319-112 A319-113 A319-114 A319-115 A319-131 CFM CFM CFM CFM IAE CFM56-5B6 CFM56-5A4 CFM56-5A5 CFM56-5B7 V2522-A5 64000 (options: 68 000) or 70 000) A319-132 A319-133 IAE IAE V2524-A5 V2527-M-A5 A31 9 Corporate Jet A320-111 A320-21 1 CFM IAE CFM CFM CFM56-5-B6/5B7 V2524-A5/V2527-M-A5 CFM56-5-A1 CFM56-5A1/5A3 62500 63000 64500 58500 59000 60500 (option A320-212 A320-214 A320-231 A320-232 A320-233 CFM CFM IAE IAE IAE CFM56-5A3 CFM56-5B4 V2500-A1 V2527-A5 V2527E-A5 75500 68000 73500 (options: from 68000 up to 77 000) А321-Ш CFM CFM56-5B1 A321-112 A321-131 CFM IAE CFM56-5B2 V2530-A5 A321-211 CFM CFM56-5B3 Mmo Vmo 0.82 350kt 61 000) 73500 (option: 74 500) 83000 (options: 78 000 or 85 000) 69 500 (option, 70 500) 16 A321-231 IAE V2533-A5 89000 75000 71500 17 A319-100 Span Length A320-100 A320-200 34.10 m 111 ft 10 in 33.91 m 111 ft 3 in 33.84 m 111 ft 11.76m 38 ft 7in Fuselage diameter Track 3.95m Max. pax Max. FL 34.10m 111 ft 10 in 37.57 m 123 ft 3in Height A321-100 44.51 m 146 ft 12ft 11 in 7.59m 24ft 11 in 145 180 JO 390 220 18 А319/А320/А321 introduction The A319/A320/A321 are narrow body, twin-engined, short / medium-range aircraft, the A319 being the shortened version of the A3 20, and the A3 21 being the stretched version of the A3 20. They both offer an increased fuselage cross-section leading to an increased revenue potential through : - greater passenger comfort with wider seats and aisle - greater overhead baggage volume - greater cargo capacity - wide-body compatible container capability - quicker turnrounds. Advanced technology applied to aerodynamics, structure, systems and powerplant offer reduced costs through : - unmatched fuel efficiency - more accurate flight path control - reduced maintenance costs - increased reliability - reduced trouble-shooting time. Introduced for airline service in March 1988, the A320 represents the largest single advance in civil aircraft technology since the introduction of the jet engine and results in a major stride forward in airline profitability. A computer-managed system gives complete protection against excursions outside the normal flight envelope and greatly improves the man / machine interface. 19 20 А319/А320/А321 electrical system The electrical power generation comprises: two engine-driven AC generators, nominal power 90 kVA one auxiliary power unit (APU) AC generator nominal power 90 kVA one emergency generator nominal power 5 kVA, hydraulically driven by the Ram Air Turbine (RAT), automatically deployed in case of main generators loss one ground connector, power 90 kVA. DC network supplied via three identical Transformer/ Rectifier Units (TRU): - two of them are normally used - the third is used : · in emergency configuration (loss of main AC generators) · in case of TR 1 or TR 2 failure Two batteries, nominal capacity 23 Ah each - on ground : to provide an autonomous source mainly for APU starting - in emergency configuration to feed some equipment: · during RAT deployment · after landing gear extension (only for A3 20). 21 22 А319/А320/А321 configuration normal electrical flight In normal configuration, both normal AC systems are split Each engine-driven generator supplies its associated AC BUS via its Generator Line Contactor (GLC). AC ESS BUS is normally supplied from AC BUS 1 via a contactor. DC BAT BUS and the DC ESS BUS are normally powered by the TR1 Two batteries are connected to the DC BAT BUS via the Battery Charge Limiter (BCL) Each battery has its own HOT BUS bar (engine / APU firesquib, ADIRS, CIDS, ELAC 1, SEC 1, slide warnings, parking brake etc). 23 24 А319/А320/А321 configuration abnormal electrical flight In case of failure, the failed generator is automatically replaced by: - the APU generator if available - the other main generator with automatic partial galley load shedding. In case of total loss of all main generators, the RAT is automatically extended and drives the emergency generator via a hydraulic motor. The EMER GEN supplies the AC ESS BUS and the DC ESS BUS via the ESS TR. The ECAM WD remains powered, with associated procedures presented. Alternate law is operative through ELAC 1 and SEC 1. 25 26 А319/А320/А321 cockpit circuit- breakers Circuit breakers (С / Bs) are constantly monitored and the tripping of a C / B will be clearly indicated: either through - activation of a system warning - a failure test - an abnormal instrument configuration or, for С / Bs monitored by the EC AM system : - six zones have been defined - each time а С / В trips, the corresponding zone is identified 27 28 29 А319/А320/А321 hydraulic system - general Three fully independent systems: Yellow, Blue. Normal operation : Green, - two engine-driven pumps (one each Green and Yellow systems) - one electric pump (Blue system) Abnormal operation : - if engine No.1 inoperative or Green pump failed: then Green system pressurized by the reversible Power Transfer Unit (PTU) - if engine No. 2 inoperative or Yellow pump failed : then Yellow system pressurized by the reversible PTU - if Yellow system pump inoperative and PTU failed : then an electric pump will pressurize the Yellow system. - if case of dual engine failure or total electrical power loss : the Ram Air Turbine (RAT) will pressurize the Blue system. On ground : - Blue and Yellow systems may pressurized by electric pumps. A handpump (operated from the ground on yellow system) facilitates maneuvering of cargo doors. - Green /Yellow system may pressurized by the PTU. be the the be 30 31 А319/А320/А321 flight control surfaces Control is achieved through conventional surfaces All the surfaces are hydraulically actuated Roll and pitch control is electrical: - elevators - ailerons - roll spoilers - trimmable horizontal stabilizers - slats and flaps (single flap surfaces for A320 and A319, double slotted surfaces for A321) - speedbrakes / ground spoilers. Yaw control is mechanical: - rudder (yaw damping, turn coordination and trim are electrically ensured) Mechanical back up: - trimmable horizontal stabilizers 32 33 А319/А320/А321 EFCS advantages The Electrical Flight Control System (EFCS) provides: Safety improvements (stall / windshear / overstress / overspeed protection) Economical aspects - weight saving = A W > 200 kg considering the impact on APS A319/A320/A321 plus same weight gain on wing structure due to integration of load alleviation function (A320 only). - maintenance costs decreased - training costs decreased - production costs decreased Improvements in handling and comfort - flight handling improvement - new cockpit concept 34 35 36 А319/А320/А321 flight control surfaces Control is achieved through conventional surfaces All the surfaces are hydraulically actuated Roll and pitch control is electrical: - elevators - ailerons - roll spoilers - trimmable horizontal stabilizers - slats and flaps (single flap surfaces for A320 and A319, double slotted surfaces for A321) - speedbrakes / ground spoilers. Yaw control is mechanical : - rudder (yaw damping, turn coordination and trim are electrically ensured) Mechanical back up : - trimmable horizontal stabilizers 37 38 А319/А320/А321 EFCS computers Flight control is achieved by three types of computer: Two ELACs (Elevator Aileron Computer) to ensure commands of: - normal elevator and stabilizer - aileron Three SECs (Spoiler Elevator Computer) - Three computers achieve spoiler control - Two of them are devoted to standby elevator and stabilizer control Two FACs (Flight Augmentation Computer) - Two computers which achieve electrical rudder control and characteristic speeds calculation for displays on PFD. In addition - two SFCCs (Slats Flaps Control Computer) - two FCDCs (Flight Control Data Concentrator) acquire data from ELACs and SECs and send them to ECAM and CFDS. 39 40 А319/А320/А321 fuel system - basic layout Total fuel capacity A319 / A320 Two outer cells 1 760 litres (1 408 kg) Two inner cells 13 849 litres (11 079kg) One center tank 8 250 litres (6 600 kg) A321 Two wing tanks 15 500 litres (12 400 kg) One center tank 8 200 litres (6 560 kg) (Weight calculated with a density of 0.8) An additional center tank (optional) increases the total fuel capacity by 2 900 litres (2 320 kg). On the A319 Corporate Jet, up to 6 additional center tanks can be added to increase the total fuel capacity by up to 17000 litres. An additional volume of 2% is available for expansion without spillage into the vent surge tank. Ventilation - Each tank is separately ventilated via surge tanks at each wing tip. - The center tank is ventilated via the LH surge tank. - The surge tanks are opened to atmosphere via flame arresters and NACA inlets. -Vent valves ensure correct operation of the vent system. - Pressure relief outlets protect the tanks from over- or underpressure. 41 42 А319/А320 fuel system - engine feed A319/A320 definition Fuel is delivered to the engines by means of booster pumps. - Each tank is equipped with two identical booster pumps. - Center tank feeds first, except during take-off and fuel recirculation when center tank pumps are switched off automatically. - Wing tank pumps operate permanently at a lower pressure than center tank pumps. - Thus, when center tank pumps stop, engine feed comes automatically from wing tank pumps. Two electrical transfer valves are installed on each wing. They automatically open when the inner cell fuel reaches a low level (about 750 kg) for fuel to drain from the outer to the inner cells. Fuel is recirculated automatically and transparently to the crew: It ensures the IDG cooling (CFM and IAE eng.) and the engine oil cooling (IAE only) through a set of valves controlled by the FADEC. 43 44 А321 ENGINE AND PRESENTATION APU FUEL FEED MAIN PUMPS Each main tank has 2 centrifugal booster pumps installed in canisters capable of supplying the engines with fuel at the required pressure and flow rate. The canisters have an inlet connected to the fuel strainers. SUCTION VALVES A by-pass suction valve is installed in the engine feed line. In the event of complete failure of both main pumps, the suction valve allows the engines to be fed by gravity. CROSSFEED VALVE A CROSSFEED VALVE permits connection of the left and right engine supply lines. The crossfeed valve is normally closed. LP VALVES The Low Pressure valves isolate the engines or APU from the fuel supply. The LP valve is open when the related engine or APU is running; it closes when engine or APU is shut down or ENG FIRE pushbutton is released out. PRESSURE SWITCHES A pressure switch for each main pump monitors the pump pressure for the low pressure warning. APU pressure switch is used for APU fuel pump control. 45 AIR RELEASE VALVE Each engine supply Line has an Air Release Valve at its highest point to enable the line to be bled. CENTER TANK XFR VALVES Two center tank XFR valves are installed at the bottom skin of the center tank. They are used to transfer fuel from center tank to wing tanks through the jet pumps. JET PUMPS The jet pumps use fuel flow from the main pumps as operating pressure to transfer the fuel from center tank to the related wing tank. NOTE: In case of a main transfer system failure, (e.g: transfer valves jammed closed) fuel will transfer from center tank to wing tank by gravi ty. Gravity feeding wilL take place only if the level of fuel in the center tank is greather than the level in the wing tanks. Approximately 2000 kg (4400 lbs) of center tank fuel wiLl not move to the wing tanks in the gravity feed configuration. APU PUMP A specific fuel pump supplies the APU if the LH main pumps are not operating. This pump takes fuel from the left supply line. 46 А 321 ENGINE AND APU FUEL FEED PRESENTATION 47 А319/А320/А321 fuel system - control and indications No crew action is required for normal operation. Indications: - fuel data (quantity, temperature) are available from a Fuel Quantity Indication (FQI) system - fuel quantity is permanently displayed on upper ECAM DU - fuel system synoptic on lower ECAM DU is displayed according to ECAM logic - low level warning is totally independent from FQI. Abnormal operations : - fuel feed sequence may be operated manually - one or both engines may be fed from any tank via cross-feed valve - gravity feed is possible from wing tanks. 48 49 А319/А320/А321 fuel system - refueling Refuel/defuel control is from an external panel located in the fuselage fairing under the RH wing within easy reach from the ground. One refuel/defuel coupling is located under the RH wing. Identical coupling on LH wing is available as an option Refuelling panel available in the cockpit as an option. Refuelling is auto sequenced : It starts with the outer cells (A319/A320) orthe wing tanks (A321). If the selected fuel quantity exceeds the wing tank capacity, the center tank is refuelled simultaneously. Refuelling time at nominal pressure approximately 20 minutes for all tanks. is Gravity refuelling can be achieved by overwing refuelling points. 50 51 А319/А320/А321 APU On ground, the APU makes the aircraft independent of pneumatic and electrical sources by: - providing bleed airfor engine start and air conditioning systems, - providing electrical power to supply the electrical system, In flight, provision of back-up power for electrical and air conditioning systems, The APU may be started using either the aircraft batteries, external power or normal aircraft supply. The normal flight envelope does not impose any limitations for starting. The APU is automatically controlled by the Electronic Control Box (ECB) which is mainly acting as FADEC for monitoring start and shut-down sequences, bleed air and speed/temperature regulation. Control and displays : - on the overhead panel for APU normal operation and fire protection - on the ECAM for APU parameters display - on the external panel, under the nose fuselage, for APU shut down. 52 53 А319/А320/А321 FMGS - AFS/FMS integration Composed of two Flight Management and Guidance Computers (FMGC), this pilot interactive system provides: - flight management for navigation, performance optimization, radio navaid tuning and information display management, - flight guidance for autopilot commands (to EFCS), flight director command bar inputs and thrust commands (to FADECs). Two FACs (Flight Augmentation Computer) provide: - rudder commands (yaw damping, rudder trim and limiting, turn coordination, automatic engine failure compensation), - flight envelope and speed computation. For operational convenience the FMGS offers two types of guidance concept: - managed according to FMGS flight plan data entered into the Multipurpose Control and Display Unit (MCDU), - selected by the pilot through the Flight Control Unit (FCU). The AP/FD achieves either: - automatic control of the aircraft with regard to speed, lateral path and vertical plan as computed by the FMGCs, - manual control of the aircraft with regard to speed and vertical plan (selected through FCU), lateral path (through FMGC or FCU). 54 А319/А320/А321 FMGS - system interface 55 А319/А320/А321 FMGS - system redundancy Two FMGCs associated to two MCDUs provide a redundant configuration. Normal mode operation: dual mode - Each FMGC makes its own computation - One FMGC is MASTER - the other one is SLAVE - Both MCDUs act independently (entries are automatically recopied on the other MCDU and applied to both FMGCs) Independent mode - Automatically operative if mismatch between FMGCs - Independent operation of FMGCs with associated MCDUs. (Data insertion and display related to the side concerned). - One FMGC remains master. Single mode - One FMGC fails - Either MCDU can be used to enter or display data related to the remaining FMGC. 56 57 A319/A320/A321 FMGS crew interface 58 А319/А320/А321 FMGS crew interface Two MCDUs on the central pedestal provide long-term interface between the crew and FMGCs in terms of: - flight plan definition and display - data insertion (speeds, weights, cruise level, etc) - selection of specific functions (direct to, offset, secondary flight plan). One FCU on the central glareshield to provide short-term interface between crew and FMGCs. Two thrust levers linked to the FMGCs and FADECs provide autothrust or manual thrust control selection to the crew. Two PFDs and two NDs provide visual interface with flight management and guidance related data such as: on PFD: - FMGS guidance targets, - armed and active modes - system engagement status on ND: - flight plan presentation - aircraft position and flight path, - navigation items (radio navaid, wind). 59 60 А319/А320/А321 FMGS flight guidance The FCU is the main crew interface for shortterm guidance with a single rule for the various control knobs : - pull + rotate = pilot input - push = return to FMGS control. As an example, a change of altitude can be achieved by a double action on the FCU : - either by selection of a new altitude through the FCU selector and validation of this new altitude by pulling (selected guidance) or pushing (management guidance) this knob, - or by selection of a V/S through the FCU selector and validation of this new V/S by pulling this knob. Actions on the FCU are displayed on the FCU as well as on the PFD in the dedicated FMA(Flight Management Annunciator) part. 61 А319/А320/А321 FMGS flight management Flight plan stringing Flight plan definition by company route or city pair. Departure and arrival procedures including associated speed/ altitude/time constraints. Flight plan revision (offset, DIR. TO, holding pattern, alternative flight plan activation,...) Secondary flight plan creation similar to primary flight plan. Navigation Automatic guidance along flight plan from take-off to approach. Aircraft position determination. Aircraft position referenced to the flight plan. Automatic VOR/DME/ILS/ADF selection. IRS alignment. Ground speed and wind computation. Optimum radio and inertial sensor mixing. Provision for GPS and MLS. 62 А319/А320/А321 management FMGS performance Flight plan optimization, through performance data base, in terms of: - optimum speeds - optimum altitudes. the The computations are based on : - flight conditions (cruise level, weights, center of gravity, meteorological data) - cost index - speed entered on the FCU or given in the flight plan. Performance predictions : - time, altitude, speed at all waypoints - estimated time of arrival, distance to destination, estimated fuel on board at destination, Advisory functions - fuel planning - optimum altitude and step climb. Full vertical guidance related to flight plan predictions from initial climb to approach. 63 А319/А320/А321 FMGS - lateral navigation 64 А319/А320/А321 FMGS - lateral navigation Position computation: - before flight, the three IRSs are aligned on airfield or gate position, (manually or via database) - at take-off, the position is automatically updated to the runway threshold - in flight, position updating is computed using GPS if installed, and radio navaids (DME, VOR, ILS) The FMGC position depends upon the IRS's mean, the GPS and the radio position. Navigation mode selection: - if the aircraft is equipped with GPS primary, the FMGC uses GPIRS position in priority - if the GPIRS position is not available or if the aircraft is not equipped with GPS primary, depending upon availability of navaids and sensors, FMGC automatically tunes the best navaids to compute the most accurate position. The navigation modes may be: En route : IRS - GPS (if GPS installed) IRS -DME IRS - VOR/DME IRS only 65 In approach : IRS - GPS (if GPS installed) IRS -DME IRS - VOR/DME IRS - ILS/DME 66 67 А319/А320/А321 FMGS - lateral navigation FMGC provides the crew with lateral position and its associated accuracy criteria which depend upon: - FMGC Error Position Estimate (EPE) - zone currently flown (en route, terminal, approach) - Airworthiness Authorities Accuracy Requirements (AAAR) If EPE < AAAR then HIGH is displayed on MCDU and the computed positions may be used without restriction. If EPE > AAAR then LOW is displayed on MCDU and the position must be cross-checked with raw data (ADF/VOR needles, DME reading). Each time HIGH (or LOW) reverts to LOW (or HIGH) the message NAV ACCY DOWNGRADED (or UPGRADED) is displayed on NDs and MCDUs. 68 А319/А320/А321 flight deck - main features 69 А319/А320/А321 FMGS - vertical profile Take off SRS control law maintains V2 + 10 up to thrust reduction altitude where max climb thrust is applied. V2 + 10 is held up to acceleration altitude (ACC ALT). Climb: Energy sharing is applied for acceleration (70% thrust) and for altitude (30% thrust) from ACC ALT up to first climb speed. Max climb thrust is kept - Altitude constraints are taken into account. CRZ: Steps may exist and/or may be inserted. Descent: Top of Descent (T/D) is provided on ND. From T/D down to the highest altitude constraint, ECON descent speed is supposed to be held on elevator and IDLE + A on thrust. Then, if this status can no longer be kept, geometric segments will be followed between the constraints. Approach: From DECEL point a deceleration allows configuration changes in level flight. Approach phase is planned to reach approach speed at 1000 ft above ground level. 70 А319/А320/А321 ECS - system schematic 71 72 А319/А320/А321 ECS - air conditioning pneumatic - general Air conditioning Continuous air renewal and temperature regulation in three independently controlled zones (cockpit, forward cabin, aft cabin). Downstream both packs, a dedicated unit mixes cold air with recirculated cabin air for distribution to the three zones. Optimized air temperature is obtained by adding engine hot air to mixing unit air via three trim air valves. Cabin and pack temperature regulation are achieved by a zone controller and two pack controllers. Ram air inlet can provide ambient air to the mixing unit. Pneumatic High pressure air is supplied for air conditioning, air starting, wing anti-ice, water pressurization, hydraulic reservoir pressurization. System operation is electrically monitored by two Bleed Monitoring Computers (BMC), and is pneumatically controlled. A leak detection system is provided to detect any overheat in the vicinity of the hot air ducts. 73 POWER PLANT GENERAL CFM 56 CONCEPT The CFM 56 turbofan engine family is a product of CFMI (Comercial Fan Motor International). CFM International is a company jointly owned by "General Electric" of the USA and "Societe Nationale d'Etude et de Construction de Moteurs d'Aviation" (SNECMA) of France. 74 CFM56-5B CONFIGURATIONS -5B: -5B EIS ( Entry |nto Service ) configuration = the 14 first -5B engines have a specific LPT configuration - LPT Nozzle sealing strip conf. - Alitalia , Air France ( ex Air Inter) -5B/2: - Dual Annular Combustor for low Nox emissions -5B/Por/2P: - 3D aero design of HPC / HPT / LPT Blades & Vanes for SFC improvement - RACC (Rotor Active Clearance Control) function deletion: RACSB (Rotor Active Clearance Start Bleed replaced by TBV (Transient Bleed Valve ) -5B/2PNAC - LPT Frame external cooling system for Nacelle Air Cooling at ground idle 75 76 FADEC FUNCTIONS Full Authority Digital Engine Control ( FADEC ) The FADEC consists of the Engine Control Unit ( ECU ), Hydromechanical Unit ( HMU ) and its peripheral components and sensors used for control and monitoring. FADEC Definition Each engine is equipped with a duplicated FADEC system. The FADEC acts as a propulsion system data multiplexer making engine data available for condition monitoring. FADEC Controls The FADEC provides the engine system regulation and scheduling to control the thrust and optimize the engine operation. The FADEC provides: - Fuel control regulation - power management - gas generator control - Turbine active clearance control - engine limit protection - feedback - flight deck indication data - Engine maintenance data - Contitioning monitoring data - thrust reverse control - automatic engine starting - Fuel return control for IDG cooling Power Management The FADEC provides automatic engine thrust control 77 and thrust parameter limits computation. The FADEC manages power according to two thrust modes: - manual mode depending on thrust lever angle (TLA ) - Autothrust mode depending on autothrust function generated by the auto flight system (AFS ). The FADEC also provides two idle mode selections: - Approach Idle: It is obtained when slats are extended in FLT. - Minimum Idle: It can be modulated up to approach idle depending on: · Air conditioning demand · Engine anti ice demand · Wing anti ice demand · Temperature Engine Oil TEO (for IDG cooling ). Engine Limit Protection The FADEC provides overspeed protection for N1 and N2, in order to prevent engine exceeding certified limits, and also monitors the EGT. Engine Systems Control The FADEC provides optimal engine operation by controlling the: - Fuel Flow - Compressor air flow and - Turbine clearence. Thrust Reverse The FADEC supervises entirely the thrust reverse 78 operation. In case of a malfunction, the thrust reverser is stowed. Start and Ignition Control The FADEC controls the engine start sequence. It monitors N1, N2 and EGT parameters and can recycle or abort an engine start. Power Supply The FADEC system is self-powered by a dedicated permanent magnet alternator when N2 is above 12%, and is powered by the aircraft electrical system for starting, as a backup and for testing with engine not running. 79 80 LANDING GEAR - GENERAL DESCRIPTION The Landing Gear (L/G) system has: · two Main Landing Gears (MLG) and their related doors (Ref. 32-10-00) · a Nose Landing Gear (NLG) and its related doors (Ref. 32-20-00) · two extension and retraction systems for the L/G and their related doors (Ref. 32-30-00) · L/G wheels and their related braking systems (Ref. 32-40-00) · a NLG steering system (Ref. 32-51-00) · a L/G indication and warning system (Ref. 32-60-00). The L/G support the aircraft on the ground and are oleo-pneumatic shock absorbers that absorb taxi and landing loads. During flight the L/G is retracted into the landing gear bays in the belly of the aircraft. When the L/G is extended or retracted the related doors close to make the aerodynamic contours of the aircraft. 81 82 PANEL DESCRIPTION 1 LANDING GEAR CONTROL LEVER A two positions selector lever provides electrical signals to the two LGCIUs which control green hydraulic supply by means of selector valves. On selection of UP or DOWN and provided the airspeed is below 260 KT : - all landing gear doors open then, - landing gears move to the new selected position then, - all doors close. (1) L / G LEVER UP: The landing gear retraction is selected. During gear door opening, mam gear wheels are automatically braked by the normal brake system. The nose gear wheels are braked by a brake band in the gear well during doors closure. DOWN: The landing gear extension is selected An interlock mechanism prevents unsafe retraction by locking the lever in DOWN position when either gear shock absorber is compressed (A/C on groundl or the nose wheel steering is not centered. When the L/G is extended the system remains pressurized (if green hydraulic pressure is available) (2) RED ARROW Illuminates red if the landing gear is not downlocked in approach configuration associated with a red ECAM warning. (Refer to warnings and cautions section). 83 2 FREE FALL EXTENSION HANDLE For gravity extension the handle must be extended, than rotated three turns clockwise. When the crank handle is operated the cutout valve shuts off the hydraulic pressure and depressurizes the landing gear system 3 LANDING GEAR POSITION INDICATOR LIGHTS Connected to LGCIU 1 which receives signals from proximity detectors UNLK lights: illuminate red if the gear is not locked in selected position. lights: illuminate green if the gear is locked down NOTE: LDG GEAR indicator lights remain available as long as LGCIU 1 is electrically supplied, even in-case of LGCIU 1 FAULT 4 ECAM WHEEL PAGE The ECAM WHEEL page shows the position of the landing gears and the gear doors (ref. to WHEEL page description). 84 85 1 A/SKID and NOSE WHEEL Steering Switch ON: - If green hydraulic pressure available · Anti-skid is available · Nose wheel steering is available - If green hydraulic pressure lost · Yellow hydraulic pressure takes over automatically to supply the brakes · Anti-skid remains available · Nose wtieel steering is lost · Brake yellow pressure is displayed on the triple indicator OFF: - Yellow hydraulic pressure supplies the brakes. · Anti-skid is deactivated. Brake pressure has to be limited by the pilot by referring to the triple indicator to avoid wheel locking · Nose wheel steering is lost · Differential braking remains available by pedals · Brake yellow pressure is displayed on the triple indicator. 2 AUTO/BRK Panel MAX, MED, LO pb sw (springloaded) The push-button controls the arming of the required deceleration rate. · MAX mode is normally selected for take off. In the event of an aborted take off, maximum pressure is sent to the brakes as soon as ground spoiler deployment order is present. · MED or LO mode is normally selected for landing. - When LO is selected, progressive pressure is sent to the brakes 4 seconds after the ground spoiler deployment in order to provide a 1,7 m/s2 86 (5,6 ft/s2) deceleration. - When MED is selected, progressive pressure is sent to the brakes 2 seconds after ground spoiler deployment order to provide a 3 m/s2 (9.8 ft/s2) deceleration. - ON: · The ON light illuminates blue to indicate positive arming. · The DECEL light illuminates green when actual aircraft deceleration corresponds to 80 % of the selected rate. - Off · The corresponding autobrake mode is deactivated. 3 BRAKE FAN P/B Switch and HOT Light ON The brake fans run provided LH main landing gear is downlocked. The ON Light Illuminates white. Off Brake fans stop. HOT Light illuminates amber associated whith ECAM caution when brake temperature becomes high. 4 BRAKES and ACCU PRESS Indicator ACCU PRESS indication: Indicates the pressure in the yellow brake accumulator BRAKES pressure indication: Indicates yellow pressure delivered to left and right brakes measured upstream of the alternate servo valves. 87 5 PARKING BRK Handle Pull handle, then turn clockwise to apply parking brake. Activation of the parking brake deactivates all other braking modes. The indication "PARK BRK" is displayed on teh ECAM memo page. 88 89 90 91 Контрольные вопросы 1. Какая система управления принята на самолетах семейства Airbus: а. тросовая в. моноблоки с. Fly-by-wire 2. Сколько батарей установлено на самолете: а. две в. три с. одна 3. От чего работает «emergency generator»: а. напрямую от RAT в. от давления в «Blue» гидросистеме с. от РТИ 4. Сколько топливных баков на А321: а. пять в. три с. семь 5. Сколько процентов тяги создает вентилятор: а. 50% в. 80% с. 70% 6. На каком экране высвечиваются синоптические страницы в нормальной конфигурации: а. на верхнем ЕСАМ в. на нижнем ЕСАМ с. на PFD 92 7. Перемещаются ли РУДы при изменении режима при полете «Autothrust»: а. нет в. перемещаются с. перемещаются на МГ 93