Unit Operations Lab Web Page - Michigan Technological University

advertisement

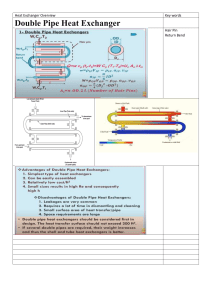

Unit Operations Lab Web Page Short Descriptions JAK 10’02 Batch Filtration Dave- Add in words please. Continuous Stirred Tank Reactors (CSTR) In this experiment, the kinetics of the phenolphthalein fading reaction are studied via a batch and a CSTR reactor scheme. The optimum concentrations of the reactants (phenolphthalein, NaOH, and NaCl) are identified and the experimental and theoretical conversions are determined and compared. Cooling Tower The performance of an induced draft cooling tower is evaluated. Among the performance criteria determined are, the approach temperature, heat loading and the “tower characteristic”. Flow Measurement The principles of operation of five common flow sensors are studied. For each case, flow measurements are determined from corresponding sensed quantities (e.g., pressure drop, electric field strength). Fluidization Dave- add in words please. Friction Loss for Water Flow through Piping The pressure drop due to frictional losses for water flow is measured as a function of flow rate and line size. Measured values are compared with model predictions/ handbook values to validate results. Heat Transfer- Double Pipe Heat Exchanger The heat transfer characteristics of a double pipe heat exchanger are evaluated. The heat transfer rate and coefficients are determined from measured temperature differences, flow rates, physical properties, and the exchanger design. Heat Transfer- Shell and Tube Heat Exchanger The heat transfer characteristics of a shell and tube heat exchanger are evaluated. The heat transfer rate and coefficients are determined from measured temperature differences, flow rates, physical properties, and the exchanger design. Liquid- Liquid Extraction Column In this countercurrent immiscible liquid-liquid extraction column, acetic acid is removed from a kerosene feed stream using water as the solvent. The processing conditions are varied (flow rates, concentrations, temperature of streams), and the total number of equilibrium stages are determined. Membrane Separation This membrane separation equipment was donated by Praxair, Inc. (check spelling of company) to Michigan Technological University in when, 2001 (Dave- fill in the correct date please). This unit separates air into a nitrogen rich and an oxygen rich stream using a membrane that contains hollow tubes. The oxygen rich stream preferentially penetrates through the hollow tube and the nitrogen rich stream preferentially remains outside the hollow tube. Pressures are flow rates are varied to determine the optimum operating conditions. Non-Newtonian Flow (Capillary Viscometer) In this experiment a Newtonian, incompressible fluid (typically glycerol of known viscosity) passes through a capillary viscometer (small diameter tube approximately 0.04” in diameter) and the flow rates are measured at various pressure drops. From this data, one can determine the equivalent diameter of this capillary tube. Then an incompressible, non-Newtonian fluid passes through this same capillary tube and flow rates are measured at various pressure drops. From this information, the apparent viscosity, flow consistency index, and flow behavior index are determined for this non-Newtonian fluid. PDMS Bench Scale Reactor In this experiment, polydimethylsiloxanes (PDMS) are produced via a polymerization reaction using a bench scale batch reactor. Polymer Extrusion In this experiment, a 27 mm co-rotating intermeshing Leistritz twin screw extruder is used to compound resins containing 20, 30, 40, and 50 wt% calcium carbonate in polypropylene. Then the melt flow index of these resins are determined and compared to that of the pure polypropylene matrix. Pumping A In this experiment, the pump curves, NPSHA, hydraulic hp, brake hp, and efficiencies are determined for a variable speed centrifugal pump. In addition, the pump affinity laws are verified. Pumping B Dave- add in words please. Vacuum Drying Dave- add in words please.